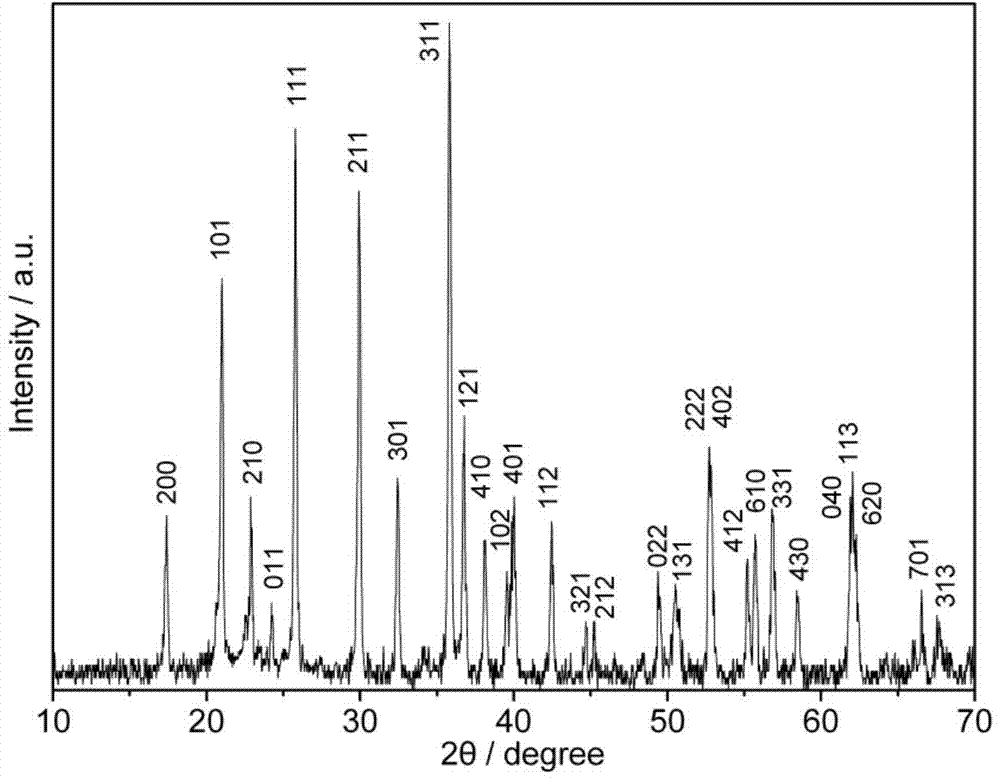

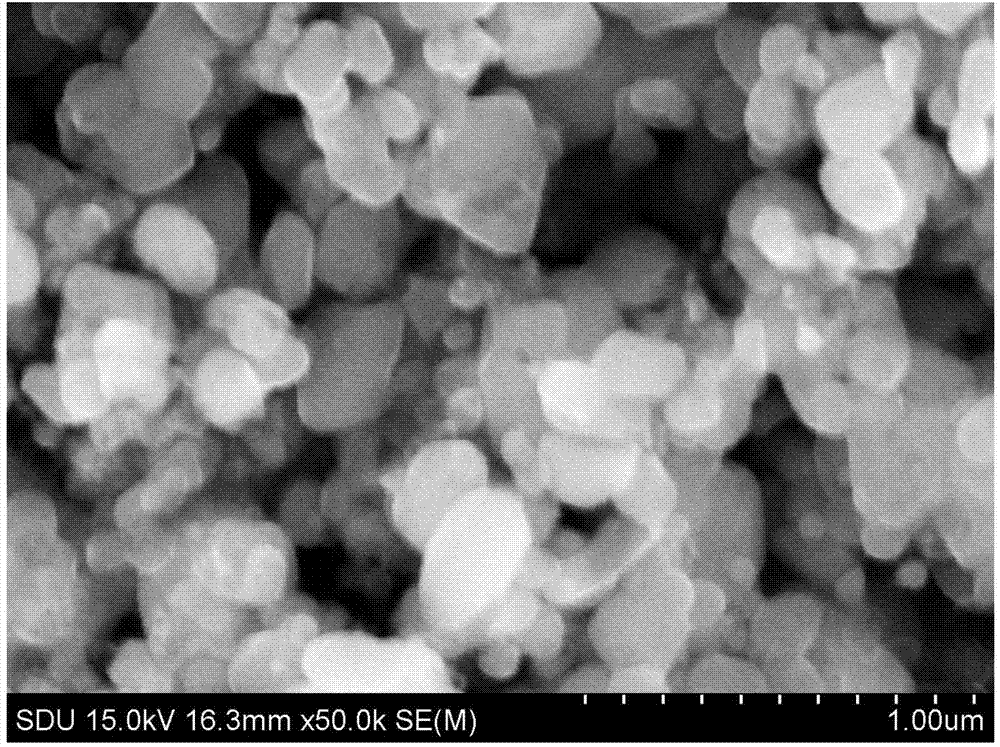

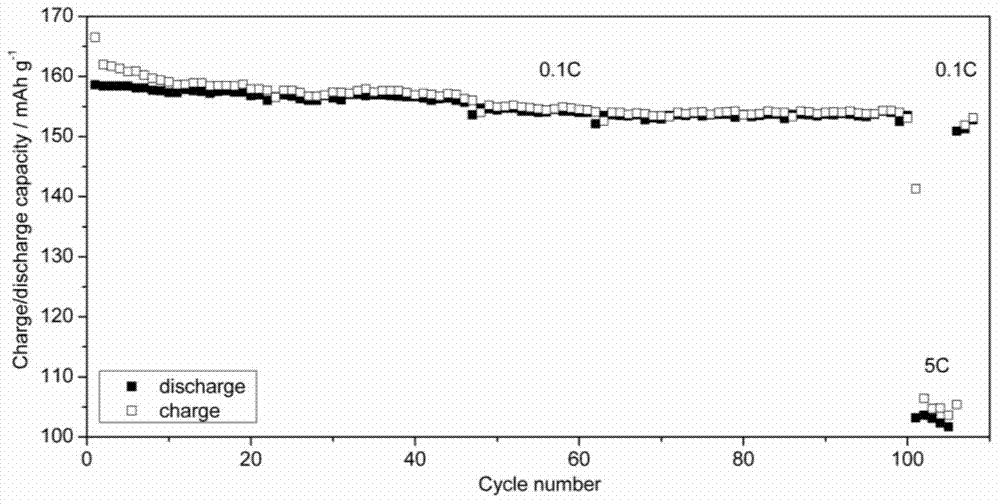

Method of preparing nanoscale lithium iron phosphate / carbon composite anode material

A lithium iron phosphate and cathode material technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of lithium iron phosphate without cost advantage and high cost, achieve high cycle and rate performance, reduce production costs, and maximize The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh 2.0786g (0.02mol) lithium dihydrogen phosphate (LiH 2 PO 4 ), 2.3168g (0.02mol) ferrous carbonate (FeCO 3 ,), 1g (0.0051mol) glucose (C 6 h 12 o 6 ·H 2 O), mix in an agate tank, add 80g of agate balls to make the ball milling body, 15ml of ethanol as the ball milling medium, 300rpm ball milling for 12h, the resulting mixed slurry is vacuum dried at 80°C for 2h to get the ball milling precursor, and the ball milling precursor is in an argon atmosphere , In a tube furnace, heat preservation at 250 degrees for 4 hours, and heat preservation at 700 degrees for 3 hours, to obtain nano-scale lithium iron phosphate / carbon composite cathode materials.

Embodiment 2

