Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

239 results about "Iron(III) sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron(III) sulfate (or ferric sulfate), is the chemical compound with the formula Fe₂(SO₄)₃. Usually yellow, it is a salt and soluble in water. A variety of hydrates are also known. Solutions are used in dyeing as a mordant, and as a coagulant for industrial wastes. It is also used in pigments, and in pickling baths for aluminum and steel.

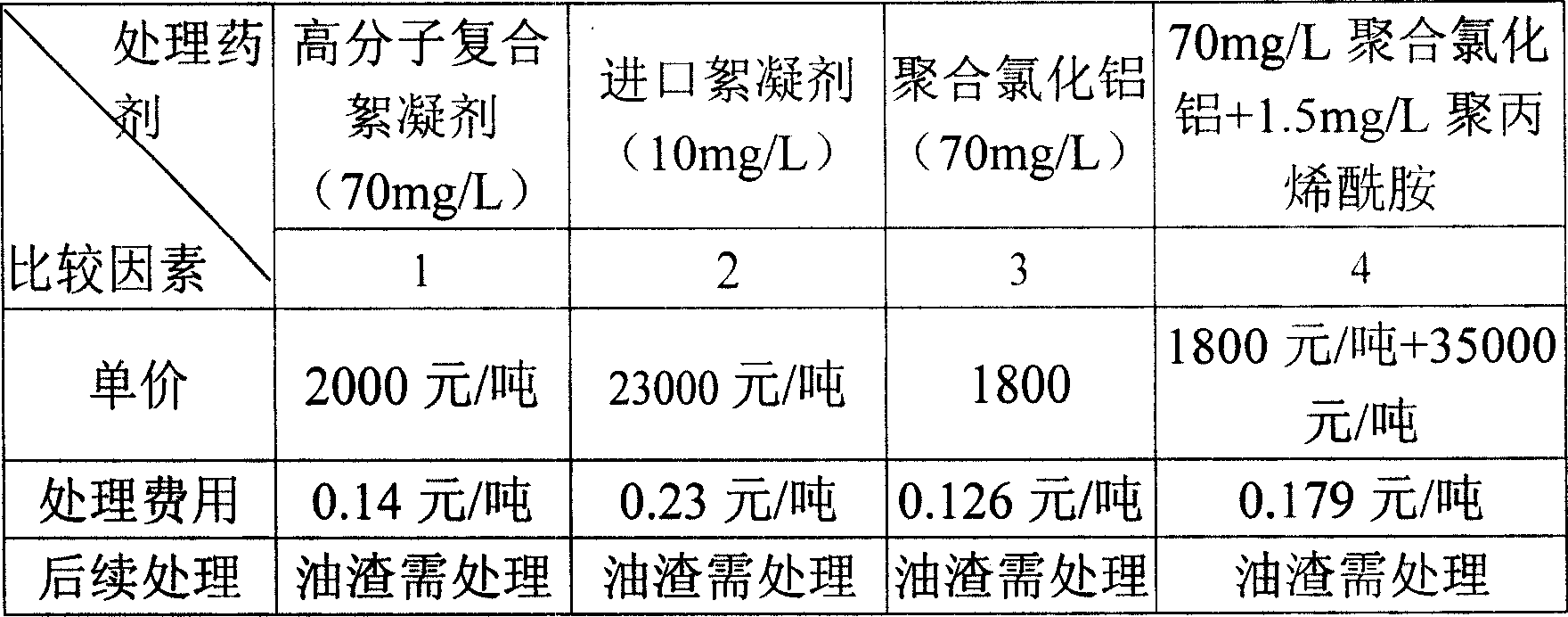

High polymer composite coagulant for treatment of oily waste water and making method thereof

InactiveCN101041495AEasy to handleLess one-time investmentWater contaminantsWater/sewage treatment by flocculation/precipitationAluminium chloridePolymer science

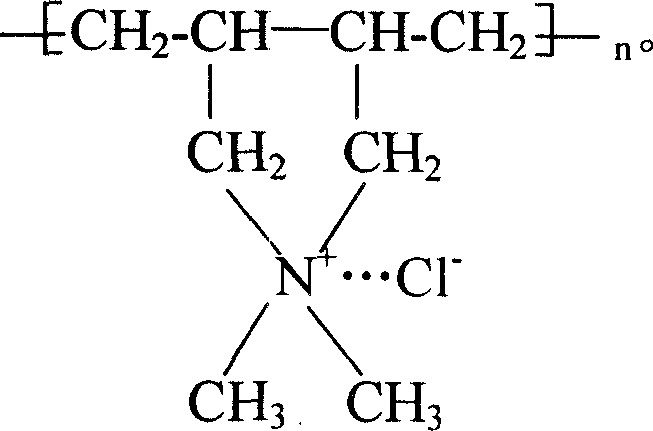

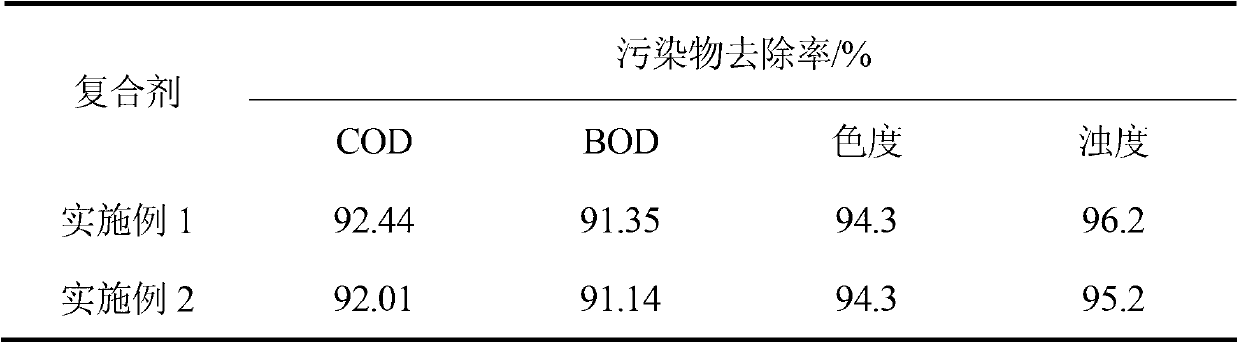

The invention discloses a high polymer composite coagulant for disposing oily wastewater and preparing method, which comprises the following steps: setting ingredient and weight ratio of high polymer composite coagulant with polymeric aluminium chloride : polymeric ferric sulfate : soluble glass : polydiene propyl dimethyl amchlor : water = 39.00:(1.90-2.10):(0.26-0.31):(1.04-1.52):(57.80-57.10); setting 0.02% basic ion polyacrylamide in polydiene propyl dimethyl amchlor; preparing finite density water solution with raw material as first step; preparing flocculant intermediate with polyaluminium chloride, polymeric ferric persulfate and sodium silicate as second step; proceeding mixed reaction with flocculating agent intermediate of the second step and polydiene propyl dimethyl amchlor of 0.02% positive ion polyacrylamide; controlling condition as temperature at 70-90 deg.c, pH value at 4-7; stirring intensity at 50-70r / min and ripening time at 6-24h.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

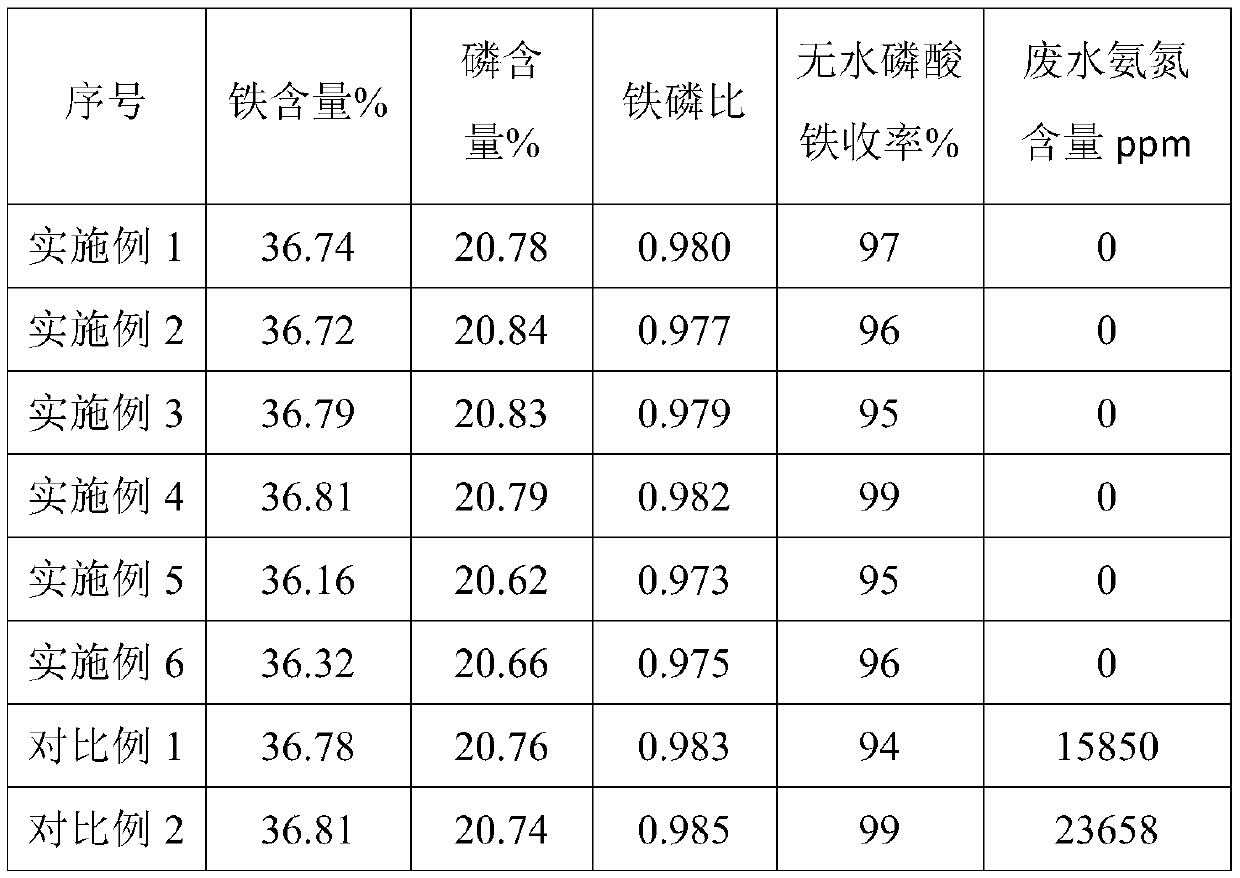

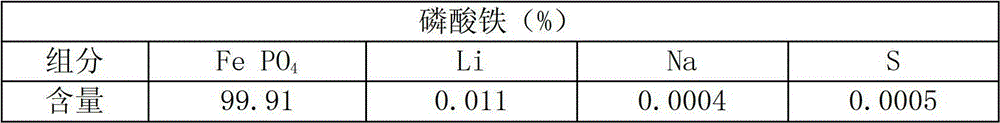

Preparation method of battery-grade iron phosphate

InactiveCN110482512AAchieving zero emissionsNothing producedSulfur compoundsNature of treatment waterEvaporationPhosphoric acid

The invention discloses a preparation method of battery-grade iron phosphate. The preparation method comprises the following steps: preparing a ferrous sulfate solution of which the mass percent of iron is 5.0-10.0%, adding an oxidizing agent and H3PO4 for oxidizing Fe <2+> into Fe <3+> to form a mixed solution of phosphoric acid and ferric sulfate, adding water to adjust the pH value to 1.5-2.5,performing a reaction to obtain iron phosphate precipitate, and washing, filtering, and drying and calcining a filter cake to obtain battery-grade iron phosphate. According to the invention, reactionpH is adjusted through pure water dilution; instead of adjusting the pH by ammonia water in a conventional route the product quality can be ensured and implementation of zero emission of ammonia nitrogen is achieved; no solid by-product is generated, the prepared battery-grade iron phosphate material is low in impurity content, dilute sulfuric acid in wastewater can be recycled through concentration, condensate water generated by heating evaporation can also be recycled for diluting and adjusting the pH value of a phosphoric acid and ferric sulfate mixed solution, zero emission of wastewater is achieved, and energy consumption and production cost are reduced.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

Preparation method of polymeric aluminum ferric sulfate flocculating agent (liquid)

InactiveCN102515330AWide variety of sourcesReduce manufacturing costWater/sewage treatment by flocculation/precipitationWater bathsIron(III) sulfate

The invention discloses a preparation method of polymeric aluminum ferric sulfate. The preparation method comprises the following steps of: with ferrous sulfate heptahydrate as industrial waste of titanium white as a main raw material, adding water to dissolve and adding concentrated sulfuric acid to acidize; then adding industrial aluminum sulfate to heat and stir under the condition that the bath temperature is 60-100 DEG C; stirring and adding concentrated nitric acid to oxidate; and carrying out polymerization for 30-60 min to obtain the polymeric aluminum ferric sulfate. The preparation method has the advantages of simple process, low cost and short reaction period. The flocculation performance of the polymeric aluminum ferric sulfate is better than that of the traditional industrial product and can be widely applied to feed water treatment and sewage treatment.

