Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Adjust the reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

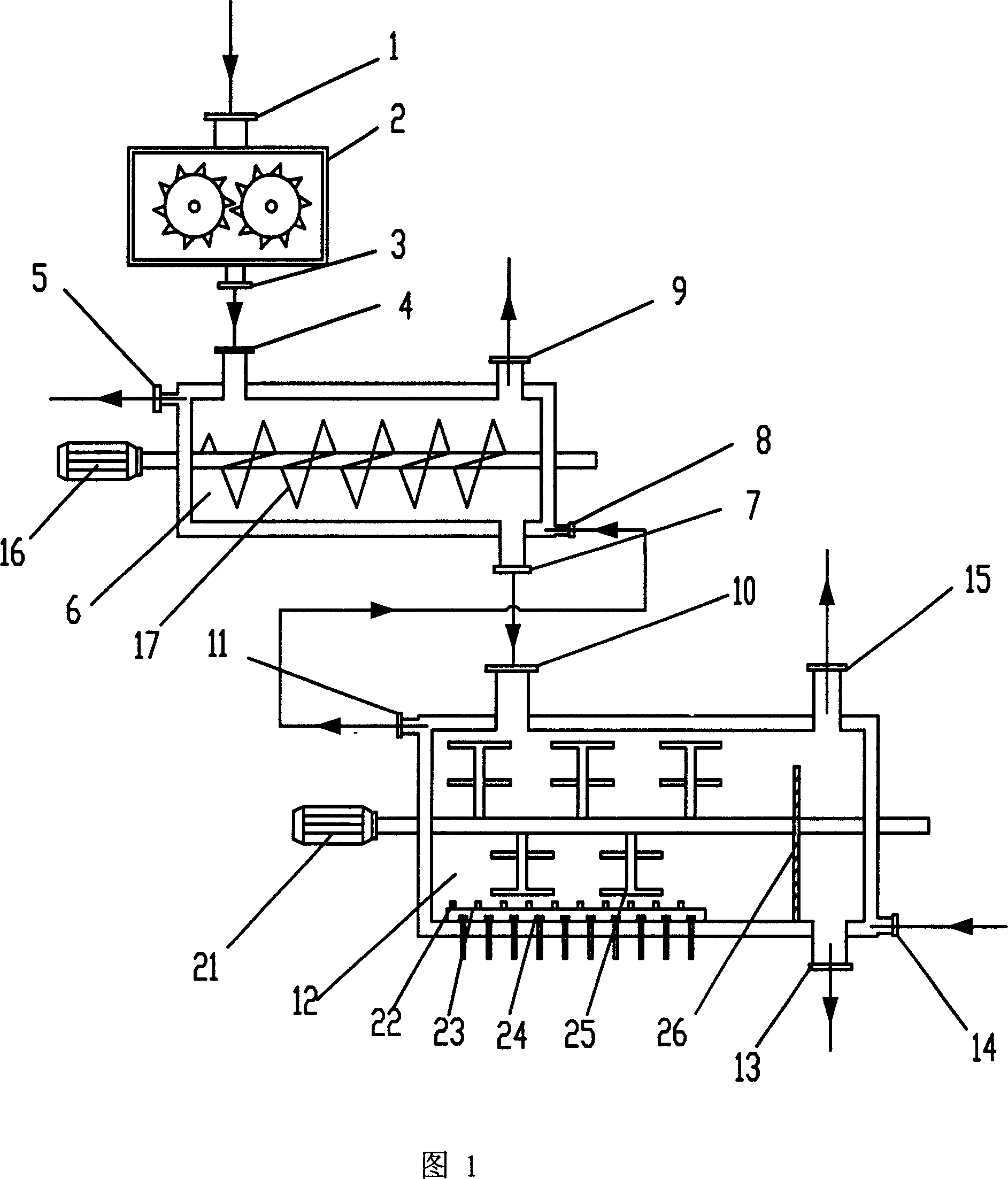

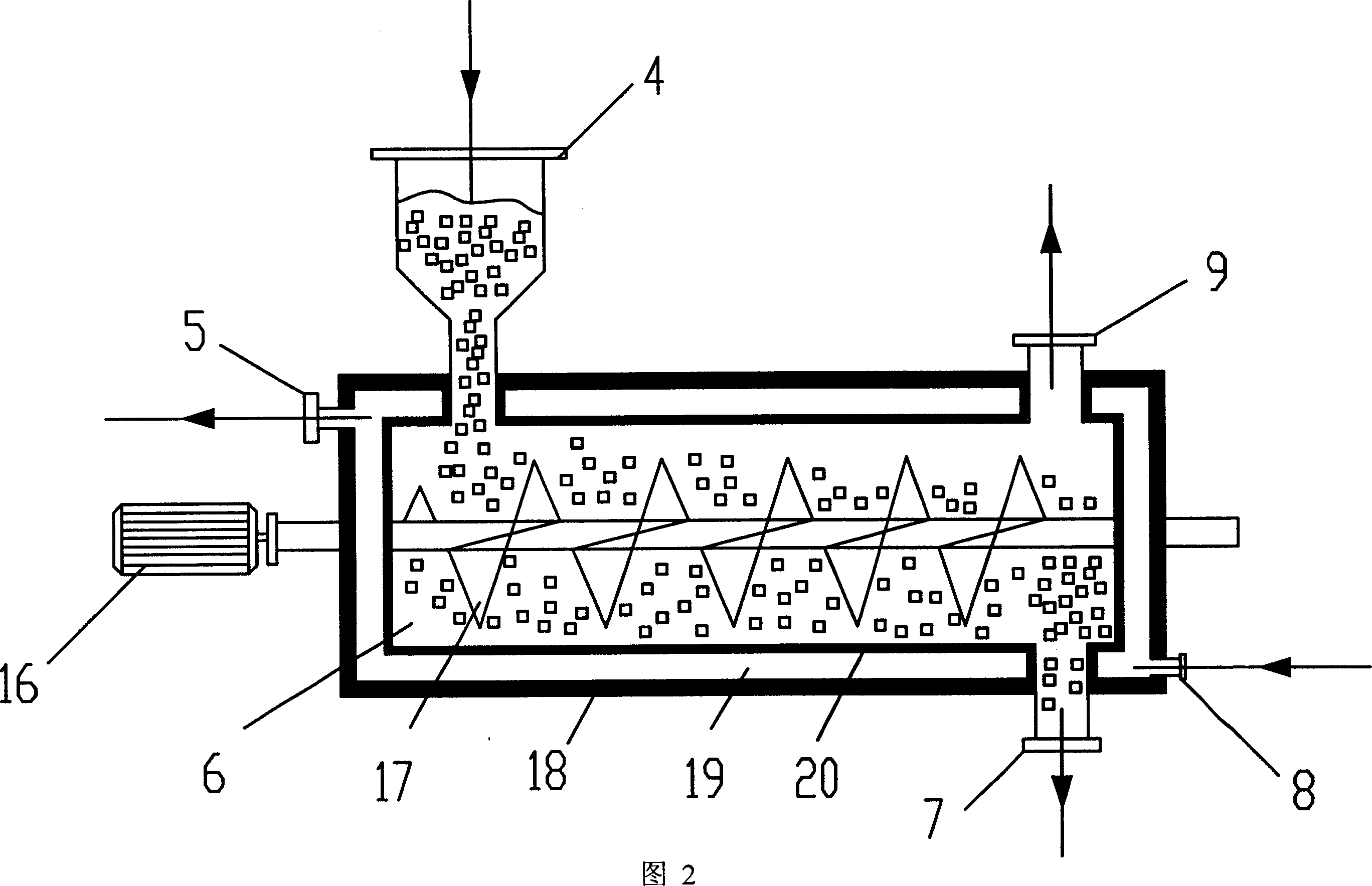

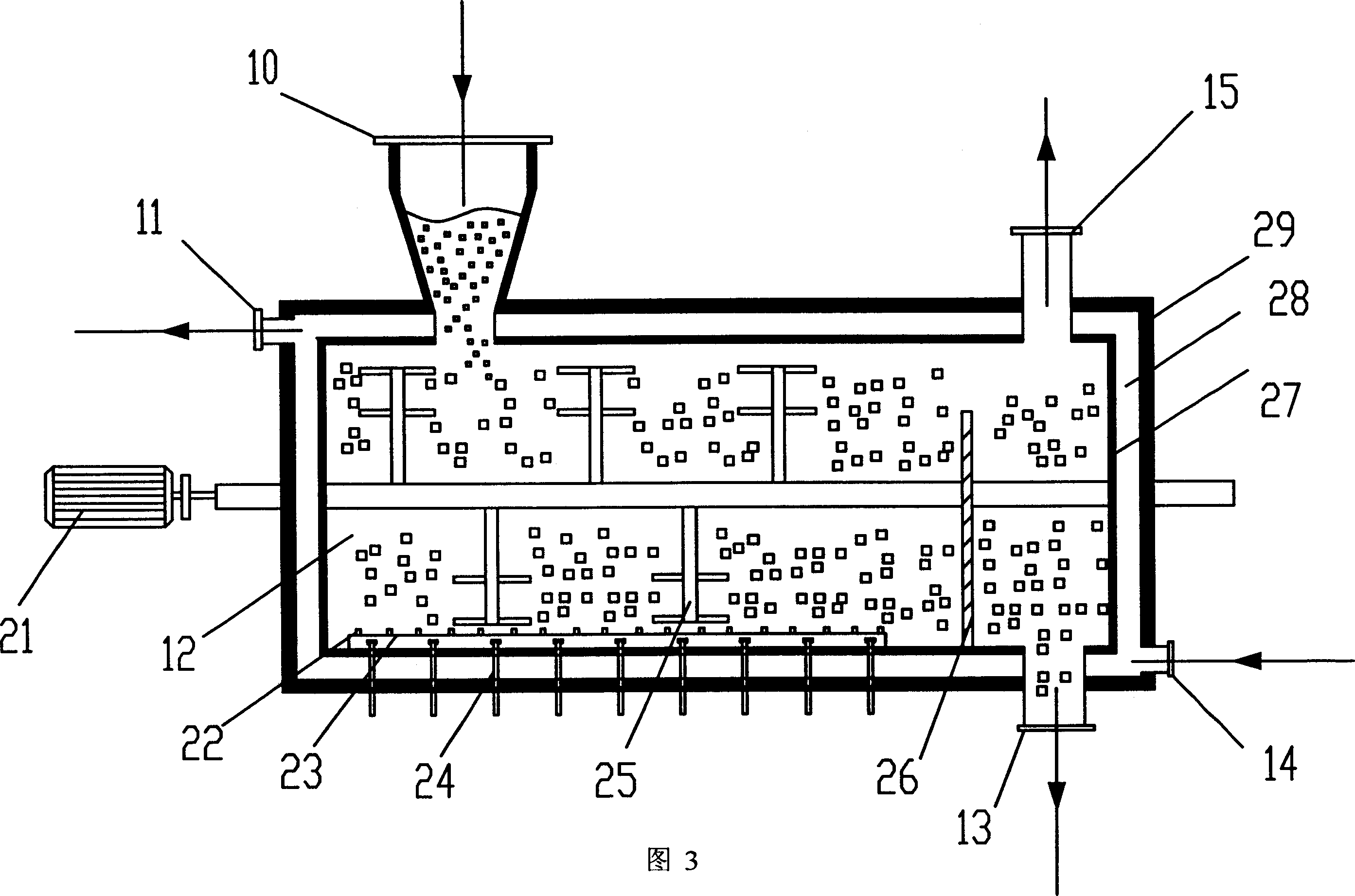

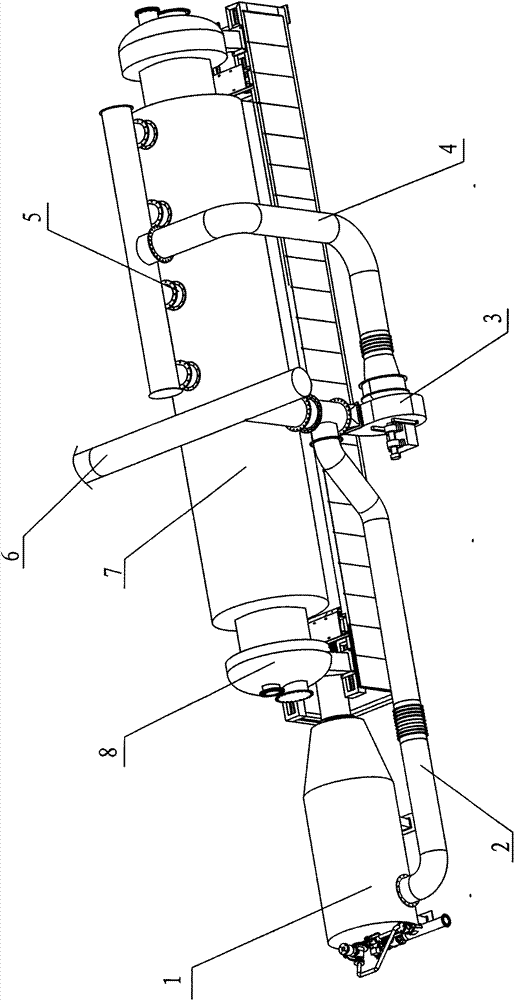

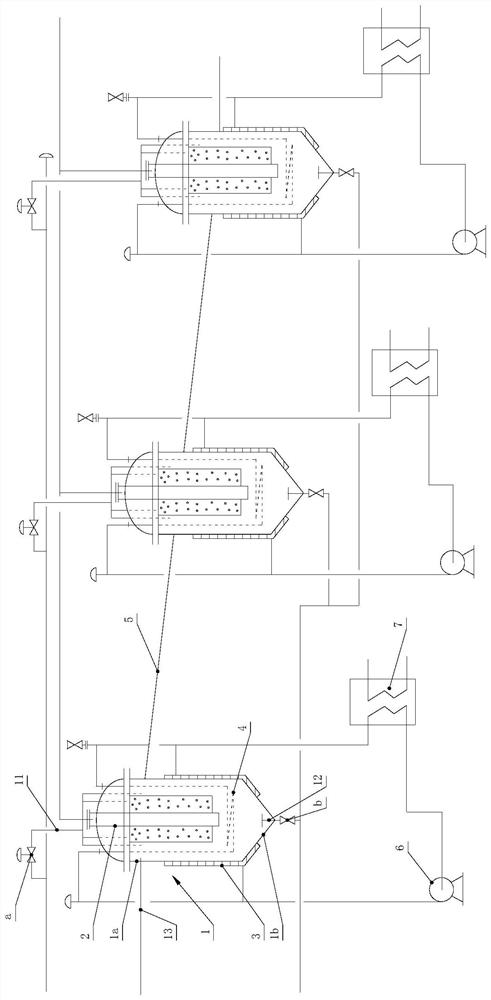

