Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

181 results about "In situ leach" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In-situ leaching (ISL), also called in-situ recovery (ISR) or solution mining, is a mining process used to recover minerals such as copper and uranium through boreholes drilled into a deposit, in situ. In situ leach works by artificially dissolving minerals occurring naturally in a solid state. For recovery of material occurring naturally in solution, see: Brine mining.

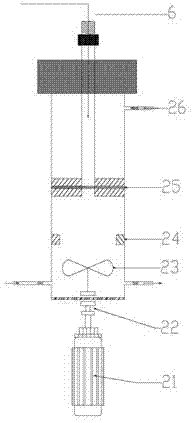

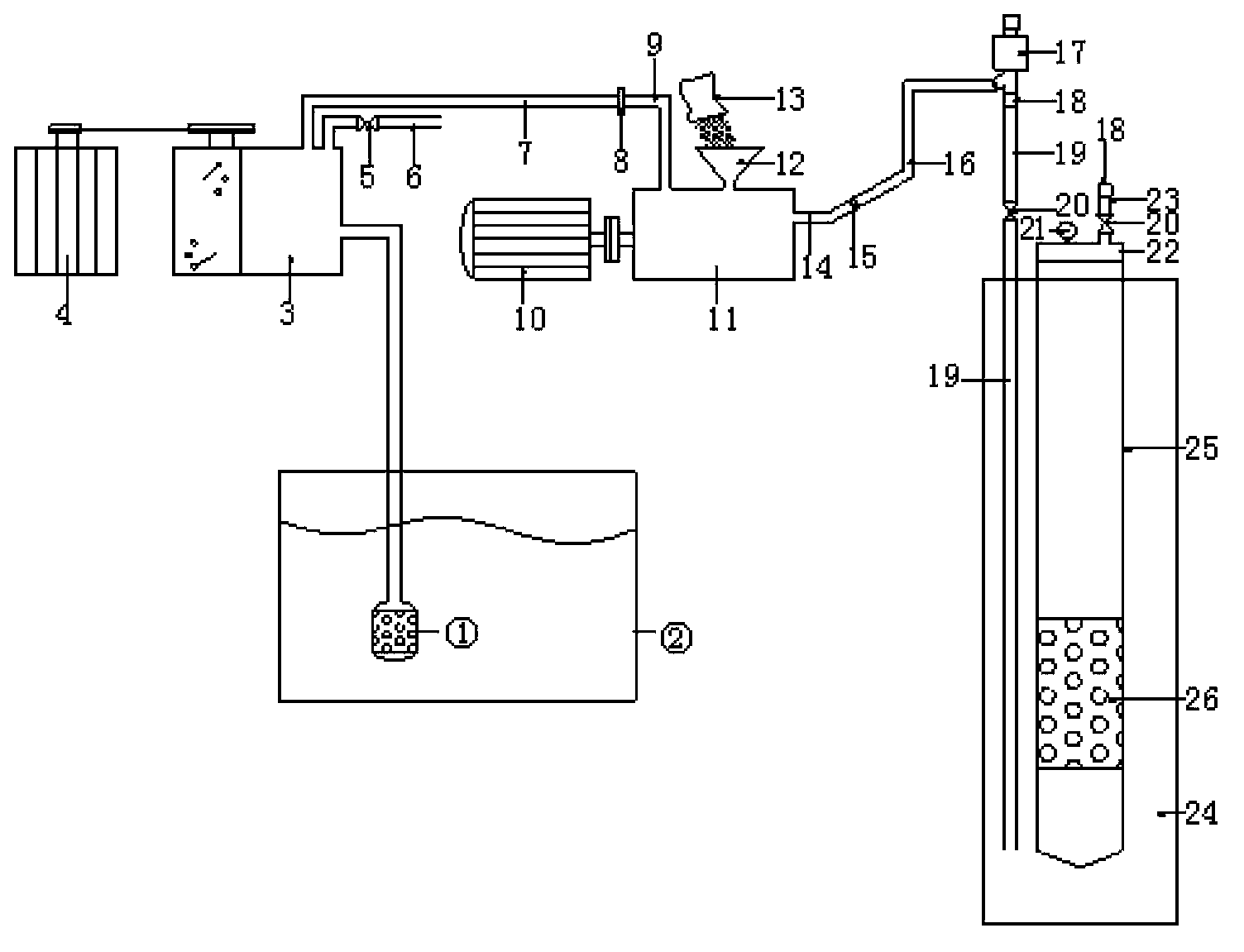

Leaching experimental facility for in-situ leaching uranium mining

ActiveCN103711462ARealize concentration measurementRapid dissolution equilibriumSurveyFluid removalMagnetic tension forceAutomatic control

The invention belongs to the technical field of experimental devices for scientific researches on in-situ leaching uranium mining, and particularly relates to a leaching experimental facility for in-situ leaching uranium mining. A gas source comprises an oxygen source and a carbon dioxide source; gas and liquid are mixed and dissolved by using a magnetic stirring device in a stirring container; dissolving pressure is controlled by a nitrogen cylinder via a stirring container pressure return valve; the pressure provided by a plunger pump is adjusted through an intermediate container pressure return valve in an experiment until the pressure in a liquid injection intermediate container is the same with the pressure in the stirring container; leaching liquid is pressed in the liquid injection intermediate container by a pressure adjusting portion; a rock core is arranged in a full-diameter rock core holding unit; a ring pressure pump and a pressure sensor are arranged at two ends of the holding unit; an outlet end is provided with a leaching pressure return valve; formation pressure is simulated; oxygen in leaching agent is controlled so that the oxygen cannot be separated out; the mass of the liquid is measured by a balance measuring system; and the experiment is automatically controlled by a computer.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Environment-friendly water-holding coal and uranium coordinated mining system and application method thereof

InactiveCN106014344AEliminate the effects ofEfficient use ofFluid removalTunnelsWater dischargeEngineering

The invention discloses an environment-friendly water-holding coal and uranium coordinated mining system. The environment-friendly water-holding coal and uranium coordinated mining system comprises a freezing mechanism, a pumping and injecting mechanism, a water storage mechanism and a mining supporting mechanism. The freezing mechanism is provided with freezing shafts. The pumping and injecting mechanism is provided with fluid injecting wells and a fluid pumping well. The water storage mechanism is provided with an underground reservoir, a security coal pillar and advance water discharge pipes. The mining supporting mechanism is provided with a road header, a coal mining machine, a scraper conveyor and a hydraulic support. The freezing shafts in the freezing mechanism conducts freezing on an aquifer on the periphery of the pumping and injecting mechanism with the pumping and injecting mechanism as the radius; the pumping and injecting mechanism conducts uranium mining by an in-situ leaching technology; the mining supporting mechanism conducts stoping on a coal seam; and the water storage mechanism stores and purifies water in the aquifer of a broken roof. Finally, under rational cooperation of the four mechanisms, coal and uranium coordinated mining is realized, underground water is recovered and purified at the same time, and the purpose of environment-friendly water-holding multi-resource coordinated mining is achieved.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