Owner:CHONGQING UNIV

Cationic flocculant based on collagen modification and preparation method thereof

ActiveCN102328979AStrong complexing abilityIncrease the amount of complexationWater/sewage treatment by flocculation/precipitationGlyoxylic acidGallic acid ester

The invention relates to a cationic flocculant based on collagen modification and a preparation method thereof. The cationic flocculant is prepared through the following steps of: 1) taking trypsin as hydrolytic agent to hydrolyze industrial gelatine to obtain collagen solution; 2) using glyoxylic acid or gallic acid to modify the obtained collagen solution aiming at increasing the content of carboxyl groups or phenolic hydroxyl groups on collagen molecules to obtain modified collagen solution; and 3) conducting complexation to the obtained modified collagen solution and ferric sulfate or aluminum sulfate according to mass ratio being 1:2 to 1:4 to obtain the cationic flocculant based on the collagen modification. The cationic flocculant can be used for treating waste drilling fluid and solves the problems that the preparation cost of the existing flocculant is high, the synthesized or degraded products are highly toxic and carcinogenic and serious environmental pollution is caused during the current treatment of the waste drilling liquid.

Owner:SHAANXI UNIV OF SCI & TECH

An economical environmental-friendly composite fertilizer containing active sludge and a preparing method thereof

An economical environmental-friendly composite fertilizer containing active sludge is disclosed. The fertilizer is characterized in that: the fertilizer is prepared from following raw materials by weight in part: 55-59 of oil tea cake, 40-44 of peanut bran, 39-43 of paulownia saw dust, 40-45 of straw powder, 50-55 of chicken manure, 9-11 of kaolin, 3-5 of humic acid, 2-4 of fern root powder, 7-9 of an EM bacterial agent, 8-9 of potassium salt of fulvic acid, 1-2 of ferric sulfate, 20-24 of the active sludge, 10-14 of calcium superphosphate, 25-29 of urea, 6-8 of a soil conditioning agent and a proper amount of water; the fertilizer is economical and environmental friendly; the active sludge is fermented into organic fertilizers and is cooperated with inorganic element fertilizers, the fertilizer efficacy is good, and the fertilizer can increase the crop yield and effectively improve the soil quality; the soil conditioning agent is added, and therefore the fertilizer has functions of promoting efficacy and promoting plant nutrition absorption; and urea melting coating is adopted so that the slow release effects are significant and the fertilizer efficacy is durable.

Owner:铜陵市银树生态养殖有限责任公司

Method for preparing metal polysilicate flocculant

InactiveCN102101711AImprove stabilityGood flocculation effectWater/sewage treatment by flocculation/precipitationFlocculationSilicic acid

The invention relates to a method for preparing a metal polysilicate flocculant. At present, the metal polysilicate flocculant is higher in production cost. The method comprises the following steps of: adding green vitriol and waste acid which are produced during production of titanium white into a reaction vessel together with industrial potassium chlorate and stirring to obtain viscous polymeric ferric sulfate; adding water to dilute sodium silicate into sodium silicate aqueous solution, wherein the weight content of SiO2 in the sodium silicate aqueous solution is 2 to 3 percent; adding the waste acid which is produced during the production of the titanium white into the sodium silicate aqueous solution, adjusting pH value of the sodium silicate aqueous solution to be between 3.5 and 4.5, and stirring at normal temperature to obtain polysilicate solution; and adding the polymeric ferric sulfate into the polysilicate solution, uniformly stirring, standing and activating for 10 to 24 hours to obtain the metal polysilicate flocculant. A byproduct produced by the production of the titanium white is low in cost; and the prepared flocculant has the characteristics of high stability, wide application range and good flocculation effect.

Owner:HANGZHOU RONGSHENG ENVIRONMENTAL PROTECTION TECH

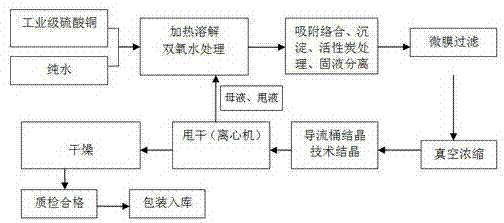

Production method of high-purity copper sulphate

InactiveCN102826584ASimple and fast operationImprove product qualityCopper sulfatesFiltrationTechnical grade

The invention discloses a production method of high-purity copper sulphate. The production method of high-purity copper sulphate comprises the following steps of: dissolving industrial grade copper sulphate into ultrapure water, heating to the temperature of 40-70 DEG C, dropwise adding sulphuric acid to regulate pH to be 1.0-2.0, stirring and dissolving, and then adding hydrogen peroxide; mixing polymeric ferric sulphate with basic copper carbonate in a mass ratio of 1: (2.5-4.5) to prepare a precipitation complexing agent, adding the precipitation complexing agent the weight of which is 0.5-2.5wt% of weight of the solution into the insulated solution, then adding activated carbon the weight of which is 0.5-2.5wt% of the weight of the solution, stirring for 3-7 hours, cooling to room temperature, and standing overnight; and carrying out rough filtration on the solution, then filtering with a microporous membrane with the size of 0.2mu m, and concentrating and crystallizing filtrate to obtain high-purity copper sulphate.

Owner:XILONG SCI CO LTD

Preparation method of magnetic nano Fe3O4 particles by biological catalysis and application of particles to treatment of uranium-containing wastewater

InactiveCN103877927AImprove adsorption capacityThe synthesis process is simpleOther chemical processesAlkali metal oxides/hydroxidesThiobacillus ferrooxidansIron(II) oxide

The invention provides an ecological and environment-friendly new method for preparing magnetic nano Fe3O4 particles by biological catalysis, and application of the particles to treatment of uranium-containing wastewater. The method comprises the following concrete steps: (1) culturing and domesticating thiobacillus ferrooxidans; (2) preparing bio-polymeric ferric sulfate; (3) synthesizing the magnetic nano Fe3O4 particles; (4) performing a test of adsorbing uranium in the uranium-containing wastewater by the magnetic nano Fe3O4 particles. The obtained magnetic nano Fe3O4 particles are simple in preparation synthesis route, mild in reaction condition and easy to operate; a biological catalysis oxidant is used for replacing a conventional chemical oxidant (nitrite), so that cancerogenic substances are prevented from being discharged to the environment and the environment-friendly effect is really achieved. Meanwhile, the obtained magnetic nano Fe3O4 particles can reduce the content of uranium in the low-concentration uranium-containing wastewater with the concentration of 0.45-0.50mg / L by more than 90% and have very important practical meaning in aspects of uranium-containing wastewater treatment, uranium recovery and the like in uranium mining and metallurgy.

Owner:NANHUA UNIV

Flocculating agent for impurity removal process of steviol glycosides

ActiveCN105037460AIncrease in sizeSettling fastSugar derivativesSugar derivatives preparationWater bathsFiltration

The invention discloses a flocculating agent for an impurity removal process of steviol glycosides. The flocculating agent comprises, by weight, 10-20 parts of modified chitosan, 15-25 parts of modified lignin, 30-40 parts of polymeric ferric sulfate, 25-35 parts of aluminium citrate, 10-15 parts of magnesium sulfate, 20-30 parts of polymeric ferric silicate-sulfate, 3-5 parts of porous pearlite powder and 4-6 parts of zeolite powder. A preparation method of the modified chitosan comprises the steps that carboxymethyl chitosan is added into a sodium hydroxide aqueous solution, after heating and heat preservation are conducted, a 3-chloro-2-hydroxypropyltrimethylammonium chloride aqueous solution is dropwise added, the heat preservation is continuously conducted, and then the mixture is adjusted to be neutral to obtain a first material; the first first material is added into ethyl alcohol, filtration is conducted, and a second material is obtained after drying; the second material is added into distilled water to be evenly stirred, water-bath heating is conducted, acrylamide and an initiating agent are sequentially and dropwise added, and a third material is obtained after the heat preservation is conducted; the third material is added into acetone, the filtration is conducted, and the modified chitosan is obtained after drying is conducted.

