Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

194 results about "Uranium mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Uranium mining is the process of extraction of uranium ore from the ground. The worldwide production of uranium in 2015 amounted to 60,496 tonnes. Kazakhstan, Canada, and Australia are the top three producers and together account for 70% of world uranium production. Other important uranium producing countries in excess of 1,000 tons per year are Niger, Russia, Namibia, Uzbekistan, China, the United States and Ukraine. Uranium from mining is used almost entirely as fuel for nuclear power plants.

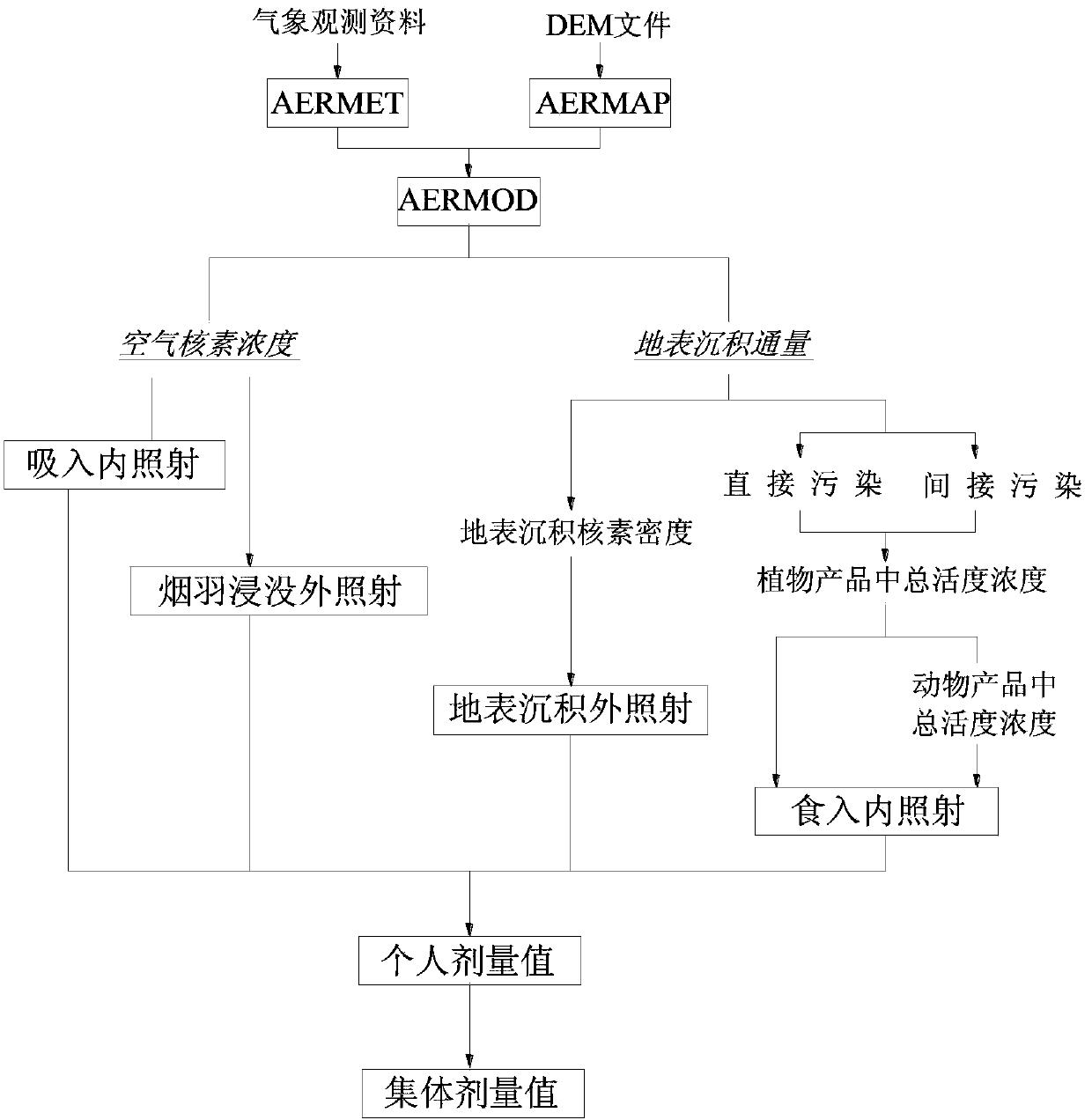

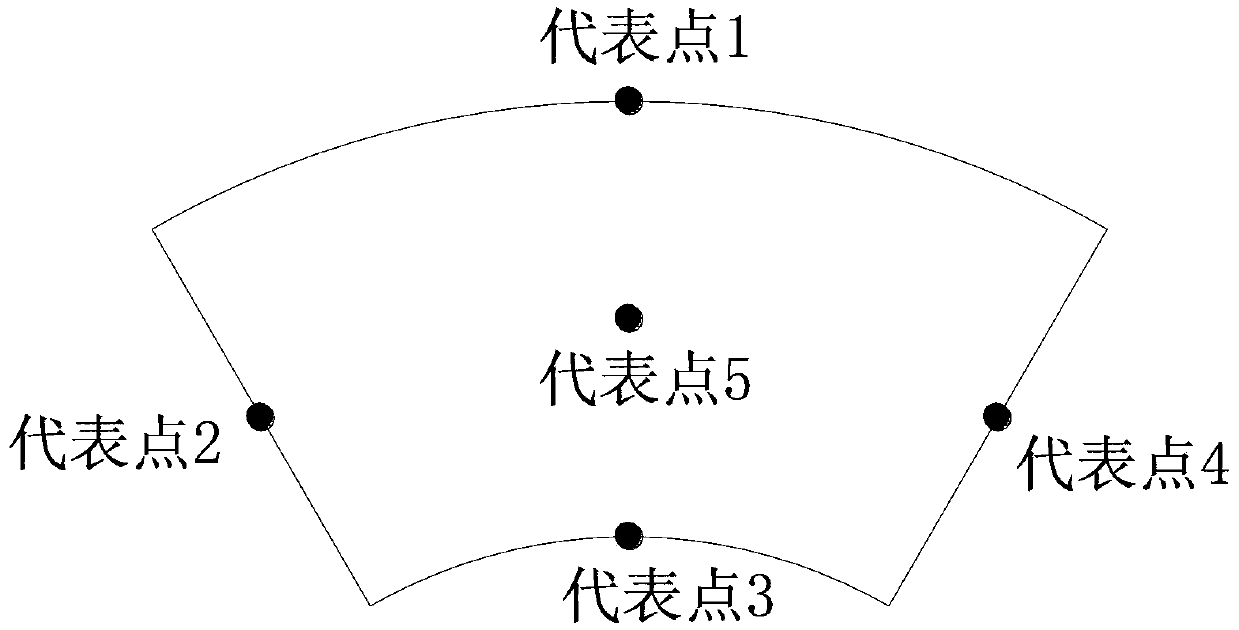

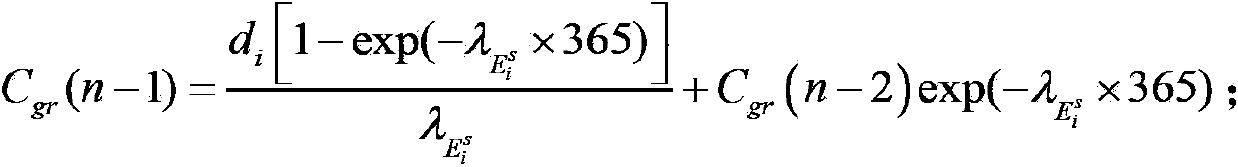

Method for comprehensive evaluation of uranium mining and milling atmospheric radiation environment

InactiveCN104424388ASolve the problem that cannot be calculated at the same timeRealize local multi-source prediction functionSpecial data processing applicationsICT adaptationTerrainEarth surface

The invention provides a method for comprehensive evaluation of uranium mining and milling atmospheric radiation environment. The method comprises the following steps: pretreating atmosphere; pretreating terrain; calculating atmospheric diffusion; determining breathed internal radiation dose; determining eaten internal radiation dose; determining dose of external radiation deposited on earth surface; determining dose of external radiation immersed in smoke plume; determining public individual dose; determining public group dose and the like. The method disclosed by the invention has the functional characteristics of being scientific, accurate, rapid and comprehensive, and is suitable for prediction and evaluation on influences of the national uranium mining and milling atmospheric radiation environment; by using the method, the calculation results can preferably satisfy the actual relocation diffusion rules of atmospheric pollutants, and the environmental influences and public dose calculation are more scientific and reasonable.

