Combined treatment process for urban garbage percolate

A technology for landfill leachate and treatment process, which is applied in the fields of water/sewage multi-stage treatment, oxidized water/sewage treatment, adsorbed water/sewage treatment, etc., which can solve the problems of difficult disposal of regenerated waste liquid and decrease of working exchange capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

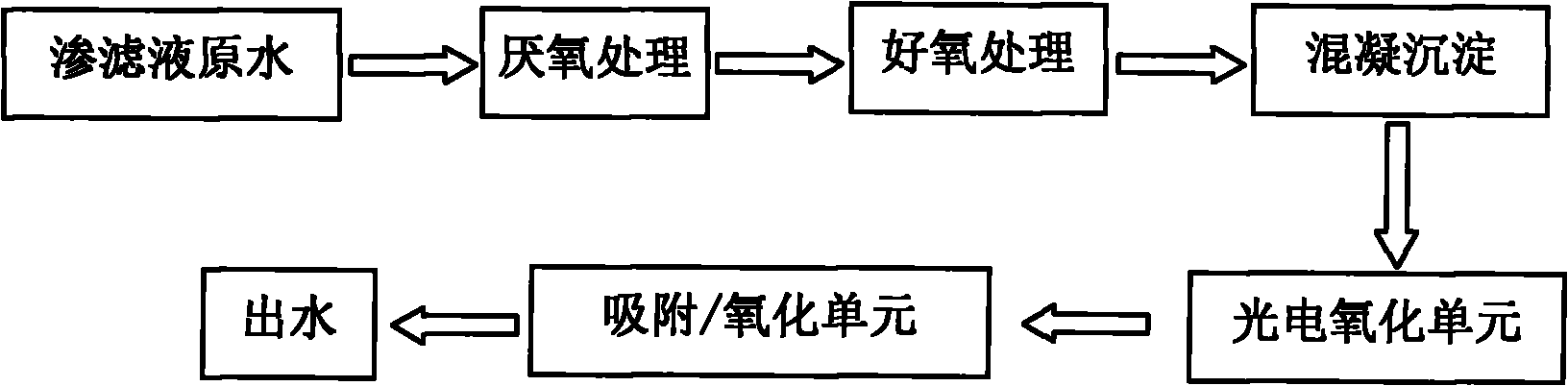

Embodiment 1

[0011] The combined process disclosed by the invention is used to treat the leachate of middle-aged and old garbage, and the leachate is collected from a landfill in Beijing. First, the anaerobic process is used for treatment, and then the aerobic biochemical treatment is carried out by the aerobic membrane bioreactor. The biochemical effluent is treated by the coagulation sedimentation unit, the coagulation sediment effluent enters the photoelectric oxidation reaction unit, and the oxidation effluent passes through the adsorption / oxidation filtration unit. That is, the water can be discharged up to the standard. Among them, the landfill leachate is collected from a landfill, and the leachate belongs to middle-aged and old-age landfill leachate. Raw water COD Cr The concentration is 4000-7000mg / L, and the concentration of ammonia nitrogen is 1500-2000mg / L. The residence times of the anaerobic and aerobic reactors were 50 and 40 hours respectively. The coagulation and sedimen...

Embodiment 2

[0013] The leachate treatment process described in Example 1 was used. The landfill leachate is collected from a landfill in the south, and the leachate belongs to fresh leachate. Raw water COD Cr The concentration is 15000-20000mg / L, the ammonia nitrogen concentration is 1000-1500mg / L, and the total nitrogen concentration is 1200-1800mg / L. The residence time of the anaerobic and aerobic units is 70 and 55 hours respectively, and the coagulation and sedimentation unit uses industrial polyaluminum chloride as the coagulant, and the dosage of the coagulant is 500 mg / L; at the same time, the coagulant polyacrylamide ( 10mg / L). The photoelectric oxidation residence time is 0.5 hours, and the oxidation / adsorption unit adopts the materials disclosed in the patent (200910080596.x), and the dosage is 500mg / L. The residence time of the adsorption / oxidation unit was 0.5 hours. Final effluent COD Cr The concentration is 20-40mg / L, the ammonia nitrogen concentration is 2-8mg / L, the t...

Embodiment 3

[0015] The leachate treatment process described in Example 1 was used. The landfill leachate is collected from a landfill in the south, and the leachate belongs to fresh leachate. Raw water COD Cr The concentration is 15000-20000mg / L, the ammonia nitrogen concentration is 1000-1500mg / L, and the total nitrogen concentration is 1200-1800mg / L. The residence time of the anaerobic and aerobic units is 70 and 55 hours respectively, and the coagulation and sedimentation unit uses industrial polyaluminum chloride and polyferric chloride as coagulants, and the total dosage of coagulants is 500 mg / L; Coagulant polyacrylamide (10mg / L). The photoelectric oxidation residence time is 0.3 hours, and the oxidation / adsorption unit adopts the materials disclosed in the patent (200910080596.x), and the dosage is 400mg / L. The residence time of the adsorption / oxidation unit was 0.5 hours. Final effluent COD Cr The concentration is 15-35mg / L, the ammonia nitrogen concentration is 2-7mg / L, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com