Owner:BENGBU HUADONG BIOLOGICAL TECH

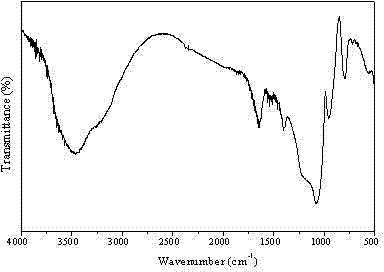

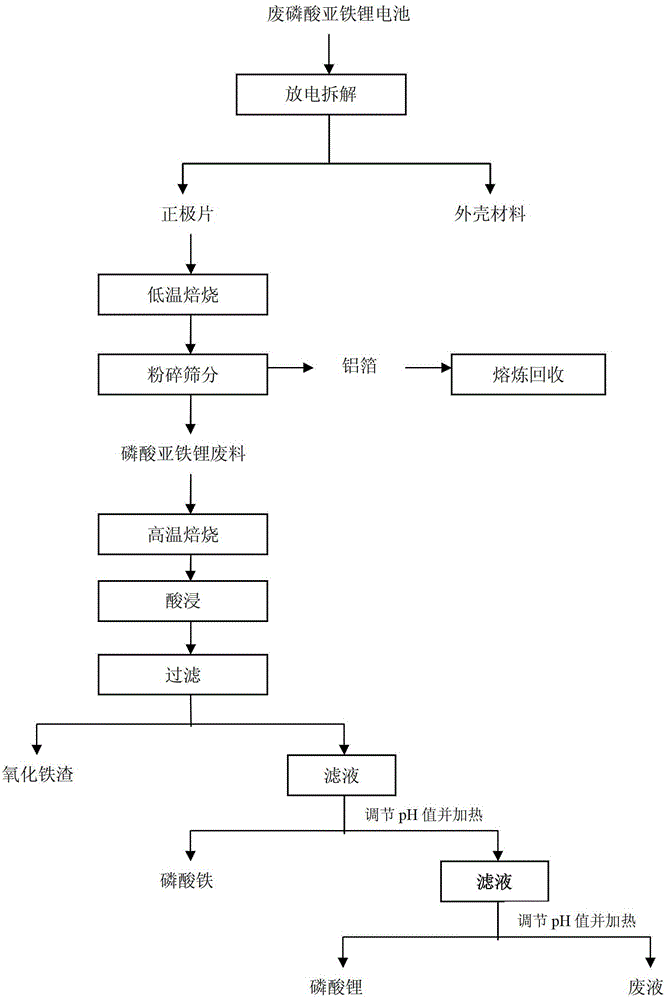

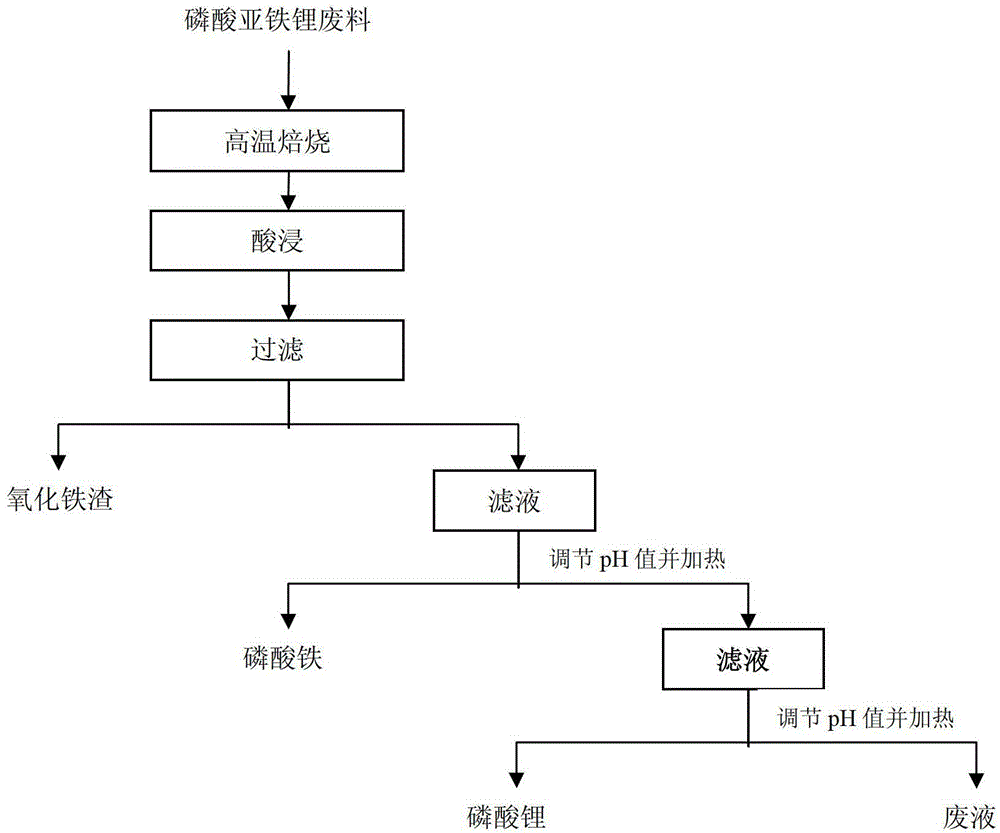

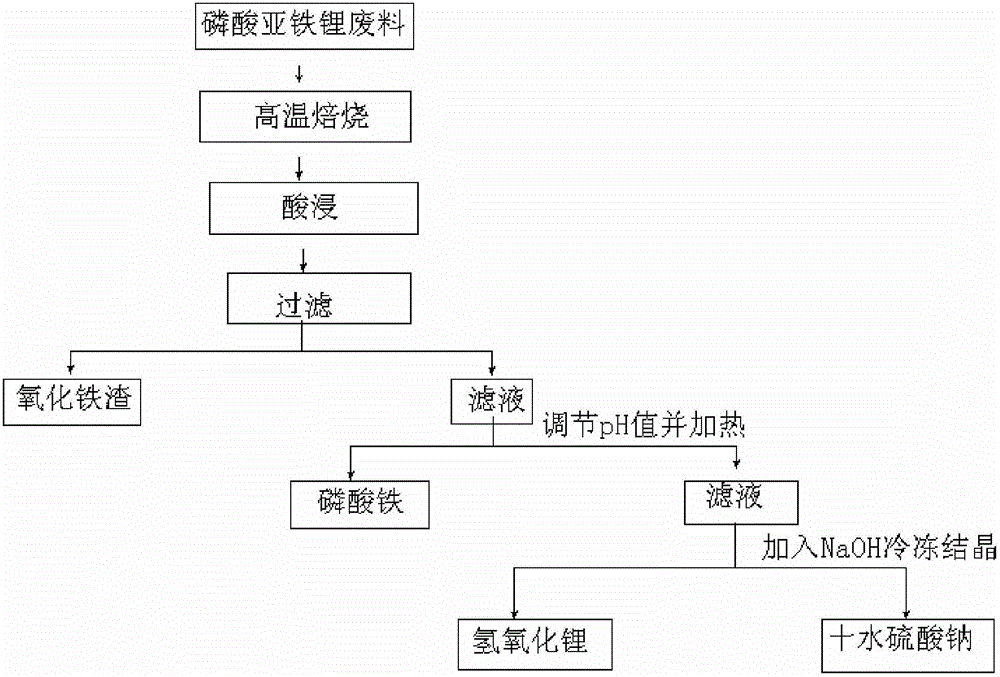

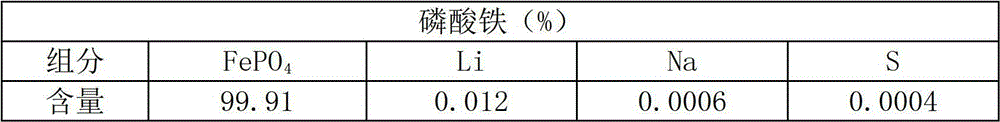

Comprehensive recycling method for lithium iron phosphate cathode material

ActiveCN102910607ASolve the problem of resource recyclingWaste accumulators reclaimingPhosphorus compoundsLithium iron phosphatePhosphate

The invention relates to a comprehensive recycling method for a lithium iron phosphate cathode material, belonging to the technical field of recycle of waste lithium ion batteries. The invention aims to provide the comprehensive recycling method for the lithium iron phosphate cathode material, comprising the following steps of: a, roasting the lithium iron phosphate cathode material at the temperature of 500-800 DEG C for 1-4h; b, adding sulfuric acid into a roasted material to leach, controlling the pH value between 0.5 and 1 during leaching, and filtering to obtain a mixed solution of lithium phosphate, ferric phosphate and ferric sulfate; c, heating the mixed solution obtained in the step b to 80-100 DEG C, adjusting the pH value of the mixed solution to 2-2.5, reacting for 1-4h, filtering, cleaning and drying to obtain the ferric phosphate; and d, adjusting the pH value of a filtrate obtained through filtering in the step c to 10-12, reacting for 0.5-2h, filtering, cleaning and drying to obtain the lithium phosphate.

Owner:天齐锂业(江苏)有限公司 +2

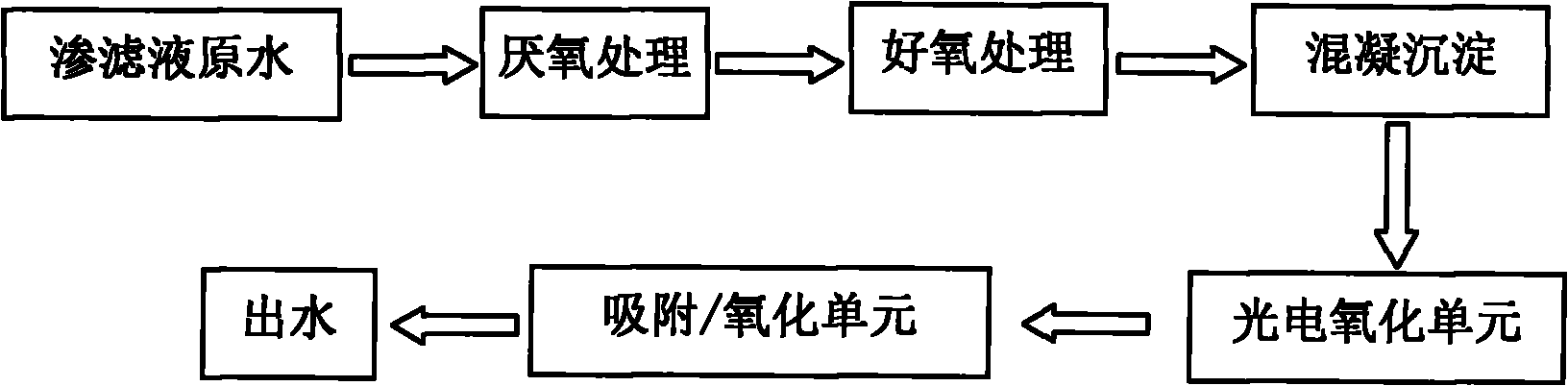

Combined treatment process for urban garbage percolate

InactiveCN102040309ATreatment with aerobic and anaerobic processesMultistage water/sewage treatmentChemical oxygen demandFiltration

The invention relates to a combined treatment process for the membrane effluent concentrated solution of urban garbage percolate. In the treatment process, a coagulation sedimentation unit, a photoelectric oxidation unit and an oxidation adsorption filtration unit are provided, wherein the coagulation sedimentation unit removes macromolecular soluble substances from biochemical effluent; by using any one of or compounding two or more of polyaluminum chloride, poly-ferric chloride, aluminum sulfate and ferric sulfate, and adding polyacrylamide serving as a coagulant aid, the removal rate of chemical oxygen demand (COD) is about 30 percent; the photoelectric oxidation unit can effectively remove ammonia nitrogen, total nitrogen and part of nondegradable organic matters, the removal rate of the ammonia nitrogen and the total nitrogen can reach 99 percent after the percolate is treated by the photoelectric oxidation unit, and the concentration of residual COD is between 1,000 and 2,000mg / L; and the oxidation / adsorption unit removes residual organic components and metal ions and has been detailedly described in the patent (200910080596.x). The combined process has the characteristics of small investment, low operating cost and the like, is simply and flexibly operated, is suitable for the innocent treatment of the percolate, and also can be applied to the treatment of salty wastewater with high ammonia nitrogen and organic matter load and large water quality fluctuation.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

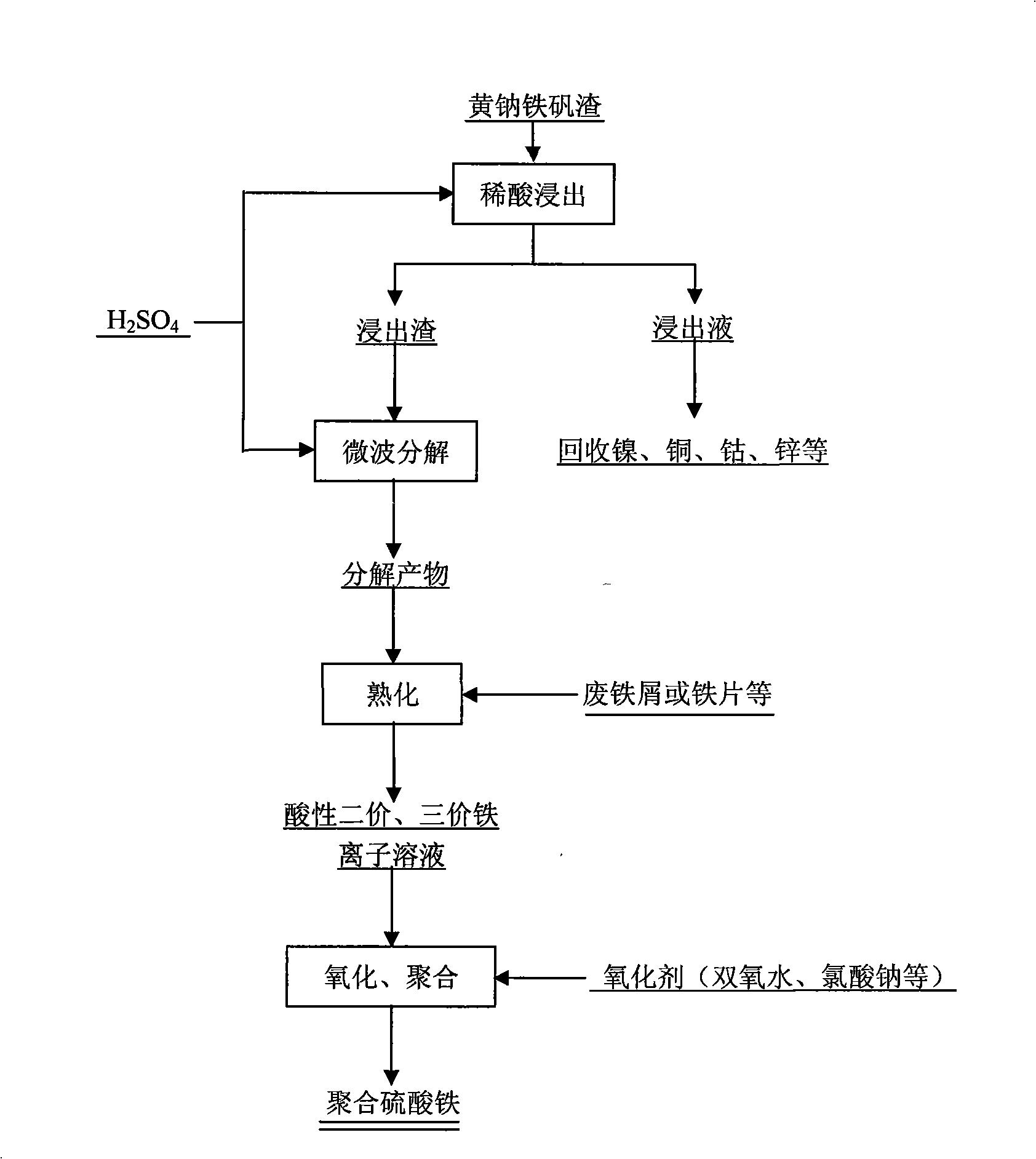

Method for comprehensively utilizing iron vitriol dreg of yellow sodium

InactiveCN101407355AReduce consumptionReduce energy consumptionWater/sewage treatment by flocculation/precipitationSlagIron(III) sulfate

The invention relates to a comprehensive utilization method of amarillite slag, which is characterized by including the following steps: (1) the valuable metals in the amarillite slag are selectively leached by using sulfuric acid solution, thus obtaining the leaching slag and the leaching agent; (2) the leaching slag and sulphuric acid are mixed then heated under microwave radiation; (3) water and a substance containing iron are added into the material after microwave radiation, quiescence and slaking are carried out at normal temperature condition and (4) the material is heated, ferrous iron in the solution is oxidized by using an oxidant, then the polymerization ferric sulfate is prepared through hydrolysis and polymerization by ferric iron. The invention effectively retrieves the valuable metals in the amarillite slag, reduces reagent consumption and energy consumption during amarillite slag treatment process, shortens the treatment time, has no environmental pollution during the treatment process, obtains the water treatment agent polymerization ferric sulfate with good quality, and can effectively solve the problems of the stockpiling and pollution of the amarillite slag.