Owner:THE FOURTH INST OF NUCLEAR ENG OF CNNC

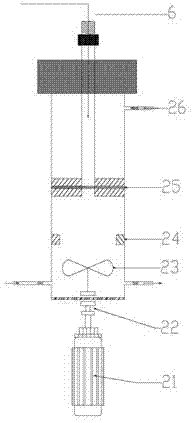

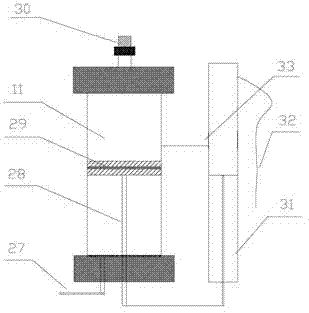

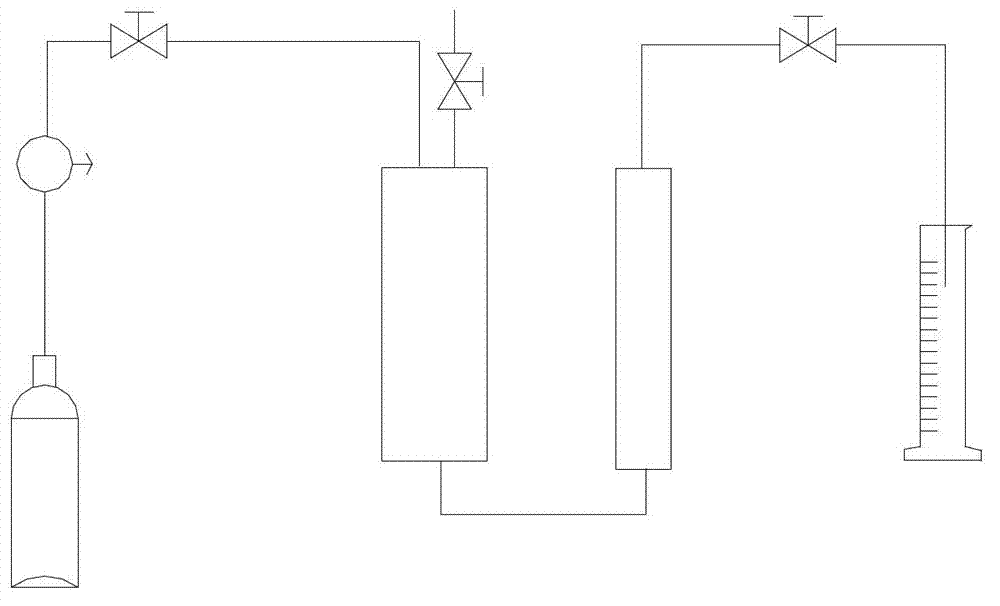

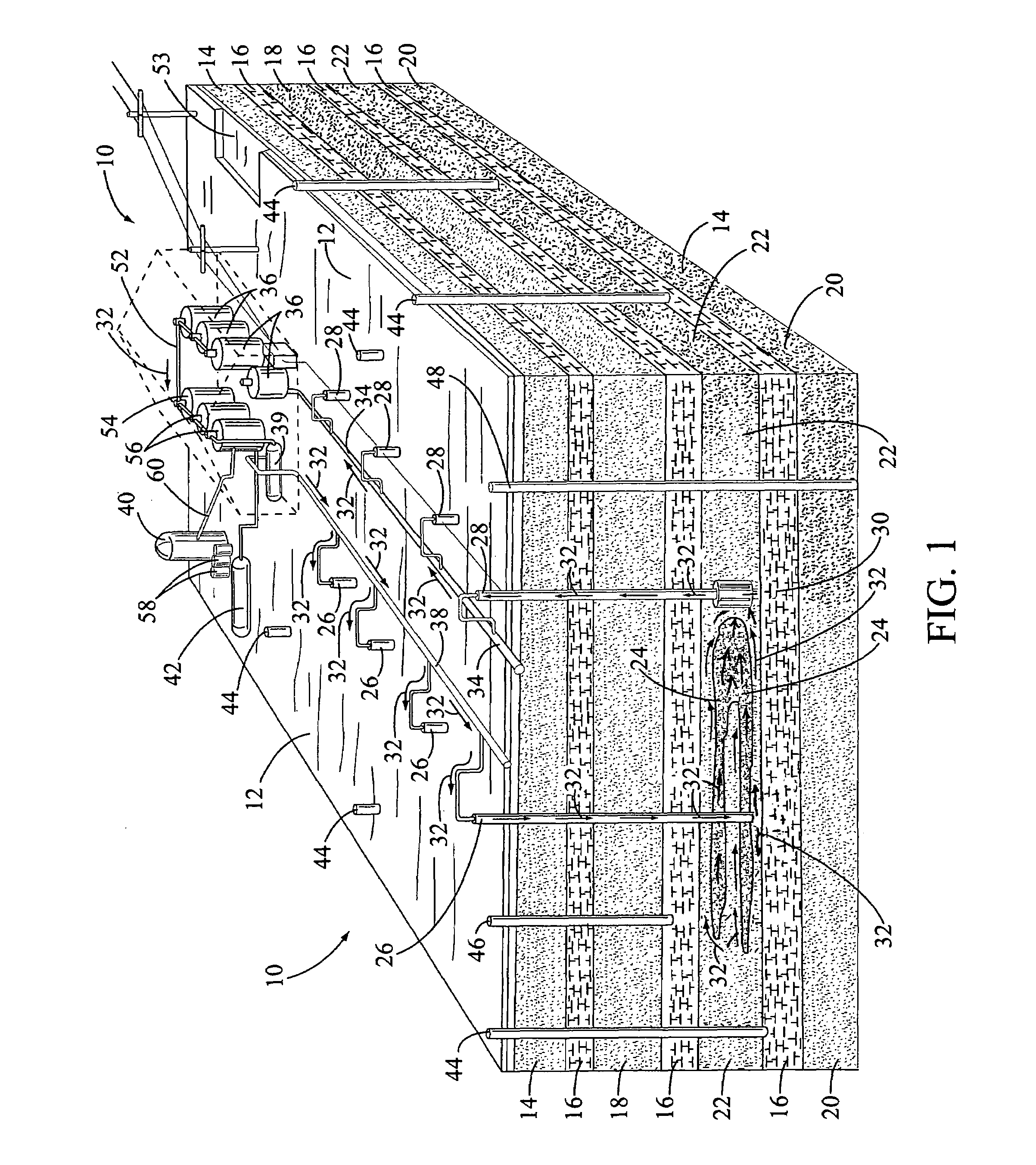

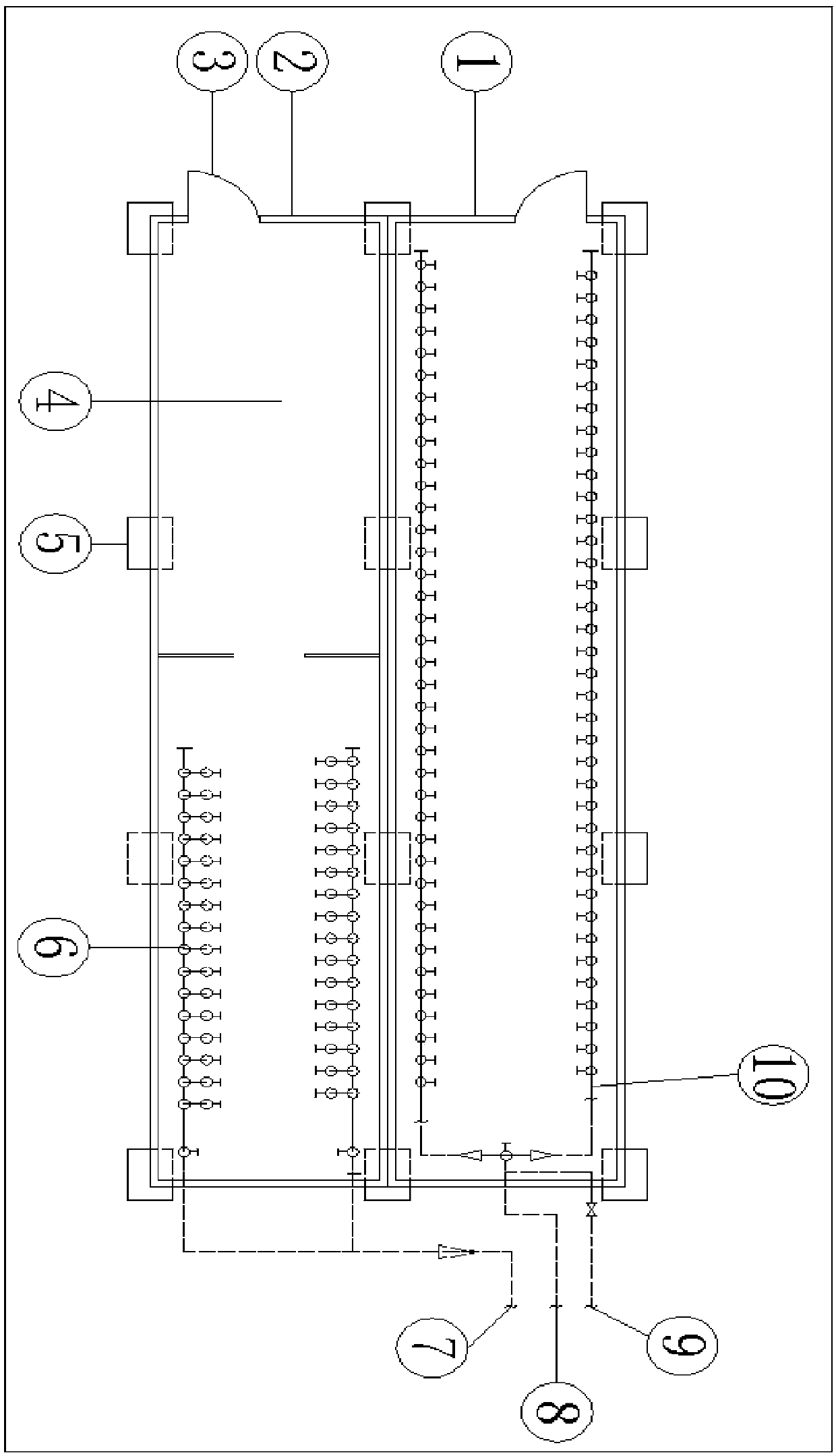

Leaching experimental facility for in-situ leaching uranium mining

ActiveCN103711462ARealize concentration measurementRapid dissolution equilibriumSurveyFluid removalMagnetic tension forceAutomatic control

The invention belongs to the technical field of experimental devices for scientific researches on in-situ leaching uranium mining, and particularly relates to a leaching experimental facility for in-situ leaching uranium mining. A gas source comprises an oxygen source and a carbon dioxide source; gas and liquid are mixed and dissolved by using a magnetic stirring device in a stirring container; dissolving pressure is controlled by a nitrogen cylinder via a stirring container pressure return valve; the pressure provided by a plunger pump is adjusted through an intermediate container pressure return valve in an experiment until the pressure in a liquid injection intermediate container is the same with the pressure in the stirring container; leaching liquid is pressed in the liquid injection intermediate container by a pressure adjusting portion; a rock core is arranged in a full-diameter rock core holding unit; a ring pressure pump and a pressure sensor are arranged at two ends of the holding unit; an outlet end is provided with a leaching pressure return valve; formation pressure is simulated; oxygen in leaching agent is controlled so that the oxygen cannot be separated out; the mass of the liquid is measured by a balance measuring system; and the experiment is automatically controlled by a computer.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Environment-friendly water-holding coal and uranium coordinated mining system and application method thereof

InactiveCN106014344AEliminate the effects ofEfficient use ofFluid removalTunnelsWater dischargeEngineering

The invention discloses an environment-friendly water-holding coal and uranium coordinated mining system. The environment-friendly water-holding coal and uranium coordinated mining system comprises a freezing mechanism, a pumping and injecting mechanism, a water storage mechanism and a mining supporting mechanism. The freezing mechanism is provided with freezing shafts. The pumping and injecting mechanism is provided with fluid injecting wells and a fluid pumping well. The water storage mechanism is provided with an underground reservoir, a security coal pillar and advance water discharge pipes. The mining supporting mechanism is provided with a road header, a coal mining machine, a scraper conveyor and a hydraulic support. The freezing shafts in the freezing mechanism conducts freezing on an aquifer on the periphery of the pumping and injecting mechanism with the pumping and injecting mechanism as the radius; the pumping and injecting mechanism conducts uranium mining by an in-situ leaching technology; the mining supporting mechanism conducts stoping on a coal seam; and the water storage mechanism stores and purifies water in the aquifer of a broken roof. Finally, under rational cooperation of the four mechanisms, coal and uranium coordinated mining is realized, underground water is recovered and purified at the same time, and the purpose of environment-friendly water-holding multi-resource coordinated mining is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Method for in-situ leaching of uranium by low concentration sulfuric acid and oxygen

ActiveCN104726725ANo chemical cloggingNo obvious chemical blockageChemical compositionGroundwater chemistry

The invention relates to a method for in-situ leaching of uranium by low concentration sulfuric acid and oxygen. In-situ leaching of metal uranium from ore beds relates to a process of recovering uranium from uranium ore deposits with non-uniformly distributed carbonate content. The method includes groundwater chemical composition analysis, oxygen injection and oxidation of ore bed, preparation of leaching solution, leaching of metal uranium by leaching solution, leaching maintaining, resin adsorption and other steps. The method can be applied to uranium ore deposits with non-uniformly distributed carbonate content to effectively control chemical clogging and improve the leaching efficiency of in-situ uranium mining. Compared with conventional acidic in-situ leaching of uranium, the method alleviates pollution to mining area groundwater environment. Effects of the leaching process by low concentration sulfuric acid and oxygen show that the method is an effective process for in-situ leaching of uranium.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Resonant Vacuum Arc Discharge Apparatus for Nuclear Fusion

InactiveUS20120008728A1Improve efficiencyImprove fusion efficiencyNuclear energy generationDirect voltage acceleratorsWell loggingNuclear fusion

The present invention relates to a resonant vacuum arc discharge apparatus for producing nuclear fusion. A resonant high-frequency high-voltage alternating current (AC) power supply is used to efficiently power a fusion tube normally containing deuterium, tritium and / or helium-3 vapor. Metals that can hold large amounts of hydrogen isotopes such as palladium and titanium can be used to increase the target density. The nuclear fusion device can be used for energy production, well logging, uranium mining, neutron activation analysis, isotope production or other applications that require a neutron source.

Owner:FLEMING RAY R

Technique for reagent-free in situ leaching uranium mining from sandstone type uranium deposit

InactiveCN101580900AEasy to extract and handleImprove product qualityProcess efficiency improvementWater insolubleUranyl

The invention relates to a technique for reagent-free in situ leaching uranium mining from a sandstone type uranium deposit, which comprises the following steps: performing preoxidation on ore beds by injecting air; injecting industrial oxygen into the ore beds in the processes of extracting and liquid charging; and forming hexavalent uranium into a stable soluble complex in bicarbonate type ground water. The technique achieves the oxidation of the metallic uranium in the ore beds under the condition of not introducing chemical reagents of acid, alkali and the like so that the water-insoluble tetravalent uranium is converted into water-soluble hexavalent uranyl ions for the convenience of performing extraction on the ground surface; besides, the technique has the advantages of stable product quality, low production cost, no pollution of an extraction-injection balanced closed cycle, easy decommissioning treatment and the like.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

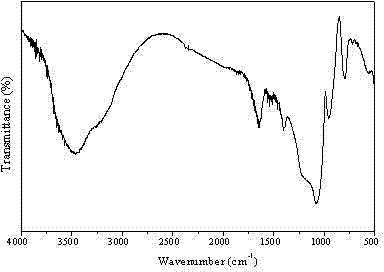

Preparation method of magnetic nano Fe3O4 particles by biological catalysis and application of particles to treatment of uranium-containing wastewater

InactiveCN103877927AImprove adsorption capacityThe synthesis process is simpleOther chemical processesAlkali metal oxides/hydroxidesThiobacillus ferrooxidansIron(II) oxide

The invention provides an ecological and environment-friendly new method for preparing magnetic nano Fe3O4 particles by biological catalysis, and application of the particles to treatment of uranium-containing wastewater. The method comprises the following concrete steps: (1) culturing and domesticating thiobacillus ferrooxidans; (2) preparing bio-polymeric ferric sulfate; (3) synthesizing the magnetic nano Fe3O4 particles; (4) performing a test of adsorbing uranium in the uranium-containing wastewater by the magnetic nano Fe3O4 particles. The obtained magnetic nano Fe3O4 particles are simple in preparation synthesis route, mild in reaction condition and easy to operate; a biological catalysis oxidant is used for replacing a conventional chemical oxidant (nitrite), so that cancerogenic substances are prevented from being discharged to the environment and the environment-friendly effect is really achieved. Meanwhile, the obtained magnetic nano Fe3O4 particles can reduce the content of uranium in the low-concentration uranium-containing wastewater with the concentration of 0.45-0.50mg / L by more than 90% and have very important practical meaning in aspects of uranium-containing wastewater treatment, uranium recovery and the like in uranium mining and metallurgy.

Owner:NANHUA UNIV

Diluted acid in-situ leaching uranium mining technology

ActiveCN104533376AIncrease injection volumeIncrease concentrationFluid removalPregnant leach solutionUranium ore

The invention provides a diluted acid in-situ leaching uranium mining technology according to the characteristics of a carbonate cement low-permeability sandstone type uranium ore deposit. Diluted hydrochloric acid serves as a leaching agent and is injected into an ore bed in an online acid adding mode, the PH value of a leaching solution is kept between 3 and 6 so that carbonate in the ore bed can be quickly dissolved, HCO3- is generated on site, and leaching is promoted. The diluted acid in-situ leaching uranium mining technology has been used in in-situ leaching uranium mining experiments and production of the Shashagetai uranium ore deposit and the Nalinggou uranium ore deposit in Ordos, the liquid injection amount is remarkably increased, and the concentration of the HCO3- and the concentration of leaching liquid uranium are obviously increased.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Acid in-situ leaching uranium mining laboratory simulation device and test method

InactiveCN107460349AAccurate calculation of leaching rateReduced risk of cloggingIon exchangeLiquid storage tank

The invention provides an acid in-situ leaching uranium mining laboratory simulation device. The acid in-situ leaching uranium mining laboratory simulation device comprises a leaching agent storage tank, a leaching column, a leaching liquid storage tank, an ion exchange column, a leaching agent preparation tank, a pump, a valve A, a valve B, a valve C, a valve D, a valve E, a valve F, a valve G and connecting pipes, wherein the leaching agent storage tank is used for storing a leaching agent; the leaching column is used for containing an ore sample and providing a site for a contact reaction between the leaching agent and ore; the leaching liquid storage tank is used for containing leaching liquid; the ion exchange column is used for containing an adsorption material of uranium; the leaching agent preparation tank is used for containing the leaching liquid generated after the uranium is adsorbed by resin; the pump is used for conveying the prepared leaching agent into the leaching agent storage tank; and the connecting pipes are used for connecting all the components. The invention further provides a test method adopting the acid in-situ leaching uranium mining laboratory simulation device. Test results of the device and the test method can provide reliable basis for in-situ test engineering leaching agent preparation and the leaching technique, the risk that according to an in-situ test leaching system, an ore bed is blocked due to accumulation and sedimentation of impurity ions is reduced, and the prevention level is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

