High polymer composite coagulant for treatment of oily waste water and making method thereof

A composite flocculant and wastewater treatment technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, chemical instruments and methods, etc., can solve complex operation management, low oil content and poor treatment effect and other problems, to achieve the effect of good treatment effect, less waste residue generation and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

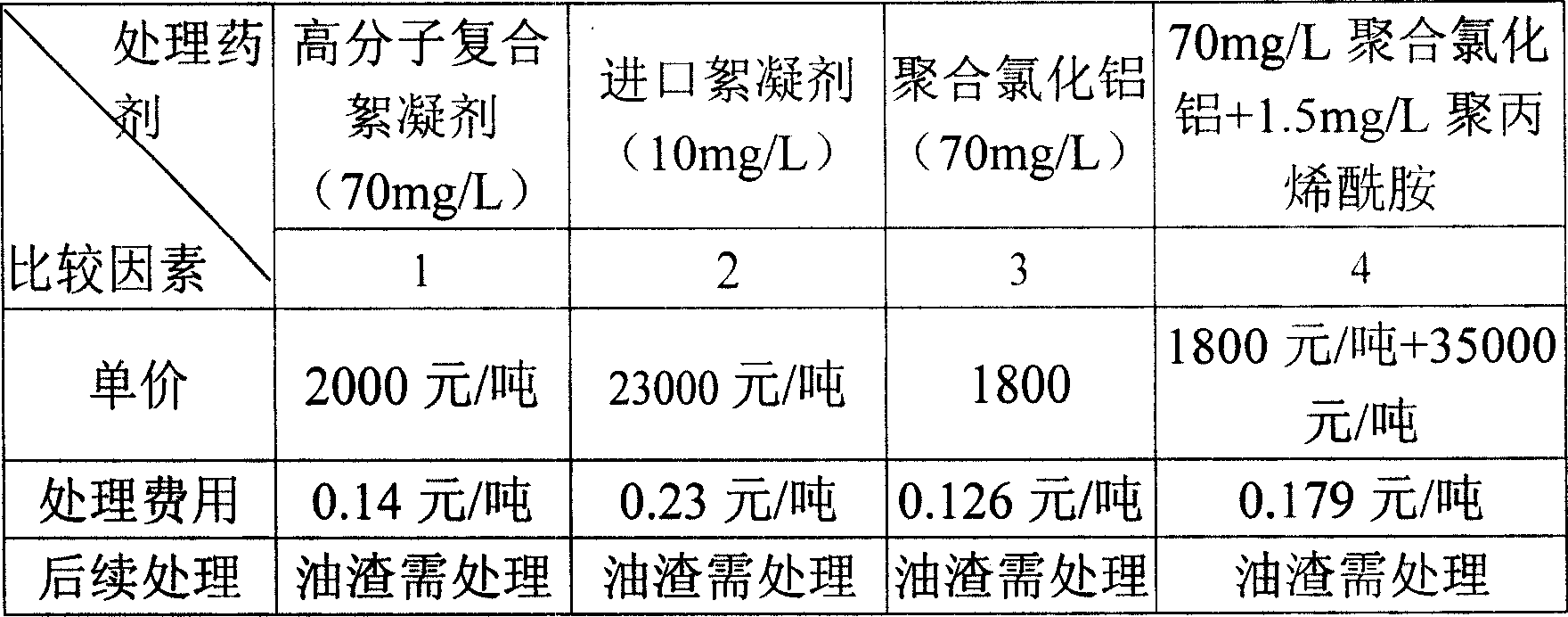

[0032] 1. Determination and preparation of the main raw materials of the polymer composite flocculant used for oily wastewater treatment of the present invention:

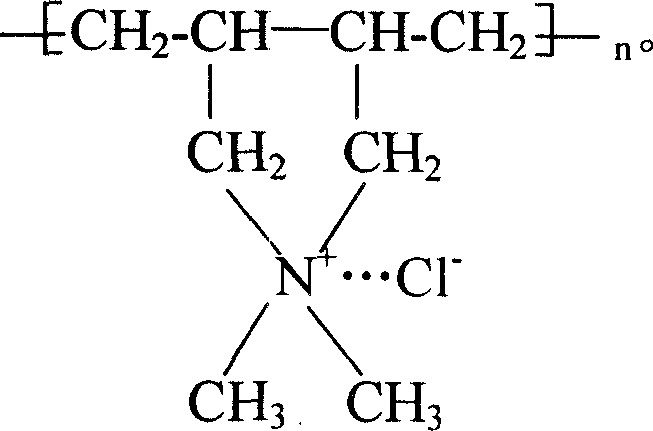

[0033] Main component and weight ratio of the present invention are polyaluminum chloride: polyferric sulfate: sodium silicate: polydiallyl dimethyl ammonium chloride: water=39.00: (1.90~2.10): (0.26~0.31): (1.04~1.52): (57.80~57.10); wherein polydiallyl dimethyl ammonium chloride contains 0.02% cationic polyacrylamide. Sodium silicate can also be potassium silicate, but sodium silicate is cheaper.

[0034] The optimal composition and weight ratio are polyaluminum chloride: polyferric sulfate: sodium silicate: polydiallyl dimethyl ammonium chloride: water=39.00: 1.90: 0.28: 1.52: 57.30.

[0035] The chemical name and characteristic description of the raw materials used:

[0036] PAC

[0037] English name: Polyaluminium chloride

[0038] Structural formula: [Al(OH) m Cl 6-m ] n , where m≤10, n=1~5.

[0039] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com