Owner:NORTHEASTERN UNIV

Method for producing polymeric ferric sulfate from raw materials industrial waste acid and scrap iron

InactiveCN105948210AEfficient use ofHigh economic valueWater/sewage treatment by flocculation/precipitationChemical oxygen demandIron(III) sulfate

The invention discloses a method for producing polymeric ferric sulfate from raw materials industrial waste acid and scrap iron. The polymeric ferric sulfate is a novel inorganic sewage flocculant, is an iron inorganic polymeric flocculant, is high in flocculation force and sedimentation velocity, and has remarkable removal effects on some heavy metal irons, COD (chemical oxygen demand), chromaticity, stink and the like during sewage treatment. An existing polymeric ferric sulfate production method is low in yield and serious in pollution during the production process. The method comprises the following steps: (1) reacting the raw materials, i.e. the waste acid and the scrap iron, to obtain ferrous iron; (2) performing oxidization reaction to obtain ferric iron by adopting potassium chlorate as an oxidant; (3) performing hydrolysis reaction; (4) carrying out a polymerization process of conversion from a low polymer to a high polymer to obtain the polymeric ferric sulfate. By the method, the polymeric ferric sulfate is produced from the raw materials, i.e. the industrial waste acid and the scrap iron.

Owner:哈尔滨云水工大环保科技股份有限公司 +1

Method used for preparing polymeric ferric sulfate from sulfuric acid waste liquid

InactiveCN105129867ASave resourcesTo achieve the purpose of treating waste with wasteIron sulfatesIron(III) sulfateOxygen

The invention discloses a method used for preparing polymeric ferric sulfate from sulfuric acid waste liquid. The method comprises following steps: (1) sulfuric acid waste liquid with a concentration ranging from 13 to 23% is delivered into a material tank, green vitriol is added at a H2SO4:FeSO4 ratio of 1:1.6-2, and an obtained mixture is mixed; (2) the mixture is delivered into a sealed reaction vessel, sodium nitrite is added into the reaction vessel slowly for polymerization, wherein each ton of the mixture is provided with 2 to 5kg of sodium nitrite, sodium nitrite is added in three to four times, the pressure of the reaction vessel is maintained to be constant in sodium nitrite adding, oxygen is added, and oxygen adding speed is controlled to as to maintain the pressure of the reaction vessel to be 0.05 to 0.1MPa; and (3) when the temperature of the reaction vessel is increased to 75 to 80 DEG C, sampling is carried out so as to measure the content of green vitriol, and polymeric ferric sulfate finished product is obtained when the content of green vitriol is lower than 0.1%. According to the method, polymeric ferric sulfate is prepared by taking sulfuric acid waste liquid as a raw material, a large amount of resource is saved, the method can be widely applied to waste water treatment of the fields such as chemical engineering, printing, medicine preparation, and town domestic sewage, and wastes are treated with wastes.

Owner:TONGLING HAILING ENVIRONMENTAL PROTECTION TECH CO LTD

Comprehensive utilization method of silicate minerals

ActiveCN104891537ABig market demandGood market demandMagnesium sulfatesFerric oxidesFerric hydroxideHigh energy

The invention discloses a comprehensive utilization method of silicate minerals. The method comprises the following steps: firstly decomposing silicate minerals by using sulfuric acid as a decomposing agent, and carrying out acid leaching of residues for preparation of white carbon black; sending an acidolysis solution into a magnesium sulfate heptahydrate crystallizer to prepare a magnesium sulfate heptahydrate product and an acidolysis solution obtained after separation of magnesium sulfate; mixing magnesium sulfate heptahydrate and water, adding an oxidizing agent, a pH regulator and an adsorbent to convert iron in the solution to a ferric hydroxide precipitate, filtering to obtain a pure magnesium sulfate solution, sending the magnesium sulfate solution into a magnesium sulfate monohydrate powder dedicated preparation system to prepare a feed-grade magnesium sulfate monohydrate product; separating an iron precipitate from the acidolysis solution by an oxidation-precipitation process, carrying out oxidation, carrying out a polymerization reaction, and solidifying to prepare a solid polymeric ferric sulfate product; and sending the acidolysis solution after separation of the iron precipitate to a follow-up process to prepare a magnesium compound. According to the invention, insufficiencies such as high energy consumption during present technical process of production, low product purity and the like are overcome; and there is no emission of ''three wastes (waste gas, waste water and industrial residue) '' during the production process, so as to minimize the influence on the environment.

Owner:河南省睿博环境工程技术有限公司

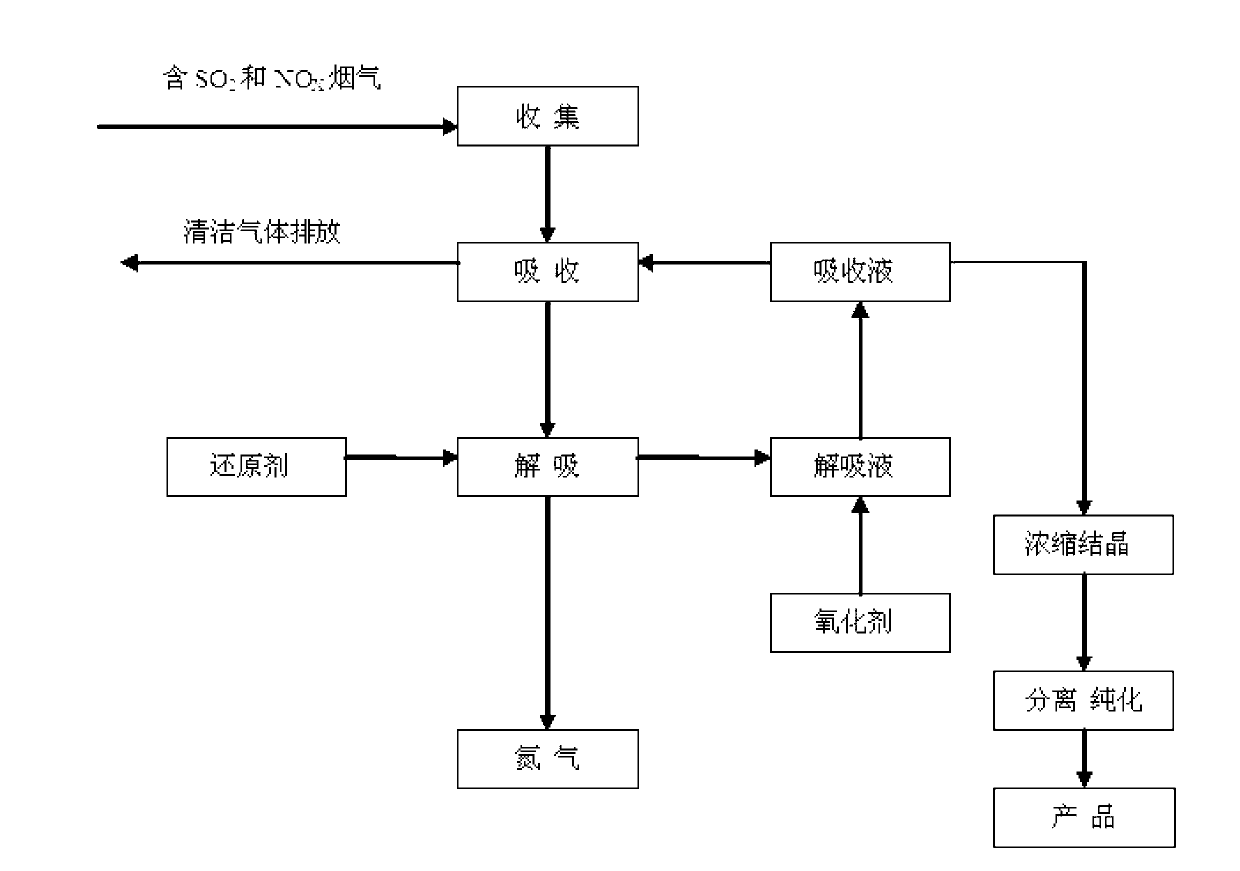

Flue gas wet reduction integrated desulfurization, denitrification, harmless treatment and resource utilization method

InactiveCN102989301AAchieve the purpose of purificationAchieve recyclingDispersed particle separationAir quality improvementNitrosoResource utilization

The invention discloses a flue gas wet reduction integrated desulfurization, denitrification, harmless treatment and resource utilization method. The method includes that flue gases containing SO2 and NOX are fed into an acid ferric iron solution or a ferric iron and ferrous iron mixed solution, and the NOX and the SO2 are absorbed at the temperatures of 0-100 DGE C to generate dark brown nitroso ferrous salt, sulfate and a small amount of mixed solution composed of nitric acid and nitrous acid. A reducing agent and a catalytic agent are added into the mixed solution so that an absorbed nitroso group is converted into nitrogen, and harmless treatment is achieved; and finally, an absorption solution which is subjected to harmless treatment is subjected to oxidization, separation and crystallization to prepare ferric sulfate or ferric chloride products, and resource utilization of the flue gases is achieved.

Owner:HENAN LVDIAN ENERGY SAVING & ENVIRONMENTAL PROTECTION TECH

Method for removing thallium in wastewater

ActiveCN105540921AReduce usageImprove effluent qualityWater treatment parameter controlSpecific water treatment objectivesWater qualityIron(III) sulfate

The invention discloses a method for removing thallium in wastewater. According to the method, ozone is delivered in to thallium-containing wastewater for oxidizing; a mixed flocculating agent is added into the wastewater, wherein the mixed flocculating agent comprises sodium hydroxide, sodium sulfide, polymeric ferric sulfate and sodium polystyrenesulfonate; after flocculation, solid-liquid separation is completed; and a ceramic material is added into a liquid part for adsorption. With the method provided by the invention, chemical agent dose can be reduced; no secondary pollution is caused; and the efficiency is high. The method is suitable for large-scale applications, and the process is simple and controllable. Outlet water quality (thallium content) is stabilized at below 0.005mg / L. The adsorption material can be recycled. The method can be used for carrying out deep treatment upon low-concentration heavy-metal-ion-polluted wastewater.