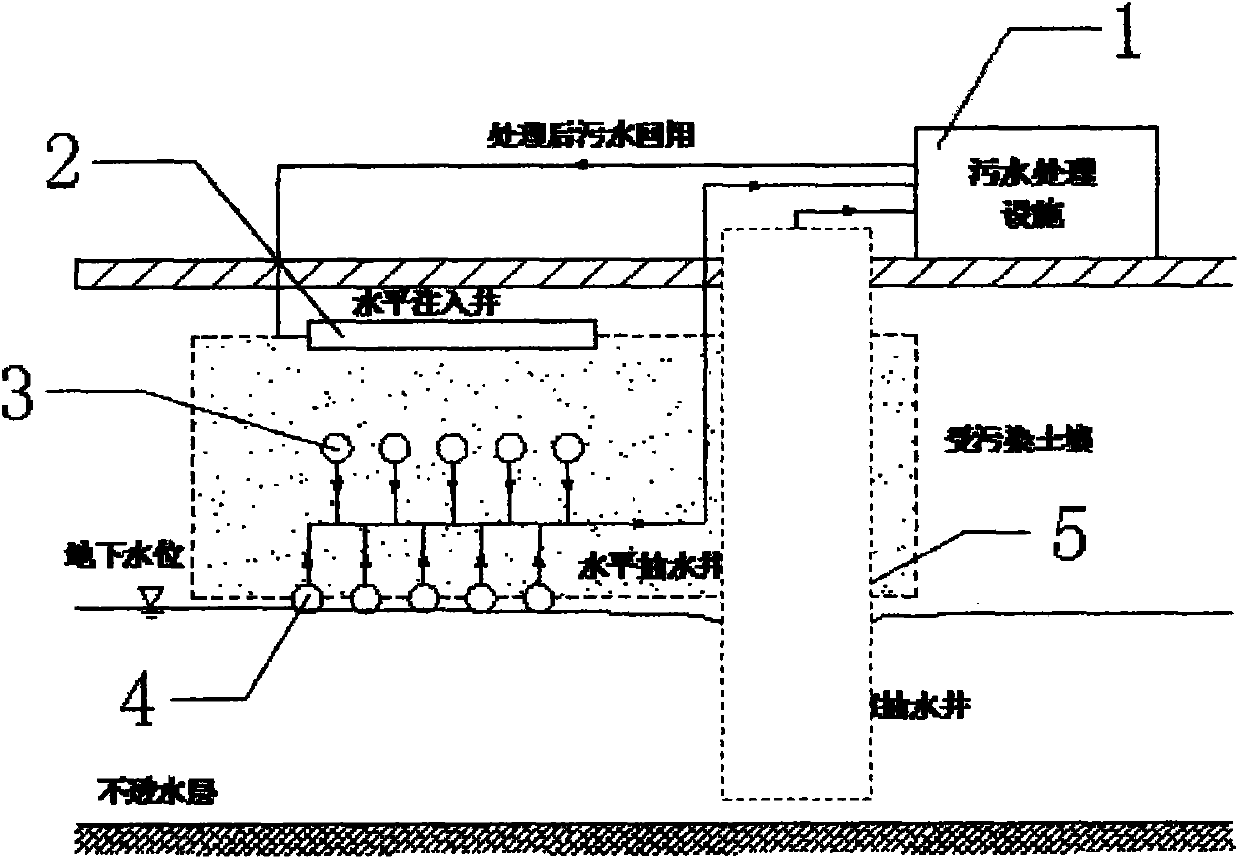

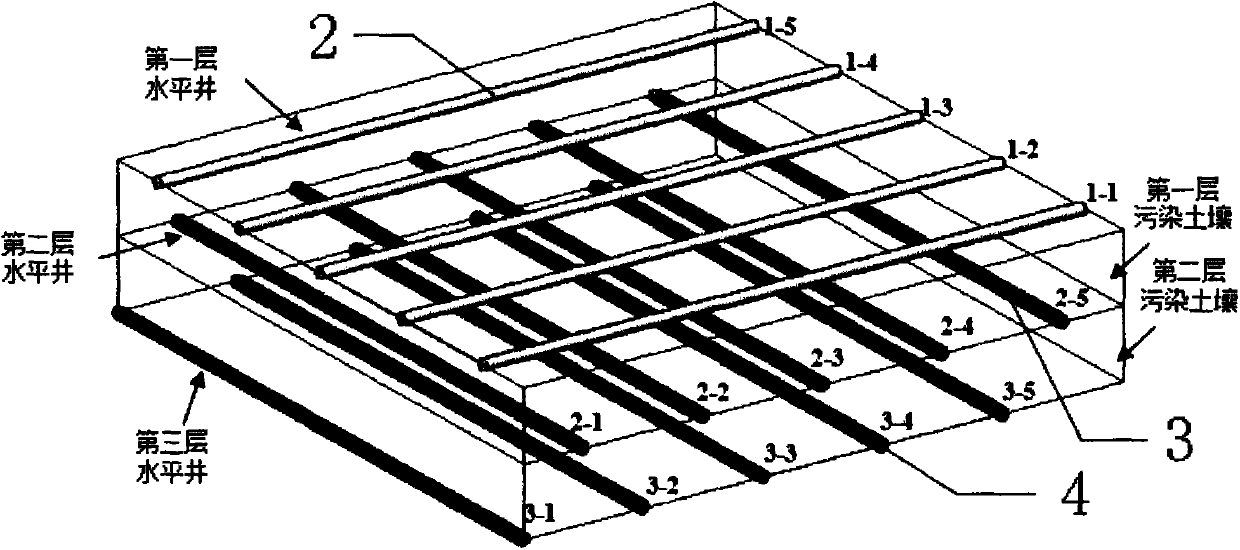

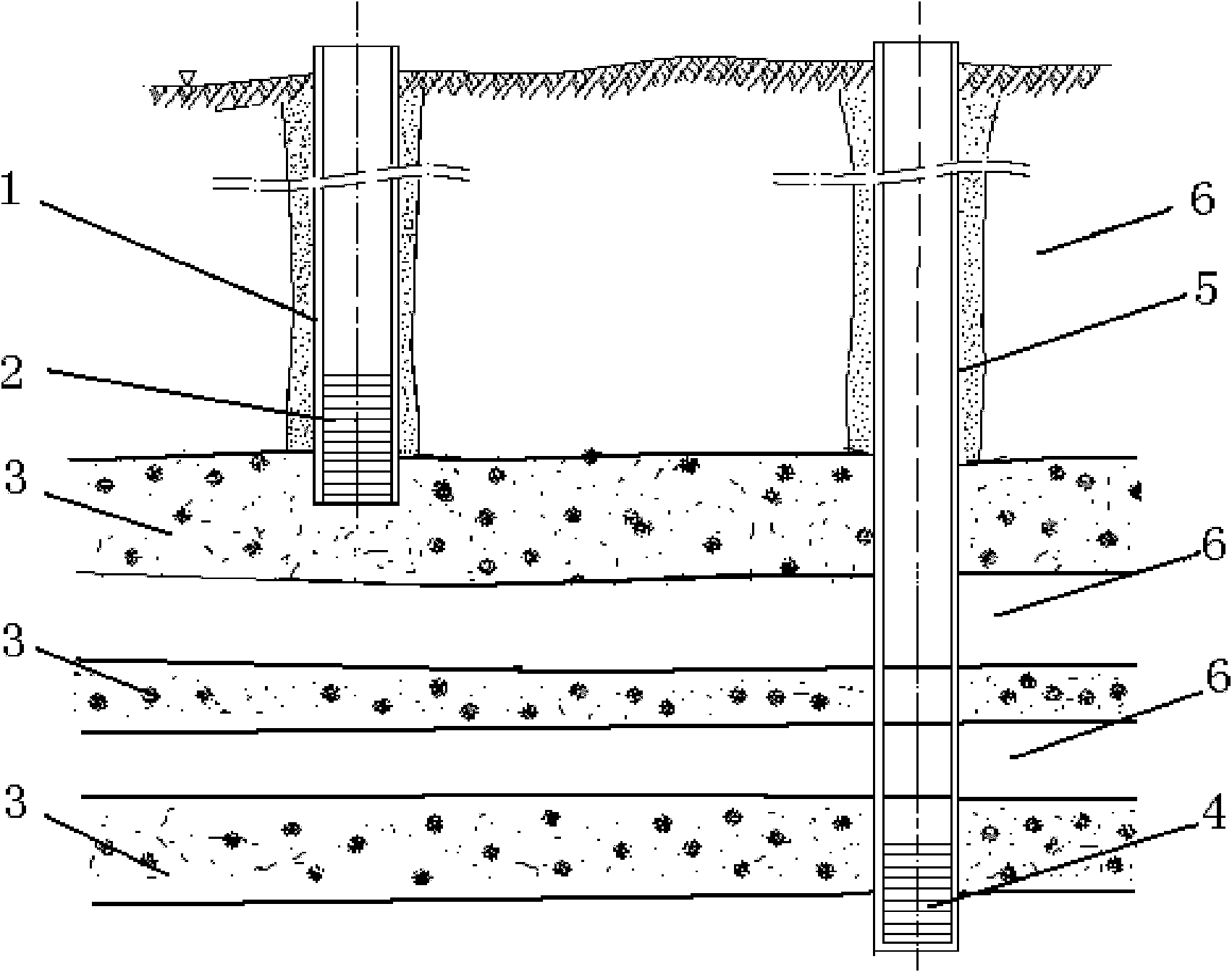

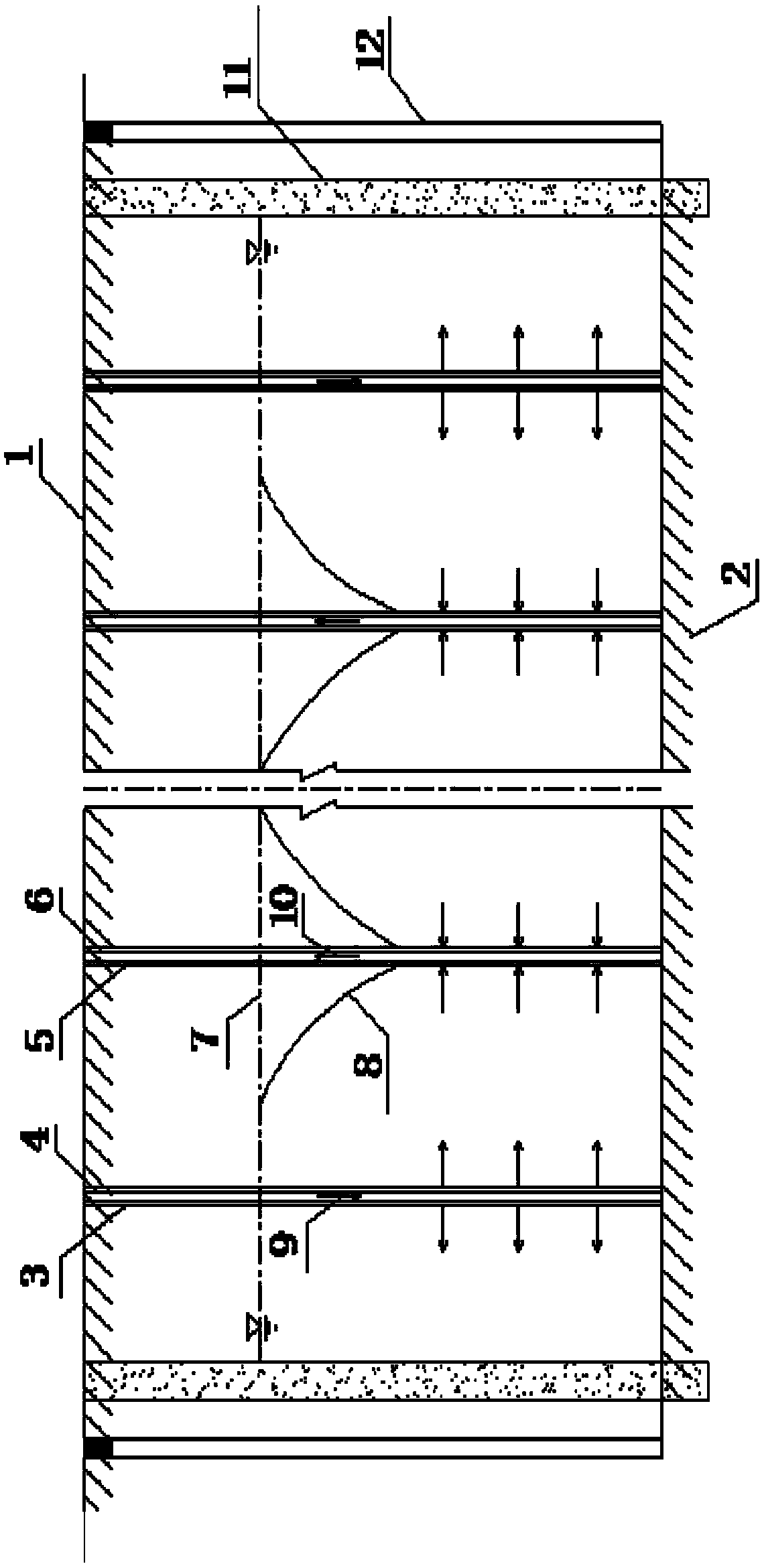

In-situ polluted soil leaching system and method

InactiveCN103736722AExpand the scope of influenceThorough governanceContaminated soil reclamationSoil scienceHorizontal wells

The invention discloses an in-situ polluted soil leaching system and method. The in-situ polluted soil leaching system comprises a sewage treatment device and a plurality of layers of horizontal wells connected with the sewage treatment device; if necessary, a vertical pumping well can be arranged. The in-situ polluted soil leaching system comprises but not limited to a first layer of horizontal well, a second layer of horizontal well and a third layer of horizontal well; all the layers of horizontal wells are arranged in a staggered manner. The method comprises the step of leaching polluted soil layer by layer. The in-situ polluted soil leaching system and method provided by the invention can be used for processing two layers of polluted soil but is not limited to two layers. With the adoption of the in-situ polluted soil leaching system and method provided by the invention, the problems caused by an existing in-situ leaching method of small influence area and non-uniform seepage can be solved to a great extent.

Owner:韩清洁

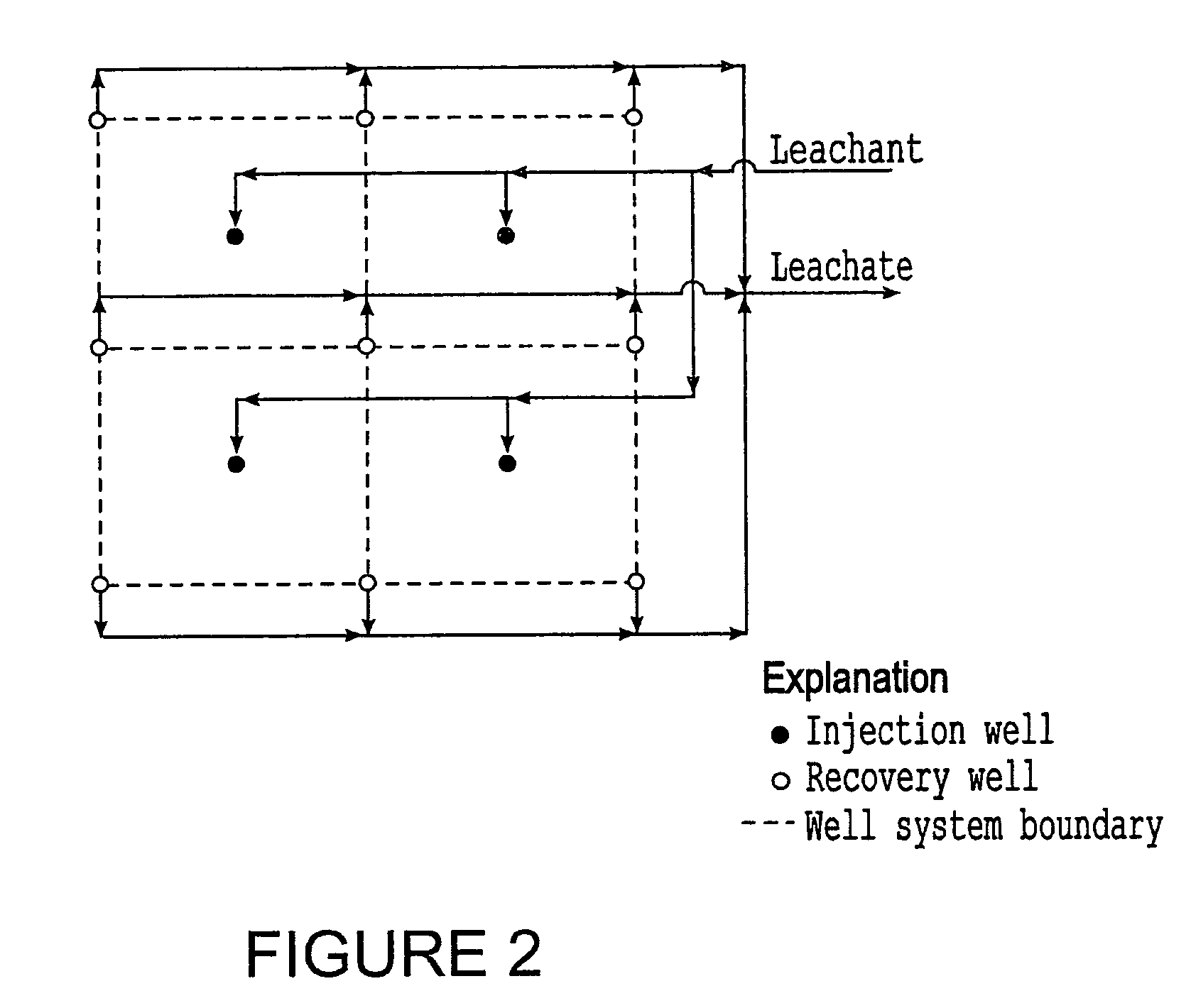

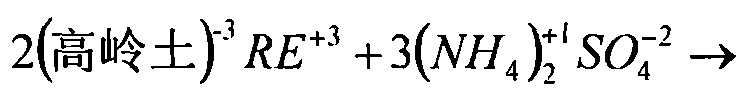

In situ leaching injection process

ActiveCN101915073AReduce wasteResidue reductionFluid removalProcess efficiency improvementRare earthIn situ leach

The invention discloses an ion adsorption rare-earth in situ leaching injection process, which is characterized by comprising the following steps of: setting an injection network with shallow injection wells and deep injection wells distributed at intervals according to mineral body space layout condition, mineral body thickness change condition, mineral soil permeability, project layout of a liquid receiving system and the like; and injecting the shallow injection wells and then injecting the deep injection wells in an injection process, and finally injecting top water to the shallow injection wells and the deep injection wells together. The in situ leaching injection process has the advantages of rare-earth leaching rate, high mother solution concentration, little mineral mother solution residue, low single leaching agent consumption, simple operation, wide application range and remarkable environment-friendly effect, meanwhile solves the problem of poor stability of a leaching dead zone and an injection process slope, and realizes controllability of flow direction, flow rate and injection strength of the leaching agent.

Owner:JIANGXI RARE EARTH & RARE METALS TUNGSTEN GRP HLDG CO LTD

Technique for reagent-free in situ leaching uranium mining from sandstone type uranium deposit

InactiveCN101580900AEasy to extract and handleImprove product qualityProcess efficiency improvementWater insolubleUranyl

The invention relates to a technique for reagent-free in situ leaching uranium mining from a sandstone type uranium deposit, which comprises the following steps: performing preoxidation on ore beds by injecting air; injecting industrial oxygen into the ore beds in the processes of extracting and liquid charging; and forming hexavalent uranium into a stable soluble complex in bicarbonate type ground water. The technique achieves the oxidation of the metallic uranium in the ore beds under the condition of not introducing chemical reagents of acid, alkali and the like so that the water-insoluble tetravalent uranium is converted into water-soluble hexavalent uranyl ions for the convenience of performing extraction on the ground surface; besides, the technique has the advantages of stable product quality, low production cost, no pollution of an extraction-injection balanced closed cycle, easy decommissioning treatment and the like.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

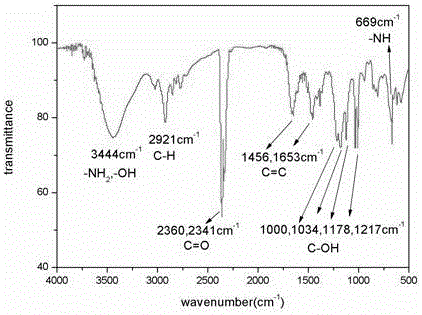

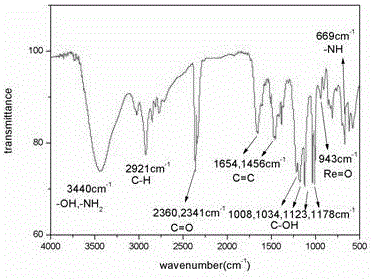

Method for recycling associated rhenium resources from sandstone-type uranium deposit in-situ leaching uranium exploration process adsorption tail liquid

ActiveCN106148737AReduce consumptionImprove overall recoveryProcess efficiency improvementRheniumIon-exchange resin

The invention discloses a method for recycling associated rhenium resources from sandstone-type uranium deposit in-situ leaching uranium exploration process lean resin. Sandstone-type uranium deposits are added into a sulfuric acid solution containing an oxidizing agent. After vibration soaking is carried out for a period at a certain temperature, anion exchange resin is used for adsorbing uranium and rhenium in leachate. After the resin is saturated, an ammonium nitrate solution is used for desorbing the uranium in the resin. The lean resin returns to the adsorption process after transforming. The desorbed uranium concentrated solution is precipitated by adopting sodium hydroxide, the rhenium in the resin is desorbed, the concentrated ammonium rhenate solution is obtained, and ammonium rhenate products are obtained after recrystallization. The method is simple in process and capable of realizing large-scale production easily. The products are high in purity, the overall recovery rate of the rhenium in the leachate reaches 80% or above, reagents used in the process are environmentally friendly, and remarkable social benefits and economical benefits are achieved.

Owner:EAST CHINA UNIV OF TECH

Outlining method for in-situ leaching sandstone-type uranium-bearing basin favorable mineralization section

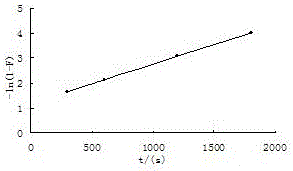

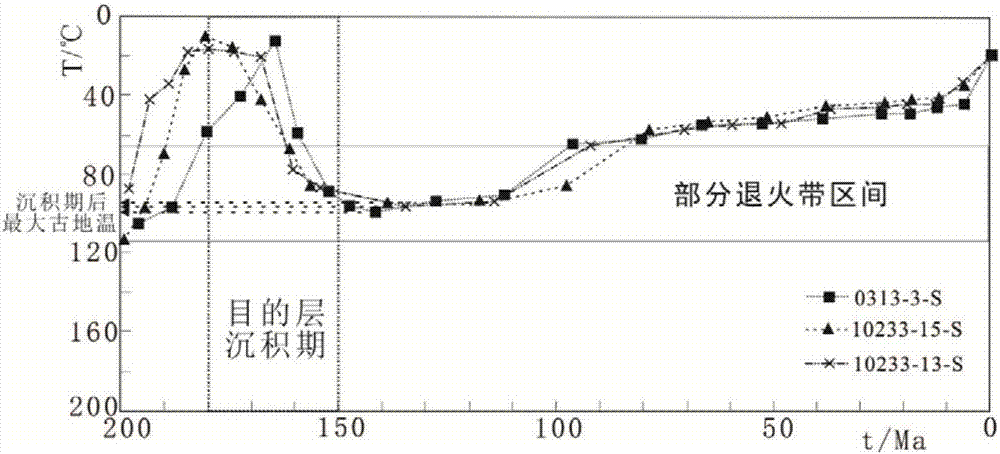

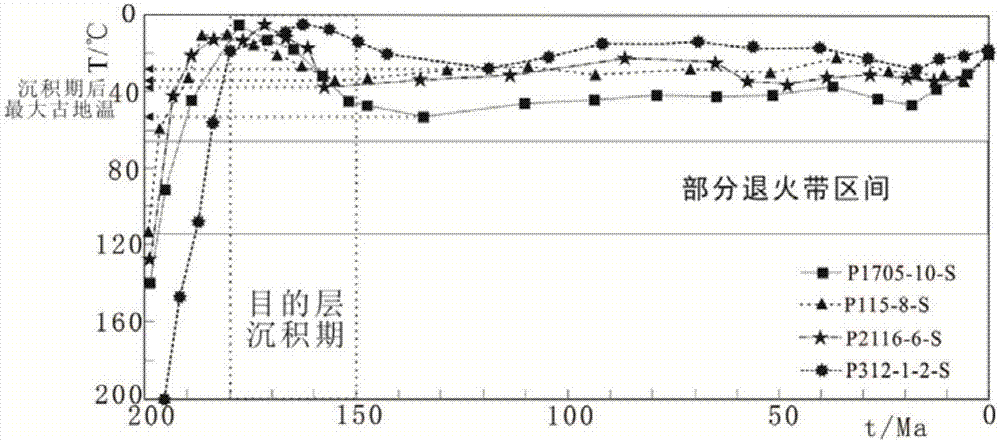

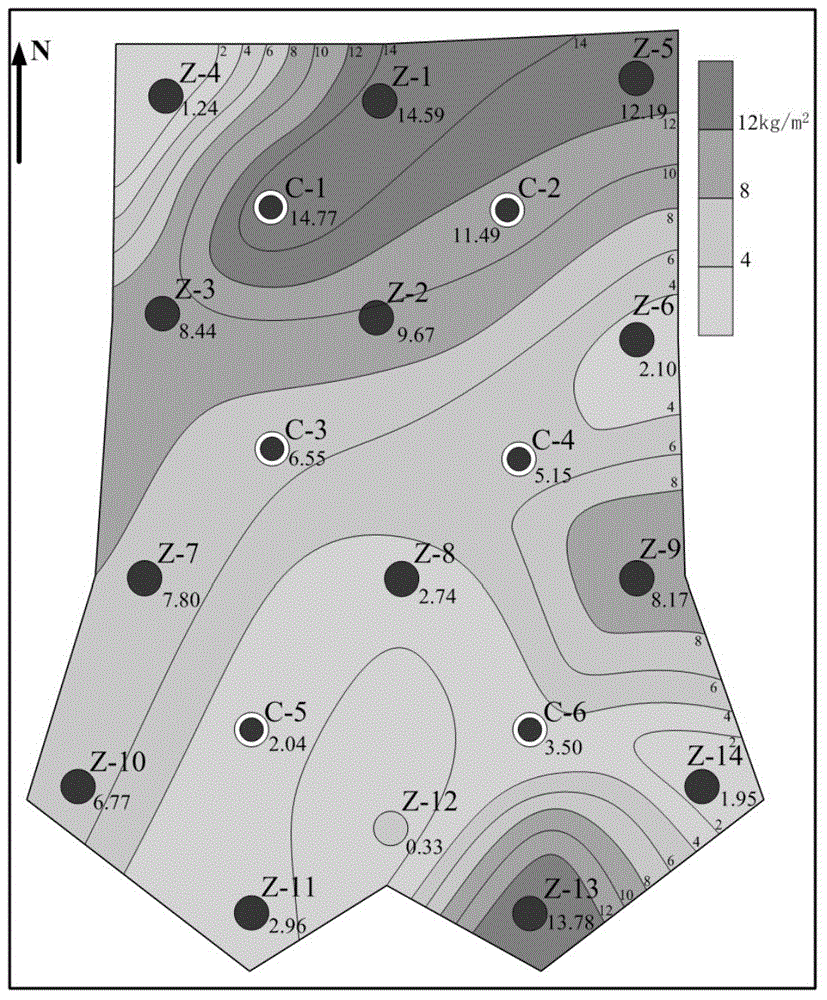

InactiveCN107367770AAccurate and quantitative calculation of uplift denudation thicknessWith process self-testGeological measurementsApatiteFission track dating

The invention belongs to the field of sandstone-type uranium ore exploration, and specifically discloses an outlining method for an in-situ leaching sandstone-type uranium-bearing basin favorable mineralization section. The method comprises the steps: determining a research area, and selecting a target layer; collecting a land surface sample of a bottom plate of a basin edge target layer, a drilled coal stone sample or a carbon mudstone sample; collecting sandstone samples of the above samples at the same layer; carrying out the vitrinite reflectance measurement of the collected coal stone sample or the collected carbon mudstone sample, and calculating the maximum burial depth of an ore-containing target layer; selecting apatite minerals from the collected mudstone sample, carrying out the fission-track dating of apatite, and carrying out the inversion of the relation between temperature and time in construction evolution; verifying whether the above inversion result is matched with the actual condition or not: extracting the measurement result if the above inversion result is matched with the actual condition, or else checking whether the sampling is standard or not; drawing an erosion thickness contour map in the research area according to an erosion thickness calculation result, carrying out the research of restriction of construction uplift erosion on uranium mineralization, and outlining a favorable mineralization section. The method is clear in sampling object, is clear in analysis flow, and is simple in operation.