[0026] Weigh 0.7388g (0.01mol) lithium carbonate (Li 2 CO 3 ), 2.3006g (0.02mol) ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ), 2.3168g (0.02mol) ferrous carbonate (FeCO 3 ), 1.141g (0.0033mol) sucrose (C 12 h 22 o 11 ), mixed in an agate jar, added 130g agate balls as ball milling body, 16ml ethanol as ball milling medium, 200rpm ball milling for 24h, 80°C vacuum drying for 2h to get ball milling precursor, ball milling precursor in argon atmosphere, tube furnace , heat preservation at 300 degrees for 2 hours, and heat preservation at 650 degrees for 4 hours to obtain nano-scale lithium iron phosphate / carbon composite cathode materials.

Embodiment 3

[0028] Weigh 1.32g (0.02mol) lithium acetate (CH 3 COOLi), 2.6411g (0.02mol) diamine hydrogen phosphate ((NH 4 ) 2 HPO 4 ), 2.3168g (0.02mol) ferrous carbonate (FeCO 3 ), 1.3641g (0.0071mol) citric acid (C 6 h 8 o 7 ), mixed in an agate jar, added 92g agate balls as ball milling body, 21ml ethanol as ball milling medium, 250rpm ball milling for 20h, 80°C vacuum drying for 2h to get the ball milling precursor, the ball milling precursor was in an argon atmosphere, in a tube furnace , heat preservation at 350 degrees for 2 hours, heat preservation at 600 degrees for 4 hours, and obtain nano-scale lithium iron phosphate / carbon composite cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com