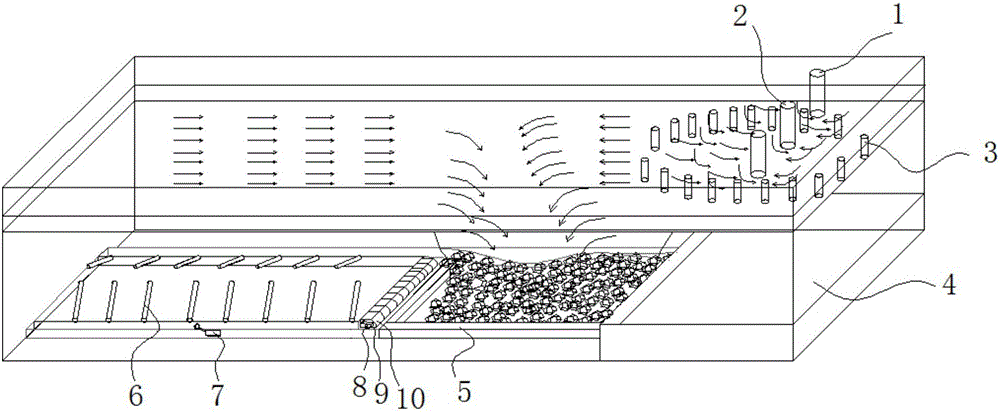

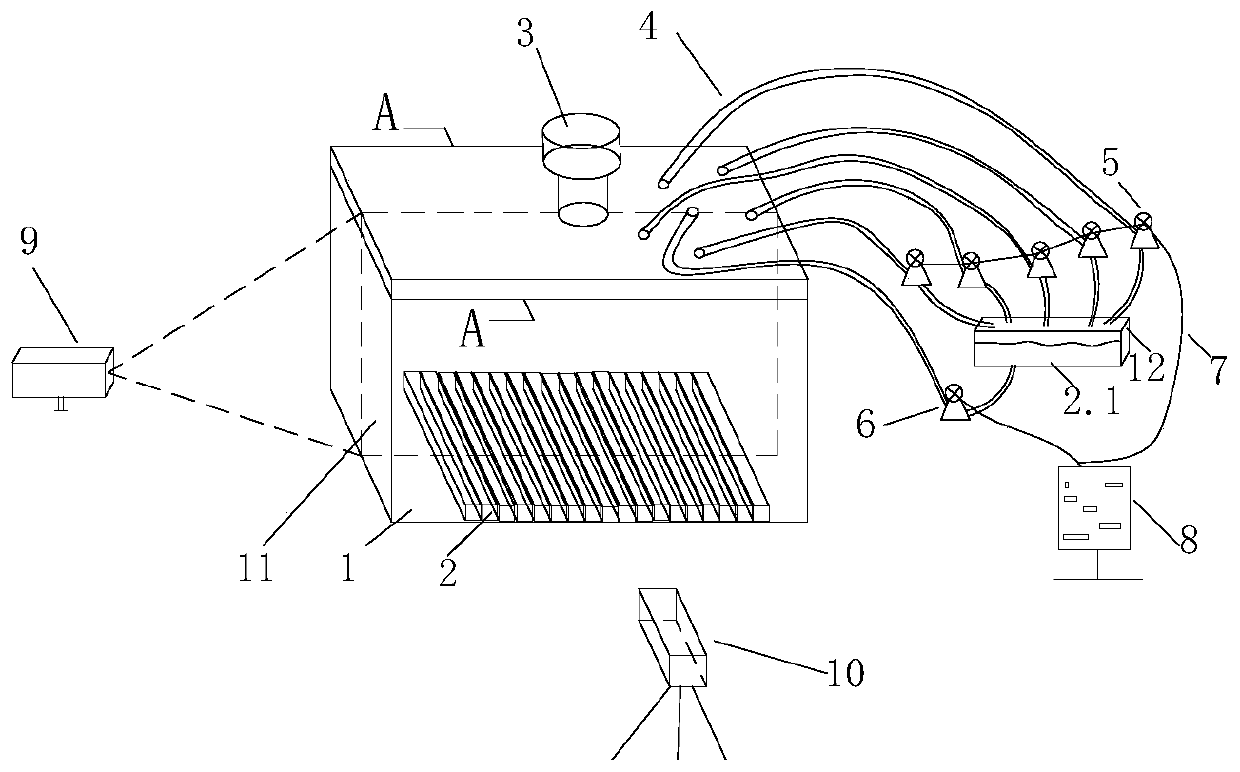

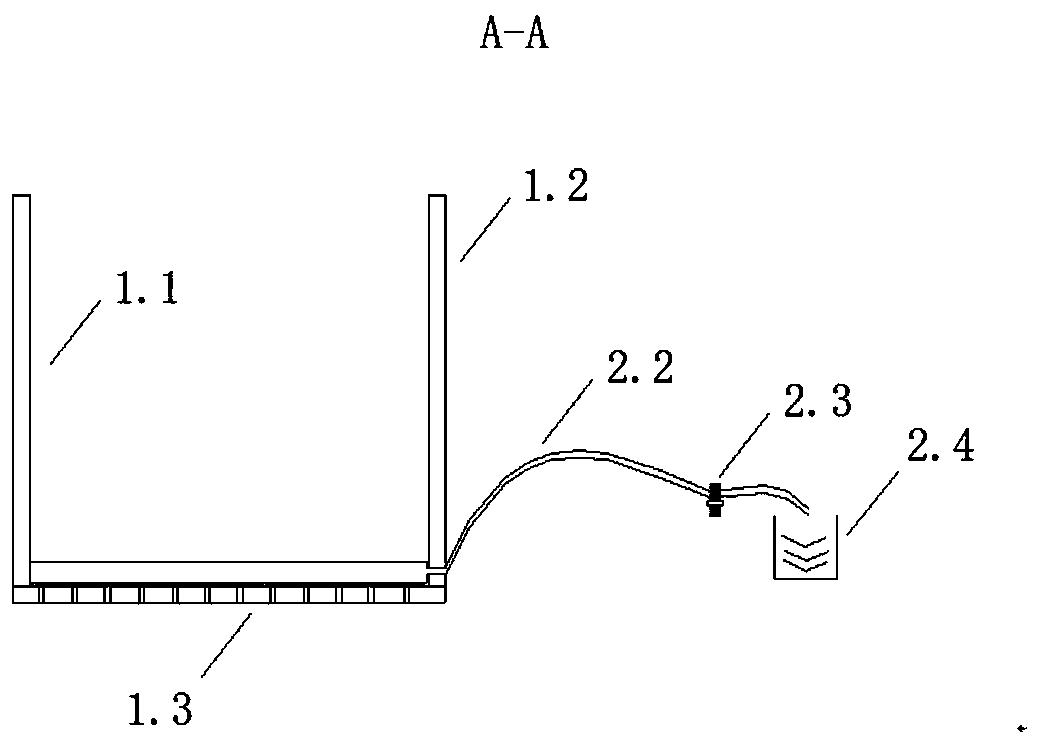

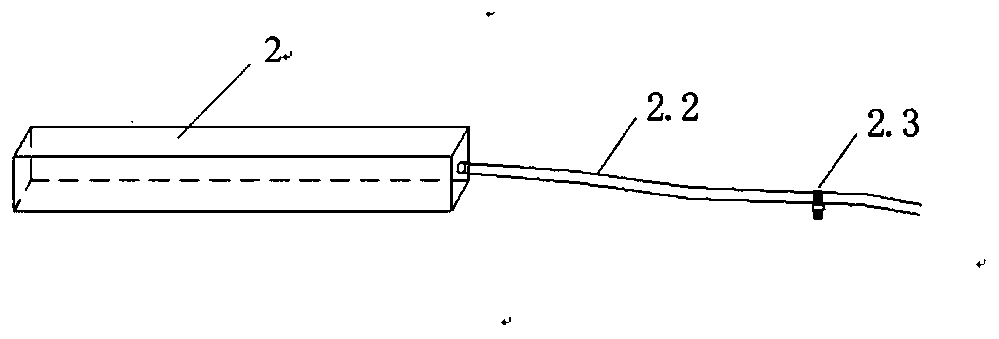

Coal and uranium coordinated mining perspective physical simulation device and application method

InactiveCN110043261AGuaranteed reliabilityImprove resource recoveryUnderground miningFluid removalPositive pressureMulti field

The invention discloses a coal and uranium coordinated mining perspective physical simulation device and application method. The coal and uranium coordinated mining perspective physical simulation device is provided with a coal mining mechanism, a uranium mining mechanism and a observing mechanism, wherein the coal mining mechanism is provided with an organic glass box, a front panel, a rear panel, a bottom panel, a top panel, a left panel, a right panel, a strip-shaped water bag, a transporting pipe, a valve, a beaker, transparent soil, a press machine pressing head and small holes; the uranium mining mechanism is provided with positive pressure pumps, negative pressure pumps, a tracer agent, a liquid storing tank, conduits, an electric wire, a liquid injecting hole, a liquid pumping holeand a centralized control table; and the observing mechanism is provided with an industrial camera and a line laser generator. According to the coal and uranium coordinated mining perspective physical simulation device and application method, the volume of the strip-shaped water bag is adjusted to simulate coal seam mining, the positive pressure pumps are adopted to internally inject the tracer agent into the transparent soil to simulate uranium mine in-situ leaching mining, the mechanisms are matched closely, a multi-field coupling evolution law of coal and uranium coordinated mining is obtained, a coal and uranium coordinated mining scheme is optimized, and the recovery rate and economic benefits of co-associated resources are improved.

Owner:ANHUI UNIV OF SCI & TECH

Uranium well air pumping dredge method

InactiveCN101435327AExtend the production cycleGood blocking performanceFluid removalDifferential pressureAir pump

The invention relates to a uranium well gas lifting stemming removing method used in a sandstone type uranium deposit regent-free uranium mining production process. The method comprises the steps: a polyethylene pipe is put in a uranium well, and a reverse circulation gas lifting mode is adopted to achieve the purpose of plug removing, wherein, the reverse circulation gas lifting mode is that high-pressure gas is injected in the annular space between a PVC casing and the polyethylene pipe so that the liquid surface in the annular space is lowered gradually, inside and outside differential pressure is formed outside the polyethylene pipe, the liquid in the polyethylene pipe is lifted out of the well mouth under pressure, then negative pressure is formed at the ore bed segment at the well bottom simultaneously so as to cause the fluid in a uranium ore bed to flow faster towards a well casing, and after that, stemming of gas, mechanical impurities and the like in the ore bed flow out to ground along with the high speed fluid by the polyethylene pipe. The method can be applied to the stemming removing operation of uranium deposit ore bed caused by gas and mechanical impurities; and by utilizing the technological method, good stemming removing effect is obtained, the production period of the uranium well is improved greatly and the uranium mining production cost is reduced.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Uranium mining method by in-situ loosening and leaching

ActiveCN106507866BImprove permeabilityReduced mechanical propertiesFluid removalClay mineralsMaterials science

The invention provides a method for mining uranium by in-situ loosening and leaching. The steps are: (a) forming the borehole structure; (b) running the casing from the borehole into the ore-bearing aquifer; (c) running the hydraulic roadhead into the bottom of the borehole along the casing to excavate Form a compensation chamber with a circular plane; (d) adopt the method of blasting, and the caving ore falls into the compensation chamber to form a loose dome; (e) run the plug and the leaching borehole filter into the , forming a liquid pumping borehole; (f) drill 2 to 4 liquid injection boreholes around the liquid pumping borehole, and the bottoms of the liquid injection borehole and the liquid pumping borehole are located at the position of the compensation chamber; (g) from The leaching solution is injected into the liquid injection borehole, and the leaching solution containing useful metal components is extracted from the liquid suction borehole. The invention improves the permeability of the ore, reduces the gluing and mechanical blockage of clay substances in the ore, and maximizes the pumping and injection volume of the ground leaching borehole.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

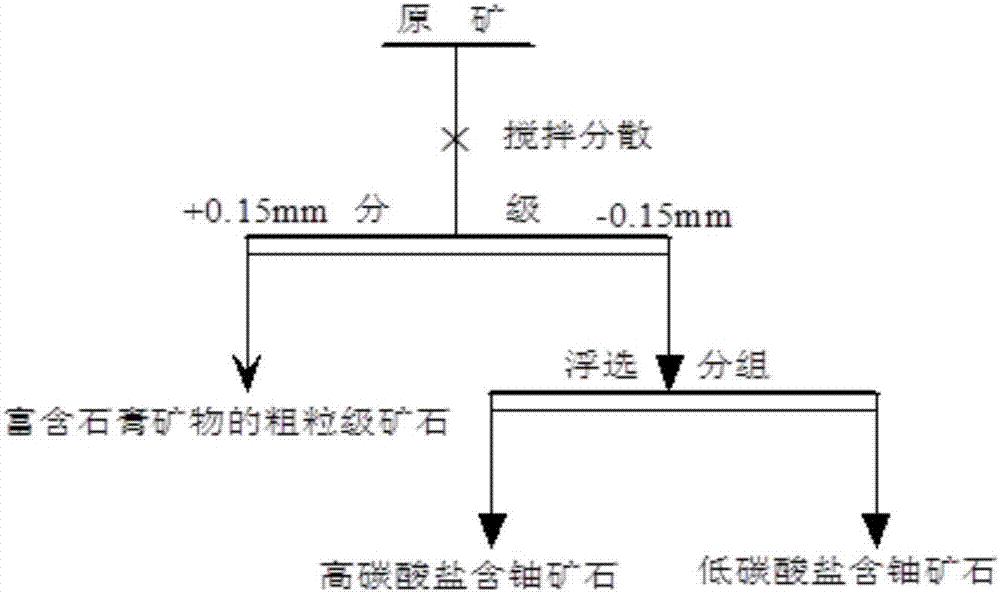

Pretreatment method for mud uranium ores

ActiveCN106944243AHigh recovery rateCost savingFlotationWet separationPretreatment methodUranium ore

The invention belongs to the technical field of uranium mining and metallurgy, and relates to a pretreatment method for mud uranium ores, in particular to a pretreatment method of mud uranium ores rich in gypsum and carbonate minerals. According to the pretreatment method for the mud uranium ores, firstly coarse-grained ores rich in the gypsum are separated, and the coarse-grained ores can recycle uranium through a dump leaching method, the ores grinding cost can be saved and the reagent consumption when fine-grained ores are leached through a alkaline process can be reduced. The fine-grained ores rich in the carbonate minerals are divided into two parts of high-carbonated uranium ores and low-carbonated uranium ores through a flotation method; the uranium can be recycled through subtractive leaching and acid leaching in the follow-up leaching, the reagent consumption can be saved, and the leaching rate is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

