Device and method for treating industrial wastewater with high salt content

A technology for industrial wastewater and treatment methods, applied in multi-stage water treatment, water/sewage treatment, heating water/sewage treatment, etc. Reach the industrial reuse standard and other issues, and achieve the effect of high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

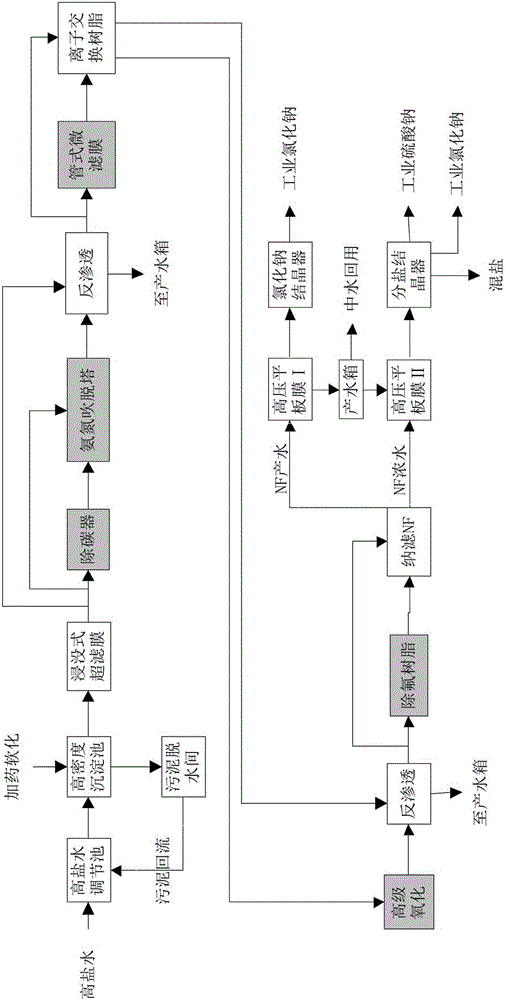

[0073] This embodiment is applicable to the case where the TDS content in the high-salt industrial wastewater treated by the pretreatment unit is less than 10,000 mg / L. figure 1 The processing apparatus and flow for this example are shown, as follows:

[0074] (1) Ultrafiltration product water enters a section of reverse osmosis membrane system for concentration treatment. After being treated by a section of reverse osmosis membrane, the reverse osmosis produced water is directly recycled, and the concentrated water enters the ion exchange resin device. At this time, the TDS of the concentrated water can reach 20000~30000mg / L. Through this device, the residual hardness (mainly calcium ions and magnesium ions) in the water is removed, and the hardness in the produced water is basically zero, which effectively avoids the risk of fouling in the subsequent treatment unit and ensures its normal operation.

[0075] (2) The water produced by the ion exchange resin enters the second-...

Embodiment 2

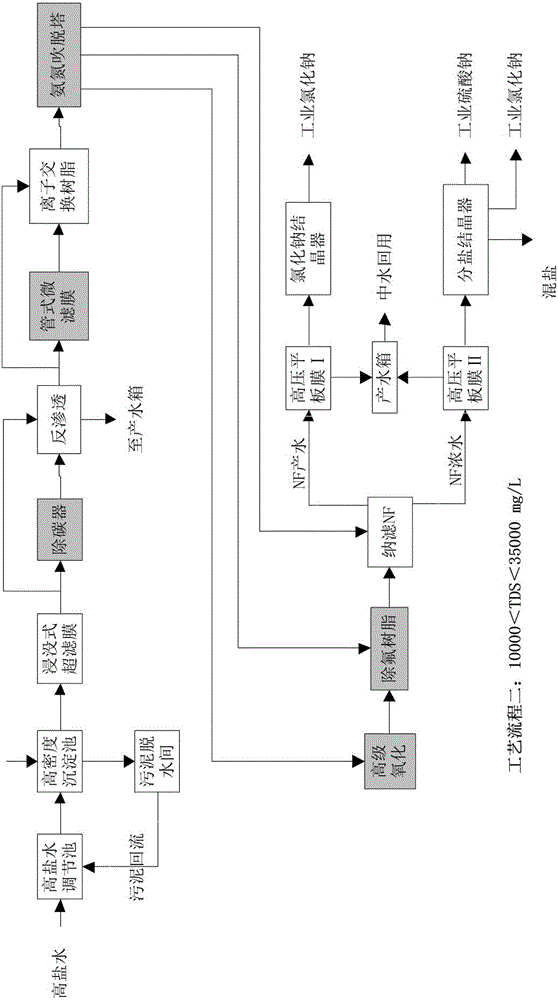

[0084] This embodiment is applicable to the case where the TDS content in the high-salt industrial wastewater treated by the pretreatment unit is 10,000 mg / L~35,000 mg / L. figure 2 The processing apparatus and flow for this example are shown, as follows:

[0085] (1) After homogenization in the adjustment tank, hard removal in the high-density sedimentation tank, and further removal of colloids and turbidity by the submerged ultrafiltration membrane, the product water directly enters the reverse osmosis membrane for concentration treatment (in this example, there is only one stage of reverse osmosis in the whole process ). After being treated by the reverse osmosis membrane, the reverse osmosis product water is directly recycled, and the concentrated water TDS reaches 30,000~60,000mg / L and enters the ion exchange resin device to further remove the residual hardness in the wastewater. The hardness of the product water is basically zero, which greatly reduces the subsequent trea...

Embodiment 3

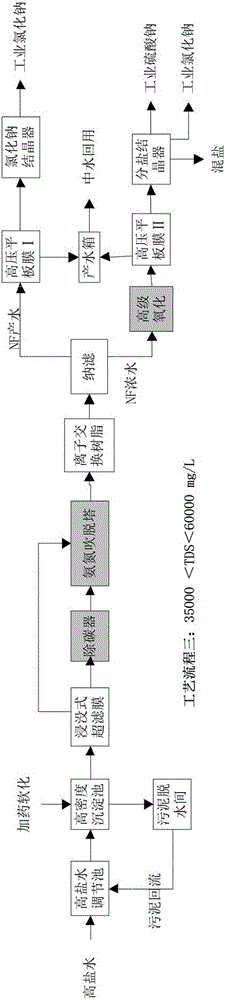

[0094] This embodiment is applicable to the case where the TDS content in the high brine treated by the pretreatment unit is 35000 mg / L~60000 mg / L, and the attached image 3 The processing apparatus and flow for this example are shown, as follows:

[0095] (1) Since the TDS of the influent water is already high, the produced water after the homogenization of the regulating tank, the removal of hardness in the high-density sedimentation tank, and the further removal of colloid and turbidity by the submerged ultrafiltration membrane can directly enter the nanofiltration system for salt separation. However, considering that the removal of hardness in high-density sedimentation tanks is not very thorough, the total hardness is generally controlled at <100mg / L. Therefore, an ion exchange resin system is installed before entering the nanofiltration membrane system. The ion exchange resin device completely removes the hardness in the product water to ensure the normal operation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com