Owner:HUNAN SAMMNS ENVIRONMENTAL PROTECTION CO LTD

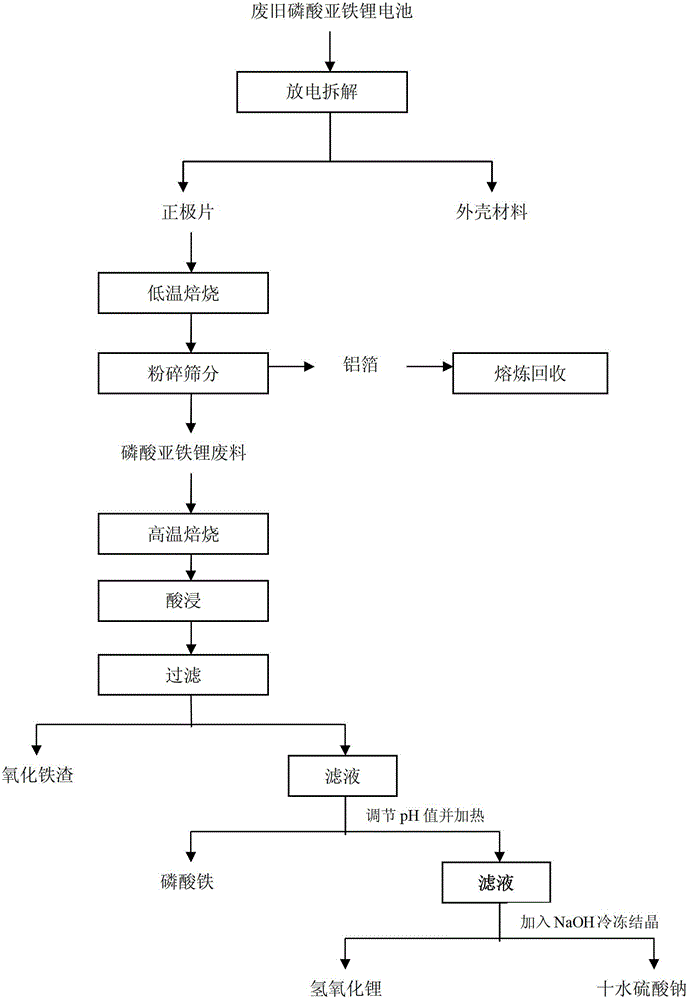

Method for recycling lithium hydrate from lithium iron phosphate waste

ActiveCN102881960ASolve the problem of resource recyclingWaste accumulators reclaimingBattery recyclingPhosphateFiltration

The invention relates to a method for recycling lithium hydrate from lithium iron phosphate waste, and belongs to the technical field of waste lithium ion battery recycling. The invention provides a method for recycling lithium hydrate from lithium iron phosphate waste, which comprises the following steps: the lithium iron phosphate waste is roasted for 1-4h at the temperature of 500-800 DEG C; sulfuric acid is added into the roasted material for leaching, and the mixed solution of lithium phosphate, ferric phosphate and ferric sulfate is obtained after filtration; the mixed solution is heated to 80-100 DEG C, the pH value of the mixed solution is adjusted to be 2-2.5, reaction is carried out for 1-4h, and the ferric phosphate is obtained after filtration, washing and drying; the pH value of filtrate obtained through filtration is adjusted to be 6-7, and calcium chloride is added for dephosphorization; and sodium hydroxide is added into the filtrate obtained through filtration after the dephosphorization, the molar ratio of SO42- / Na+ is adjusted to be (0.9-1.1):1, the mixture is cooled to -5+ / -3 DEG C under a stirring condition, the obtained filtrate is heated and evaporated until the liquid-solid ratio is (0.8-1.1):1, and then a lithium hydroxide crude product is obtained through cooling, crystallization and filtration.

Owner:天齐锂业(江苏)有限公司 +2

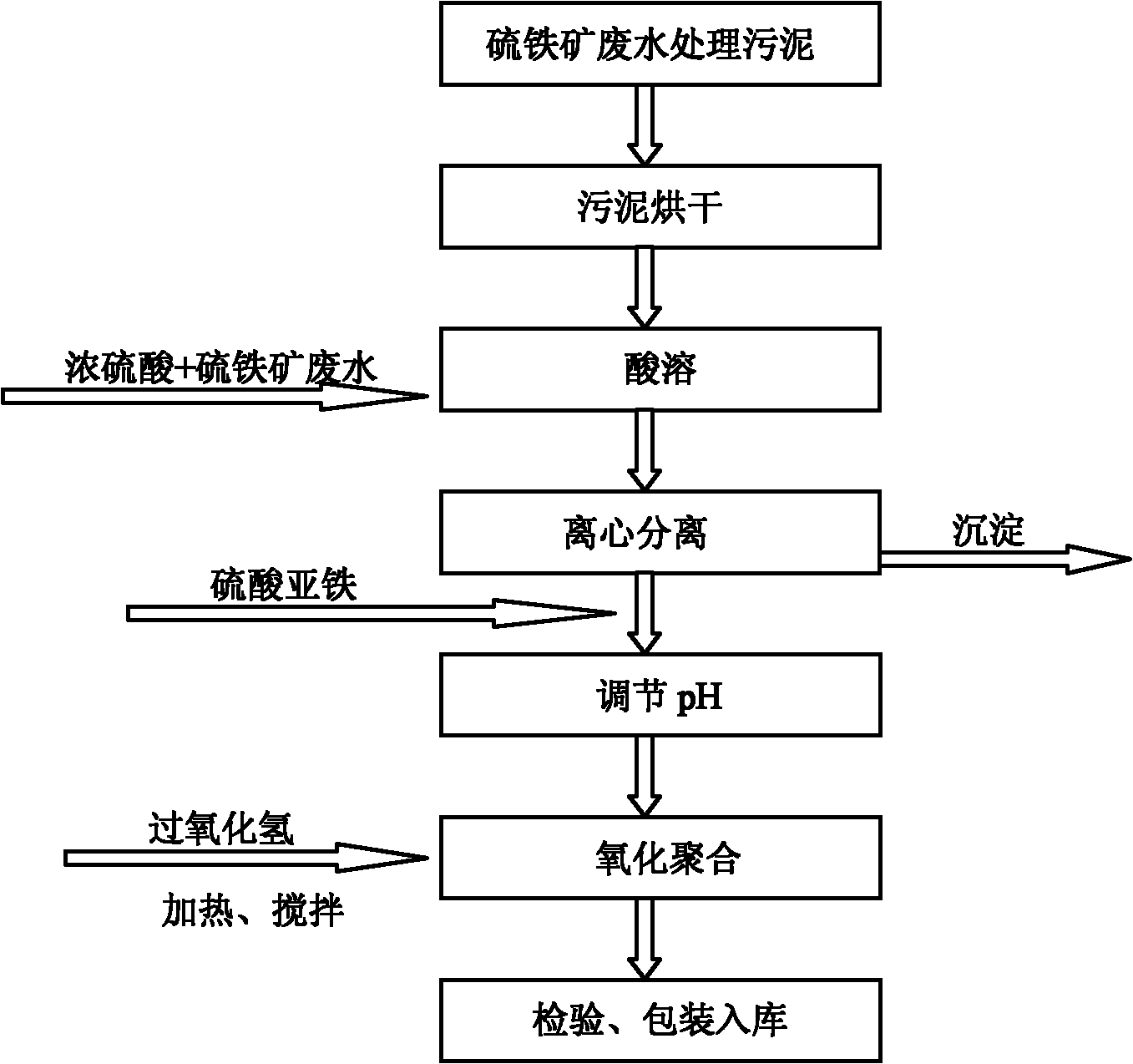

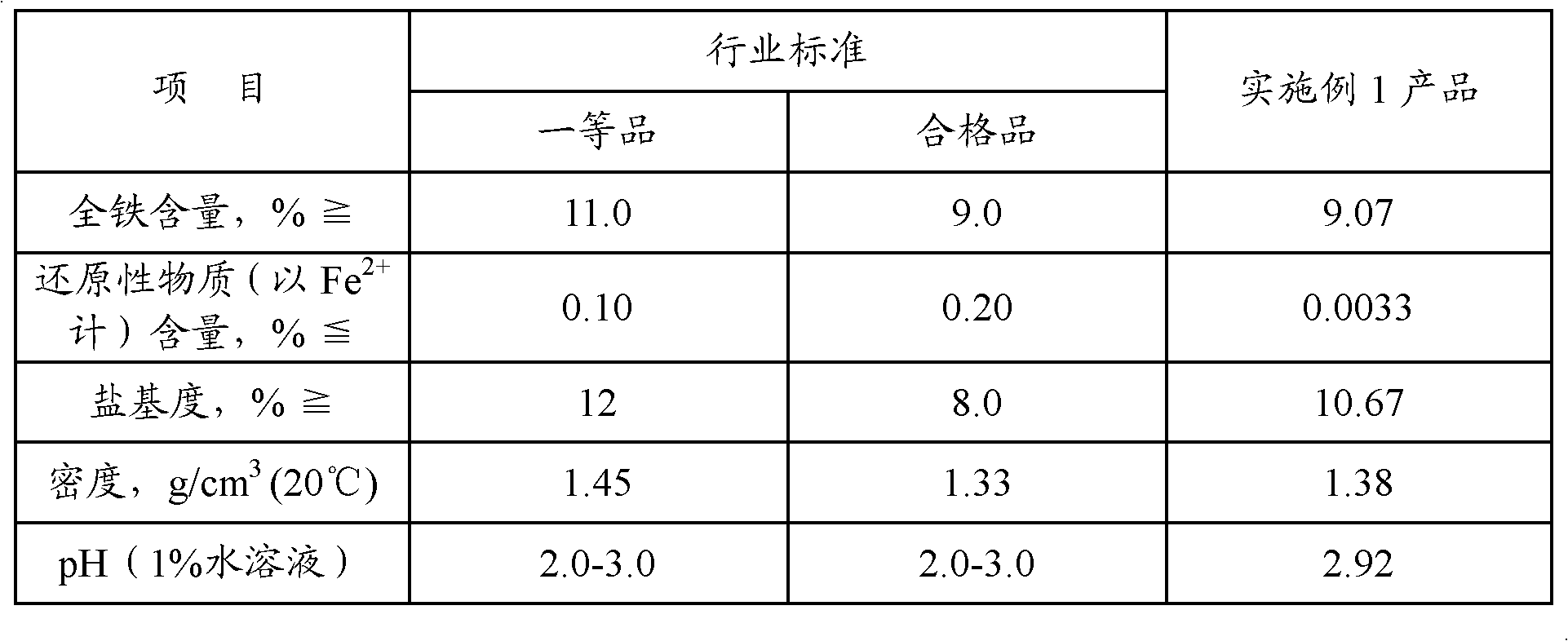

Preparation method of polymeric ferric aluminous sulphate by using pyrite wastewater and treatment sludge

The invention discloses a preparation method of polymeric ferric aluminous sulphate by using pyrite wastewater and treatment sludge, comprising the following steps: drying the treatment sludge of the pyrite wastewater and then pulverizing to obtain the acid solution; stirring for 10 to 30 minutes at 50 to 80 DEG C; centrifuging and removing the precipitate to obtain an acid extract; adding the ferrous sulphate into the acid extract, and dropwise adding the concentrated sulfuric acid to regulate the pH value to 0.6 to 1.0; and adding the oxidizing agent and stirring to react for 1 to 3 hours at 30 to 60 DEG C, thus finally obtaining the polymeric ferric aluminous sulphate. The invention has the beneficial effects that the invention solves the environmental pollution problem of the pyrite wastewater and treatment sludge, as well as realizes the recycling process of the wastes through the preparation of the polymeric ferric aluminous sulphate by using the useful components in the pyrite wastewater and treatment sludge. The method of the invention can be widely used in the recycling of the pyrite wastewater and the treatment sludge, and has significant social and environmental benefits.

Owner:日照高远汽车配件有限公司

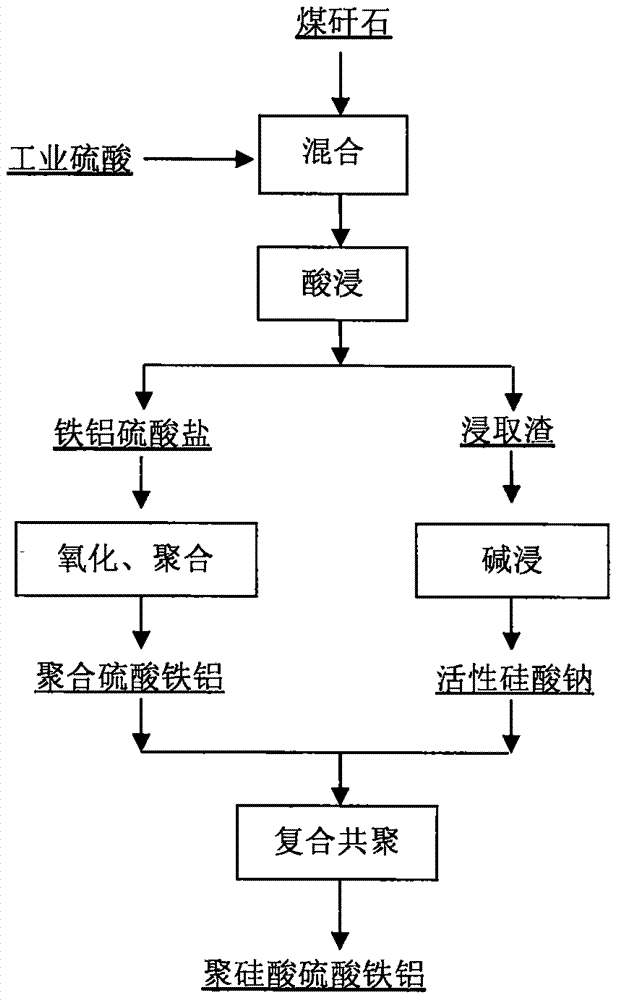

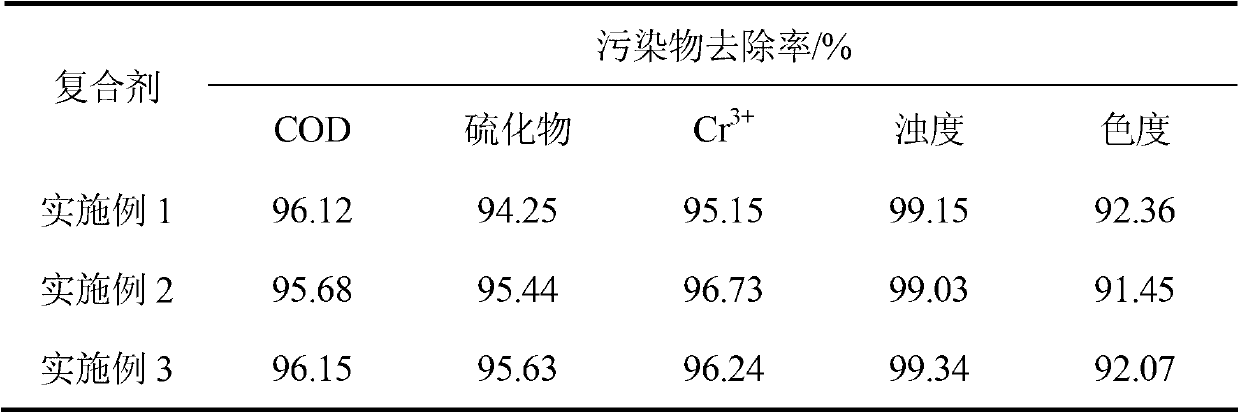

Method for preparing high performance polysilicate ferric aluminum sulfate from coal gangue