Owner:BEIJING RES INST OF URANIUM GEOLOGY

Diluted acid in-situ leaching uranium mining technology

ActiveCN104533376AIncrease injection volumeIncrease concentrationFluid removalPregnant leach solutionUranium ore

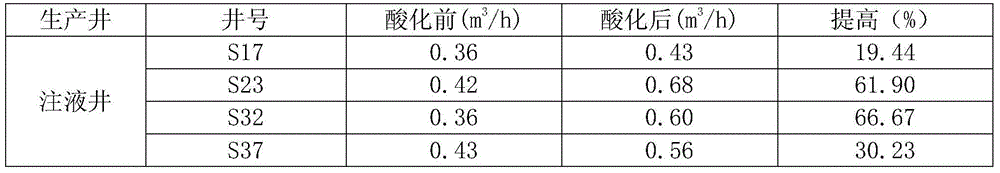

The invention provides a diluted acid in-situ leaching uranium mining technology according to the characteristics of a carbonate cement low-permeability sandstone type uranium ore deposit. Diluted hydrochloric acid serves as a leaching agent and is injected into an ore bed in an online acid adding mode, the PH value of a leaching solution is kept between 3 and 6 so that carbonate in the ore bed can be quickly dissolved, HCO3- is generated on site, and leaching is promoted. The diluted acid in-situ leaching uranium mining technology has been used in in-situ leaching uranium mining experiments and production of the Shashagetai uranium ore deposit and the Nalinggou uranium ore deposit in Ordos, the liquid injection amount is remarkably increased, and the concentration of the HCO3- and the concentration of leaching liquid uranium are obviously increased.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

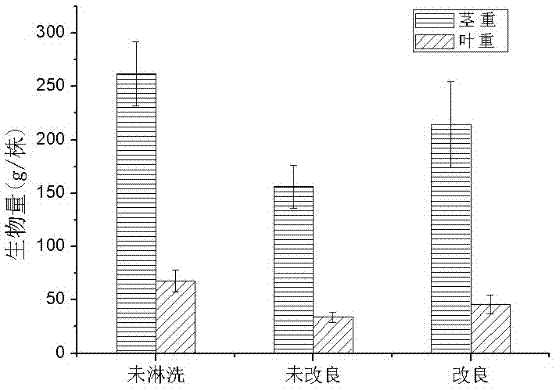

Method for jointly remediating soil contaminated by heavy metals

ActiveCN107138511AEnvironmentally friendlyDoes not damage the structureContaminated soil reclamationPhytoremediationMaterials science

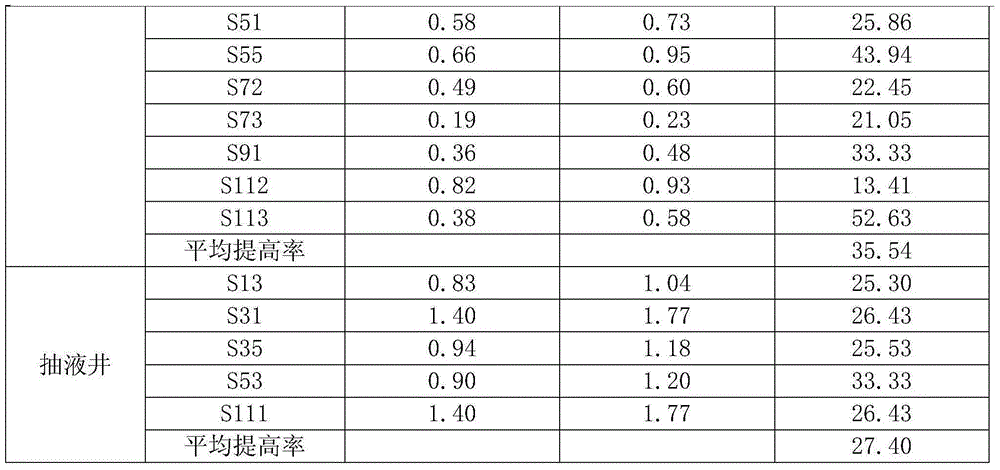

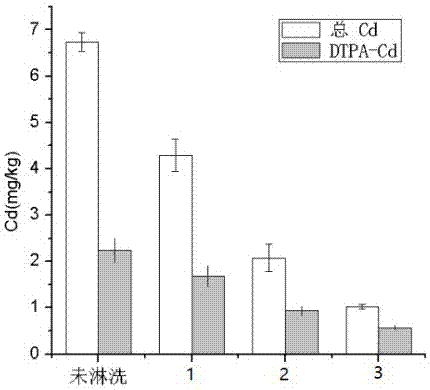

The invention discloses a method for remediating soil contaminated by heavy metals such as cadmium by combining in-situ leaching, deep-layer fixing and phyto-extracting. According to the method, the heavy metals are leached into a deep layer along with a leaching solution through the in-situ leaching in a surface layer and are fixed in the deep layer, then willow with the heavy metal accumulation function is planted after organic fertilizer is applied, and therefore the residual heavy metals can be further removed, and the soil function can be restored; the heavy metals in a plough layer are leached to the deep layer, the absorption of crops to the heavy metals is reduced, the heavy metals which are leached to the deep layer are fixed, underground water is not polluted, and therefore the residual heavy metals can be further removed through phytoremediation, and the soil function can be restored; an iron-containing compound used in the method does not destroy the soil structure and can serve as a rice field soil conditioner; and compared with the phytoremediation, the method has the advantage that the remediation efficiency can be improved, and compared with leaching remediation, the method has the advantage that the steps of excavating, stirring, separating and the like can be omitted. The invention provides the remediation method. The remediation method has the advantages of being short in time, low in cost and high in efficiency and having a wide application prospect in the field of remediation of a large-scale farmland contaminated by the heavy metals.

Owner:NANJING UNIV

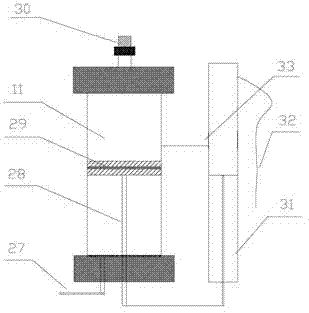

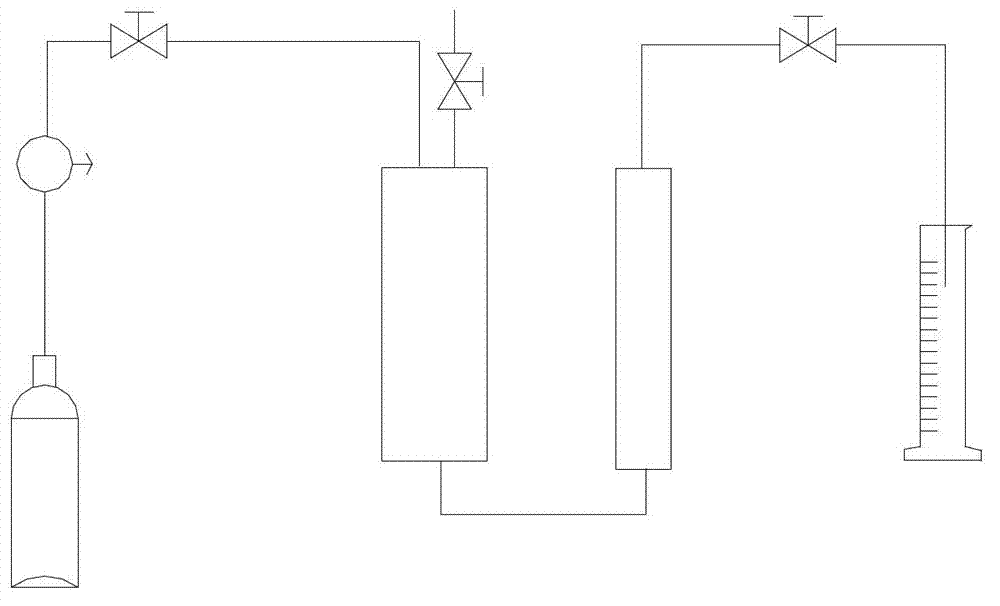

Acid in-situ leaching uranium mining laboratory simulation device and test method

InactiveCN107460349AAccurate calculation of leaching rateReduced risk of cloggingIon exchangeLiquid storage tank

The invention provides an acid in-situ leaching uranium mining laboratory simulation device. The acid in-situ leaching uranium mining laboratory simulation device comprises a leaching agent storage tank, a leaching column, a leaching liquid storage tank, an ion exchange column, a leaching agent preparation tank, a pump, a valve A, a valve B, a valve C, a valve D, a valve E, a valve F, a valve G and connecting pipes, wherein the leaching agent storage tank is used for storing a leaching agent; the leaching column is used for containing an ore sample and providing a site for a contact reaction between the leaching agent and ore; the leaching liquid storage tank is used for containing leaching liquid; the ion exchange column is used for containing an adsorption material of uranium; the leaching agent preparation tank is used for containing the leaching liquid generated after the uranium is adsorbed by resin; the pump is used for conveying the prepared leaching agent into the leaching agent storage tank; and the connecting pipes are used for connecting all the components. The invention further provides a test method adopting the acid in-situ leaching uranium mining laboratory simulation device. Test results of the device and the test method can provide reliable basis for in-situ test engineering leaching agent preparation and the leaching technique, the risk that according to an in-situ test leaching system, an ore bed is blocked due to accumulation and sedimentation of impurity ions is reduced, and the prevention level is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

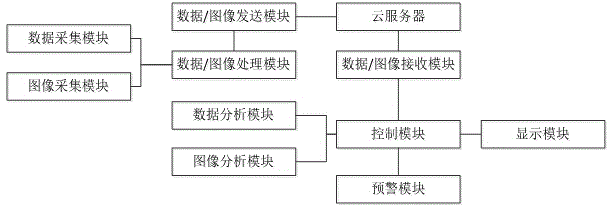

Remote on-line monitoring and early warning system for stability of ion type rare earth slope

ActiveCN104916077ARealize real-time monitoringEnsure stope safetyAlarmsEarly warning systemImaging processing

The invention provides a remote on-line monitoring and early warning system for stability of an ion type rare earth slope. With the system, real-time monitoring of stability of an in-situ leaching landslide of a rare earth mine can be realized; automatic early warning can be realized when the landslide occurs at the mine; and thus the stope slop safety during the exploitation period and after exploitation of the mine can be guaranteed. A data acquisition module collects feature parameter data of the rare earth in-situ leaching ore; an image collection module collects image information in a monitoring region; a data / image processing module extracts effective feature parameter data and effective image information respectively; and a remote monitoring module compares effective collation data of all sensors with thresholds, determines whether a landslide accident is going to happen, and uses an early warning module to send out an early warning signal when the landslide accident is going to happen. Besides, the remote monitoring module also contains a display module for display effective image information.

Owner:JIANGXI UNIV OF SCI & TECH +1

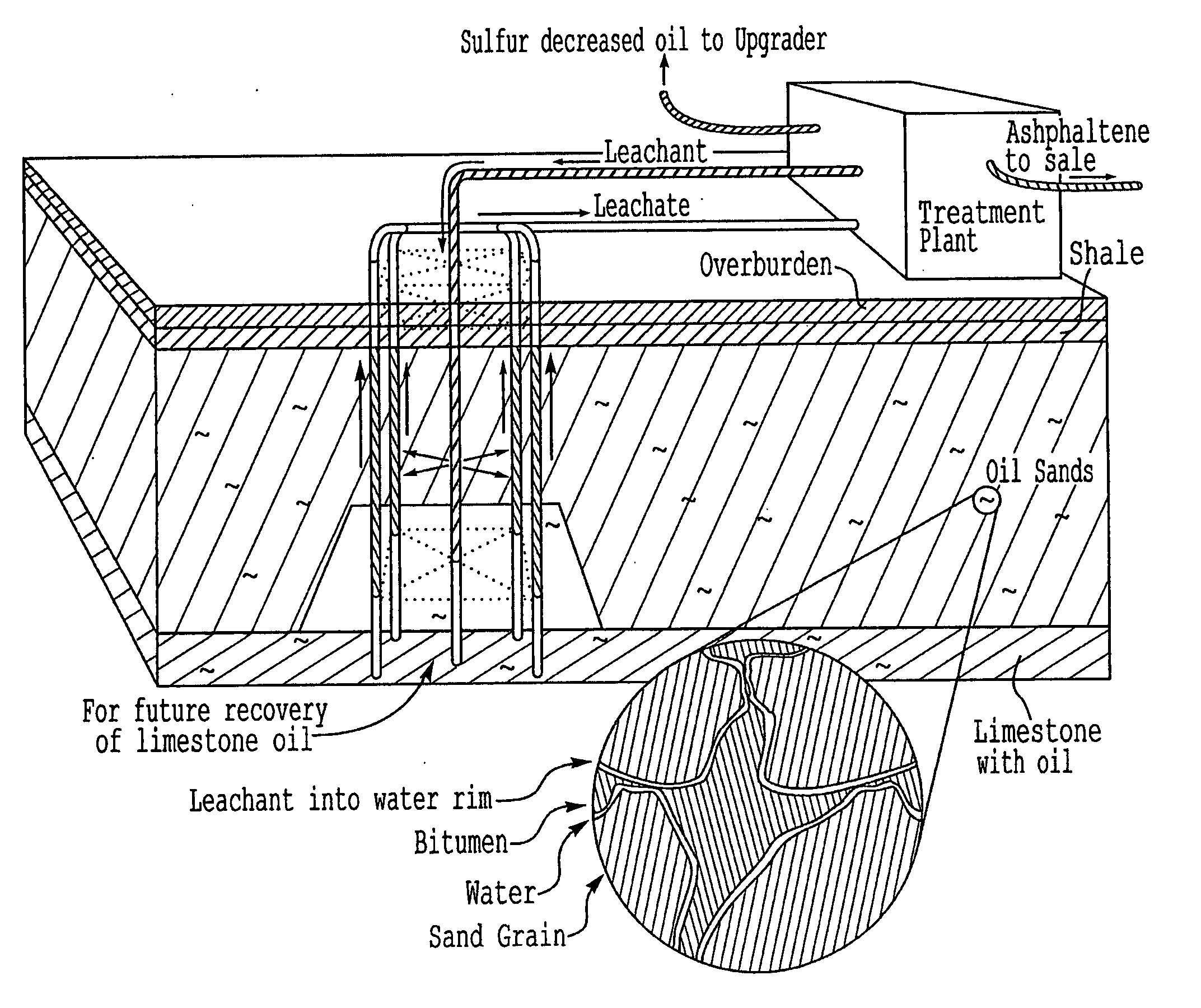

Leach recovery of oil from oil sands and like host materials

ActiveUS20090236899A1Promote recoveryAccelerates the biodegradation processDisloding machinesUnderground miningSite RemediationsResource development

Oil sands and like host materials are leached with a selected leachant to render pumpable the oil (including heavy oil, bitumen or kerogen and asphaltenes) as leachate. In a preferred embodiment, natural deposits are in situ leached and the leachate recovered and removed for treatment. The leachant is separated and recycled. The leachant is selected to be biodegradable and to not precipate asphaltenes, and to comprise monoterpenes of the formula C10H16. The overall process allows environmentally acceptable resource development and contaminated site remediation.