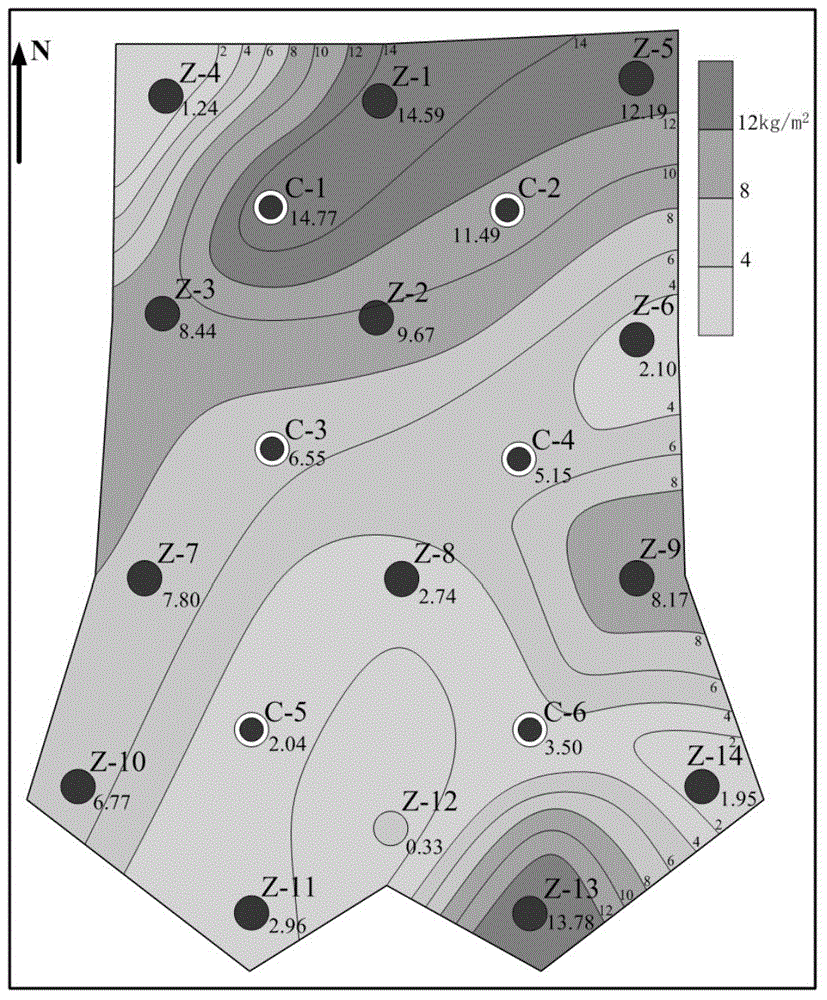

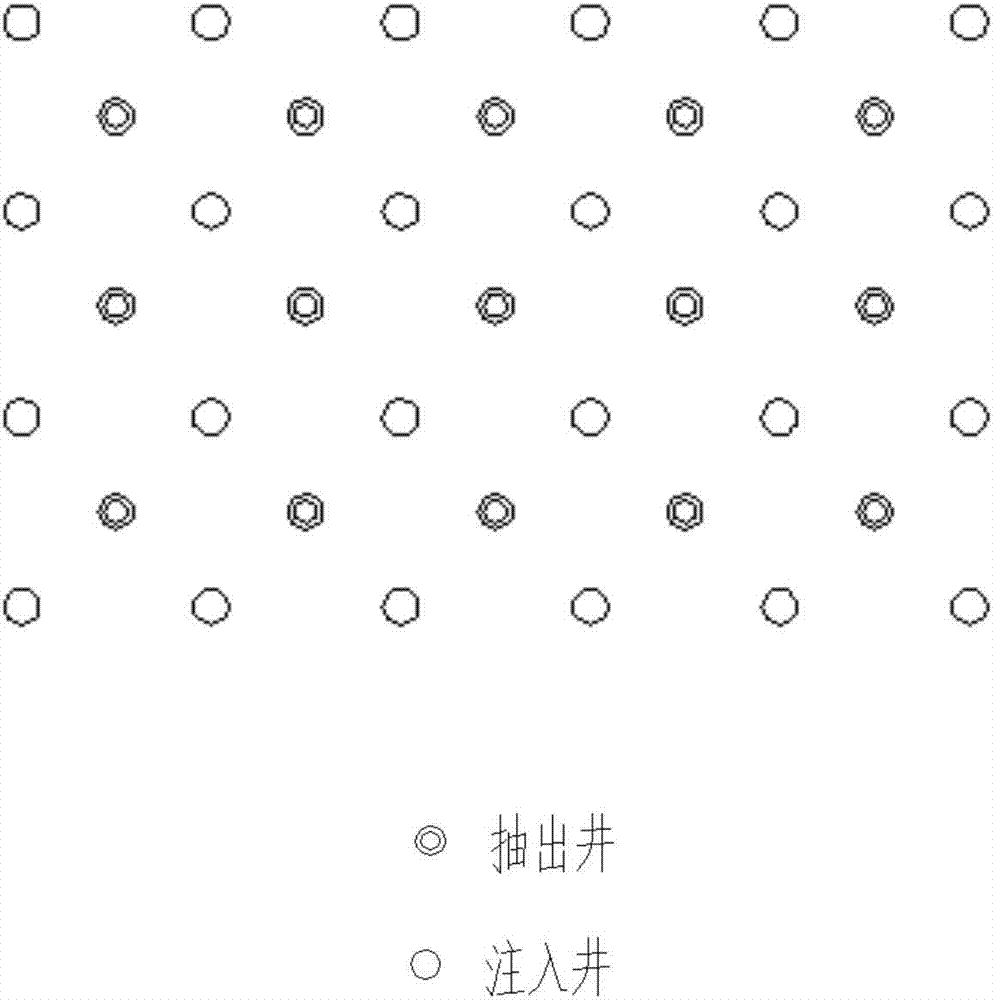

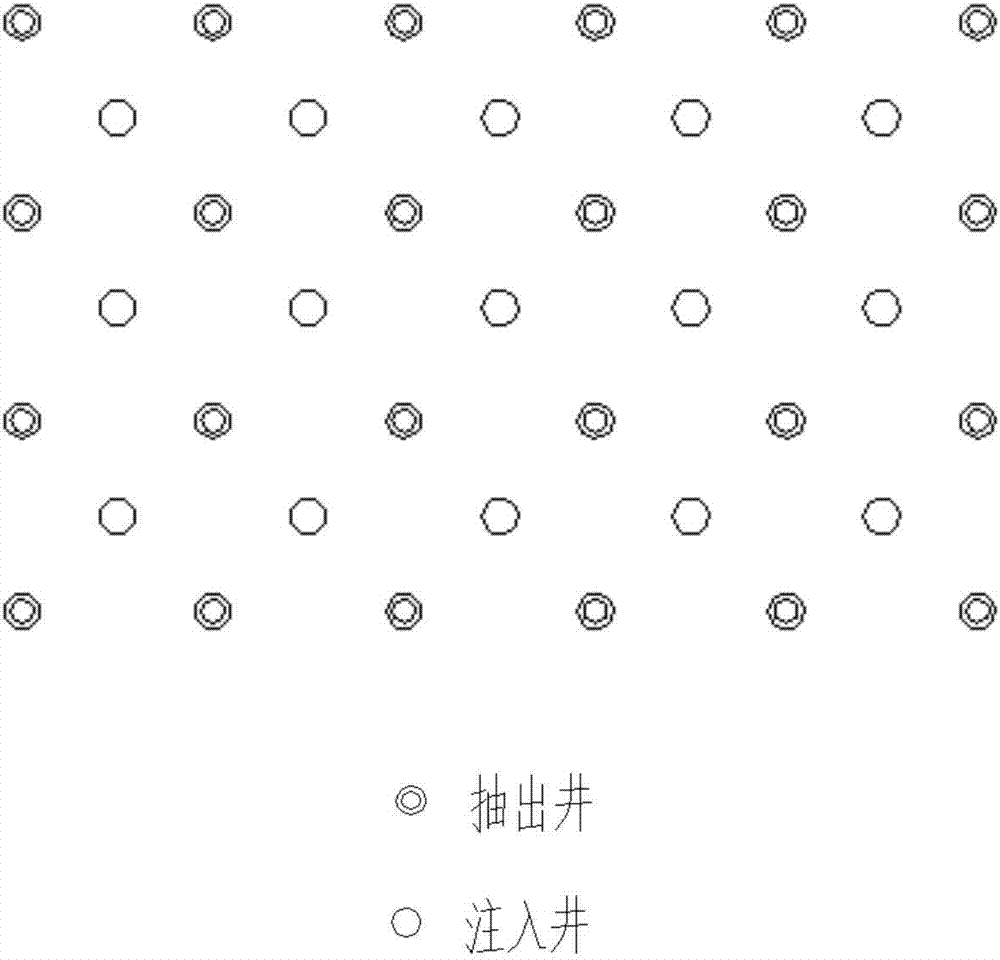

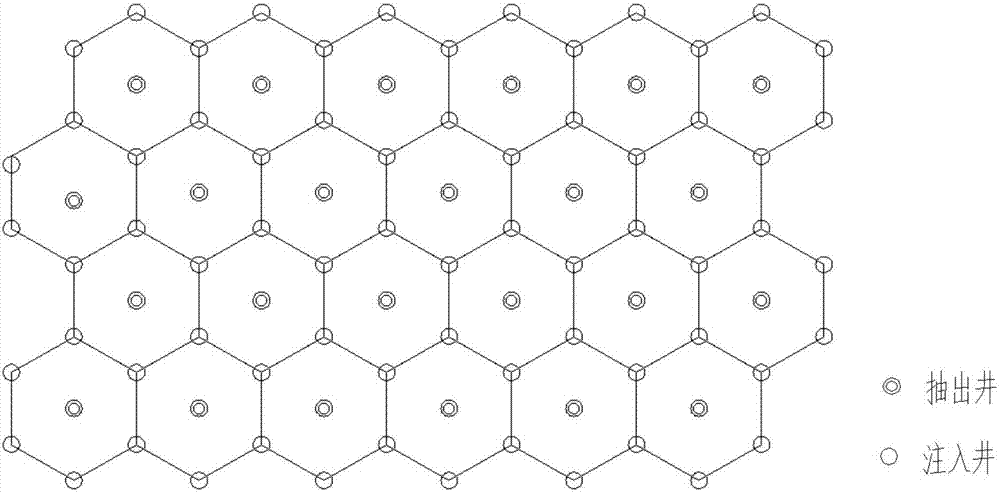

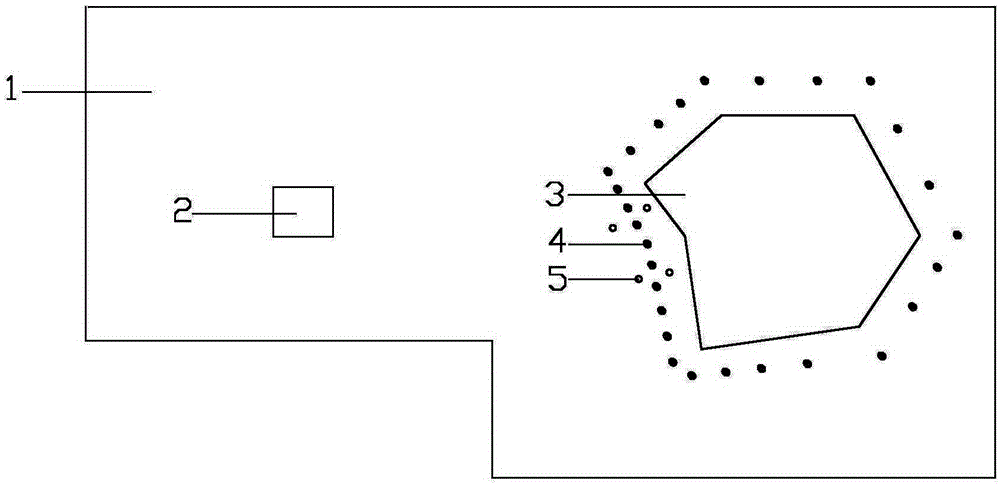

Optimization and recombination method for well network of in-situ leaching uranium mining

ActiveCN106930747AImprove leaching rateSolve the problem of low resource leaching rateFluid removalQuincunxHydrology

The invention provides an optimization and recombination method for a well network of in-situ leaching uranium mining. The method comprises the steps that when the uranium concentration of leachate of a certain leaching mining units of a well site mining area is 3-10 mg / L, or the leaching rate reaches 60%-75%, the positions of liquid extracting wells and liquid injecting wells are adjusted; the injecting wells at the boundary of the mining area are not adjusted to be extracting wells, and it is guaranteed that wells on the periphery of the mining area are all the injecting wells; when a well type is a quincunx type, the adjacent extracting wells are connected into straight lines, the adjacent injecting wells are connected into straight lines, the original extracting wells are changed into injecting wells, the original injecting wells are changed into extracting wells, and it is guaranteed that the well type after adjusting is still the quincunx type; and when the well type is a seven-point type, the extracting wells are connected into lines, the two injecting wells are located between every two extracting wells, translation is conducted in the same direction of the straight lines, after translation, the original extraction wells are changed into injecting wells, the adjacent injecting wells along the straight lines are changed into extracting wells, and it is guaranteed that the well type after adjusting is still the seven-point type. The optimization and recombination method is a secondary stoping method improving the leaching rate of the uranium resource and solves the problem that through a fixed well type, leaching dead angels exist at the time of leaching, so that the resource leaching rate is low.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +1

Process for restoration of ground water used in in-situ uranium mining

ActiveUS7294271B1Increase contactEasy to cleanContaminated soil reclamationWater/sewage treatment by ion-exchangeWater useWater cycling

A process for biological restoration of ground water in a mineralized sandstone formation using a nutrient source. The process is used in conjunction with mining uranium using in-situ pump and treat technology. The restoration of the ground water is designed to meet federal and state regulations. The process includes pumping the contaminated ground water from the mineralized sandstone formation using production wells to the ground surface. The ground water is then circulated through at least one ion exchange column. The ion exchange column is used to capture any residual uranium remaining in solution. The treated ground water then flows from the ion exchange column through at least one reverse osmosus unit. The reverse osmosus unit is designed to help decrease any remaining dissolved solids in solution, such as sodium and chloride. From the reverse osmosus unit, the ground water is circulated through at least one de-carbonation column. The de-carbonation column is used to remove residual carbon dioxide in the ground water. Upon exiting the de-carbonation column, a nutrient source is introduced into the ground water for stimulating the indigenous bacteria in the mineralized sandstone formation. The ground water is now pumped back into the ground where it is reintroduced into the sandstone formation.

