Water treatment compound agent based on potassium ferrate and preparation method of water treatment compound agent

A technology of potassium ferrate and preparation method, which is applied in the field of water treatment, can solve the problems of late development time, high price, and treatment cost limitation on the application of potassium ferrate, and achieve the effects of reducing cost input, low price, and increasing water treatment performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A water treatment composite agent based on potassium ferrate, containing by mass percentage: 22% potassium ferrate, 35% polyferric sulfate, 30% diatomaceous earth, 10% calcium hydroxide, 3% sodium hydroxide, and its preparation method Method: first take 22% of potassium ferrate, 35% of polyferric sulfate, 30% of diatomaceous earth, 10% of calcium hydroxide and 3% of sodium hydroxide according to the mass percentage, then add the above ingredients into a dry container one by one, and pass it into Under the protection of dry argon, stir at room temperature for 20 minutes until the mixture is uniform at a stirring speed of 50 rpm, and store in an argon environment, sealed, water-proof, and dark place.

Embodiment 2

[0018] A water treatment composite agent based on potassium ferrate, containing by mass percentage: 12% potassium ferrate, 40% polyferric sulfate, 25% diatomaceous earth, 20% calcium hydroxide, 3% sodium hydroxide, its preparation method Method: first take 12% of potassium ferrate, 40% of polyferric sulfate, 25% of diatomaceous earth, 20% of calcium hydroxide and 3% of sodium hydroxide according to the mass percentage; Protected by dry argon, stir at room temperature for 30 minutes until the mixture is uniform, and the stirring speed is 30 rpm, and store in an argon environment, sealed, water-proof, and dark place.

Embodiment 3

[0020] A water treatment composite agent based on potassium ferrate, containing by mass percentage: 30% potassium ferrate, 30% polyferric sulfate, 20% diatomaceous earth, 17% calcium hydroxide, 3% sodium hydroxide, its preparation method Method: first take 30% of potassium ferrate, 30% of polyferric sulfate, 20% of diatomaceous earth, 17% of calcium hydroxide and 3% of sodium hydroxide according to the mass percentage, and then add the above ingredients into a dry container one by one, and pass them into Under dry nitrogen protection, stir at room temperature for 40 minutes until uniformly mixed at a stirring speed of 60 rpm, and store in a nitrogen environment, sealed, water-free, and dark place.

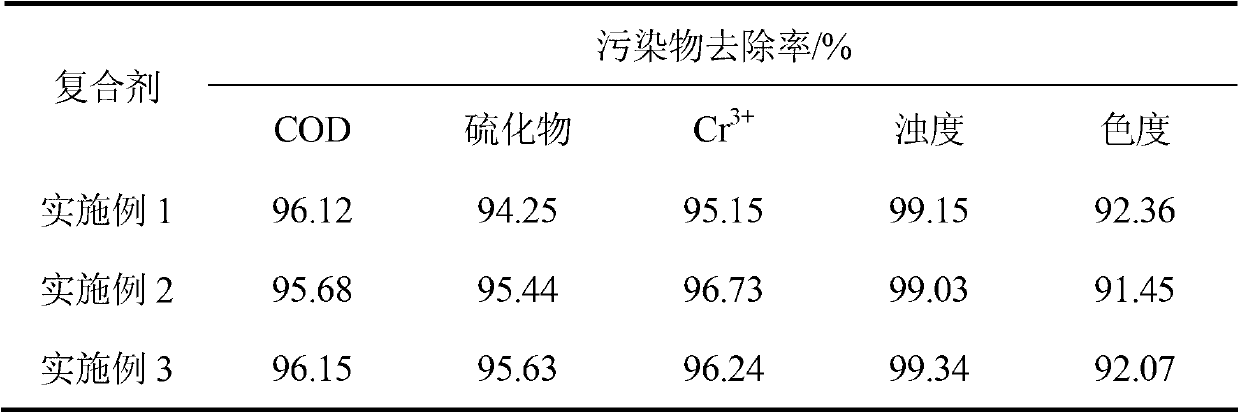

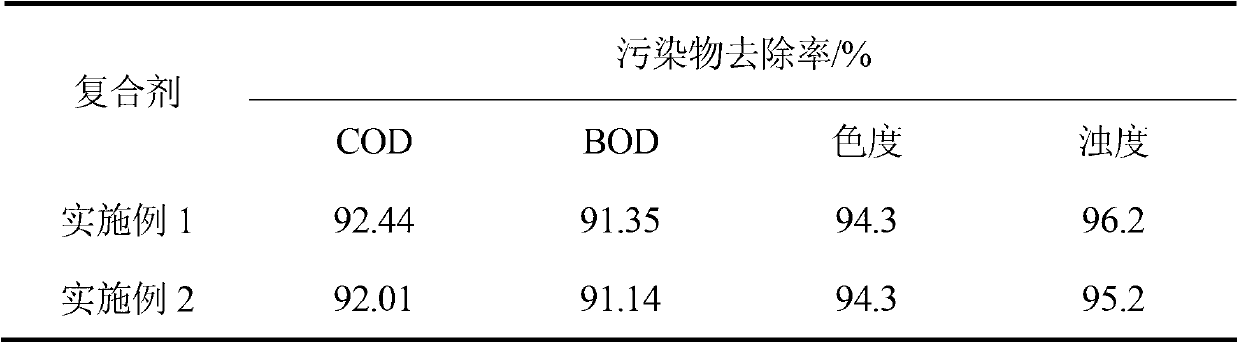

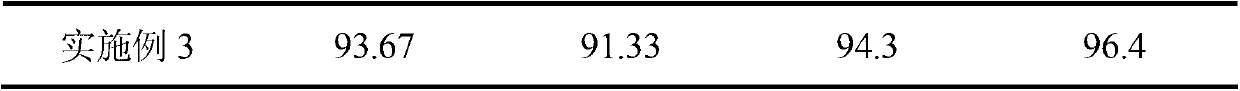

[0021] Specific use effect

[0022] Wastewater 1: The comprehensive tannery wastewater used in the experiment comes from a tannery in Haining City, Zhejiang Province. The wastewater has not been treated in any way. Its pH value is 5.9, chromaticity is 1300 times, COD Cr It is 5602...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com