Owner:GEISLER ROBERT

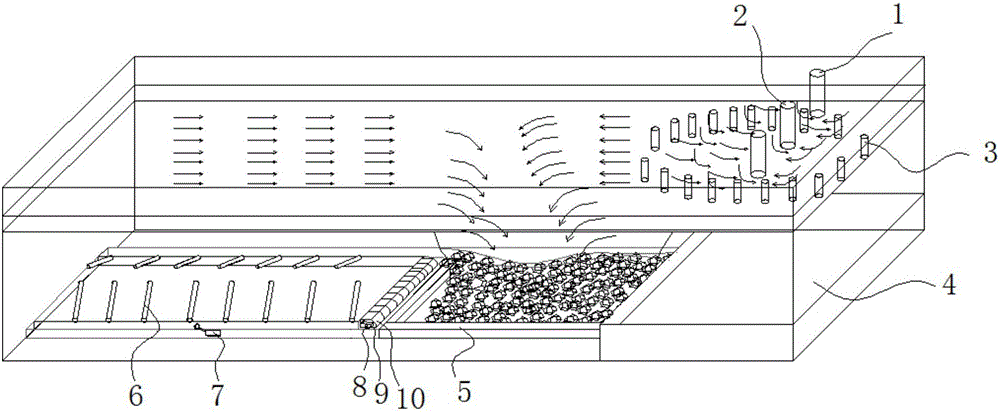

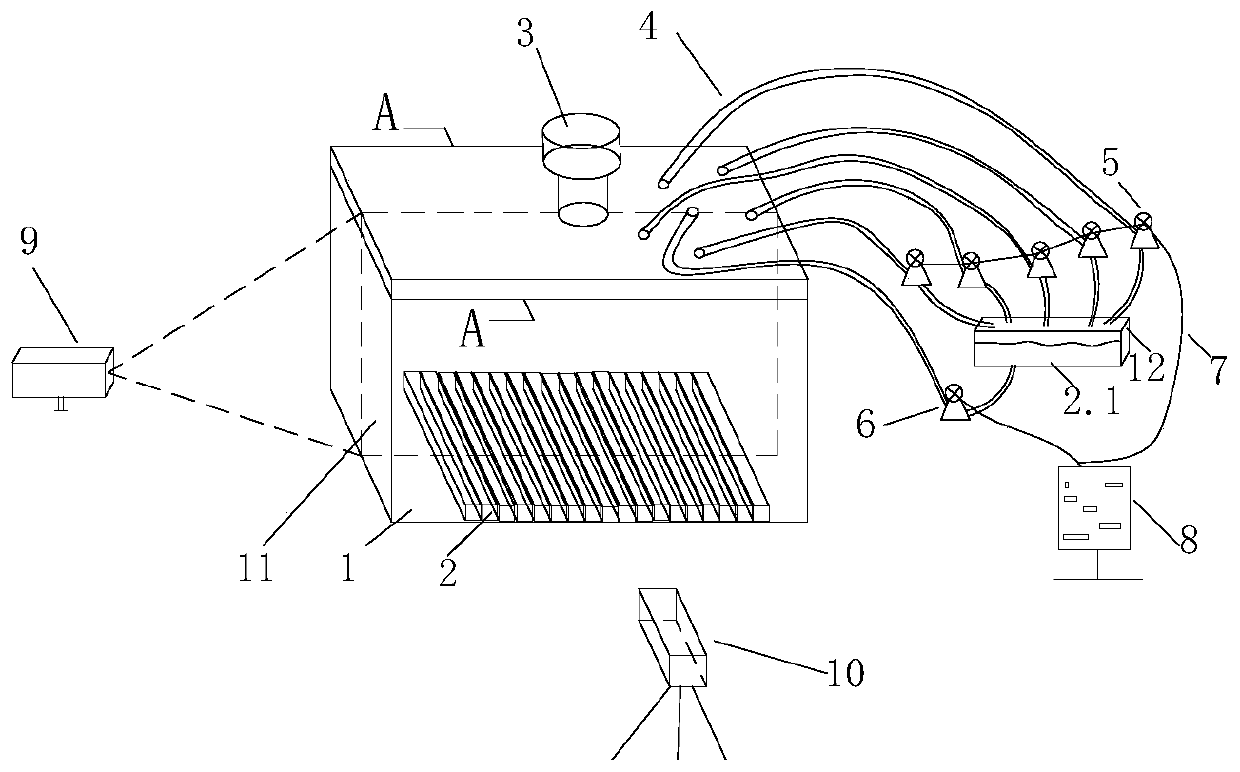

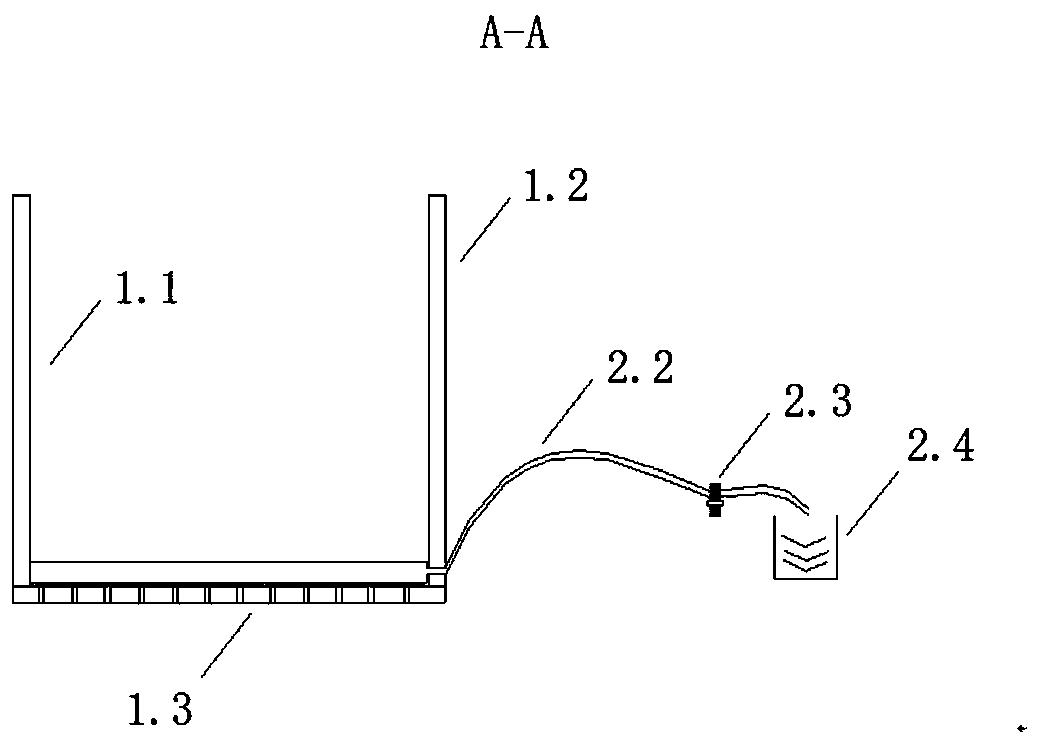

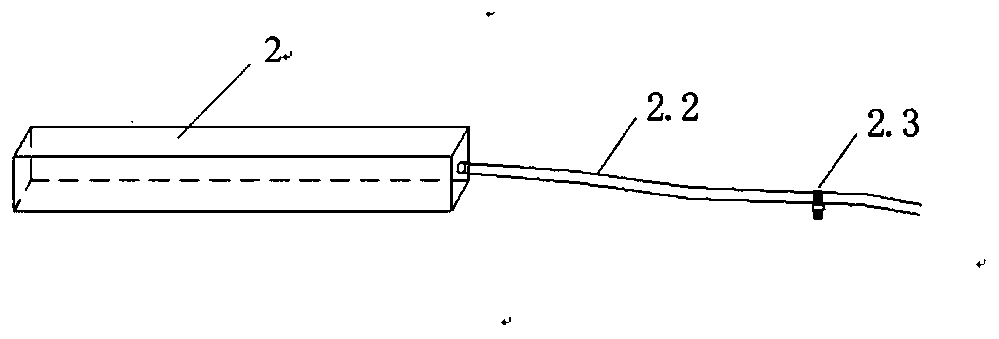

Coal and uranium coordinated mining perspective physical simulation device and application method

InactiveCN110043261AGuaranteed reliabilityImprove resource recoveryUnderground miningFluid removalPositive pressureMulti field

The invention discloses a coal and uranium coordinated mining perspective physical simulation device and application method. The coal and uranium coordinated mining perspective physical simulation device is provided with a coal mining mechanism, a uranium mining mechanism and a observing mechanism, wherein the coal mining mechanism is provided with an organic glass box, a front panel, a rear panel, a bottom panel, a top panel, a left panel, a right panel, a strip-shaped water bag, a transporting pipe, a valve, a beaker, transparent soil, a press machine pressing head and small holes; the uranium mining mechanism is provided with positive pressure pumps, negative pressure pumps, a tracer agent, a liquid storing tank, conduits, an electric wire, a liquid injecting hole, a liquid pumping holeand a centralized control table; and the observing mechanism is provided with an industrial camera and a line laser generator. According to the coal and uranium coordinated mining perspective physical simulation device and application method, the volume of the strip-shaped water bag is adjusted to simulate coal seam mining, the positive pressure pumps are adopted to internally inject the tracer agent into the transparent soil to simulate uranium mine in-situ leaching mining, the mechanisms are matched closely, a multi-field coupling evolution law of coal and uranium coordinated mining is obtained, a coal and uranium coordinated mining scheme is optimized, and the recovery rate and economic benefits of co-associated resources are improved.

Owner:ANHUI UNIV OF SCI & TECH

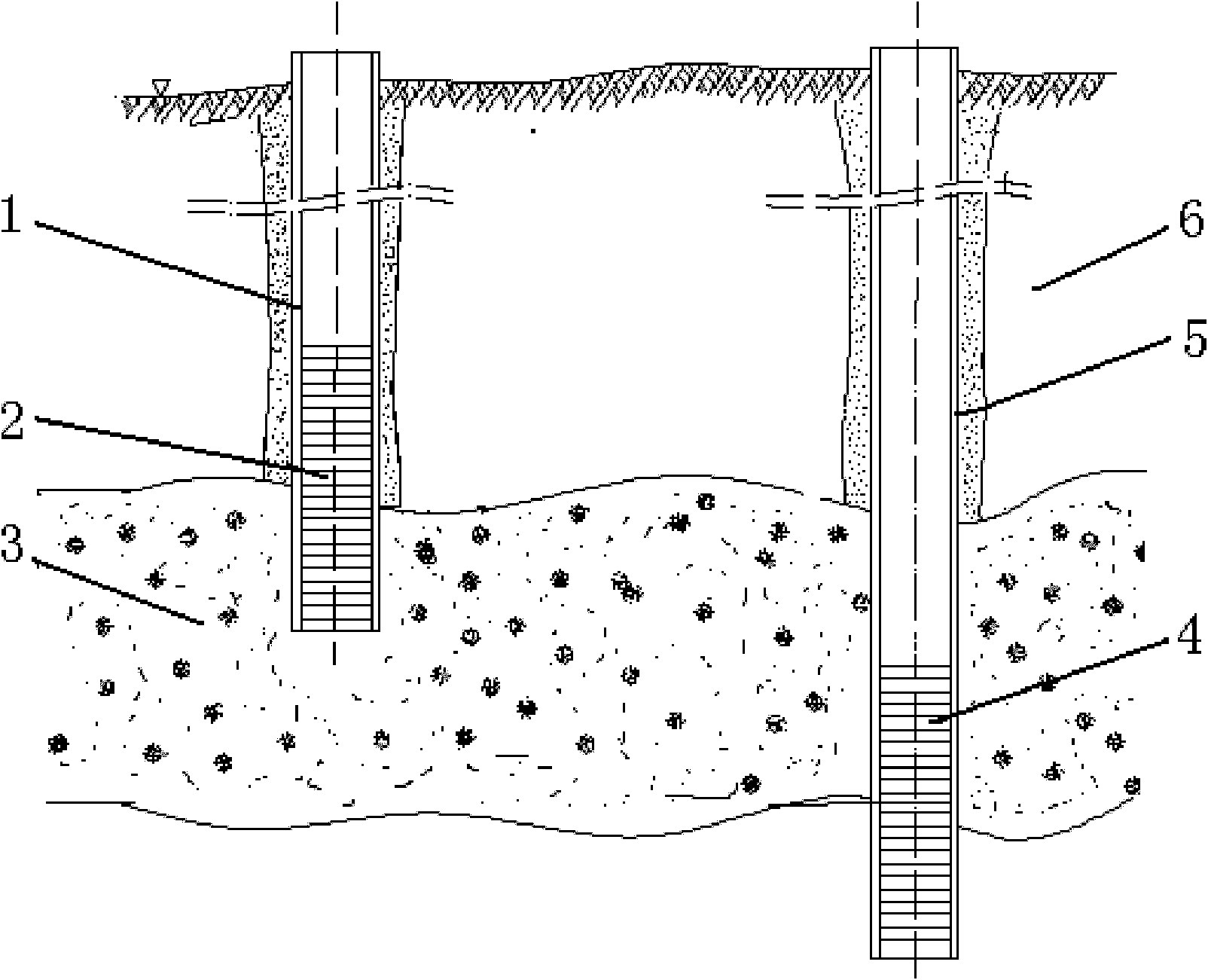

Method for arranging in-situ leaching hole drilling filter

The invention relates to a method for arranging an in-situ leaching hole drilling filter. If a uranium ore has a single vein, the length of a liquid injection hole drilling filter is three fourths to four fifths the thickness of the uranium ore layer, the bottom of the liquid injection hole drilling filter is positioned between the top part and the middle part of the uranium ore layer, the top of the liquid injection hole drilling filter is extended to a non ore layer, the length of an extraction hole drilling filter is three fourths to four fifths the thickness of the uranium ore layer, the top of the extraction hole drilling filter is positioned between the middle part and the bottom of the uranium ore layer and the bottom of the extraction hole drilling filter is extended to the non ore layer; and if the uranium ore has multiple veins, the length of the liquid injection hole drilling filter is three fourths to four fifths the thickness of the topmost uranium ore layer, the bottom of the liquid injection hole drilling filter is positioned between the top part and the middle part of the topmost uranium ore layer, the top of the liquid injection hole drilling filter is extended to the non ore layer, the length of the extraction hole drilling filter is three fourths to four fifths the thickness of the lowest uranium ore layer, and the top of the extraction hole drilling filter is positioned between the middle part and the bottom of the lowest uranium ore layer and the bottom of the extraction hole drilling filter is extended downward to the non ore layer. By the method, leaching liquid can flow directionally, the full and effective contact between the leaching liquid and ore is guaranteed, and the uranium concentration of the leaching liquid is improved.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