Owner:POWER RESOURCES

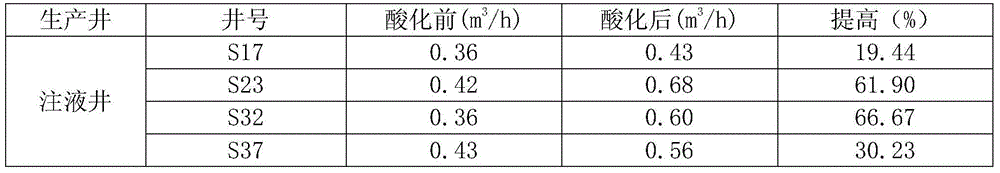

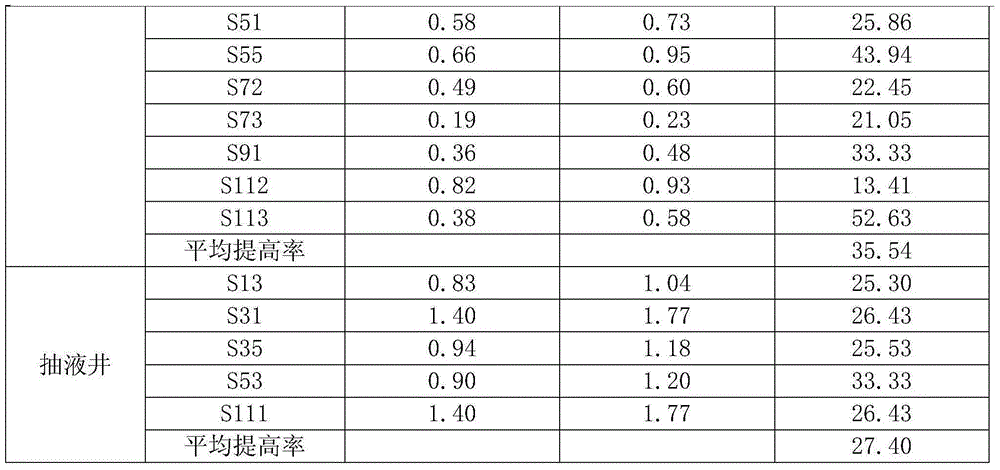

Permeable in-situ leaching uranium mining leaching process for hydrochloric acid modified sand layer

ActiveCN106930738AStable controlImprove the ability of pumping and injecting fluidFluid removalPregnant leach solutionResource quality

The invention belongs to the technical field of in-situ leaching uranium mining and particularly relates to a permeable in-situ leaching uranium mining leaching process for a hydrochloric acid modified sand layer. The purpose is to solve the technical problem that traditional mining processes of sulfuric acid in-situ leaching and alkaline in-situ leaching cannot meet mining requirements under the condition of decreasing of the uranium resource quality. In practical use, the leaching process is stable in control and compact in joining, liquid extracting and injecting capacity is improved, oxidation of uranium minerals is accelerated and achieved, uranium-containing leachate is obtained, and the condition of production concentration treatment in later period can be met. In the leaching mining process at a Shihongtan 1# mining area, by adopting the leaching process, the liquid injecting capacity is increased from 108 m<3> / h to 132 m<3> / h; oxygen is dissolved effectively and injected into the ore-containing sand layer, the oxygen content in the leachate is 18 mg / l, the average peak value of the uranium concentration of the leachate is 27.8 mg / l, and the uranium concentration peak value of a single well is 64 mg / l; and accordingly the effects that the uranium resource of the mining area is exploited, and the recovery rate of the uranium resource of the mining area reaches 76.5% are achieved.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

Method for preventing decline of underground water level in uranium mining through in-situ leaching

ActiveCN105370285ATake advantage ofGuaranteed recyclingUnderground miningSurface miningEconomic benefitsUranium ore

The invention belongs to the technical field of uranium-coal paragenesis mining, and particularly relates to a method for preventing a decline of an underground water level in uranium mining through in-situ leaching for uranium-coal co-mining. According to the technical scheme, a hydraulic barrier is built on the periphery of a uranium mining district through distribution of water injection drill holes, and when underground water is drained for a coal mine, the decline of the underground water level of the uranium mining district is prevented. The method for preventing the decline of the underground water level in uranium mining through in-situ leaching has the advantages that it can be guaranteed that two resources are mined at non-overlapped districts at the same time, the two resources can be fully utilized, the economic benefit of enterprises is improved, and the recovery of the geological resource is guaranteed.

