Method for preparing high performance polysilicate ferric aluminum sulfate from coal gangue

A technology of polysilicate ferric sulfate and polyferric aluminum sulfate, which is applied in the fields of ferric sulfate, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of low economical practicability of treatment technology, no further treatment of leached slag, high Solve problems such as heavy metal residues, and achieve the effects of high added value, favorable specific surface area, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

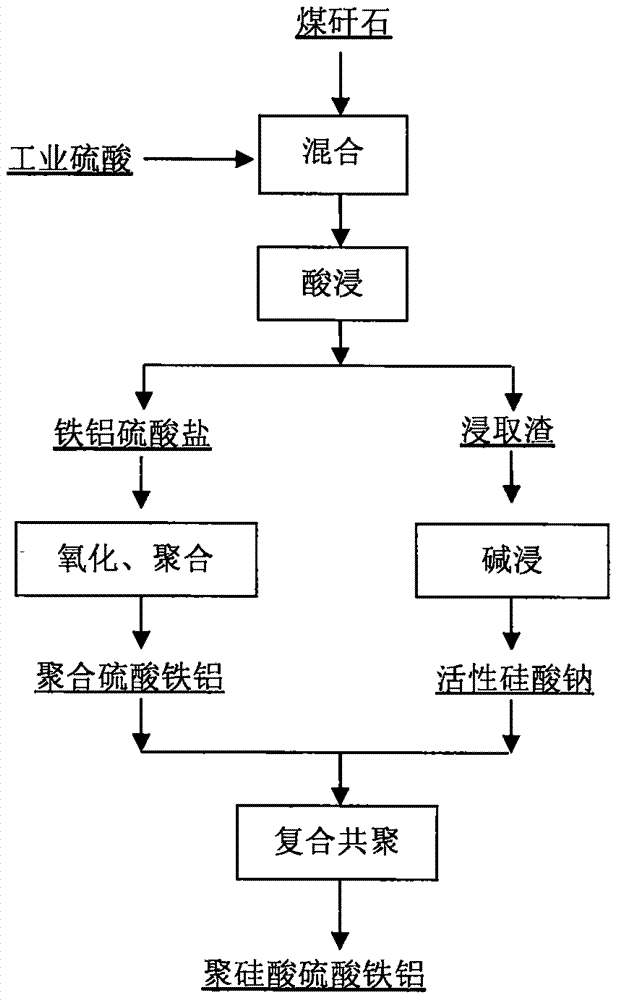

Method used

Image

Examples

Embodiment 1

[0016] Weigh a certain amount of coal gangue, mix it with 85% industrial sulfuric acid and coal gangue at a mass ratio of 1.2, react in a closed manner at 120°C for 60 minutes, dissolve and filter in a water bath at 80°C to obtain iron-aluminum sulfate solution, and use hydrogen peroxide Iron oxide aluminum sulfate is polymerized at room temperature for 30 minutes to obtain polyferric aluminum sulfate; coal gangue leaching slag is leached with 4mol / L NaOH alkali to obtain active sodium silicate solution, according to the volume ratio of polyferric aluminum sulfate and active sodium silicate 2:1, the mass concentration of active sodium silicate is 10% and the compound copolymerization is carried out, and the polysilicate ferric aluminum sulfate product is obtained after the copolymerization for 1 hour.

[0017] The dosage of PAFSS flocculant is 5mL / L. After flocculation treatment, the turbidity removal rate of wastewater reaches 98.9%, which drops to 0.40NTU; the chroma removal ...

Embodiment 2

[0019] Weigh a certain amount of coal gangue, mix it with 85% industrial sulfuric acid and coal gangue at a mass ratio of 1.2, react in a closed manner at 120°C for 60 minutes, dissolve and filter in a water bath at 80°C to obtain iron-aluminum sulfate solution, and use hydrogen peroxide Iron oxide aluminum sulfate is polymerized at room temperature for 60 minutes to obtain polyferric aluminum sulfate; coal gangue leaching slag is leached with 4mol / L NaOH alkali to obtain active sodium silicate solution, according to the volume ratio of polyferric aluminum sulfate and active sodium silicate 3:1, the mass concentration of active sodium silicate is 20% to carry out composite copolymerization, after copolymerization for 2 hours, polysilicate ferric aluminum sulfate product is obtained.

[0020] The dosage of PAFSS flocculant is 6mL / L. After flocculation treatment, the turbidity removal rate of wastewater reaches 99.3%, which drops to 0.35NTU; the chroma removal rate reaches 93.7%;...

Embodiment 3

[0022] Weigh a certain amount of coal gangue, mix it with 85% industrial sulfuric acid and coal gangue at a mass ratio of 1.2, react in a closed manner at 120°C for 60 minutes, dissolve and filter in a water bath at 80°C to obtain iron-aluminum sulfate solution, and use hydrogen peroxide Iron oxide aluminum sulfate is polymerized at room temperature for 90 minutes to obtain polyferric aluminum sulfate; coal gangue leaching slag is leached with 4mol / L NaOH alkali to obtain active sodium silicate solution, according to the volume ratio of polyferric aluminum sulfate and active sodium silicate 4:1, the mass concentration of active sodium silicate is 30% and the compound copolymerization is carried out. After the copolymerization for 3 hours, the polysilicate ferric aluminum sulfate product is obtained.

[0023] The dosage of PAFSS flocculant is 7mL / L. After flocculation treatment, the turbidity removal rate of wastewater reaches 99%, which drops to 0.39NTU; the chroma removal rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com