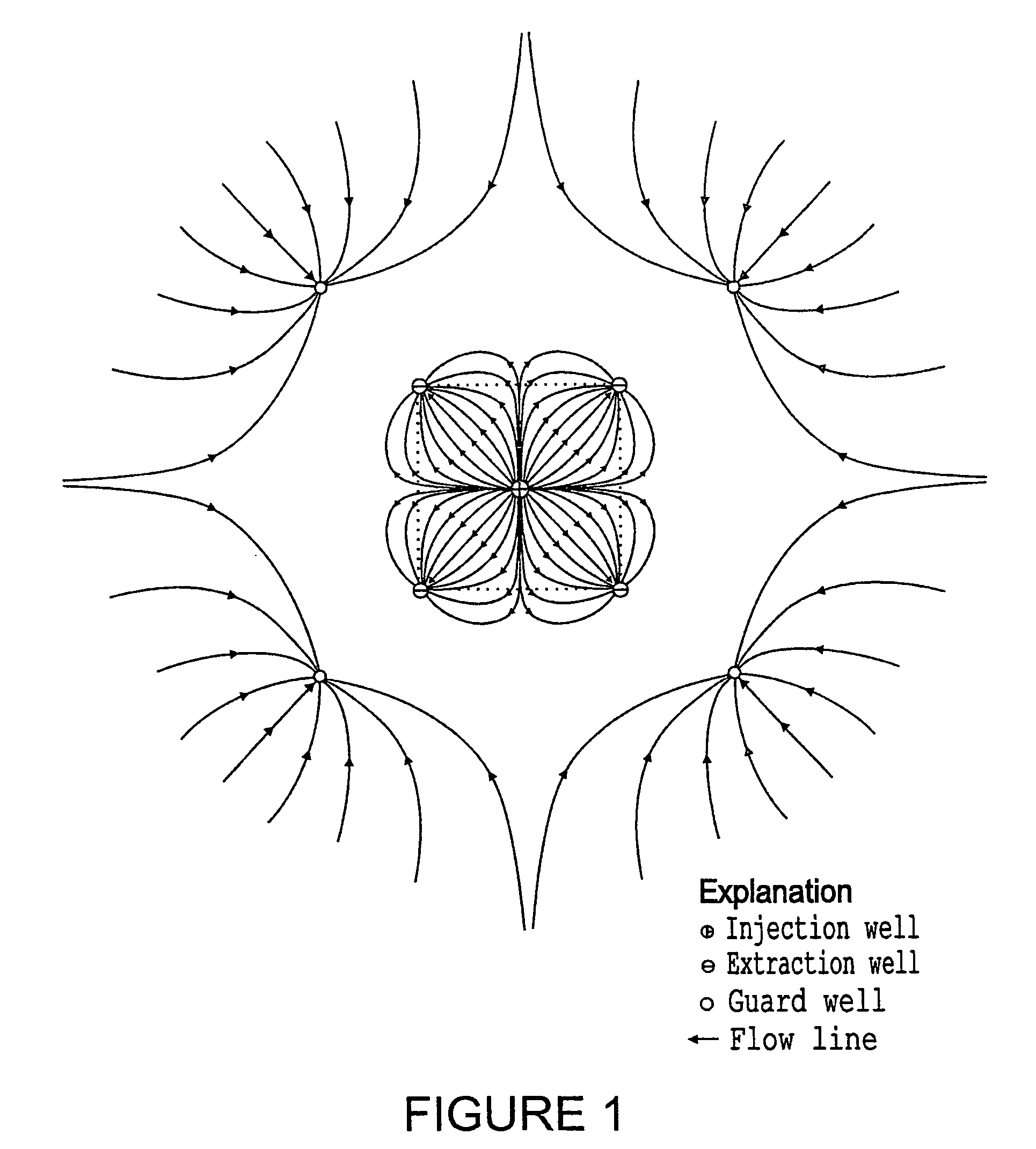

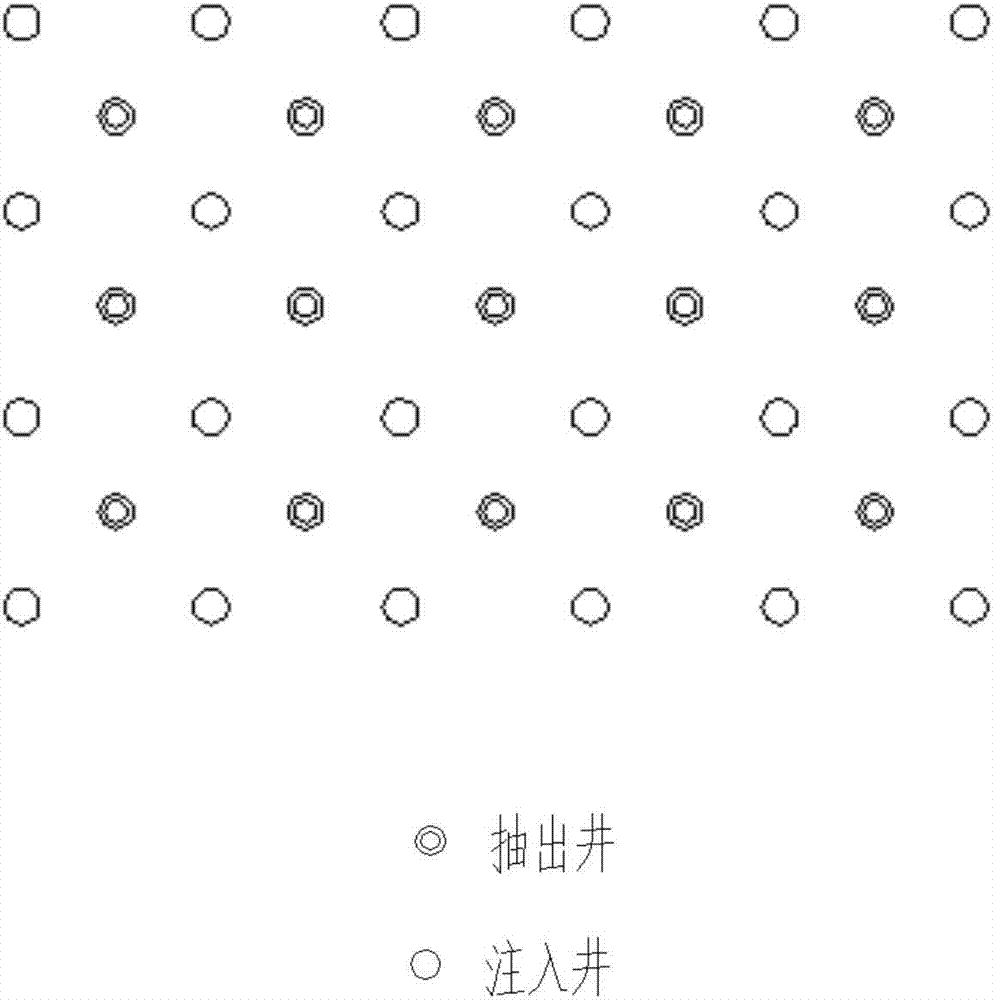

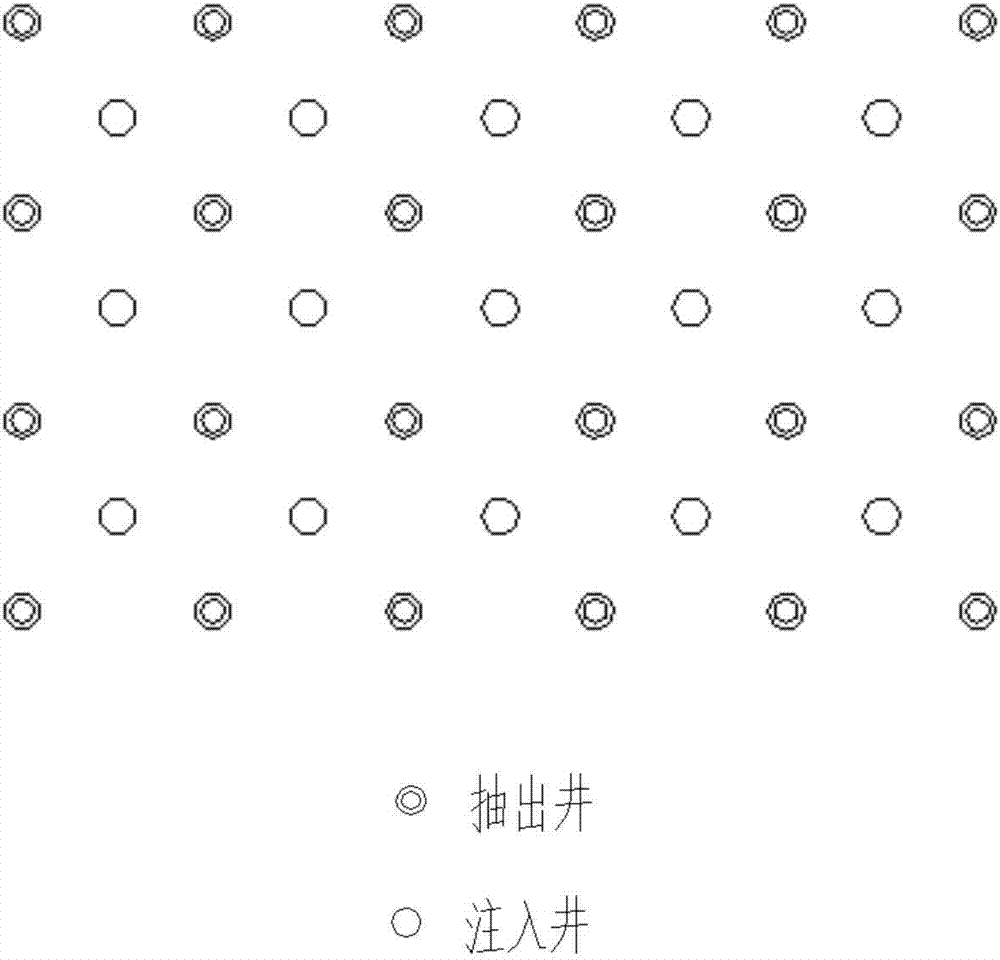

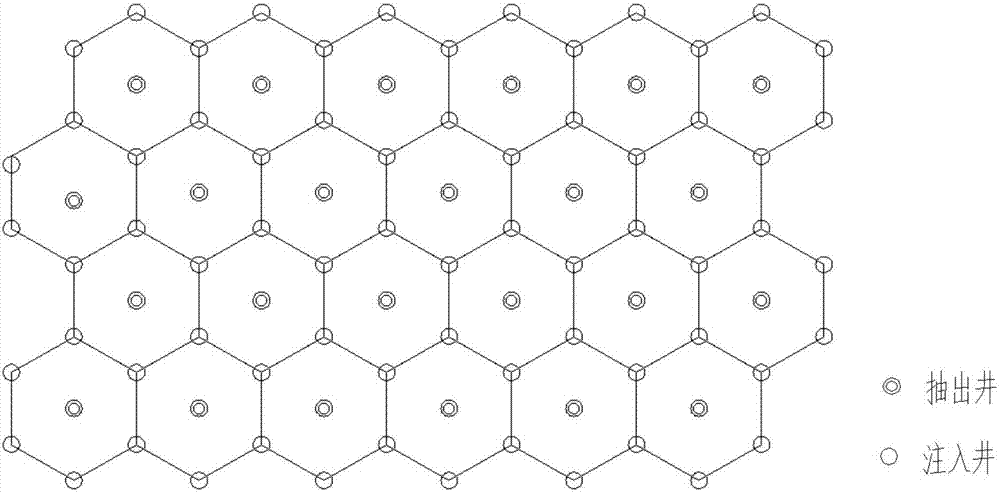

Optimization and recombination method for well network of in-situ leaching uranium mining

ActiveCN106930747AImprove leaching rateSolve the problem of low resource leaching rateFluid removalQuincunxHydrology

The invention provides an optimization and recombination method for a well network of in-situ leaching uranium mining. The method comprises the steps that when the uranium concentration of leachate of a certain leaching mining units of a well site mining area is 3-10 mg / L, or the leaching rate reaches 60%-75%, the positions of liquid extracting wells and liquid injecting wells are adjusted; the injecting wells at the boundary of the mining area are not adjusted to be extracting wells, and it is guaranteed that wells on the periphery of the mining area are all the injecting wells; when a well type is a quincunx type, the adjacent extracting wells are connected into straight lines, the adjacent injecting wells are connected into straight lines, the original extracting wells are changed into injecting wells, the original injecting wells are changed into extracting wells, and it is guaranteed that the well type after adjusting is still the quincunx type; and when the well type is a seven-point type, the extracting wells are connected into lines, the two injecting wells are located between every two extracting wells, translation is conducted in the same direction of the straight lines, after translation, the original extraction wells are changed into injecting wells, the adjacent injecting wells along the straight lines are changed into extracting wells, and it is guaranteed that the well type after adjusting is still the seven-point type. The optimization and recombination method is a secondary stoping method improving the leaching rate of the uranium resource and solves the problem that through a fixed well type, leaching dead angels exist at the time of leaching, so that the resource leaching rate is low.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY +1

In-situ combined remediation technology for contaminated soil

InactiveCN103722007AReduced mobilityReduce biological activityContaminated soil reclamationPollution soilCombined use

The invention discloses an in-situ combined remediation technology for contaminated soil. The in-situ combined remediation technology adopts a method for combined use of an in-situ leaching technology and an in-situ stabilization solidification technology, and comprises the following steps: feeding leaching liquid into an injection well, extracting the pollutant-containing leaching liquid through an extraction well, and treating the pollutant-containing leaching liquid in wastewater treatment equipment; after leaching, injecting a stabilization agent into a polluted region through the injection well adopted in an in-situ leaching process, and controlling the flow direction of the stabilization agent by virtue of the extraction well to realize recycling; after stabilizing, injecting a solidification agent by virtue of the injection well, isolating site pollutants from an environment, and filling soil gaps. According to the in-situ combined remediation technology, the advantages of in-situ leaching and in-situ stabilization / solidification are combined and a treatment effect is good.

Owner:QINGDAO NEW WORLD ENVIRONMENT PROTECTION CO LTD

Ion-type rare-earth seepage control in-situ mining method

ActiveCN110055414AImprove efficiencyImprove the level ofProcess efficiency improvementVacuum extractionRare earth

The invention discloses an ion-type rare-earth seepage control in-situ mining method for solving the problems of immersion liquid leakage, landslide and ecological damage in an existing in-situ leaching process of an ion adsorption type rare earth mine. The ion-type rare-earth seepage control in-situ mining method is characterized in that a comprehensive geophysical prospecting method is introduced into the existing in-situ leaching process for detecting fault, fracture and crushing development conditions of a bed rock bottom plate; a grouting technology is introduced into the existing in-situleaching process to construct an impervious layer on the bed rock bottom plate with poor development, so that the loss of rare-earth resources, caused by the fact that immersion liquid enters underground water through the bed rock bottom plate, is prevented; and an injection-extraction self-control system composed of an infiltration line automatic monitoring sensor, an automatic liquid injectiondevice and vacuum extraction equipment is introduced into the existing in-situ leaching process, so that the injection-extraction of the immersion liquid is accurately controlled, and the constructionof a digital mine is assisted. The method is particularly suitable for the ion adsorption type rare earth mines with poor bottom plate development and poor permeability.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Permeable in-situ leaching uranium mining leaching process for hydrochloric acid modified sand layer

ActiveCN106930738AStable controlImprove the ability of pumping and injecting fluidFluid removalPregnant leach solutionResource quality

The invention belongs to the technical field of in-situ leaching uranium mining and particularly relates to a permeable in-situ leaching uranium mining leaching process for a hydrochloric acid modified sand layer. The purpose is to solve the technical problem that traditional mining processes of sulfuric acid in-situ leaching and alkaline in-situ leaching cannot meet mining requirements under the condition of decreasing of the uranium resource quality. In practical use, the leaching process is stable in control and compact in joining, liquid extracting and injecting capacity is improved, oxidation of uranium minerals is accelerated and achieved, uranium-containing leachate is obtained, and the condition of production concentration treatment in later period can be met. In the leaching mining process at a Shihongtan 1# mining area, by adopting the leaching process, the liquid injecting capacity is increased from 108 m<3> / h to 132 m<3> / h; oxygen is dissolved effectively and injected into the ore-containing sand layer, the oxygen content in the leachate is 18 mg / l, the average peak value of the uranium concentration of the leachate is 27.8 mg / l, and the uranium concentration peak value of a single well is 64 mg / l; and accordingly the effects that the uranium resource of the mining area is exploited, and the recovery rate of the uranium resource of the mining area reaches 76.5% are achieved.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

Method for preventing decline of underground water level in uranium mining through in-situ leaching

ActiveCN105370285ATake advantage ofGuaranteed recyclingUnderground miningSurface miningEconomic benefitsUranium ore

The invention belongs to the technical field of uranium-coal paragenesis mining, and particularly relates to a method for preventing a decline of an underground water level in uranium mining through in-situ leaching for uranium-coal co-mining. According to the technical scheme, a hydraulic barrier is built on the periphery of a uranium mining district through distribution of water injection drill holes, and when underground water is drained for a coal mine, the decline of the underground water level of the uranium mining district is prevented. The method for preventing the decline of the underground water level in uranium mining through in-situ leaching has the advantages that it can be guaranteed that two resources are mined at non-overlapped districts at the same time, the two resources can be fully utilized, the economic benefit of enterprises is improved, and the recovery of the geological resource is guaranteed.