Owner:THE FOURTH INST OF NUCLEAR ENG OF CNNC

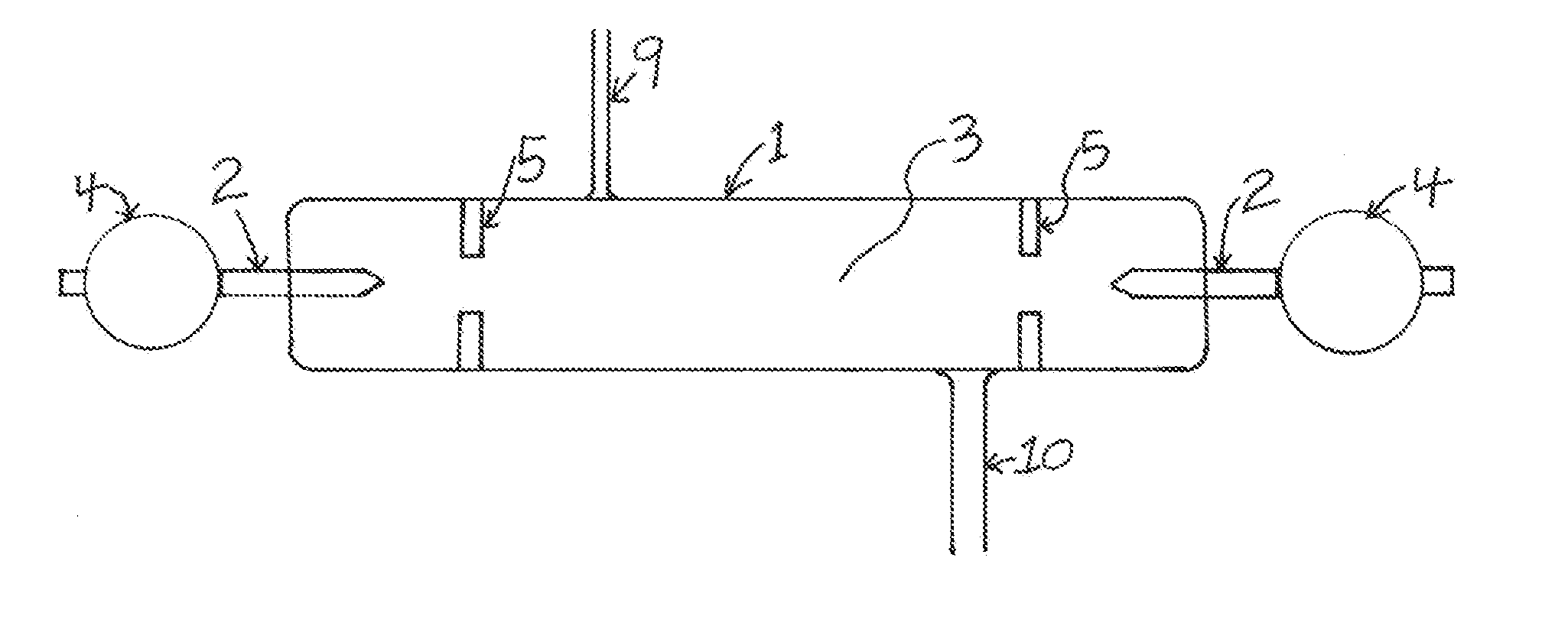

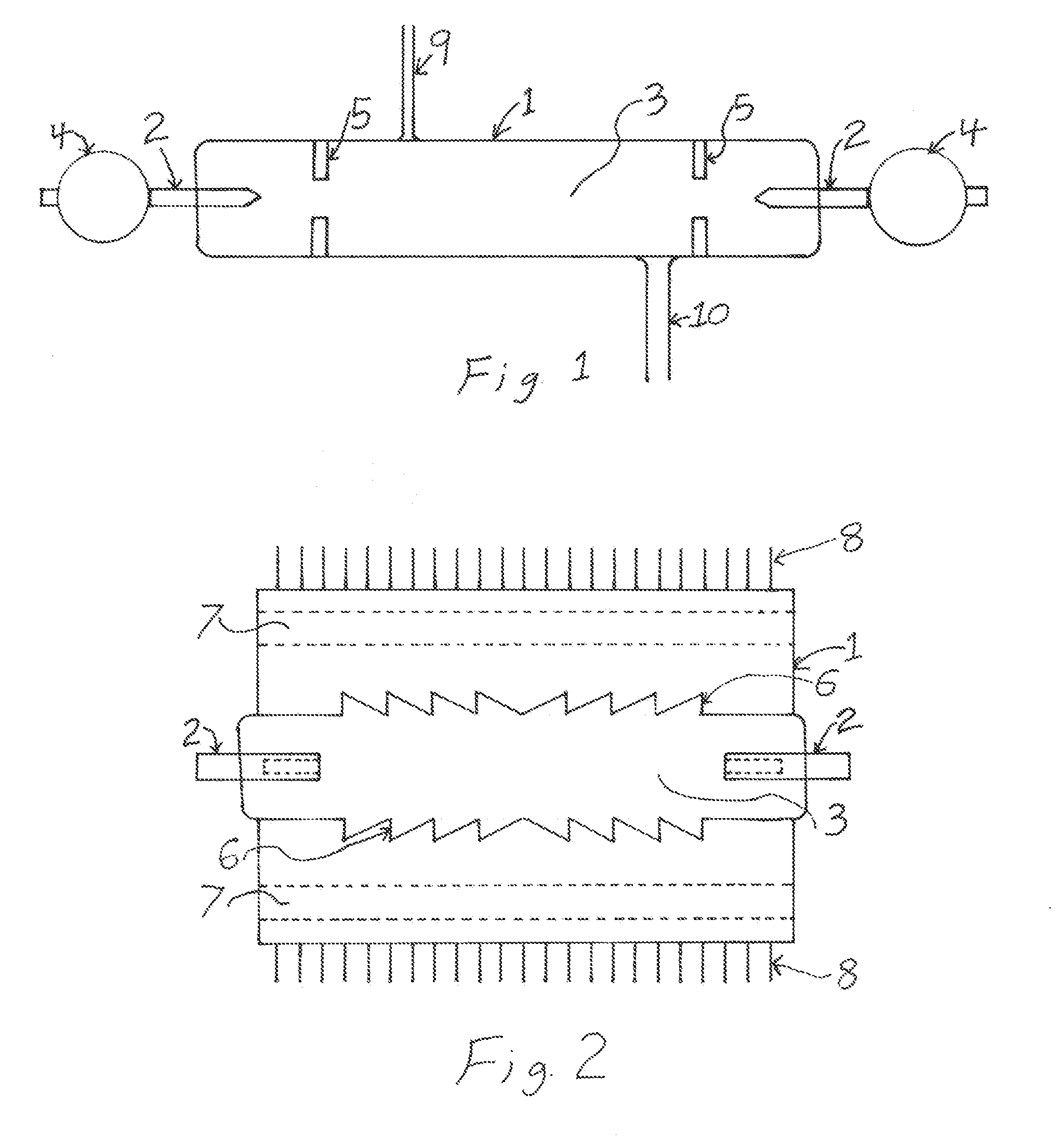

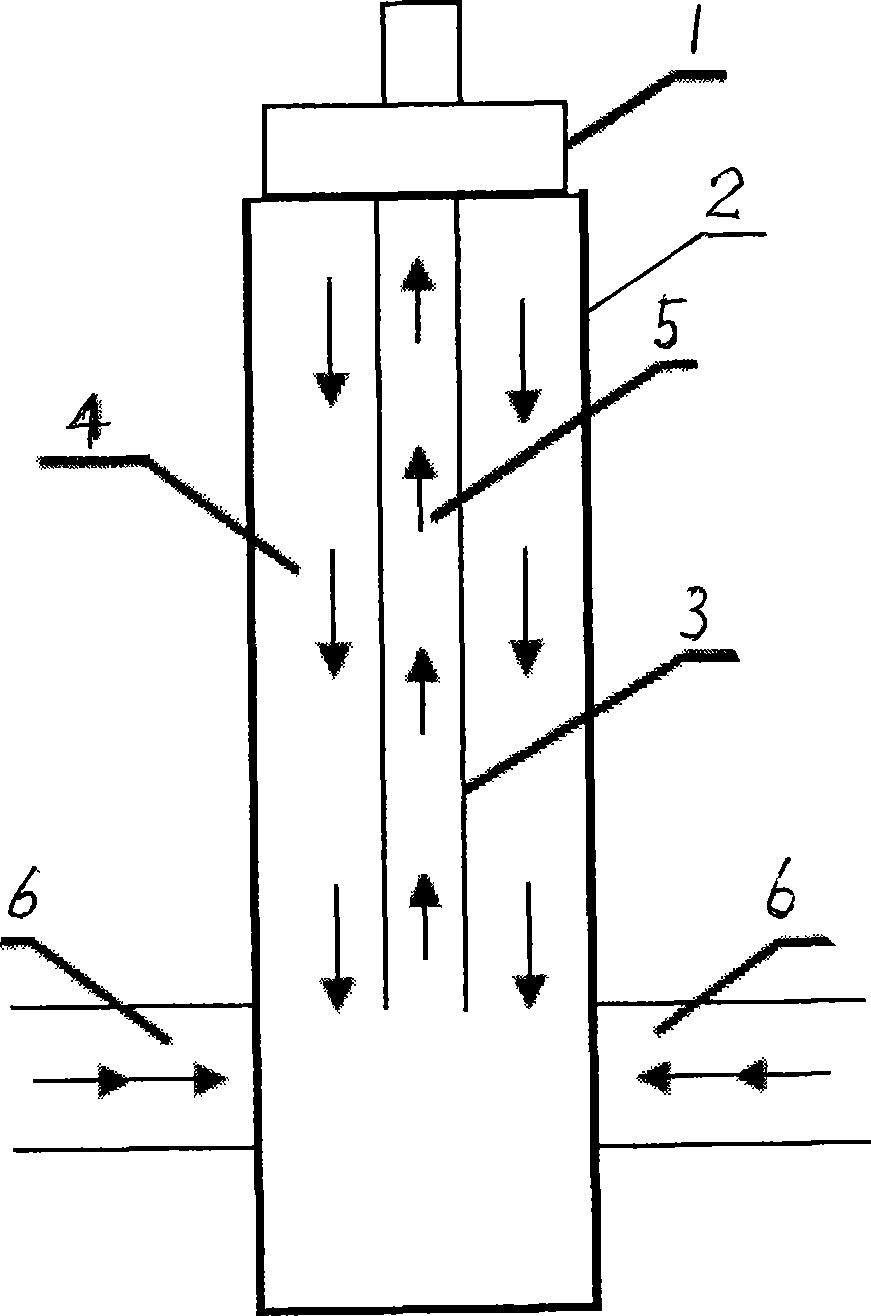

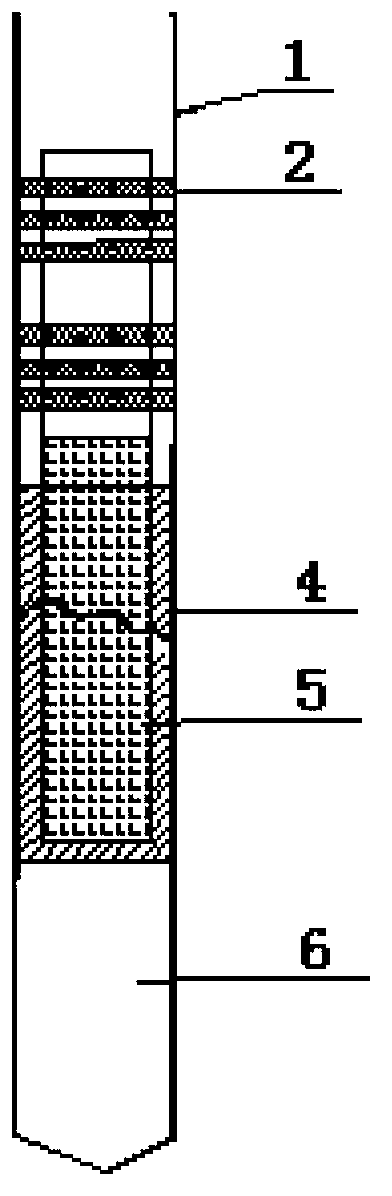

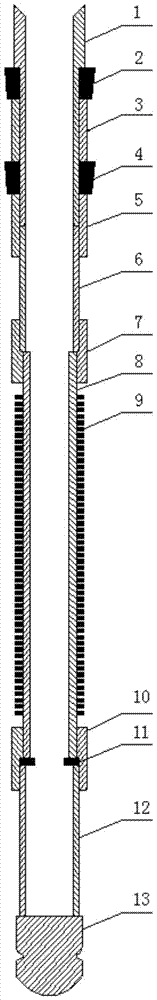

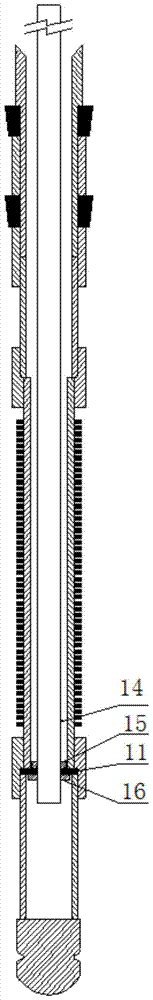

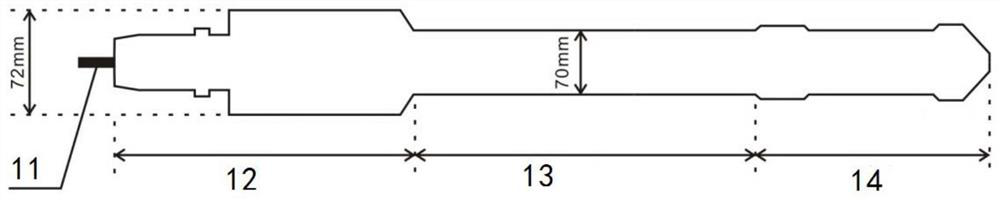

Method for repairing damaged drilled hole for in-situ leaching uranium mining through a plurality of layers of expanding materials

ActiveCN103899244AEffective blockingResume normal cycle pumping functionSealing/packingDrilling machines and methodsWell loggingIn situ leach

The invention belongs to the technical field of mine production for in-situ leaching uranium mining, and particularly relates to a method for repairing a damaged drilled hole for in-situ leaching uranium mining through a plurality of layers of expanding materials. The method sequentially includes the following steps that whether a well pipe (1) or a filter is damaged is initially judged; under the condition that the well pipe (1) is damaged, the cracked position of the well pipe (1) is determined through well logging, a plastic smaller than the well pipe (1) in inner diameter serves as a casing pipe (3), the expanding materials (2) are wound around the casing pipe (3), the casing pipe (3) is put downwards to align with the cracked position of the well pipe (1), and the expanding materials (2) expand and squeeze the inner wall of the well pipe (1) to form a new channel; under the condition that the filter is damaged, the drilled hole is washed to be clean, the expanding materials (2) are wound around a built-in filter smaller than the original filter in outer diameter, the built-in filter is put downwards to be close to the original filter (4), the expanding materials (2) expand when making contact with water and squeeze the well pipe (1), and a new filter is formed in the drilled hole.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

In-situ leaching of uranium by adding o2 to bicarbonate-type groundwater

ActiveCN106507865BMeet industrial production requirementsEconomical and effective uranium leaching processFluid removalOxygenEarth surface

The invention provides a bicarbonate-type groundwater plus O2 leaching uranium mining process, which adopts an in-situ leaching method to mine uranium ore layers in a bicarbonate-type aquifer. In this process, O2 is directly mixed with the leaching solution and then injected into the ground. After adding oxygen to the groundwater containing HCO3-, the uranium in the ore is oxidized and leached to form [UO2(CO3)3]4- or [UO2(CO3)2]2 -The leaching solution of complex anions is then extracted from the surface and sent to the hydrometallurgy process for processing. The invention adds O2 as an oxidant and utilizes HCO3- ions in bicarbonate groundwater as a leaching agent for uranium, which can effectively control the occurrence of chemical blockage and improve the leaching rate of uranium in situ leaching. Compared with the traditional acid leaching and alkali leaching processes, the process cost is reduced and the mining environment is better protected. From the test results, the concentration of uranium leached by adding O2 in bicarbonate-type groundwater can reach 30mg / L, which meets the requirements of industrial production.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

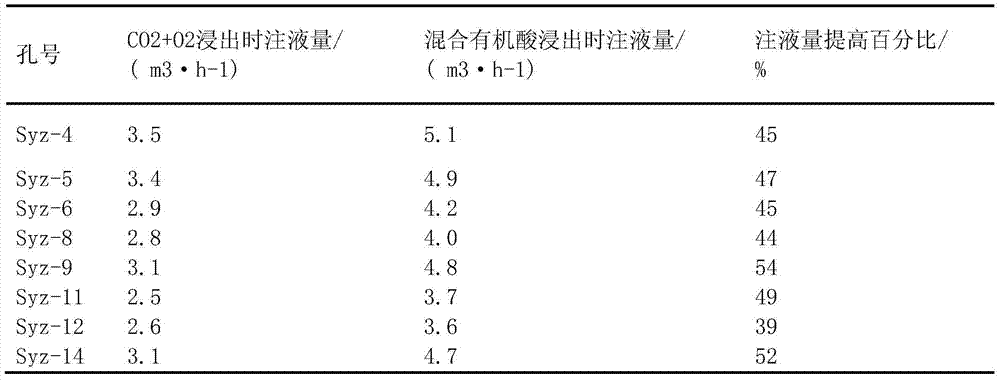

In-situ leaching uranium mining method by using mixing organic acidity as leaching agent

The invention discloses an in-situ leaching uranium mining method by using mixing organic acidity as a leaching agent, which is characterized in that oxalic acid and citric acid are taken as the leaching agent, the leaching agent is injected into an ore bed by using an on-line mode addition mode, pH value of an immersion liquid is kept at 3-6, so that an organic matter for coating metal uranium can be dissolved, and leaching can be promoted; in addition, when the carbonate in the ore bed is corroded by oxalic acid and citric acid, its organic function group generates complexation with elements such as calcium, magnesium and iron in ore without deposition generation, on one hand, leaching reaction can be continuously carried out, on the other hand, penetration performance of the ore bed can be increased, and liquid injection amount of the boring is obviously increased. The method can be used in Ordos uranium deposit in-situ leaching uranium mining tests and production, liquid injection amount is obviously increased, and uranium concentration of leachate is obviously increased.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

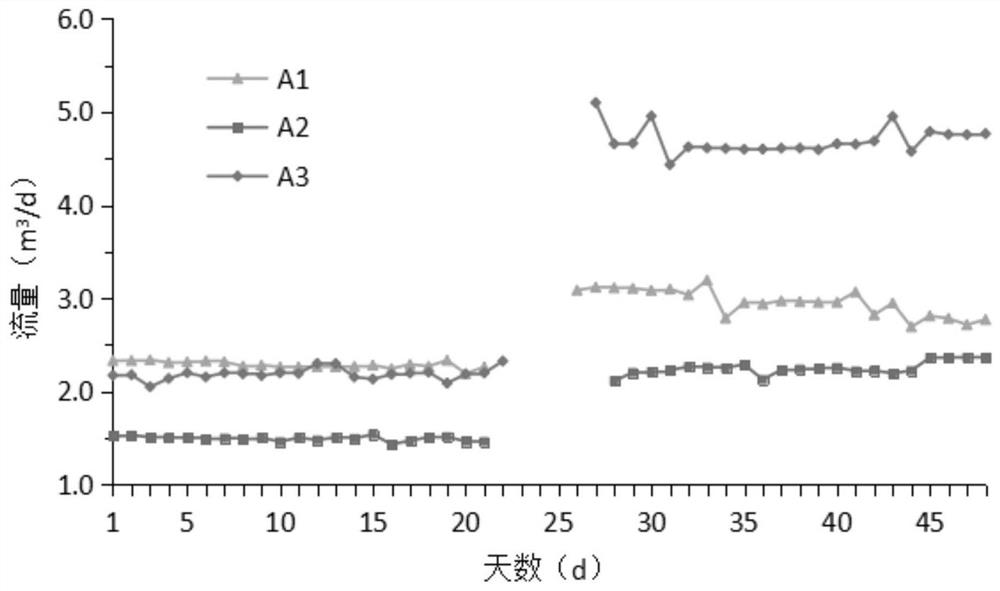

Leaching range monitoring method in in-situ leaching uranium mining process

InactiveCN105631137AControl the spread of pollutionReduce consumptionSpecial data processing applicationsSoil scienceIn situ leach

The invention provides a leaching range monitoring method in an in-situ leaching uranium mining process. The monitoring method includes the steps that 1, a numerical model is established through computer numerical simulation software, wherein the steps of conducting model generalization, conducting model numeralization, establishing the numerical model, correcting the numerical model and designing a drill hole arrangement mode are included; 2, interwell tracer tests are conducted on a test unit and a production unit, wherein the steps of selecting a tracer agent, calculating feeding quantity of the tracer agent, feeding and sampling the tracer agent, conducting concentration analysis on the tracer agent, analyzing tracer agent test data and simulating numerical values are included. According to the monitoring method, an interwell tracer method is introduced to the leaching uranium mining process, a numerical value simulation technology is utilized, estimation, monitoring and predicting of the flow direction, the flow rate and the leaching range of a leaching solution are achieved through numerical value simulation of the flow direction, the flow rate and the diffusion range of a groundwater flow field and the tracer agent, accordingly in-situ leaching tests and drill hole arrangement in production are guided, consumption of raw materials is greatly lowered, production cost is saved, and dispersal of pollution to in-situ leaching mine is controlled.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

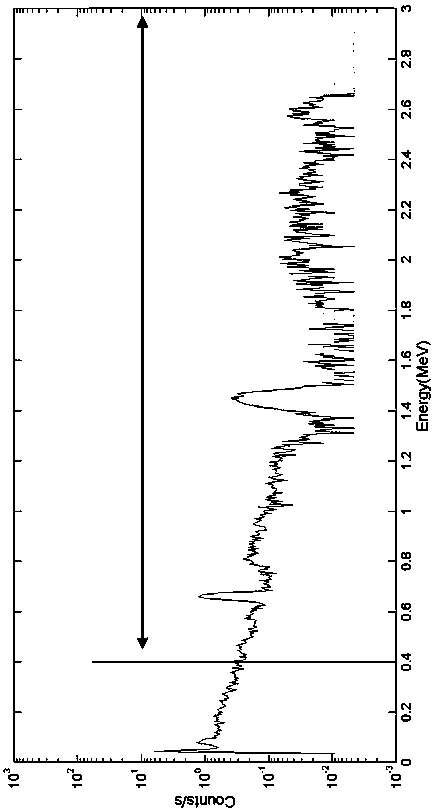

Uranium ore well logging quantitative method combined with instantaneous neutron time spectrum to correct natural gamma total amount

ActiveCN108457640AShorten the quantitative cycleImprove logging speedSurveyTime spectrumWell logging

The invention discloses a uranium ore well logging quantitative method combined with instantaneous neutron time spectrum to correct natural gamma total amount in the field of uranium exploration and in-situ leaching uranium mining. Specifically, the uranium ore well logging quantitative method comprises the steps that for uranium-bearing rock ore beds in a borehole, two types of well logging datawhich are natural gamma total well logging and instantaneous neutron time spectrum well logging are used for constructing a uranium ore quantitative interpretation method with uranium-radium-radon balance correction, wherein the uranium ore quantitative interpretation method is based on the natural gamma total well logging; and well logging data of standard model wells are used for contrasting a calculating method of scale parameters such as conversion coefficient and background response required for uranium ore quantification. Compared with the uranium ore quantitative method of single instantaneous neutron time spectrum well logging or natural gamma total amount well logging, the uranium ore well logging quantitative method does not need core sampling and chemical analysis methods, so that the balance coefficient of uranium-radium-radon can be calculated, the well logging speed further be greatly improved, the advantages of improving drilling efficiency, reducing exploration cost andshortening uranium quantitative period are further provided, and the field analysis of uranium ore quantification by computer programming is realized.

