Production method of high-purity copper sulphate

A production method, the technology of copper sulfate, applied in the direction of copper sulfate, etc., can solve the problems that the purity is difficult to meet the quality requirements of high-end product processing in the electronics manufacturing industry, the product quality is not high, and the use requirements of the printed circuit board industry cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

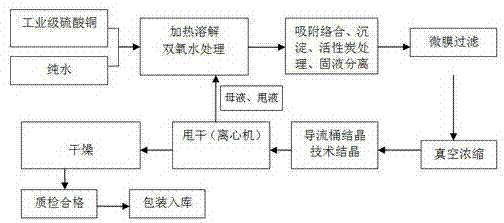

Image

Examples

Embodiment Construction

[0018] Add 1000L of water and 250Kg of industrial copper sulfate into a 1500L reactor equipped with a stirring, thermometer and reflux condenser, stir to dissolve and heat to 60°C, add sulfuric acid dropwise to adjust the pH to 1.5, and add an appropriate amount of 30% hydrogen peroxide while hot Oxidize the low-valent metal ions that may exist in the solution, add hydrogen peroxide at a speed that is not excessively violent, stir for 2 hours and keep warm for 3 hours after adding. Then add polyferric sulfate and basic copper carbonate precipitation complexing agent mixed in a mass ratio of 1:3, the precipitation complexing agent is 1.5% of the total weight of the solution, and add 0.25% of the total weight of the solution. Activated carbon, stirred for 4-5 hours, cooled to room temperature, and left to stand overnight. The above solution was preliminarily filtered and then filtered through a 0.2 μm microporous membrane. The filtrate is concentrated under reduced pressure by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com