Owner:THE FOURTH INST OF NUCLEAR ENG OF CNNC

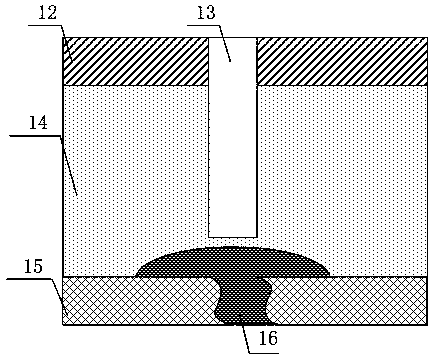

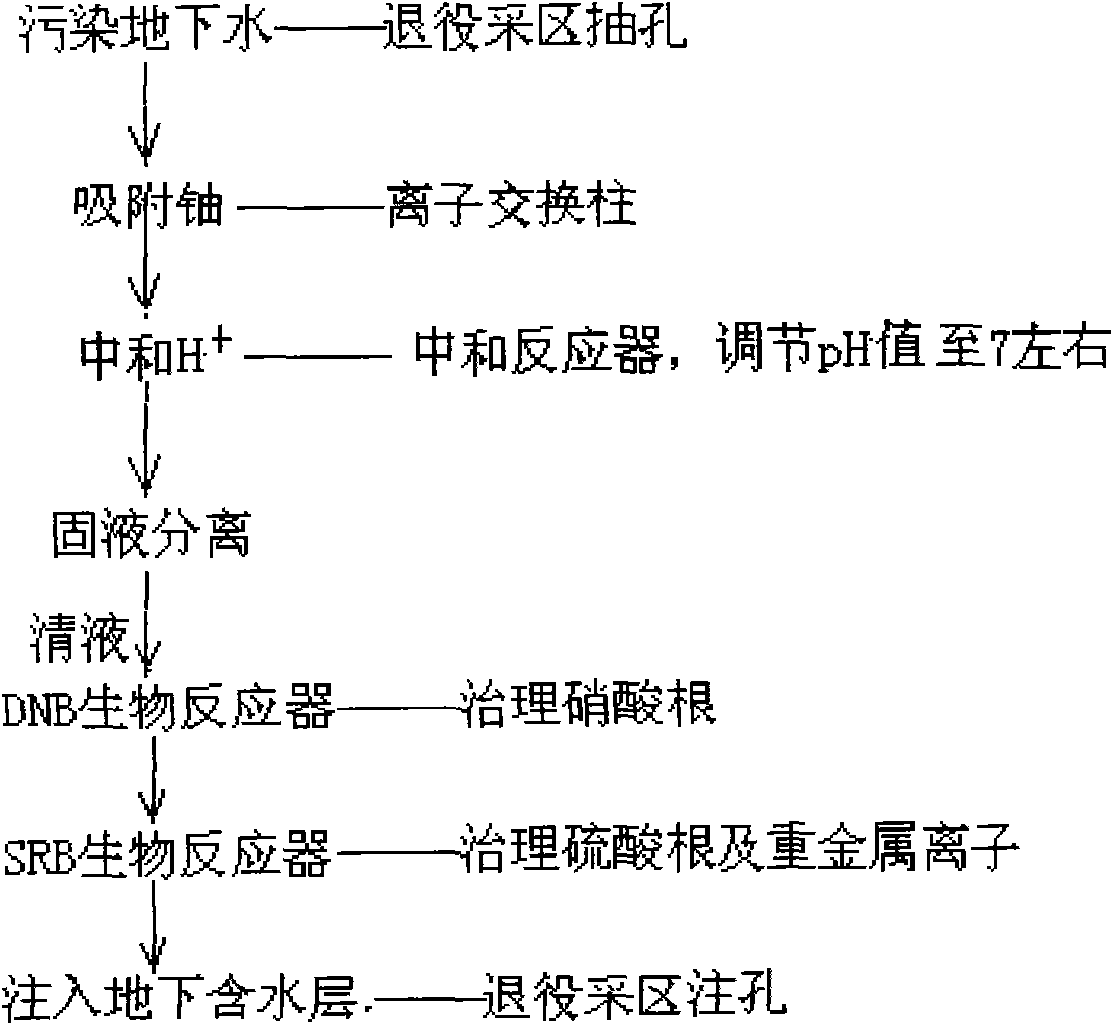

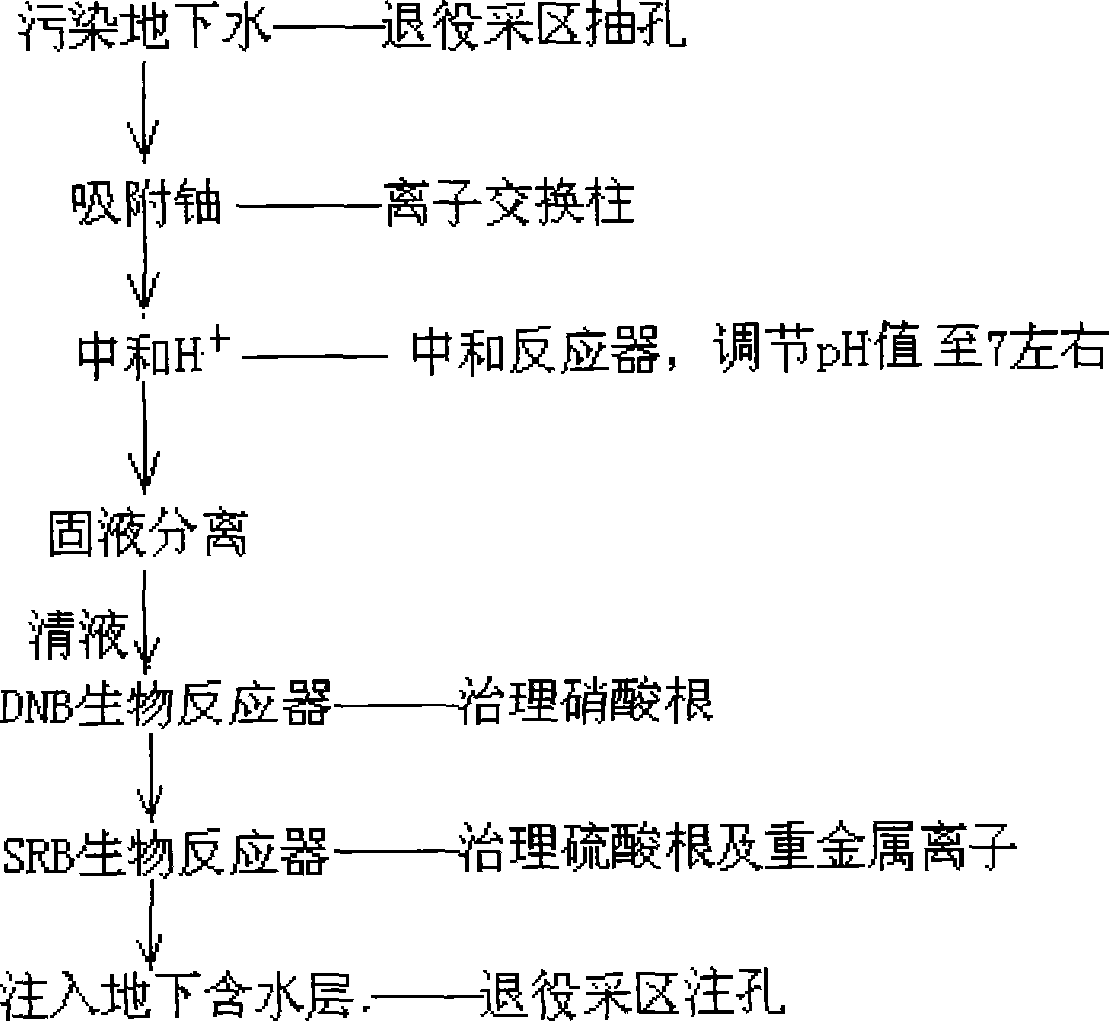

Process for treating polluted groundwater of retired mining area of acid in-situ leaching uranium mine by using microbial method

The invention relates to a process for treating polluted groundwater of a retired mining area of an acid in-situ leaching uranium mine by using a microbial method. The process comprises the follow steps of: pumping the polluted groundwater of the retired mining area from draw holes, carrying out exchange adsorption to process uranium by using ion exchange resin, regulating the pH value of sewage solution to 7 approximately, allowing clear solution to enter a DNB bioreactor first, and reducing nitrate in the solution with DNB, wherein the removal rate of the nitrate is over 95 percent; and secondly, degrading sulfate and removing heavy metal ions of the solution in which the nitrate is degraded with a SRB bioreactor. The removal rate of the nitrate of the processed polluted groundwater is over 95 percent; the removal rate of the sulfate is between 60 and 70 percent, and the removal rate of the heavy metal ions is over 85 percent.

Owner:NANHUA UNIV +1

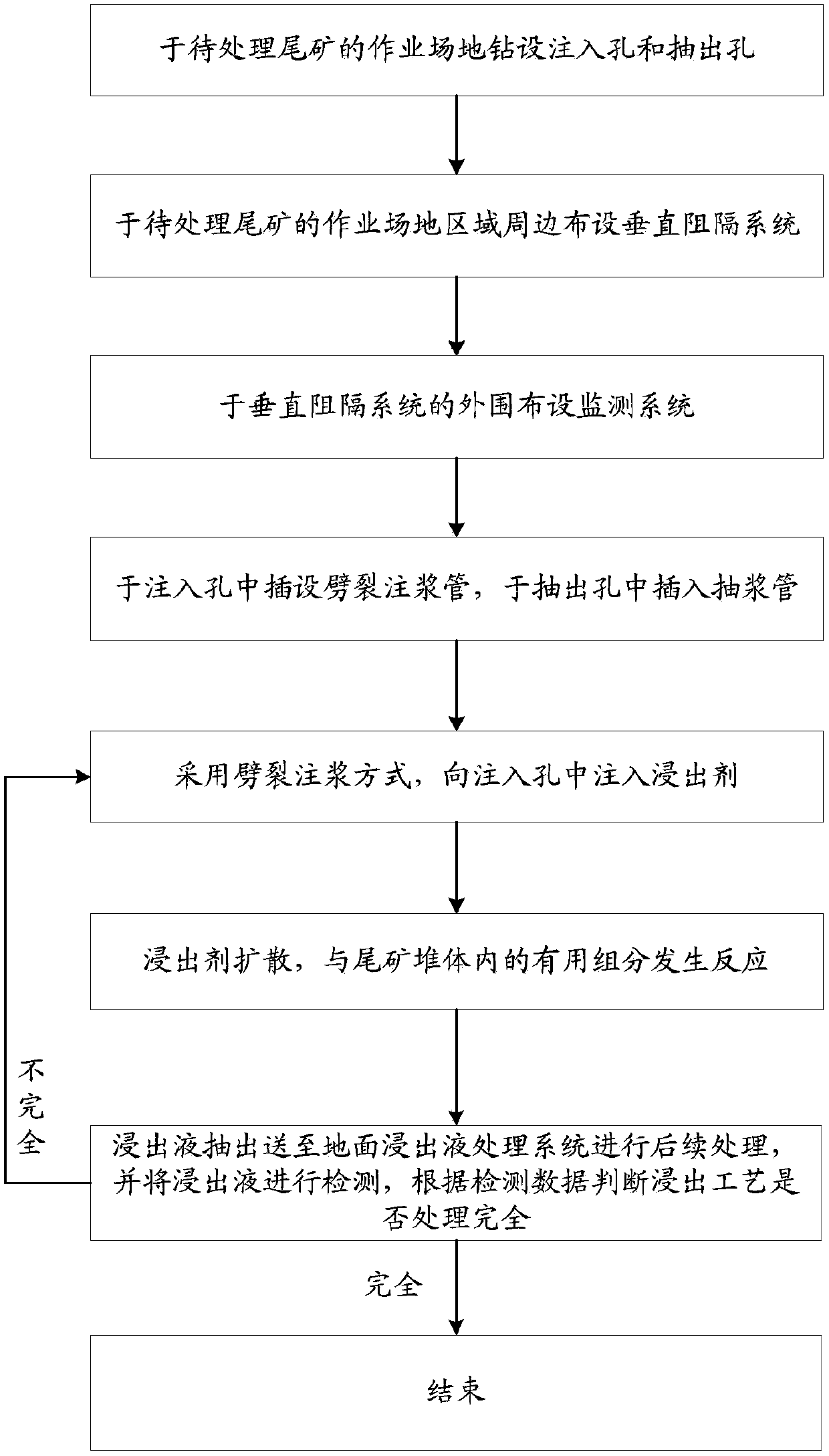

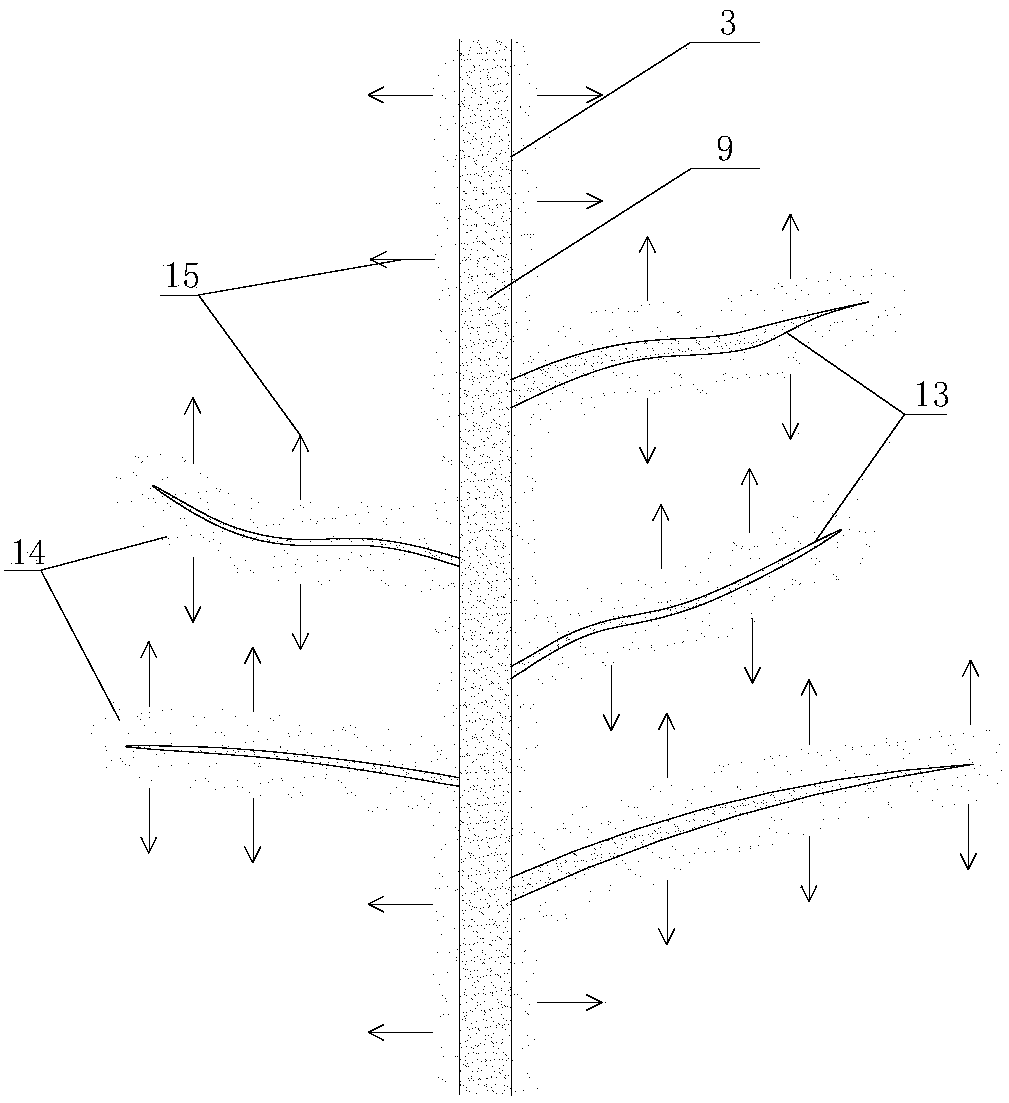

Tailing in-situ leaching process and system

InactiveCN108034815AAvoid secondary excavation and transferEfficient recyclingProcess efficiency improvementPregnant leach solutionMonitoring system

The invention relates to a tailing in-situ leaching process and system. The tailing in-situ leaching process comprises the steps that injection holes and pumping-out holes are drilled in an operationsite of to-be-treated tailings; vertical obstruction systems are arranged on the periphery of the operation site of the to-be-treated tailings; monitoring systems are arranged on the peripheries of the vertical obstruction systems; cleaving slurry-injection pipes are inserted in the needed injection holes, and slurry pumping-out pipes are inserted in the needed pumping-out holes; leaching agents are injected into the injection holes through a cleaving slurry-injection mode; the leaching agents are diffused and react with useful components in a tailing heap body; and leachate formed in the reaction is pumped out by the slurry pumping-out pipes and conveyed to a ground leachate treatment system to be subjected to subsequent treatment. The useful components can be recycled effectively under the low-cost condition, secondary pollution can be avoided through combining of the tailing in-situ leaching system with the vertical obstruction systems and the monitoring systems, the tailing in-situleaching process and system are widely applied to in-situ leaching of the heavy metal tailings, and the various problems caused by tailing heaping and loss and waste of resources are avoided.