ActiveCN107021552AIncrease profitReduce dosageIron sulfatesWater/sewage treatment by flocculation/precipitationEmission standardTurbidity

A method for preparing high performance polysilicate ferric aluminum sulfate from coal gangue aims to provide a method for preparing the high performance polysilicate ferric aluminum sulfate from the coal gangue as a main raw material, and provides a new approach for efficient intergraded recycling utilization of the coal gangue, and a new the technology for an iron and aluminum inorganic polymer flocculant is explored. Industrial sulfuric acid and the coal gangue by leached in an acid to obtain ferric aluminum sulfate, the ferric aluminum sulfate is oxidized and polymerized to obtain poly ferric aluminum sulfate, active sodium silicate is obtained from leaching residue by alkali leaching, the poly ferric aluminum sulfate and the active sodium silicate are added for compounding and copolymerization in accordance with the volume ratio and different mass concentrations to obtain a polysilicate ferric aluminum sulfate product after copolymerization for 1-3H. The comprehensive utilization of the coal gangue is complete, the prepared product has high added value, the method has the advantages of convenient operation, low energy consumption, simple process, and the like, can solve the problem of high turbidity, high chroma and high heavy metal residues and the like of all kinds of wastewater, and the wastewater can meet national emission standards.

Owner:宁夏师范学院

Method for reinforcing bacterial preoxidation of arsenic-containing gold ore

The invention provides a method for reinforcing bacterial preoxidation of an arsenic-containing gold ore. Two additives (separately silver nitrate and ferric sulfate or ferric nitrate) are added. When being in use, a chloride-free 9K solution is prepared with the concentration of Ag(I) and Fe(III) reaching 0.005-0.05 g / L and 1-10 g / L respectively; then the arsenic-containing gold ore is added to the solution; and finally, a certain amount of a bacterium liquid is inoculated to the system for bacterial preoxidation. Under the synergistic effects of Ag(I) and Fe(III), the bacterial oxidation rate of the arsenic-containing gold ore can reach higher than 90%; and oxidation time is greatly shortened. On one hand, the synergistic reinforcement of Ag(I) and Fe(III) accelerates the dissolution of the arsenopyrite; on the other hand, toxicity of As (III) in the system toward to the bacteria is lowered, so that the bacterial oxidation of the arsenic-containing gold ore is reinforced; and important theoretical and technical guidance for increasing efficiency bacterial preoxidation-cyanide gold leaching process of the gold ore.

Owner:CENT SOUTH UNIV

Water treatment compound agent based on potassium ferrate and preparation method of water treatment compound agent

InactiveCN103121745AEasy to handleReduce cost inputWater/sewage treatment by flocculation/precipitationWater/sewage treatment by sorptionBiocompatibility TestingTherapeutic effect

The invention discloses a water treatment compound agent based on potassium ferrate. The water treatment compound agent comprises the following components by mass percent: 8-35 percent of potassium ferrate, 25-50 percent of polymeric ferric sulfate, 20-40 percent of diatomite, 5-20 percent of calcium hydroxide and 3-8 percent of sodium hydroxide. A preparation method of the water treatment compound agent comprises the following steps of: adding the components into a dry vessel one by one, introducing dry inert gas to carry out protection, uniformly mixing under the condition of room temperature, and storing a mixture in the inert gas environment and a sealed and dark position without water. With the adoption of the water treatment compound agent, the cost investment in the water treatment process is effectively lowered, and the water treatment effect of potassium ferrate can also be further improved; and the water treatment compound agent is wide in component source and good in biocompatibility, has low cost, does not have environmental toxicity and accords with the requirement of greening of water treatment.

Owner:XIJING UNIV

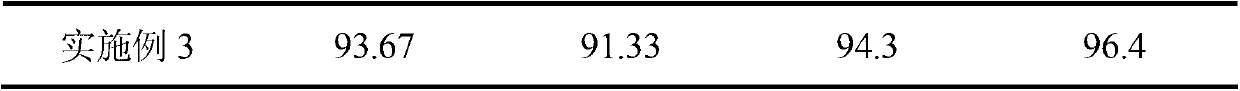

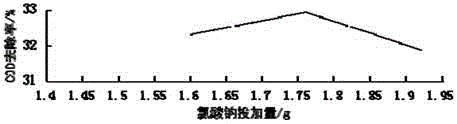

Experimental method for preparation of poly-iron-based flocculating agent for coking wastewater advanced treatment

InactiveCN105000640AOptimum Acid DosageImprove stabilityWater/sewage treatment by flocculation/precipitationSilicic acidTurbidity

