Preparation method of battery-grade iron phosphate

An iron phosphate, battery-level technology, applied in chemical instruments and methods, phosphorus compounds, heating water/sewage treatment, etc., can solve the untargeted problems of high ammonia nitrogen wastewater, low value of by-products, low anion content, etc., and achieve reduction Energy consumption, low impurity content and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

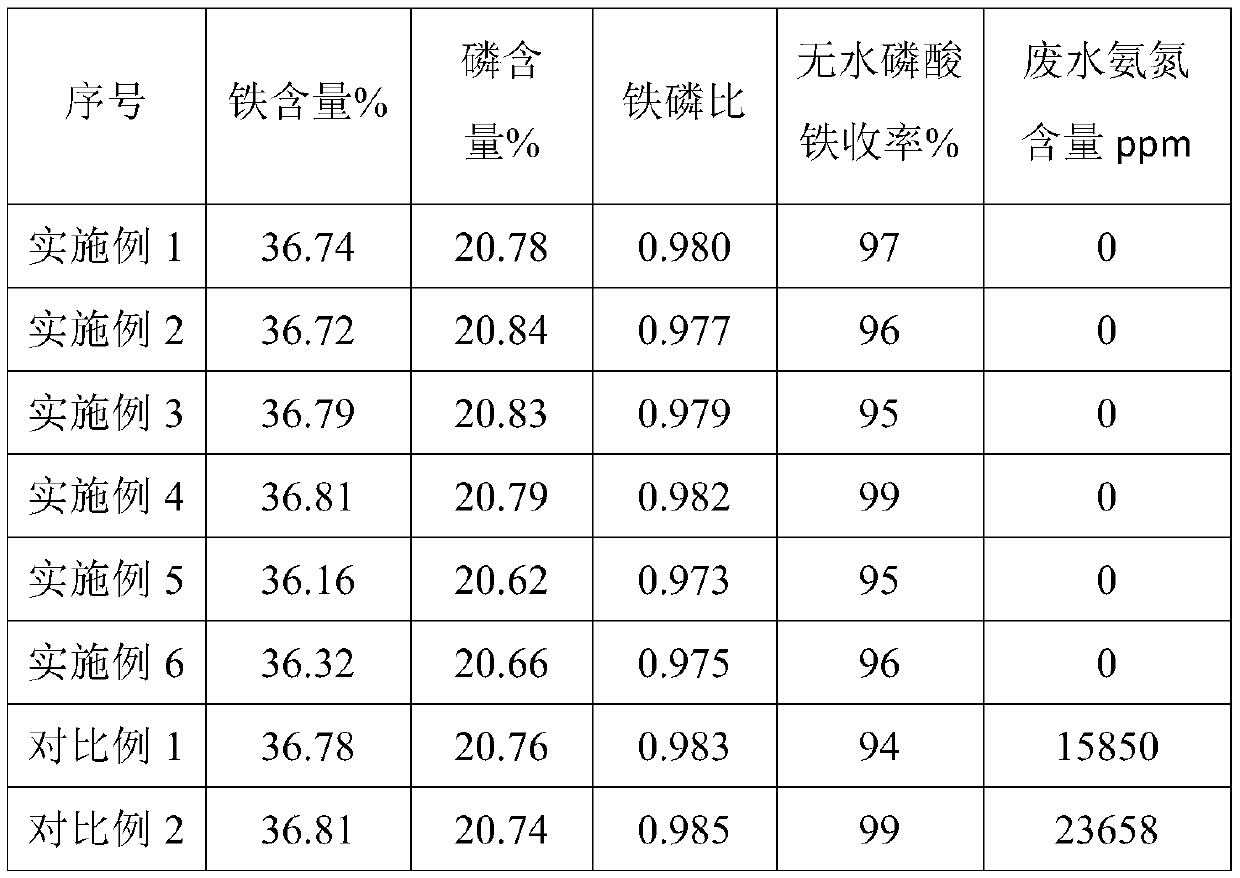

Examples

Embodiment 1

[0030] A preparation method of battery-grade iron phosphate, comprising the steps of:

[0031] S1. Use 99% iron powder as raw material, add 10% dilute sulfuric acid solution, obtain ferrous sulfate solution after fully dissolving, iron mass fraction 5.4%;

[0032] S2. be that 5.4% ferrous sulfate solution 1716kg is added in the reactor with iron massfraction, the stirring speed of reactor is 180rpm, with massfraction be 27.5% hydrogen peroxide 133kg, massfraction is 85% H 3 PO 4 193kg, added into the reactor to form a mixed solution of phosphoric acid and ferric sulfate, wherein the oxidizing agent: H 3 PO 4 : the mol ratio of ferrous sulfate is 0.65:1.01:1;

[0033] S3. Add pure water to the mixed solution of phosphoric acid and ferric sulfate for dilution, adjust the pH value of the mixed solution to 1.7, and the reaction time is 2 hours, and the temperature is controlled at 40 ° C to make Fe 3+ with PO 4 3- combine and settle down;

[0034] S4. After the iron phosph...

Embodiment 2

[0036] A preparation method of battery-grade iron phosphate, comprising the steps of:

[0037] S1. Use 99% iron powder as raw material, add 10% dilute sulfuric acid solution, obtain ferrous sulfate solution after fully dissolving, iron mass fraction 5.4%;

[0038] S2. adding the ferrous sulfate solution that the iron mass fraction is 5.4% in the reactor, the reactor stirring speed is 180rpm, with the hydrogen peroxide that the mass fraction is 27.5%, the H that the mass fraction is 85% 3 PO 4 , added into the reactor to form a mixed solution of phosphoric acid and ferric sulfate, in which the oxidizing agent: H 3 PO 4 : the molar ratio of ferrous sulfate is 0.6:1:1;

[0039]S3. Add pure water to the mixed solution of phosphoric acid and ferric sulfate for dilution, adjust the pH value of the mixed solution to 1.7, and the reaction time is 2 hours, and the temperature is controlled at 40 ° C to make Fe 3+ with PO 4 3- combine and settle down;

[0040] S4. After the iron ...

Embodiment 3

[0042] A preparation method of battery-grade iron phosphate, comprising the steps of:

[0043] S1. Use 99% iron powder as raw material, add 10% dilute sulfuric acid solution, obtain ferrous sulfate solution after fully dissolving, iron mass fraction 5.4%;

[0044] S2. adding the ferrous sulfate solution that the iron mass fraction is 5.4% in the reactor, the reactor stirring speed is 180rpm, with the hydrogen peroxide that the mass fraction is 27.5%, the H that the mass fraction is 85% 3 PO 4 , added into the reactor to form a mixed solution of phosphoric acid and ferric sulfate, in which the oxidizing agent: H 3 PO 4 : the mol ratio of ferrous sulfate is 0.75:1.05:1;

[0045] S3. Add pure water to the mixed solution of phosphoric acid and ferric sulfate for dilution, adjust the pH value of the mixed solution to 1.7, and the reaction time is 2 hours, and the temperature is controlled at 40 ° C to make Fe 3+ with PO 4 3- combine and settle down;

[0046] S4. After the ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com