Owner:BEIJING GEOENVIRON ENG & TECH

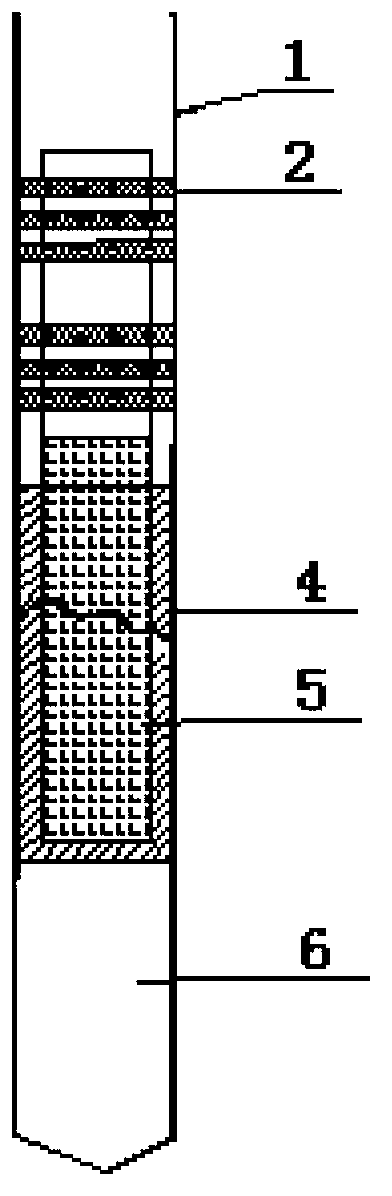

Method for repairing damaged drilled hole for in-situ leaching uranium mining through a plurality of layers of expanding materials

ActiveCN103899244AEffective blockingResume normal cycle pumping functionSealing/packingDrilling machines and methodsWell loggingIn situ leach

The invention belongs to the technical field of mine production for in-situ leaching uranium mining, and particularly relates to a method for repairing a damaged drilled hole for in-situ leaching uranium mining through a plurality of layers of expanding materials. The method sequentially includes the following steps that whether a well pipe (1) or a filter is damaged is initially judged; under the condition that the well pipe (1) is damaged, the cracked position of the well pipe (1) is determined through well logging, a plastic smaller than the well pipe (1) in inner diameter serves as a casing pipe (3), the expanding materials (2) are wound around the casing pipe (3), the casing pipe (3) is put downwards to align with the cracked position of the well pipe (1), and the expanding materials (2) expand and squeeze the inner wall of the well pipe (1) to form a new channel; under the condition that the filter is damaged, the drilled hole is washed to be clean, the expanding materials (2) are wound around a built-in filter smaller than the original filter in outer diameter, the built-in filter is put downwards to be close to the original filter (4), the expanding materials (2) expand when making contact with water and squeeze the well pipe (1), and a new filter is formed in the drilled hole.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

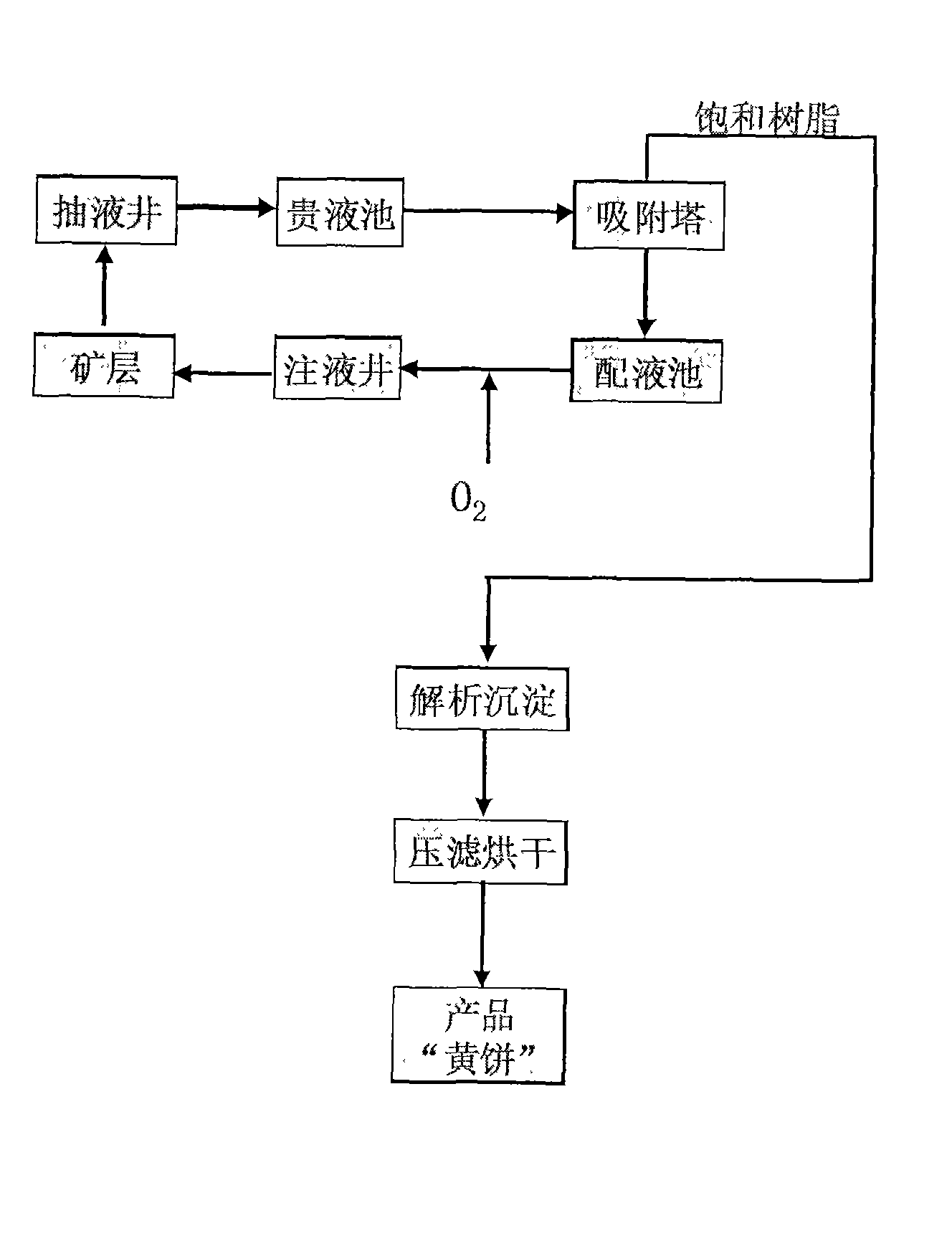

In-situ leaching of uranium by adding o2 to bicarbonate-type groundwater

ActiveCN106507865BMeet industrial production requirementsEconomical and effective uranium leaching processFluid removalOxygenEarth surface

The invention provides a bicarbonate-type groundwater plus O2 leaching uranium mining process, which adopts an in-situ leaching method to mine uranium ore layers in a bicarbonate-type aquifer. In this process, O2 is directly mixed with the leaching solution and then injected into the ground. After adding oxygen to the groundwater containing HCO3-, the uranium in the ore is oxidized and leached to form [UO2(CO3)3]4- or [UO2(CO3)2]2 -The leaching solution of complex anions is then extracted from the surface and sent to the hydrometallurgy process for processing. The invention adds O2 as an oxidant and utilizes HCO3- ions in bicarbonate groundwater as a leaching agent for uranium, which can effectively control the occurrence of chemical blockage and improve the leaching rate of uranium in situ leaching. Compared with the traditional acid leaching and alkali leaching processes, the process cost is reduced and the mining environment is better protected. From the test results, the concentration of uranium leached by adding O2 in bicarbonate-type groundwater can reach 30mg / L, which meets the requirements of industrial production.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

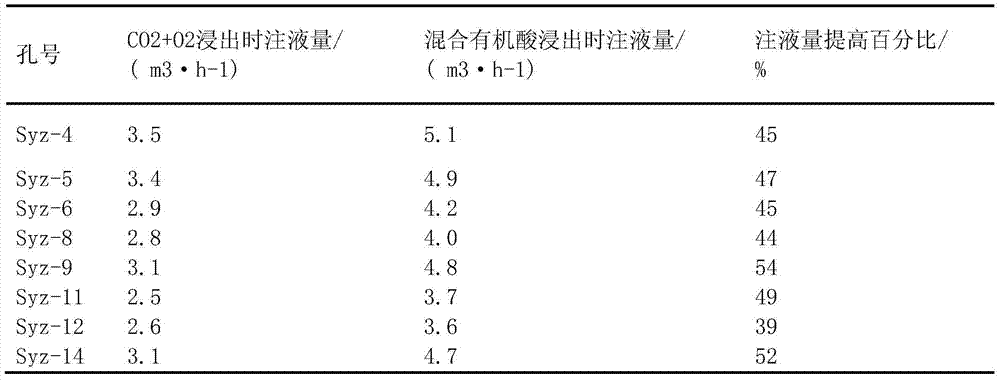

In-situ leaching uranium mining method by using mixing organic acidity as leaching agent

The invention discloses an in-situ leaching uranium mining method by using mixing organic acidity as a leaching agent, which is characterized in that oxalic acid and citric acid are taken as the leaching agent, the leaching agent is injected into an ore bed by using an on-line mode addition mode, pH value of an immersion liquid is kept at 3-6, so that an organic matter for coating metal uranium can be dissolved, and leaching can be promoted; in addition, when the carbonate in the ore bed is corroded by oxalic acid and citric acid, its organic function group generates complexation with elements such as calcium, magnesium and iron in ore without deposition generation, on one hand, leaching reaction can be continuously carried out, on the other hand, penetration performance of the ore bed can be increased, and liquid injection amount of the boring is obviously increased. The method can be used in Ordos uranium deposit in-situ leaching uranium mining tests and production, liquid injection amount is obviously increased, and uranium concentration of leachate is obviously increased.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

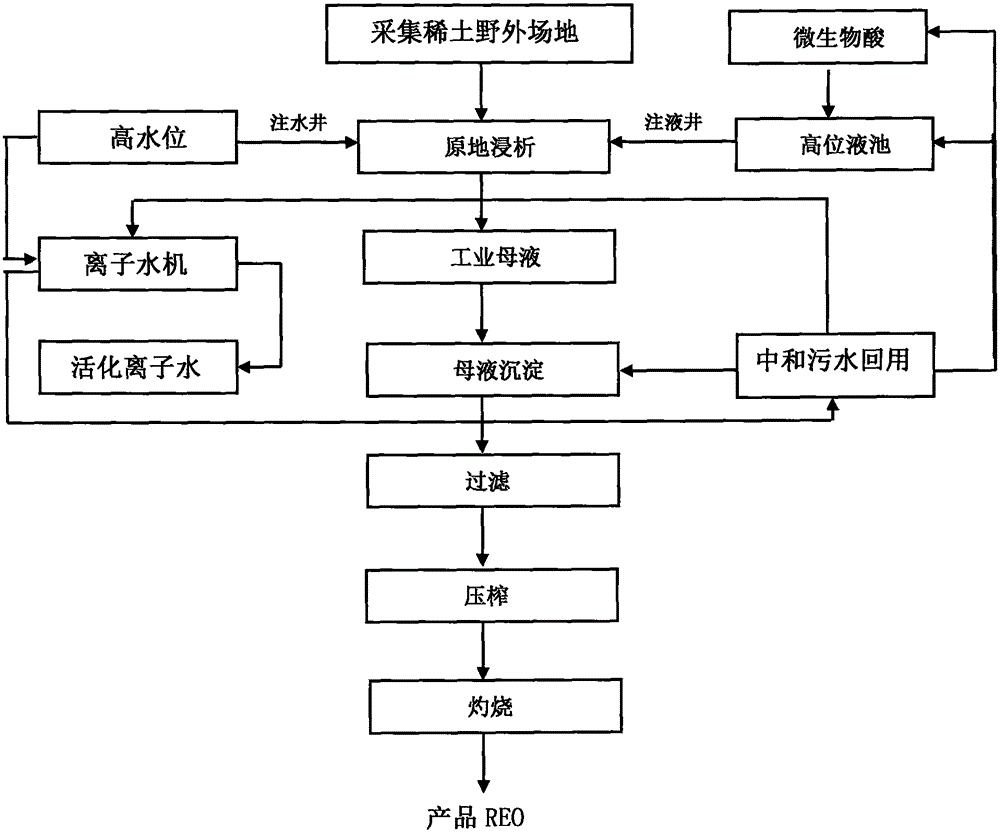

Technology for improving ion type rare earth in-situ leaching method by activated ion water and microorganism acid

The invention discloses an extracting solution and a precipitator formula for improving an existing ion type rare earth in-situ leaching mining method and a technology thereof. Microorganism acid is used for replacing ammonium sulfate and serves an extracting agent of a leaching technology; activated ion water is used for replacing oxalic acid and serves as a precipitator for mother liquid subjected to leaching. Strong-alkaline water produced by preparation of activated ion water is used as a neutralizing agent for purifying sewage produced in the technical process so as to reproduce the microorganism acid and realize re-electrolysis and can be repeatedly used, so that zero emission of sewage is realized; the new preparation, namely microorganism acid and the activated ion water in the novel technology are environment-friendly substances and are harmless to human, water sources and plants; meanwhile, the production cost is reduced, the mining efficiency and the resource utilization rate are improved, and the method is an entirely new green and environment-friendly ion type rare earth collection technology.

Owner:朱上翔

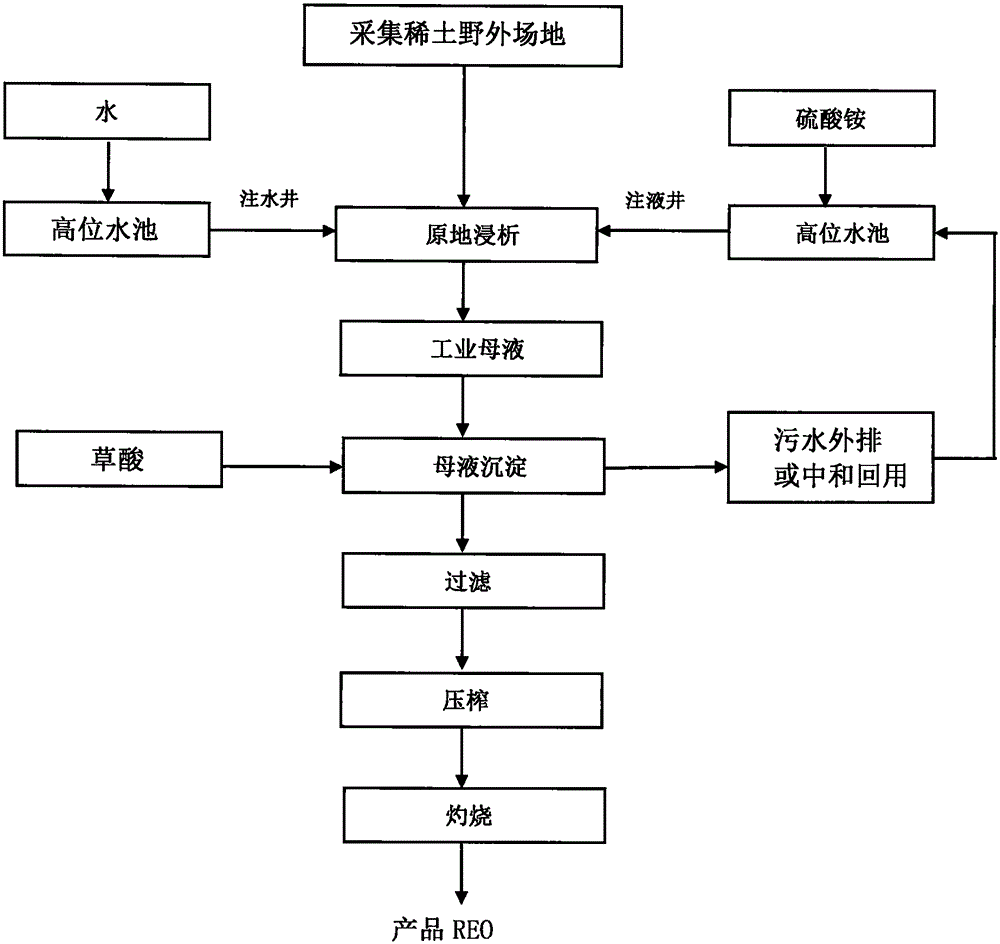

Ammonia-free mining method for rare earth ore in south China

InactiveCN105907959AReduce pollutionReduce manufacturing costProcess efficiency improvementMagnesium saltRare earth

Provided is an ammonia-free mining method for rare earth ore in south China. Magnesium ions and sodium ions are combined to serve as an ore leaching agent, and meanwhile magnesium salt serves as an enrichment agent. The ammonia-free mining method for rare earth ore in the south China includes the steps of leaching of rare earth ore, collection of rare earth mother liquor, pre-enrichment of rare earth, dissolution of rare earth hydroxide, rare earth sulfate double salt precipitation and rare earth sulfate double salt conversion. According to the ammonia-free mining method for rare earth ore in the south China, the ore leaching agent and precipitant which have no ammonia nitrogen and are relatively friendly to water are combined with the in-situ leaching mode, rare earth compounds meeting the use demands of a rare earth separation plant are generated through rare earth double salt precipitation, the production cost is low, and environmental pollution is greatly reduced.