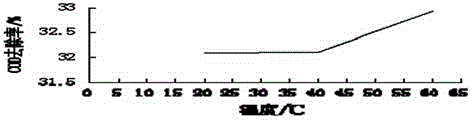

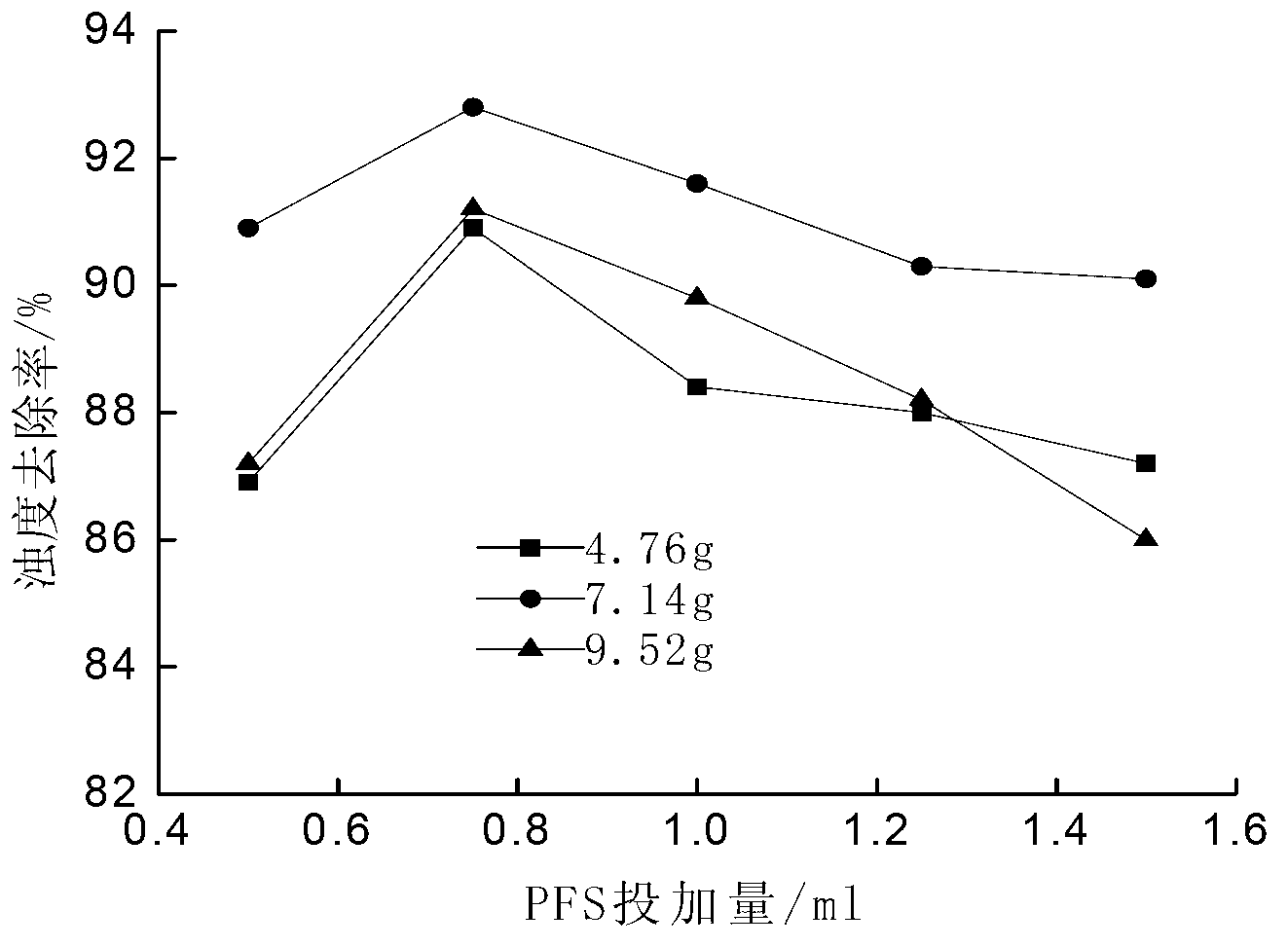

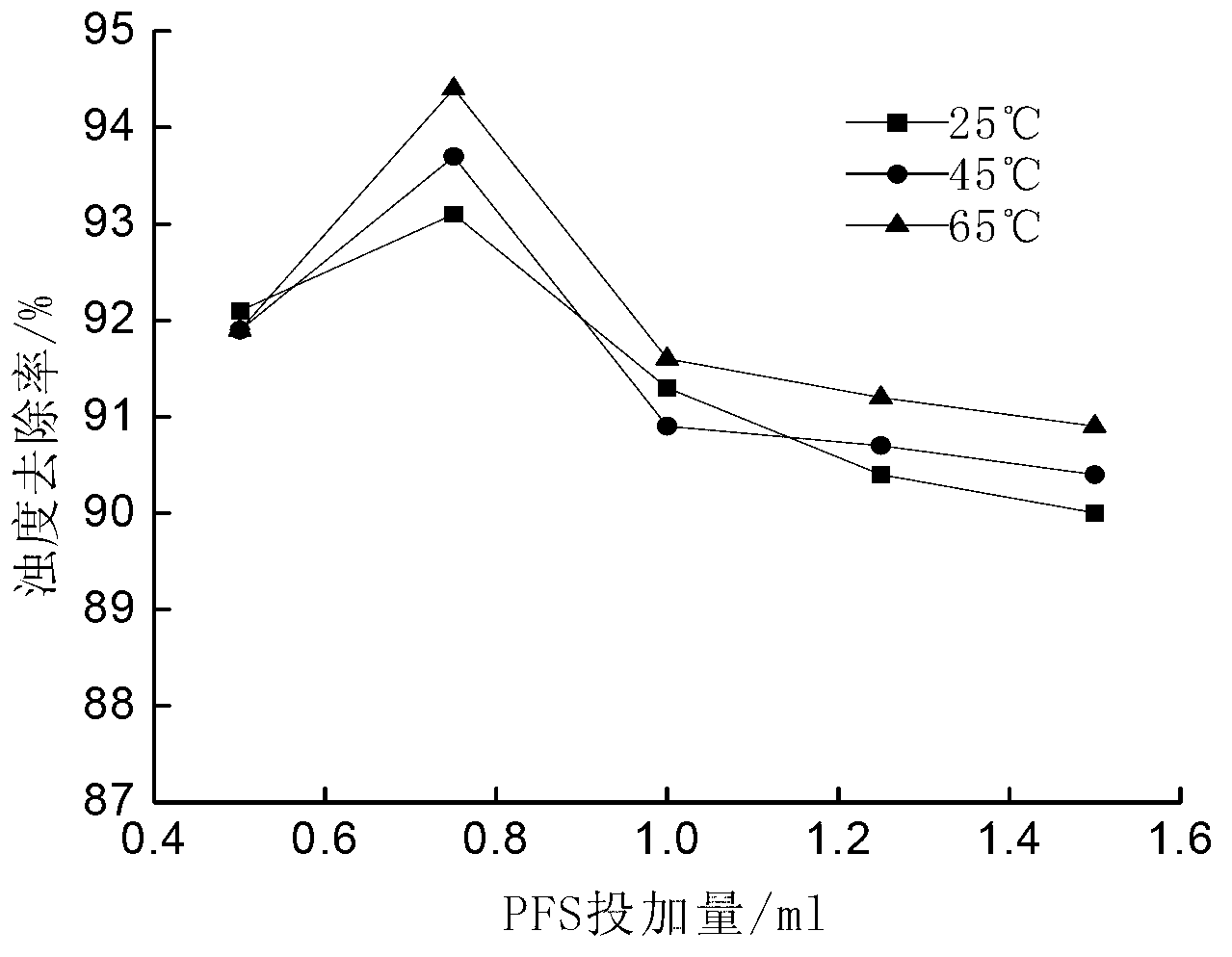

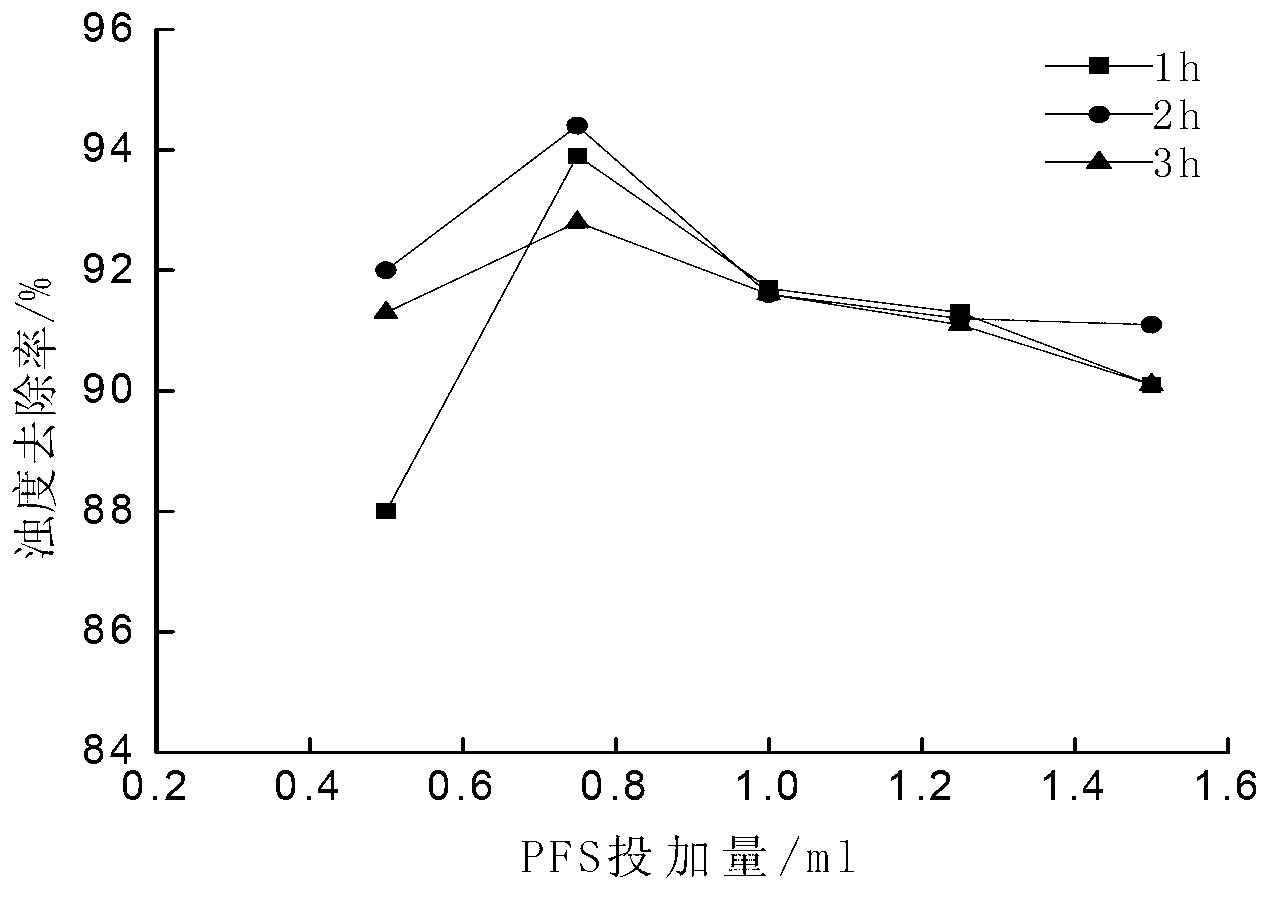

The invention relates to an experimental method for the preparation of a poly-iron-based flocculating agent for coking wastewater advanced treatment. The experimental method comprises the specific operating steps that 1, the optimal preparation conditions of polymeric ferric sulfate are determined through an orthogonal experiment method; 2, on the basis of the optimal conditions of the polymeric ferric sulfate, an aluminum ingredient is added, and the optimal molar ratio of Fe to Al is determined through a coagulation experiment; 3, on the basis of polymeric ferric aluminum sulfate, activated silicic acid and positive polyacrylamide ingredients are added, and the optimal iron-aluminum proportion is determined through a coagulation experiment; 4, polysilicate ferro-alumium sulfate is applied to the coking wastewater advanced treatment, and the optimal technological conditions of the flocculating agent are determined. According to the experimental method for the preparation of the poly-iron-based flocculating agent for coking wastewater advanced treatment, under the conditions that the pH value of the flocculating agent is 7 and the dosing quantity is 0.83 mL / L, the CODcr removing rate of a coking wastewater sample can reach 50%, the turbidity removing rate reaches 95.96%, the chroma removing rate reaches 50%, through the research and development of the optimal flocculating agent matching, the efficiency of coking wastewater coagulation treatment is improved, and the load of follow-up treatment units is reduced.

Owner:辽宁中冠环境工程股份有限公司

Wastewater treatment agent for paper mill

InactiveCN103102020ALow costGrowth inhibitionScale removal and water softeningWaste water treatment from plant processingPhosphateIron(III) sulfate

The invention relates to a wastewater treatment agent for a paper mill. The wastewater treatment agent for the paper mill comprises the following components: 50-80 parts of biomass charcoal powder, 20-40 parts of synergist formed by polymeric ferric sulfate or aluminium polychlorid or poly propylene amide or carboxymethyl starch, 30-40 parts of ethidene diamine, and 10-15 parts of phosphate, wherein the phosphate is one or more of sodium or potassium salt containing phosphate radical, hydrogen phosphate or dihydrogen phosphate radical. By adopting the wastewater treatment agent disclosed by the invention, the wastewater treatment agent can effectively play the roles of corrosion inhibition, scale inhibition, and inhibition of growth of algae after being added to a circulating water system, and plays a good protection role on a cooling water system; no 'three wastes' are discharged in the entire process; the pollution of black liquor of a pulping paper mill is solved; the wastewater treatment agent is used for treatment of wastewater, treats the waste by the waste, is simple in treatment process, less in dosage and good in effect; the cost of water treatment is effectively reduced; and the wastewater treatment agent has good economic benefit and wide social benefit.

Owner:青岛海颐天仪器有限公司

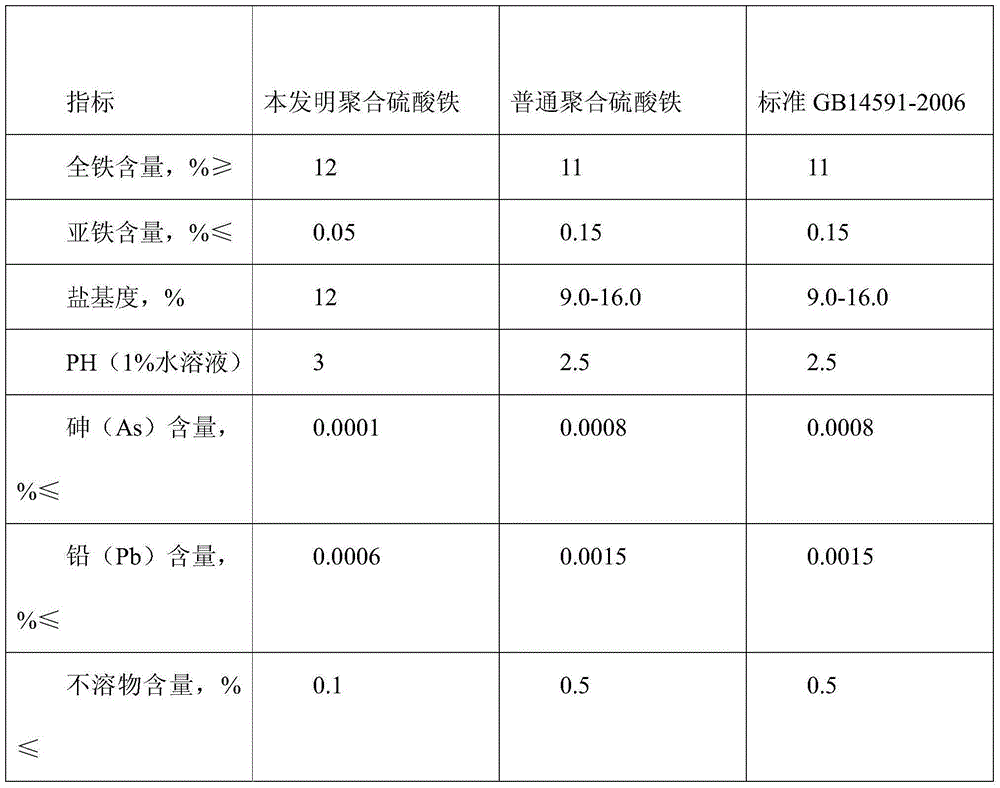

Preparation method of polyferric sulfate (PFS)

InactiveCN103241779AImprove the coagulation effectHigh turbidity removal rateIron sulfatesWater/sewage treatment by flocculation/precipitationWater bathsPersulfate

The invention relates to a preparation method of polyferric sulfate (PFS). The method comprises the following steps of dissolving a certain amount of bivalent ferric salt into water; adjusting the pH value through sulfuric acid, and heating and stirring in a water bath; adding a certain amount of persulfate serving as an oxidant to oxidize Fe<2+> in solution; and performing hydrolytic polymerization to obtain PFS. A novel method is provided for the preparation of PFS. The method disclosed by the invention has a simple process; a prepared PFS coagulant has a good coagulation effect and high turbidity removal rate of up to 94.6 percent; moreover, various indexes of the prepared PFS coagulant are consistent with the requirement of PFS serving as a GB14591-2006 water treatment agent; furthermore, the using amount of ferrous sulfate required to be added in the method is small, the adding speed of sodium persulfate serving as an oxidant is easy to control, and ferrous iron is fully oxidized; and moreover, the method has the advantages of simple operating process, no corrosion, wide pH application range, low cost, high performance and a very good market prospect.

Owner:XIAN UNIV OF SCI & TECH

Method for producing solid poly ferric sulfate

ActiveCN102718268AReduce manufacturing costLow costIron sulfatesWater/sewage treatment by flocculation/precipitationIron(III) sulfateChemistry

The invention relates to a method for producing solid poly ferric sulfate. The key point of the technical scheme of the invention is as follows: the method for producing solid poly ferric sulfate comprises the following steps: weighing 100 parts by weight of industrial ferrous sulfate (FeSO4.7H2O), adding into an acidproof reaction kettle, heating to 80-130 DEG C, and electrically stirring to become slurry; respectively adding 10-13 parts by weight of 98% (mass concentration) concentrated sulfuric acid and 20-30 parts by weight of 50% (mass concentration) oxydol in a spraying mode, and stirring to react for 1-4 hours; and adding 2-6 parts by weight of industrial ammonium salt, uniformly stirring, then transferring all the products to a condensing tank, cooling, and standing for 8-36 hours to obtain powdery solid poly ferric sulfate. The invention has the advantages of low production cost, low energy consumption, simple operation procedure, low equipment cost and the like. The produced solid poly ferric sulfate conforms to the requirements of national standard (GB14591-2006 Water treatment chemical-Poly ferric sulfate) and can be widely used. The solid poly ferric sulfate can be used for purifying both sewage and drinking water.

