Ferrous carbonate hexahedron and preparation method thereof

A ferrous carbonate and hexahedral technology, which is applied in the field of materials to achieve the effects of simple reaction process, high crystallinity and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1 of the present invention proposes a kind of preparation method of ferrous carbonate hexahedron, comprises the steps:

[0020] S1. Dissolve 3 mmol of ferrous chloride tetrahydrate and 10 mmol of urea in 50 mL of deionized water, and obtain a uniform solution under stirring with a magnetic stirrer;

[0021] S2. Add the uniformly stirred solution in S1 into a polytetrafluoroethylene autoclave liner with a volume of 70 mL, then put the autoclave into an oven, heat to 160° C., and keep it warm for 10 hours;

[0022] S3, after the autoclave is naturally cooled to room temperature, the reaction product is taken out, the reaction product is repeatedly washed with deionized water and absolute ethanol until the aqueous solution is neutral, and then centrifuged to obtain a precipitate and the precipitate is dried in an oven to obtain sulfite Iron hexahedral powder.

Embodiment 2

[0024] Embodiment 2 of the present invention proposes a kind of preparation method of ferrous carbonate hexahedron, comprises the steps:

[0025] S1. Dissolve 2.5mmol of ferrous chloride tetrahydrate and 8mmol of urea in 48mL of deionized water, and obtain a uniform solution under stirring with a magnetic stirrer;

[0026] S2. Add the uniformly stirred solution in S1 into a polytetrafluoroethylene autoclave liner with a volume of 70 mL, then put the autoclave into an oven, heat to 170° C., and keep it warm for 8 hours;

[0027] S3, after the autoclave is naturally cooled to room temperature, the reaction product is taken out, the reaction product is repeatedly washed with deionized water and absolute ethanol until the aqueous solution is neutral, and then centrifuged to obtain a precipitate and the precipitate is dried in an oven to obtain sulfite Iron hexahedral powder.

Embodiment 3

[0029] Embodiment 3 of the present invention proposes a kind of preparation method of ferrous carbonate hexahedron, comprises the steps:

[0030] S1. Dissolve 4 mmol of ferrous chloride tetrahydrate and 14 mmol of urea in 54 mL of deionized water, and obtain a uniform solution under stirring with a magnetic stirrer;

[0031] S2. Add the uniformly stirred solution in S1 into a polytetrafluoroethylene autoclave liner with a volume of 70mL, then put the autoclave into an oven, heat to 150°C, and keep it warm for 15 hours;

[0032] S3, after the autoclave is naturally cooled to room temperature, the reaction product is taken out, the reaction product is repeatedly washed with deionized water and absolute ethanol until the aqueous solution is neutral, and then centrifuged to obtain a precipitate and the precipitate is dried in an oven to obtain sulfite Iron hexahedral powder.

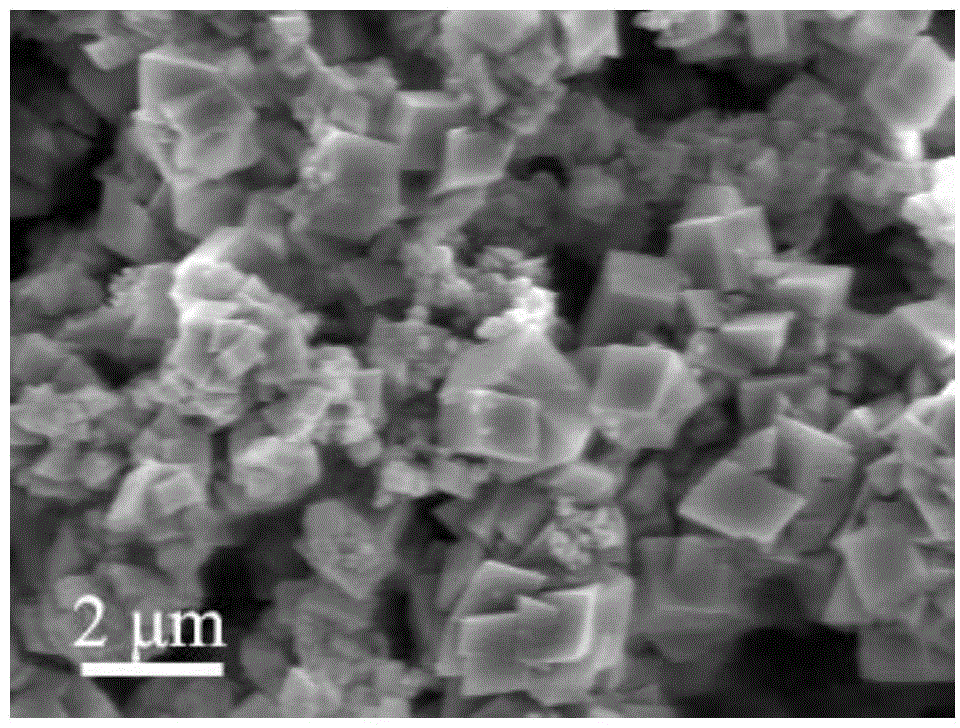

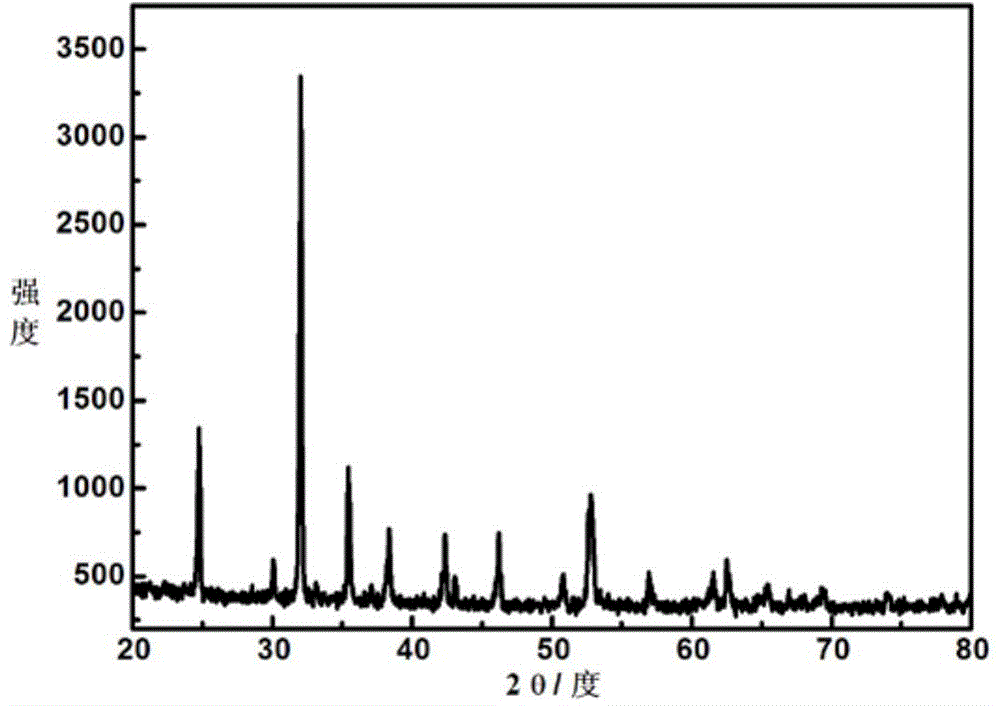

[0033] SEM observation and XRD analysis were carried out on the ferrous carbonate hexahedron prepared ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com