Owner:EAST CHINA UNIV OF TECH

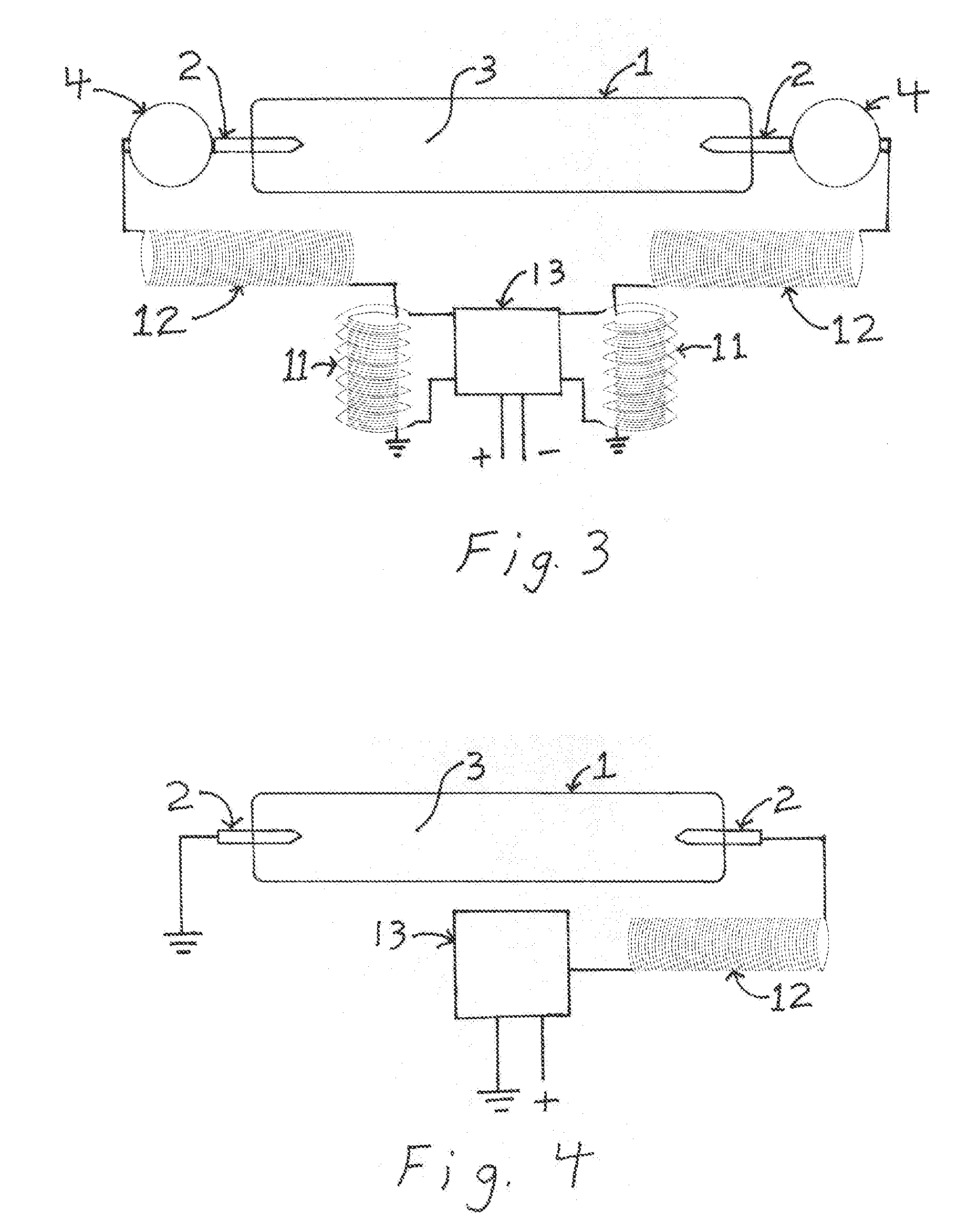

Method for improving leaching rate of in-situ leaching uranium mining using ultrasonic waves

ActiveCN106947877AImprove permeabilityImprove leaching effectFluid removalPregnant leach solutionChemical reaction

The invention relates to the technical field of in-situ leaching uranium mining, in particular to a method for improving the leaching rate of in-situ leaching uranium mining using ultrasonic waves. The method comprises the following steps that one leaching unit including one pumping hole and four injection holes in a in-situ leaching uranium mining field is selected, four sets of ultrasonic energy gathering devices are put into the four injection holes, the putting depth is the distance to the middle position of an ore bed; when an target leaching unit is in the normal pumping injection operation, the four sets of ultrasonic generators are opened at the same time, the ultrasonic waves at the same time act on the target ore bed through the ultrasonic energy gathering devices in the injection holes; the operation cycle of the ultrasonic energy gathering devices and the ultrasonic generators is 2-6 months, the daily available machine time is not less than 2-8 hours, leaching liquid flow and target element concentration are measured and recorded, and the changes of ore bed permeability coefficient and leaching rates are calculated. According to the method for improving the leaching rate of the in-situ leaching uranium mining using the ultrasonic waves, the uniform and effective contact between leaching agents and ores is realized, the chemical reaction rate is accelerated, the purpose of increasing the leaching liquid concentration and the leaching rate is achieved, the mining speed is accelerated and the recovery rate is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

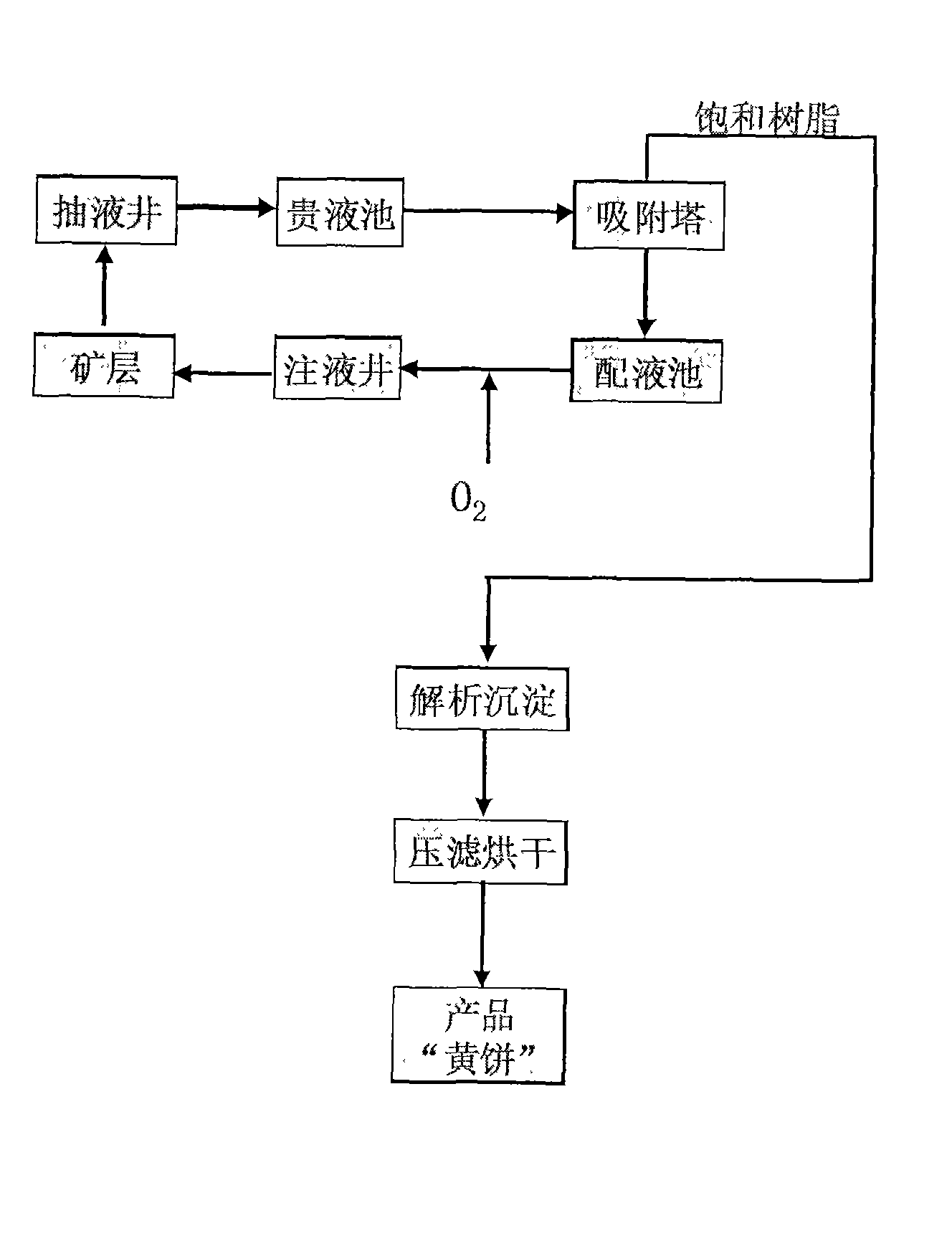

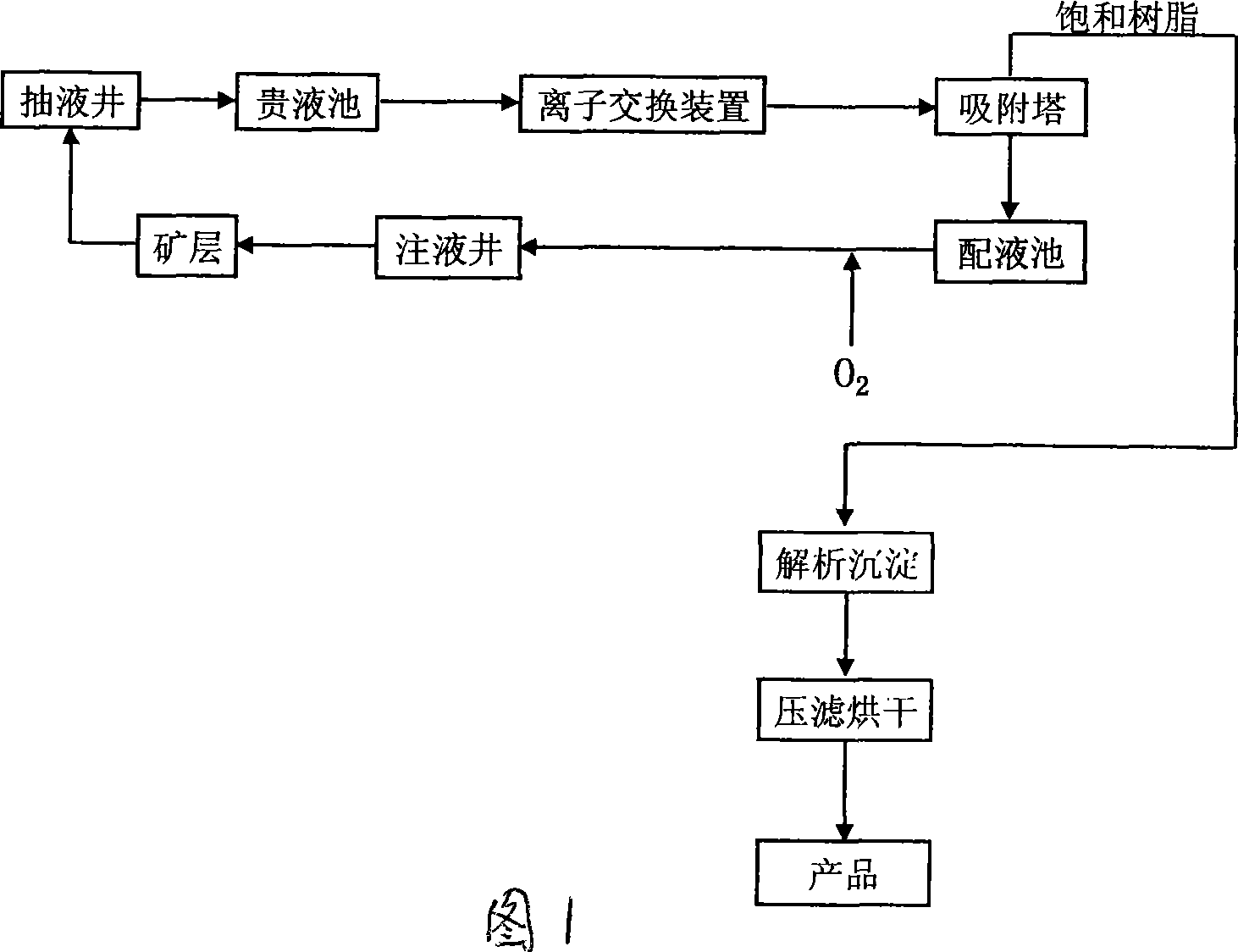

Non-reagent ground dipping uranium extracting process flow

InactiveCN101435320AGuarantee continuous and stable operationReduce supplementationFluid removalIon exchangeMaterials science

The invention relates to a reagent-free in-situ leaching uranium mining technological process which is additionally provided with a set of ion interchange unit consisting of an ion exchanger, a blast blower, a sand filtering tank, a regenerant tank and a waste liquid pool before a medium entering an absorption tower on the basis of the conventional reagent-free in-situ leaching uranium mining technological process. Leaching solution containing an oxidizing agent is injected into an ore bed through an injection hole so that the uranium in the ore bed is changed into the form of uranyl ions or other complex icons which are dissolved in leaching solution groundwater, then leaching solution containing uranium components is extracted to ground through an extracting hole, the leaching solution is injected back to the ore bed for recycling after carrying out sedimentation, icon exchange treatment and adsorption, and a uranate product is obtained after carrying out the procedures of analyzing, sedimentation, filter pressing and the like to saturated resin containing uranium. The method has the advantages of little investment, mature operative technique, obvious anti-blocking effect and the like. The utilizing of the process method can guarantee the continuous and stable running of uranium mining wells and a production system, and improve the production time efficiency and the product output.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

Modular device and method for centralized control room of ground leaching uranium mining areas

PendingCN107605438ARealize standardized constructionSave construction areaFluid removalUranium oreEnvironmental engineering

The invention provides a modular device for a centralized control room of ground leaching uranium mining areas. The modular device comprises two container modules. The two container modules comprise the liquid injecting control module and the power distribution and liquid pumping control module correspondingly. A method comprises the steps that oxygen is mixed into a liquid injecting main pipe through an oxygen main pipe, the liquid injecting main pipe injects a dissolving and leaching liquid with the oxygen into each row of liquid injecting branch pipes, and then the dissolving and leaching liquid with the oxygen is injected into liquid injecting wells of a plurality of ground leaching uranium mining areas through a plurality of liquid injecting branches on each row of liquid injecting branch pipes and injected into an underground seam; the dissolving and leaching liquid injected into the underground seam and an ore body are subjected to oxidation reaction, and an ore-bearing leachingliquid is formed; a leaching fluid in a liquid pumping well is pumped into a plurality of liquid pumping branches on each row of liquid pumping branch pipes, and then all rows of liquid pumping branch pipes are aggregated and enter into a liquid pumping main pipe. The modular device can realize standardization construction of a factory, construction investment is reduced, the construction periodis shortened, and construction waste is reduced, thus damage to the natural environment is reduced, and the modular device has the advantage of green environmental protection.

