High-transmittance infrared-resistant energy-saving colored glass and melting device thereof

A melting device and anti-infrared technology, which is applied in glass furnace equipment, glass manufacturing equipment, furnaces, etc., can solve the problems of reduced visible light transmittance and reduced ultraviolet absorption of glass, achieve strong anti-infrared performance, and save production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

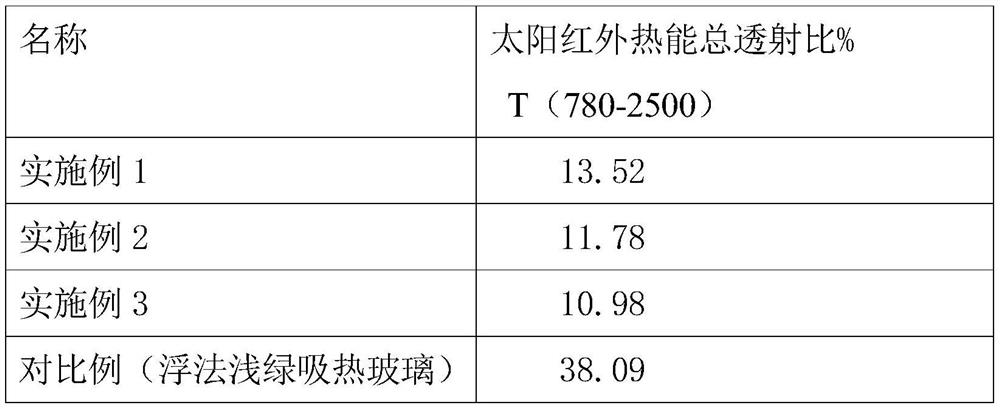

Embodiment 1

[0023] The glass formula is: including the following components by weight percentage: SiO 2 70%, Al 2 o 3 1.0%, CaO 8.0%, MgO 4.00%, Na 2 O 13.925%, Fe 2 o 3 0.43%, composite reducing agent 2%, sodium sulfate 0.6% and carbon powder 0.045%. The molar percentage of ammonium chloride, oxalic acid, nano-aluminum powder, nano-silicon powder and stannous oxide in the composite reducing agent is 10:6:1:4:3.

[0024] Specific preparation steps: 1) Stir the nano-aluminum powder, nano-silicon powder, ammonium chloride, oxalic acid, and stannous oxide with an ultrasonic device for 30 minutes, then grind to obtain a powder with uniform particles, and then stir for 30 minutes. Obtain composite reducing agent;

[0025]2) Weigh each component of the glass formula according to the formula, and fully mix each component to obtain a mixture;

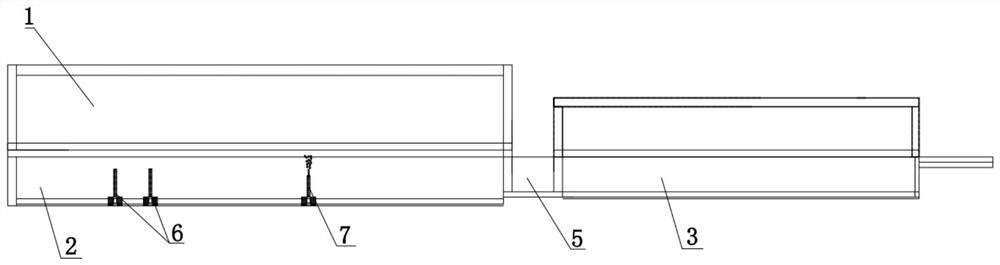

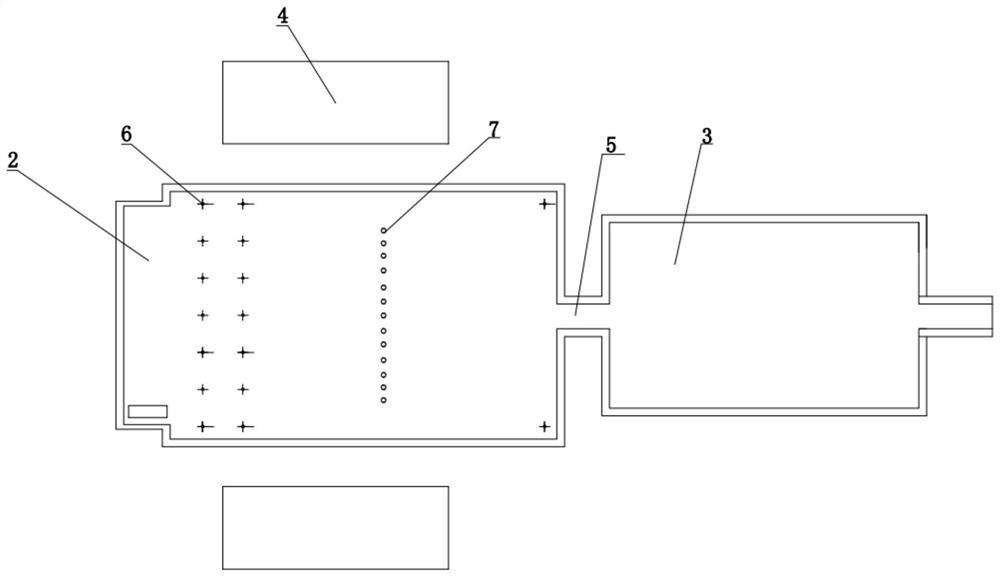

[0026] 3) Add the obtained mixture into the melting pool 2 in the melting furnace, heat it to 1450-1600°C by using the flame space 1 and the reg...

Embodiment 2

[0030] The glass formula is: including the following components by weight percentage: SiO 2 69.5%, Al 2 o 3 0.8%, CaO 7.9%, MgO 3.9%, Na 2 O 13.925%, Fe 2 o 3 0.43%, composite reducing agent 3%, sodium sulfate 0.6% and carbon powder 0.045%. The molar percentage of ammonium chloride, oxalic acid, nano-aluminum powder, nano-silicon powder and stannous oxide in the composite reducing agent is 10:6:1:4:3.

[0031] The preparation steps are the same as in Example 1.

Embodiment 3

[0033] The glass formula is: including the following components by weight percentage: SiO 2 69%, Al 2 o 3 0.8%, CaO 7.9%, MgO 3.5%, Na 2 O 13.725%, Fe 2 o 3 0.43%, composite reducing agent 4%, sodium sulfate 0.6% and carbon powder 0.045%. The molar percentage of ammonium chloride, oxalic acid, nano-aluminum powder, nano-silicon powder and stannous oxide in the composite reducing agent is 10:6:1:4:3.

[0034] The preparation steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com