Method used for preparing polymeric ferric sulfate from sulfuric acid waste liquid

A technology for polymerizing ferric sulfate and sulfuric acid waste liquid, applied in the direction of ferric sulfate, etc., can solve the problems of waste of resources, ecological environment hazards, water body and soil acidification, etc., and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

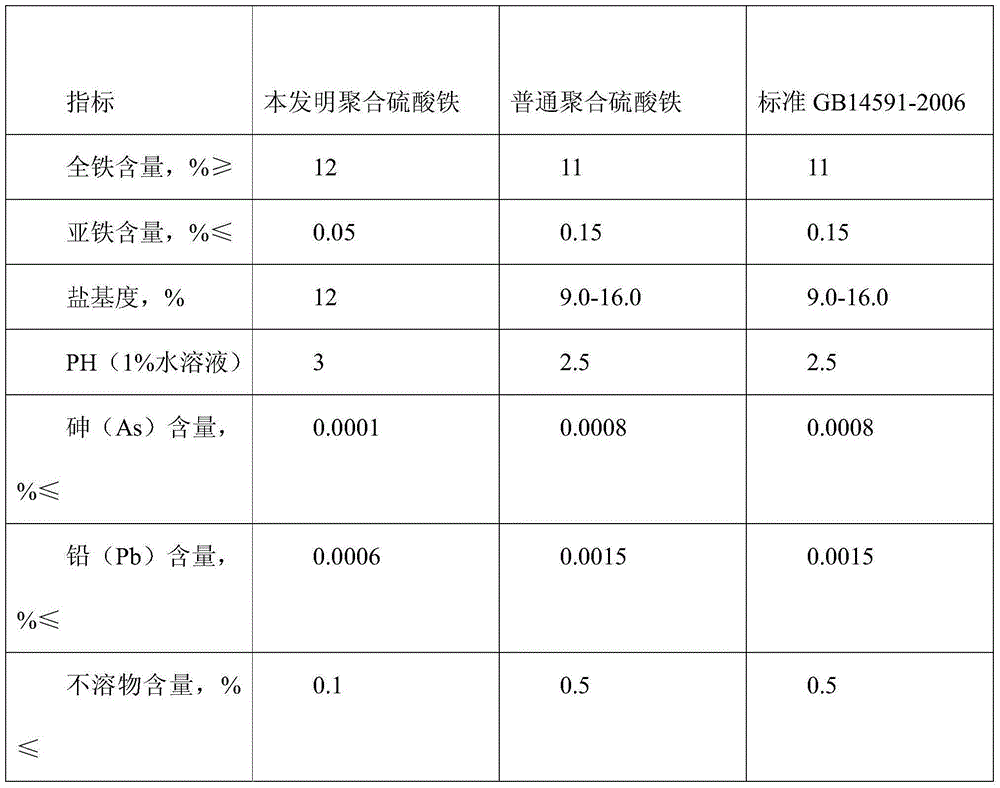

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of method utilizing sulfuric acid waste liquid to prepare polyferric sulfate, comprises the following steps:

[0020] (1) Adding the sulfuric acid waste liquid with a concentration of 13% in the batching tank, and then according to the mass ratio H 2 SO 4 :FeSO 4 =1:1.6 ratio adds ferrous sulfate heptahydrate, mixes batching; Described ferrous sulfate heptahydrate is the powdered solid of centrifugal dehydration after removing impurity through hydrolysis;

[0021] (2) After the batching is completed, put it into the closed reaction kettle, slowly add sodium nitrite into the reaction kettle according to the ratio of 2kg per ton of product for polymerization reaction, add sodium nitrite in three to four times, and react when adding The pressure of the kettle is constant, and oxygen is introduced at the same time, and the speed of oxygen injection is such that the pressure of the reactor is maintained at 0.05MPa;

[0022] (3) When the temperature of the reaction ...

Embodiment 2

[0024] A kind of method utilizing sulfuric acid waste liquid to prepare polyferric sulfate, comprises the following steps:

[0025] (1) Adding the sulfuric acid waste liquid with a concentration of 20% in the batching tank, and then according to the mass ratio H 2 SO 4 :FeSO 4 =The ratio of 1:2 adds ferrous sulfate heptahydrate, mixes batching; Described ferrous sulfate heptahydrate is the powdered solid of centrifugal dehydration after removing impurity through hydrolysis;

[0026] (2) After the batching is completed, put it into the closed reaction kettle, and slowly add sodium nitrite into the reaction kettle at a rate of 5kg per ton of product to carry out polymerization reaction. When adding, the pressure of the reaction kettle is constant, and oxygen is introduced at the same time , the oxygen dosing speed is to maintain the pressure of the reactor at 0.1MPa; after adding sodium nitrite twice, take a sample to test the ferrous content, determine the amount of sodium ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com