Preparation method of carbon/iron oxide composite and lithium-ion battery

A technology of ferroferric oxide and composite materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low product output, high cost, and low output, and achieve high specific capacity, stable structure, and high conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

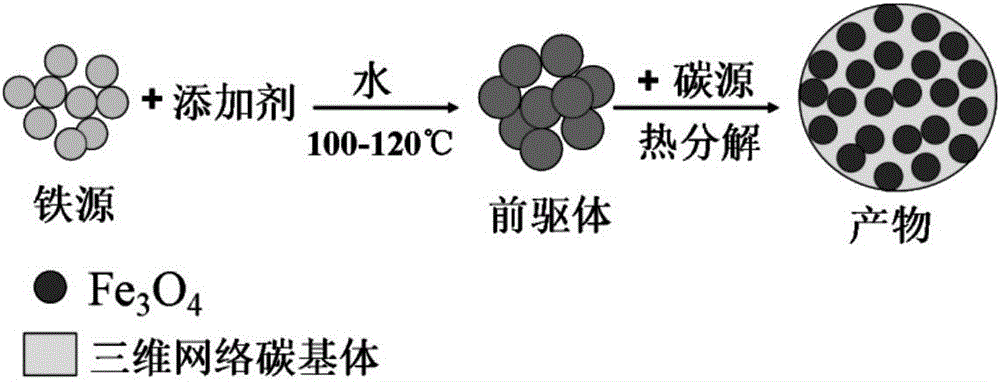

[0031] The invention provides a method for preparing a carbon / iron tetroxide composite material, comprising: mixing ferrous carbonate with macromolecular organic matter, heating and calcining in a protective atmosphere to obtain the carbon / iron tetroxide composite material.

[0032] The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0033] All the raw materials in the present invention have no special limitation on their purity, and the present invention preferably adopts analytical purity or conventional purity used in the storage battery field.

[0034] Wherein, the ferrous carbonate is preferably micron-sized particles, more preferably prepared according to the following steps: mixing ferrous salt, urea and carbonate in water, and performing hydrothermal reaction to obtain ferrous carbonate.

[0035] The ferrous salt can be a compound containing ferrous ions well known to those skilled in ...

Embodiment 1

[0052] 0.995g FeCl 2 4H 2 O, 0.3g urea (CO(NH 2 ) 2 ) and 0.2g NH 4 HCO 3 Dissolved in 40ml of water, heated to 120°C, and hydrothermally reacted for 12 hours to obtain and collect the precursor ferrous carbonate.

[0053] Mix 0.3460g of precursor ferrous carbonate with 0.1730g of cellulose acetate [mass ratio is 2:1], add 2ml of ethanol, ball mill for 5h, dry the mixture, and heat it to 500°C under the protection of argon, keep 5h, natural cooling, to obtain carbon / ferric oxide composite material.

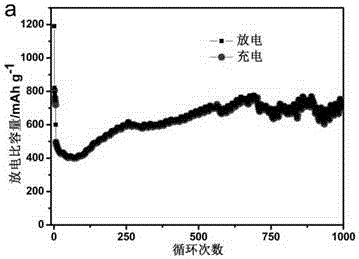

[0054] The carbon / iron tetroxide composite material obtained in Example 1 is detected by a specific surface analyzer, and its specific surface area is 67.296m 2 / g; the pore size distribution has a larger distribution at 3.8 and 5nm, indicating that the material is a mesoporous material, which is conducive to the storage and rapid transport of electrolytes in the active material.

[0055] Utilize scanning electron microscope to analyze the precursor ferrous carbonate obta...

Embodiment 2

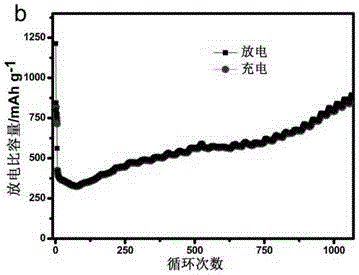

[0059] 1.4g FeSO 4 ·7H 2 O, 0.3g CO(NH 2 ) 2 and 0.2g NH 4 HCO 3 Dissolved in 40ml of water, heated to 120°C, and hydrothermally reacted for 10 hours to obtain and collect the precursor ferrous carbonate. Subsequent experiments were the same as in Example 1.

[0060] The carbon / ferric oxide composite material that obtains in embodiment 2 has been carried out specific surface analysis, the result shows, product has 67.3m 2 The specific surface area per gram, and its pore size distribution is 4-5nm, which is a typical mesoporous material, which is conducive to the storage and rapid transport of electrolytes inside the active material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com