Owner:中核通辽铀业有限责任公司

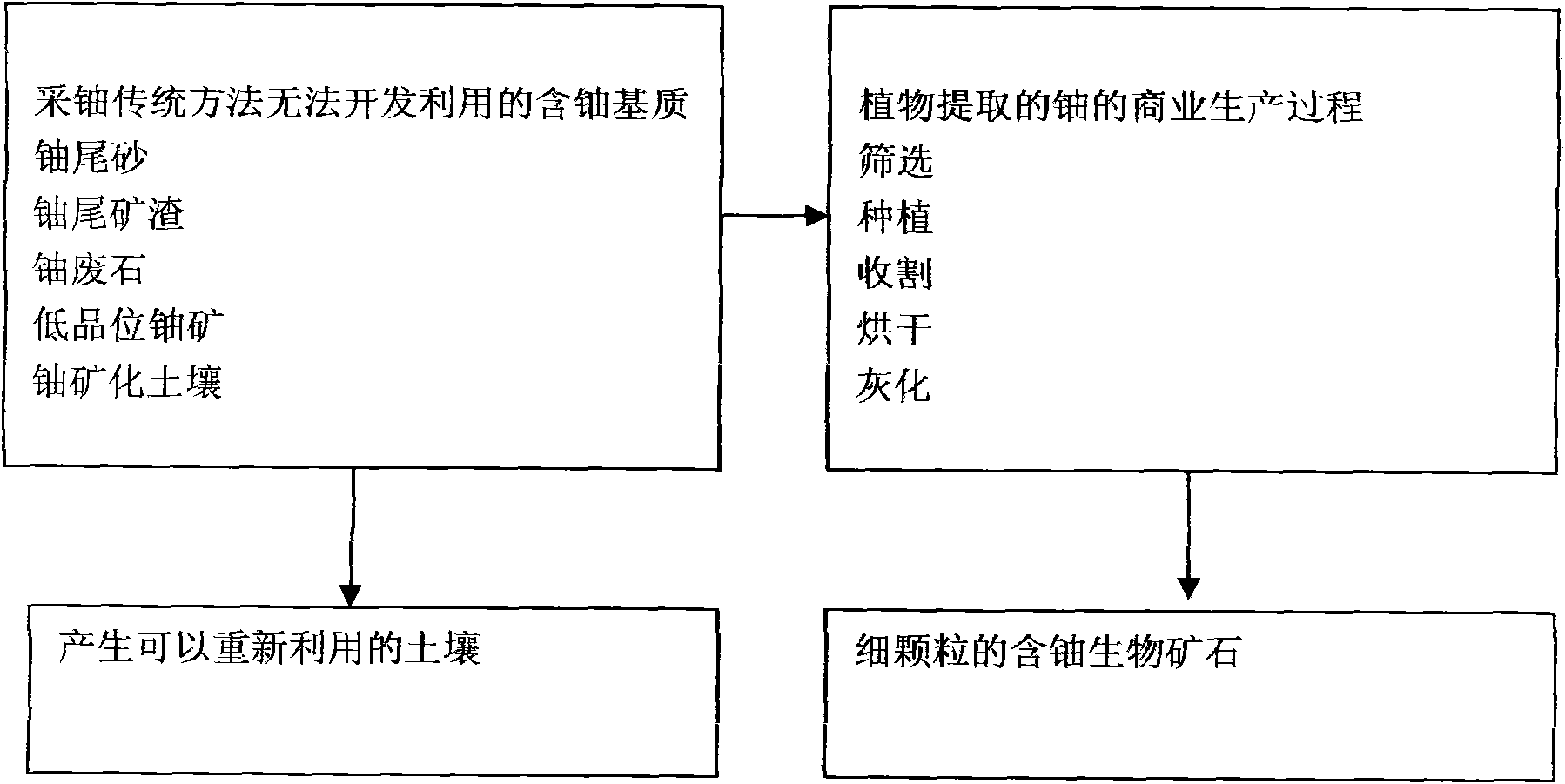

New uranium mining method-plant uranium mining method

ActiveCN101672180ASolve problems that cannot be exploitedNon-destructiveUnderground miningSurface miningUranium mineLower grade

The invention relates to a plant uranium mining method, which is a method achieved as follows: high-biomass uranium-enriched plants are used for enriching uranium in uranium tailings, tailing residues, uranium waste rock, low-grade uranium mine, and uranium-mineralized soil which are stacked on the ground surface to the overground parts of the plants, the uranium is intensively harvested and driedafter being enriched to a certain extent, and then uranium-containing biologic minerals are formed after the uranium is incinerated at high temperature. The method comprises the following concrete steps: (1) screening the high-biomass uranium-enriched plants; (2) sterilizing seeds; (3) potting, transplanting seeding to uranium-containing substrates; (4) intensively harvesting and drying the uranium after the uranium is enriched to a certain extent in plant bodies; and (5) incinerating the harvested plant bodies at high temperature, wherein ash component generated by incineration are the uranium-containing biologic minerals. The invention has the advantages of convenient material obtainment, low cost, simple processing step, favorable environment, energy saving, no destruction and the like.

Owner:NANHUA UNIV +1

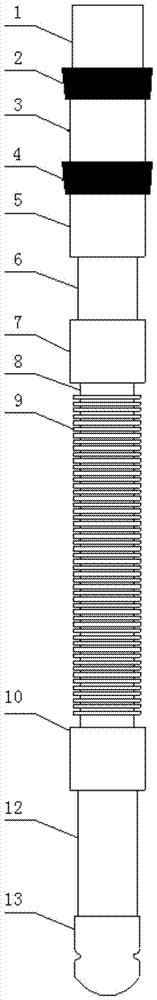

Replaceable filter for in-situ leaching uranium mining drilling

The invention belongs to the technical field of in-situ leaching uranium mining and particularly relates to a replaceable filter for in-situ leaching uranium mining drilling to solve the cleaning and replacing problems of a well completion filter and a latter filter in an in-situ leaching drilling construction process. The replaceable filter is characterized by comprising a righting head, an upper sand-closed retaining rubber drum, an upper adjustment pipe hoop, a lower sand-closed retaining rubber drum, a lower adjustment pipe hoop, a connecting pipe, an upper reducing pipe hoop, a filtering pipe, a filter annular skeleton, a lower reducing pipe hoop, a suspension clamp ring, a sand setting pipe and an anchoring head. The replaceable filter has the characteristic of convenient replacement, and the filter can be rapidly and conveniently pulled out from a drilling hole to be cleaned or repaired or directly replaced when needing to be cleaned or failing so that the in-situ leaching drilling hole can keep a normal working state at any time. The replaceable filter is already applied to scientific research and production work of the Tianshan Uranium Industry Company, the failure rate of the in-situ leaching drilling hole is greatly decreased, and carrying-out of in-situ leaching uranium mining work is facilitated.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC +1

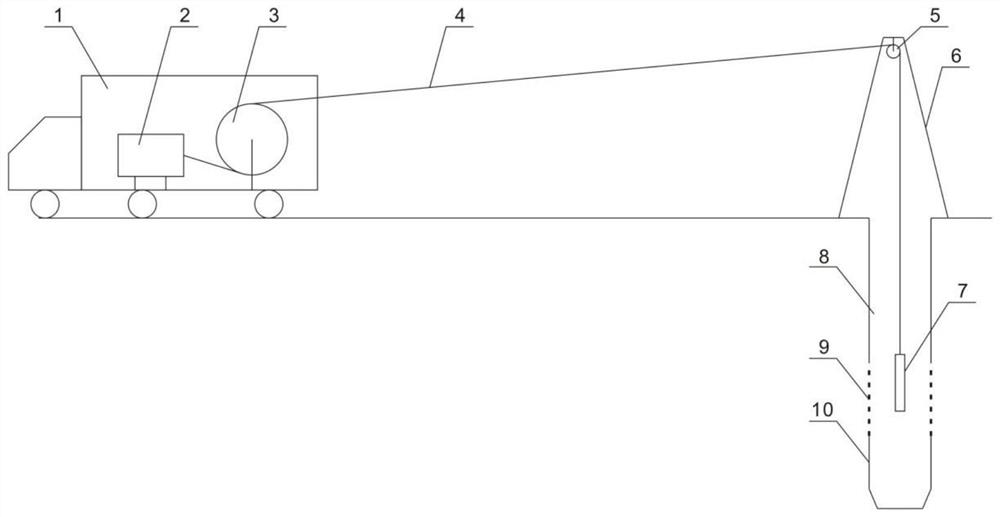

In-situ uranium mine high-power ultrasonic blockage removing and permeability increasing device and method

InactiveCN111878049ASafe and effective removalReduce the impactConstructionsFluid removalWell drillingUranium mine

The invention discloses an in-situ leaching uranium mine high-power ultrasonic blockage removing and permeability increasing device and method, and relates to the technical field of in-situ leaching uranium mining. The main structure of the device comprises an ultrasonic well washing vehicle, an ultrasonic special cable, a wellhead support, a pulley and an ultrasonic transducer, wherein the wellhead support is arranged at the wellhead of a liquid pumping and injecting well, the pulley is arranged on the wellhead support, one end of the ultrasonic special cable is arranged on the ultrasonic well washing vehicle, and the other end of the ultrasonic special cable bypasses the pulley and then extends into the liquid pumping and injecting well; and the ultrasonic transducer is arranged at the end part of the other end of the special ultrasonic cable. Scales on a filter are oscillated and removed through the ultrasonic transducer, and then compressed air is injected through the air compressor to discharge the scales and water at the same time, so that the scales on the filter and near wellbore zones are safely and effectively removed, the well drilling liquid pumping and injecting capacity is effectively recovered, and influence on the environment is small.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Pipe simulation in-situ bioremediation device and method thereof

InactiveCN111825222AImprove repair efficiencyReduce economic costsWaste water treatment from quariesWater treatment parameter controlIn situ remediationIn situ bioremediation

The invention relates to a pipe simulation in-situ bioremediation device. The device comprises an in-situ bioremediation test tube, an ex-situ treatment effluent adjusting tank connected with the in-situ bioremediation test tube and a high-position carbon source supply tank, the in-situ bioremediation test tube is internally and uniformly filled with simulated ore-bearing and water-bearing stratumore, and the two ends of the in-situ bioremediation test tube are blocked and provided with a plurality of sampling monitoring openings; the in-situ bioremediation method of the pipe simulation in-situ bioremediation device comprises the steps: S1, an in-situ remediation simulation test and S2, simulation research of a seepage field and a water chemical field in the in-situ remediation process. In-situ bioremediation is simulated through the pipe, technical support is provided for actual in-situ bioremediation of the in-situ leaching uranium mining underground water, in-situ bioremediation processing of the ore-bearing and water-bearing stratum underground water in the decommissioned mining area of in-situ leaching uranium mining through the industrial acid method is achieved, the economic cost is saved, and the in-situ bioremediation efficiency is also improved.

Owner:EAST CHINA UNIV OF TECH

Ion exchange eluting column for compact moving bed

ActiveCN107460314ASimple structureLow running costProcess efficiency improvementFixed bedIon exchange

The invention relates to the technical field of uranium mining and metallurgy, and particularly discloses an ion exchange eluting column for a compact moving bed. The eluting column comprises an exchange column, a resin inlet, a liquid inlet, an exhaust port, a plurality of liquid outlet devices and a resin outlet; the resin inlet and the liquid inlet are formed in the top end of an upper sealing head arranged at the upper end of the exchange column; the resin outlet is formed in the center of a lower sealing head arranged at the lower end of the exchange column, and meanwhile the liquid outlet devices are arranged on the lower sealing head; a compact resin bed layer is arranged in the exchange column; the resin inlet is of a detachable flange cylinder structure; and the exhaust port is of a detachable pipe connecting flange assembly structure. According to the eluting column, the flow and the concentration are both suitable for the eluting column under the working pressure of 0.6 MPa, the using amount of eluting liquid is low, material liquid is distributed uniformly, deflected flowing and channeling are prevented, the space utilization rate of resin is high, the system using resin amount is low, resin eluting and converting achieved through a fixed bed and resin feeding and discharging achieved through the moving bed alternate freely, and the eluting liquid is qualified.

Owner:THE FOURTH INST OF NUCLEAR ENG OF CNNC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com