Owner:赣州稀土开采技术服务有限公司

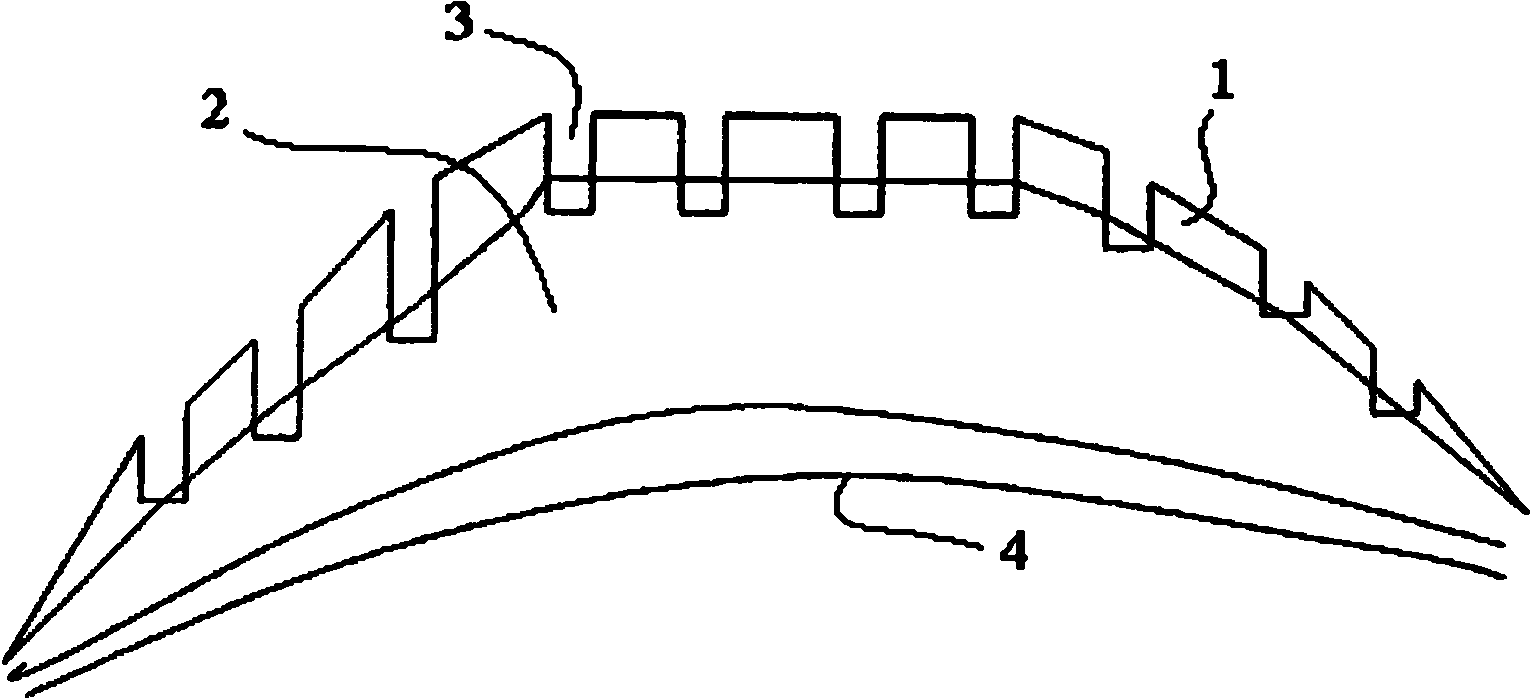

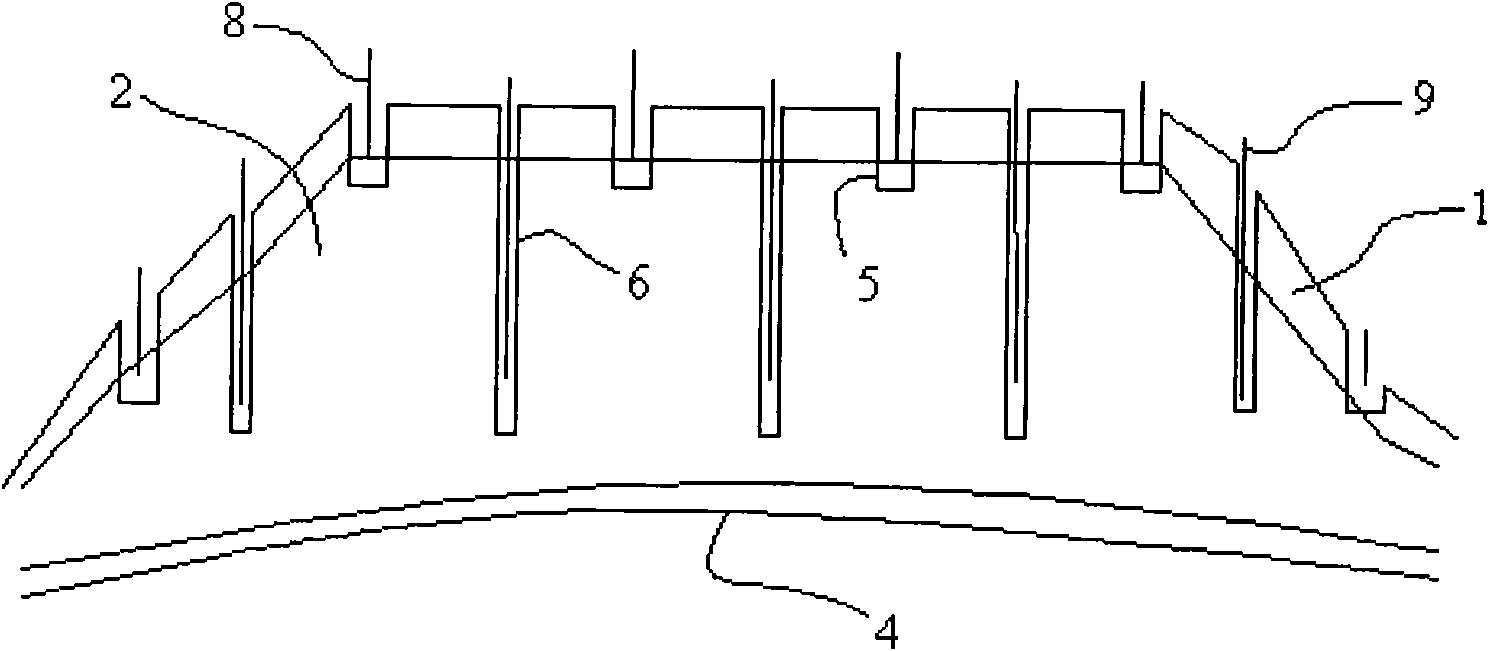

Active extraction method for ion type rare earth ore in-situ leaching

ActiveCN109593957AReduce entryImprove the efficiency of liquid extractionProcess efficiency improvementTerrainGeomorphology

The invention discloses an active extraction method for ion type rare earth ore in-situ leaching. According to the mine lot terrain, the hydrology geology, the fracture development part, the ore bodyspace position and other situations, one or more composite schemes in three well array arranging schemes are adopted for conducting active extraction; a row of horizontal vacuum wells are arranged atthe trough slope toe position, and a closed loop is adopted along the mountain body; light vacuum well points are arranged in the area where the upper covered soil and ore body depth is not larger than 6 m; vacuum deep wells are arranged at certain intervals in the mine lot along the trough position, the trough serves as a liquid accumulating groove, and an extraction curtain is formed through thevacuum deep wells at the seepage downstream position; according to the stratum situation, the reasonable hole forming manner is adopted, the drilling hole diameter is 90-300 mm, and the drilling vertical depth is not larger than 8 m; and drilling is conducted at the trough slope toe position or the special terrain position, the following pipe diameter is 108 mm-219 mm, the hole forming hole diameter is 90-300 mm, a water filter pipe is immediately lowered after drilling is finished, and then a casing pipe is pulled out. The active extraction method has the advantages that the active extraction manner is adopted, and the mother liquor recovery ratio is improved.

Owner:四川共拓岩土科技股份有限公司

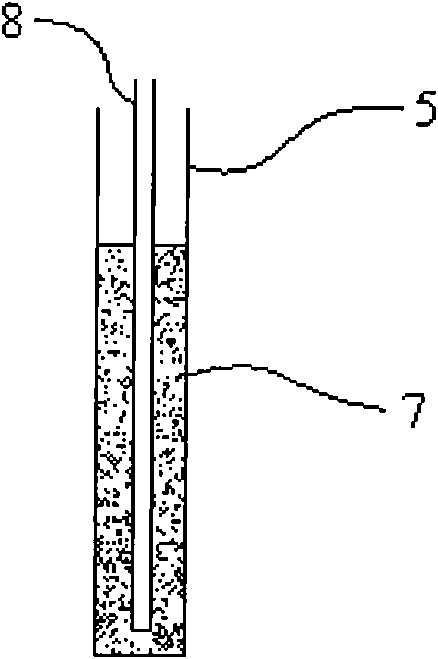

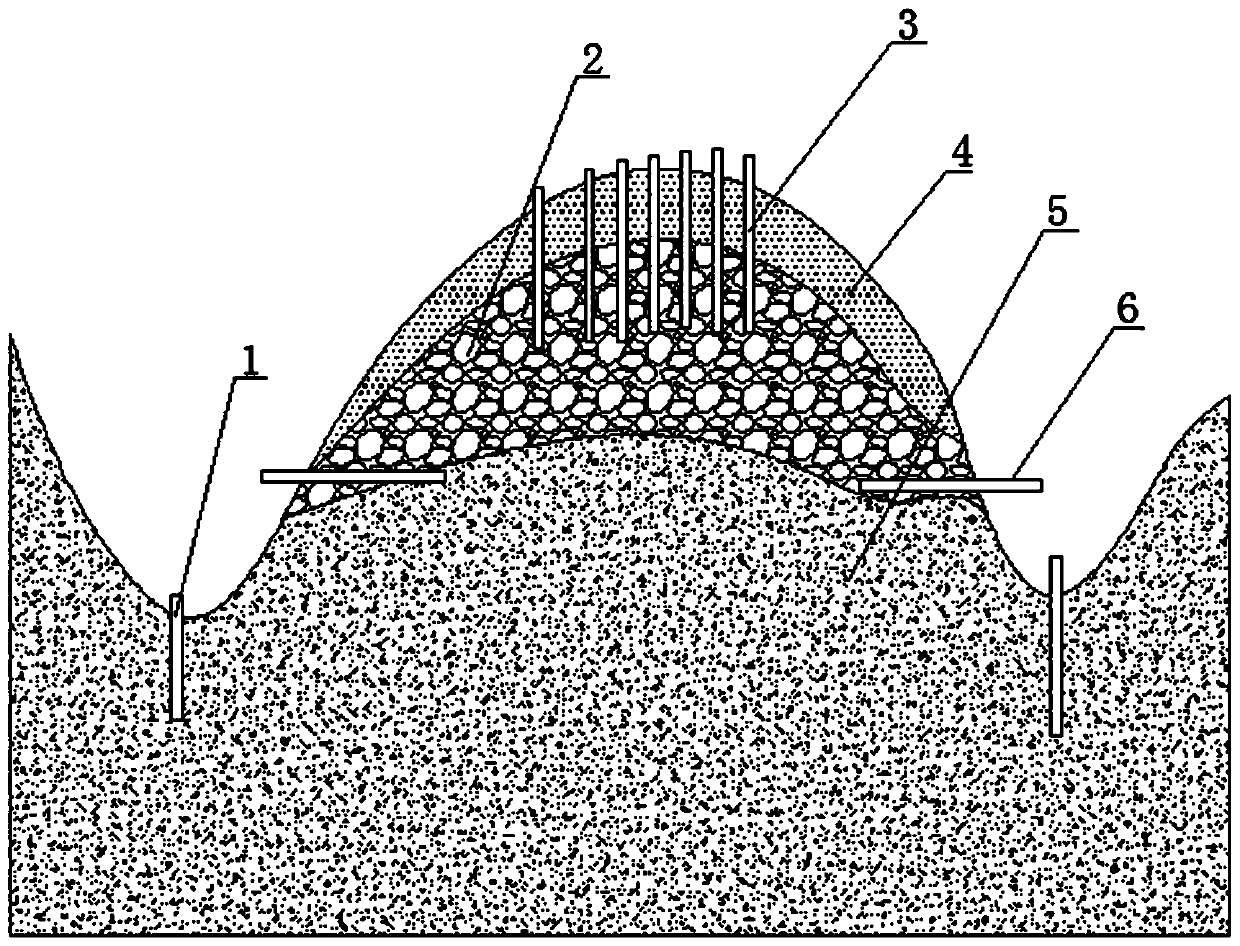

Gravel pump gravel filling method

The invention belongs to the technical field of in-situ leaching mine gravel filling type structure drilling construction, and particularly relates to a gravel pump gravel filling method. According to the technical scheme, a gravel pump (11) is used for injecting water and throwing gravels into a gravel throwing pipe (19), when gravels are thrown, gravel (13) filling heights are measured, when the gravels (13) reach the required height position as designed, cement is used for sealing holes, and the gravel throwing pipe (19) is used for measuring the gravel filling height. Due to the fact that injection pressure of the gravel pump (11) is small, once the filling gravels (13) are flush with an opening of the gravel throwing pipe (19), the gravel pump (11) stops throwing gravels, water returns from a gravel throwing funnel (12), the gravel throwing height can be measured according to the principle, and quantification control of gravel throwing is achieved. By means of the technical scheme, gravel filling speed is high, efficiency is high, gravel filling position is precise, and pollution of mud on ore beds is reduced due to the fact that drilled holes are flushed when gravel is thrown.

Owner:XINJIANG TIANSHAN URANIUM IND CO LTD CNNC

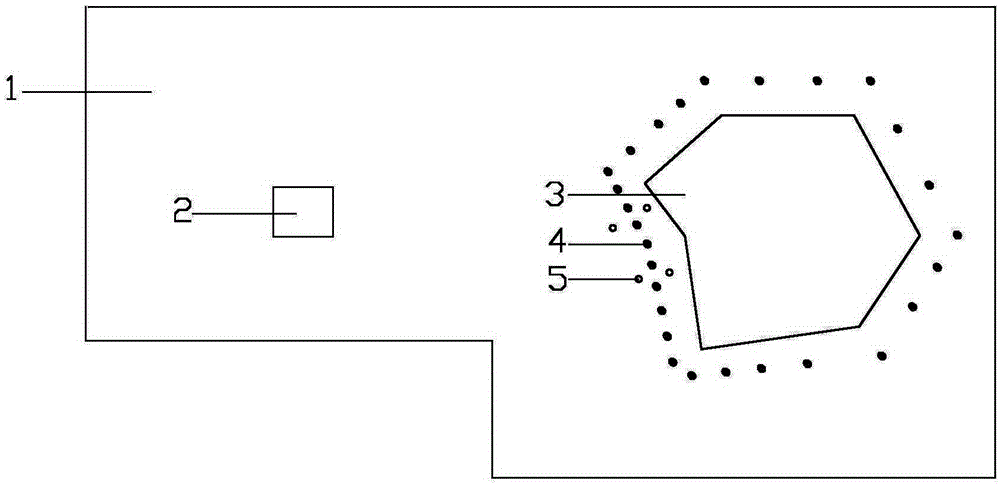

Leaching range monitoring method in in-situ leaching uranium mining process

InactiveCN105631137AControl the spread of pollutionReduce consumptionSpecial data processing applicationsSoil scienceIn situ leach

The invention provides a leaching range monitoring method in an in-situ leaching uranium mining process. The monitoring method includes the steps that 1, a numerical model is established through computer numerical simulation software, wherein the steps of conducting model generalization, conducting model numeralization, establishing the numerical model, correcting the numerical model and designing a drill hole arrangement mode are included; 2, interwell tracer tests are conducted on a test unit and a production unit, wherein the steps of selecting a tracer agent, calculating feeding quantity of the tracer agent, feeding and sampling the tracer agent, conducting concentration analysis on the tracer agent, analyzing tracer agent test data and simulating numerical values are included. According to the monitoring method, an interwell tracer method is introduced to the leaching uranium mining process, a numerical value simulation technology is utilized, estimation, monitoring and predicting of the flow direction, the flow rate and the leaching range of a leaching solution are achieved through numerical value simulation of the flow direction, the flow rate and the diffusion range of a groundwater flow field and the tracer agent, accordingly in-situ leaching tests and drill hole arrangement in production are guided, consumption of raw materials is greatly lowered, production cost is saved, and dispersal of pollution to in-situ leaching mine is controlled.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

Method for calculating influence radius of ion type rare earth in-situ leaching single-bore injection

The invention relates to a method for calculating an influence radius of ion type rare earth in-situ leaching single-bore injection and is applicable to designs of in-situ leaching injection bore mesh parameters. The method disclosed by the invention respectively comprises the following seven steps: (1) testing saturated volumetric water content of an ore body; (2) testing a soil-water characteristic curve of the ore body; (3) setting saturation degree of a single-bore injection influence boundary, and calculating a suction head value of the influence boundary; (4) calculating an average permeability coefficient in a single-bore injection influence range; (5) calculating a distance between an influence boundary on a plane where the injection bore bottom is positioned and the injection bore periphery; (6) calculating a constant of change speed of the volumetric water content along with a radial distance; and (7) calculating the influence radius of the single-bore injection. According to the method disclosed by the invention, the influence radius of the single-bore injection can be calculated by utilizing an established model on the basis of testing soil property parameters, and a basis is provided for the in-situ leaching injection bore mesh parameter design.

Owner:JIANGXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com