Owner:HENAN NORMAL UNIV

Organic sewage treatment complexing agent

InactiveCN1482074APromote mutual cohesionIncrease lethalityWater/sewage treatment by flocculation/precipitationWater qualityIron(III) sulfate

The chemical compound for sewage treatment consists of aluminum chloride polymer 94-98 wt% and iron trichloride 2-6 wt%. Here, aluminum chloride polymer may be replaced with iron sulfate polymer; and polyacrylamide, copper dichloride, symclosene, etc. may be also added into the chemical compound for suiting varying sewage. The chemical compound may be recovered for reuse, and has low water treating cost. The treated water can reach GB / 14848-2001V standard.

Owner:深圳市金朝阳环保科技有限公司 +1

Preparation method of polymeric ferric sulfate

InactiveCN105776354AShorten the production cycleNo impuritiesIron sulfatesWork in processIron(III) sulfate

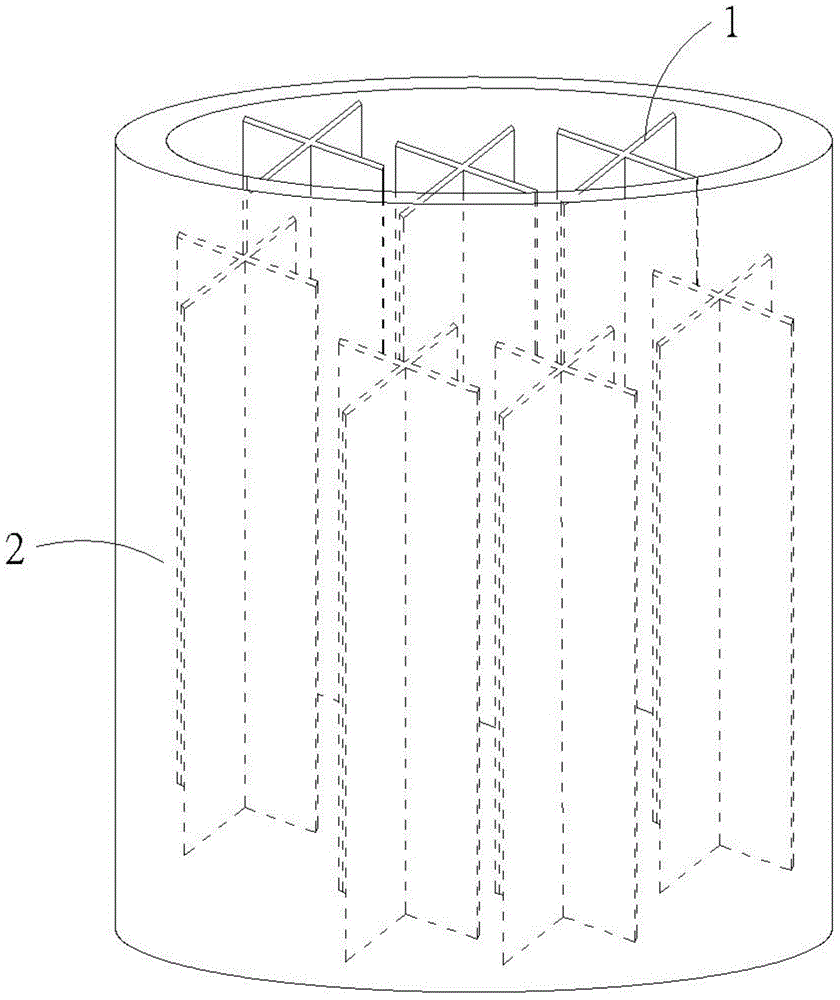

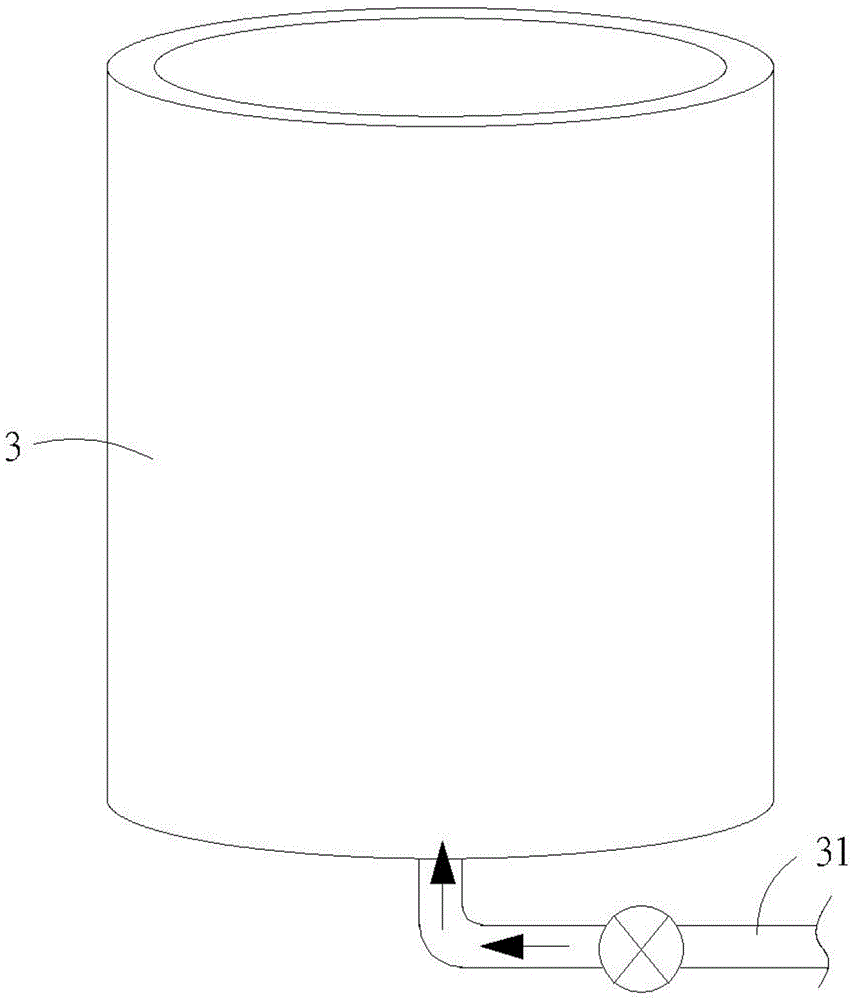

A preparation method of polymeric ferric sulfate comprises the following steps in sequence: step a, providing waste sulfuric acid; step b, adding and mixing: sequentially adding at least one iron sheet, waste sulfuric acid obtained in the step (a), and water into a first reaction tank, wherein the volume ratio of waste sulfuric acid to water is 1:1.5-3, and carrying out reactions to form a ferrous sulfate semi-finished product with a ferrous sulfate content of 4 to 6%; step c, providing a second reaction tank for oxidation, adding the ferrous sulfate semi-finished product, water, and sulfuric acid into the second reaction tank, heating the mixture to a temperature of 30 to 45 DEG C, and adding hydrogen peroxide to obtain polymeric ferric sulfate, wherein the volume ratio of ferrous sulfate semi-finished product to water to sulfuric acid to hydrogen peroxide is 100:1:3:3.

Owner:YOUDING YONGAN OPTOELECTRONICS MATERIAL

Straw/polyferric sulfate composite water treatment material and preparation method thereof

ActiveCN104261541AGood adsorption and flocculation performanceSuitable for large-scale processingWater contaminantsWater/sewage treatment by flocculation/precipitationHigh concentrationHuman health

The invention discloses a straw / polyferric sulfate composite water treatment material and a preparation method thereof. A composite material with a good water treatment effect is prepared by using straw and polyferric sulfate as raw materials through a liquid phase method. The raw materials of the composite water treatment material are low in price, the composite water treatment material can be prepared under the conditions of normal temperature and normal pressure, reaction conditions are mild, the process is simple, and the preparation process is easy to control; the prepared composite material can play the advantages of a ferric salt polymer in the water treatment process, the iron content of treated water is reduced, the flocculating performance is good, the composite material has high wastewater treatment capacity, the negative effects caused by the fact that ferric ions enter the environment can be improved to the greatest extent, the problems that the water treated by a ferric salt flocculating agent is commonly colored and contains high-concentration high-valence state iron are solved, the injury to the human health is effectively avoided, and the composite material is applicable to large-scale wastewater treatment.

Owner:FUJIAN MELTS SPRINGS DTC CO LTD

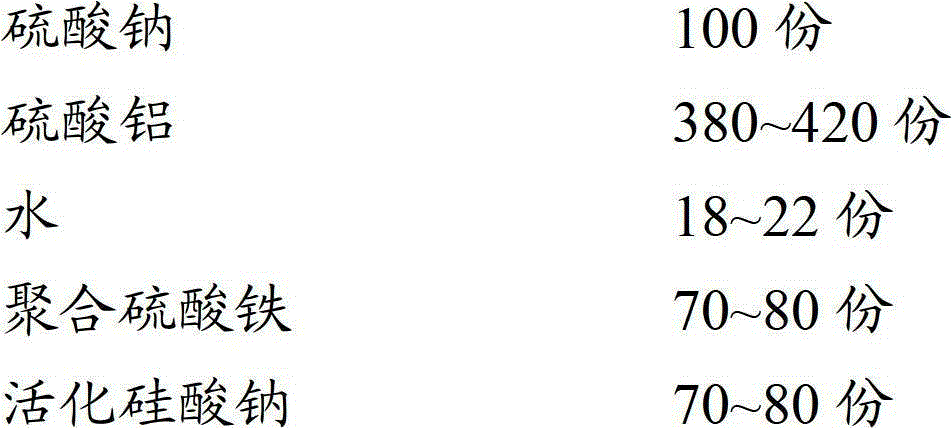

Compound medicament for treating coking wastewater and preparation method thereof

InactiveCN102718295AStable structureEasy to makeWater/sewage treatment by flocculation/precipitationChemical oxygen demandDyeing wastewater

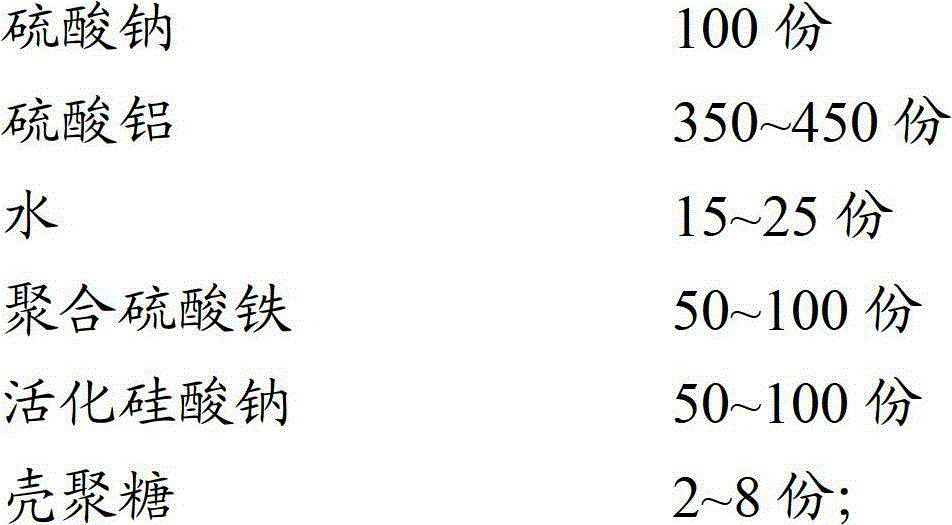

The invention discloses a compound medicament for treating coking wastewater and a preparation method thereof and belongs to the technical field of material and environment engineering. The compound medicament comprises the following components in part by mass: 100 parts of sodium sulfate, 350-450 parts of aluminum sulfate, 15-25 parts of water, 50-100 parts of polymeric ferric sulfate, 50-100 parts of activated sodium silicate and 2-8 parts of chitosan. The preparation method comprises the following steps: carrying out hydrothermal reaction after the sodium sulfate, the aluminum sulfate and the water are mixed according to the proportion, cooling, then adding the polymeric ferric sulfate, the activated sodium silicate and the chitosan according to the proportion, agitating, uniformly mixing, and drying at a constant temperature to obtain the compound medicament. The medicament prepared by the method has good removal effect on the treatment of biochemical effluent water of coking wastewater, pharmaceutical wastewater, printing and dyeing wastewater and garbage leachate wastewater, and particularly has better effect for removing both COD (Chemical Oxygen Demand) and chromaticity inthe coking wastewater.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com