Biomass deep dehydration carbonization continuous processing technology and device thereof

ActiveCN1928013AHigh thermal efficiencyNo or less pyrolysis reactionBiofuelsSpecial form destructive distillationReaction temperatureProduct gas

Continuous biomass deeply dewatering and carbonizing process and apparatus are disclosed. The technological process includes the steps of deeply dewatering biomass to separate out water at 120-160 deg.c with external heat source, and carbonizing biomass at 300-500 deg.c to obtain biomass charcoal and pyrolytic fuel gas. The apparatus includes one drier and one carbonizing unit with material inlet connected to the outlet of the drier and sandwiched heat exchange cavity connected to that of the drier. Inside the carbonizing unit, there is also one gas assistant jetting device for controlling the reaction temperature in the carbonizing process. The present invention has high heat efficiency, high heat value of the pyrolytic gas and high biomass charcoal yield.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

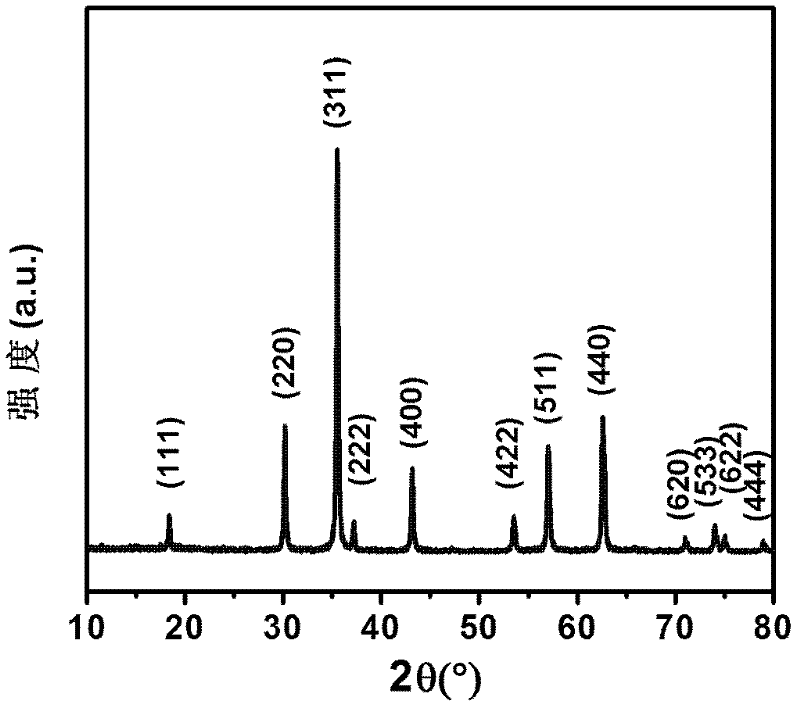

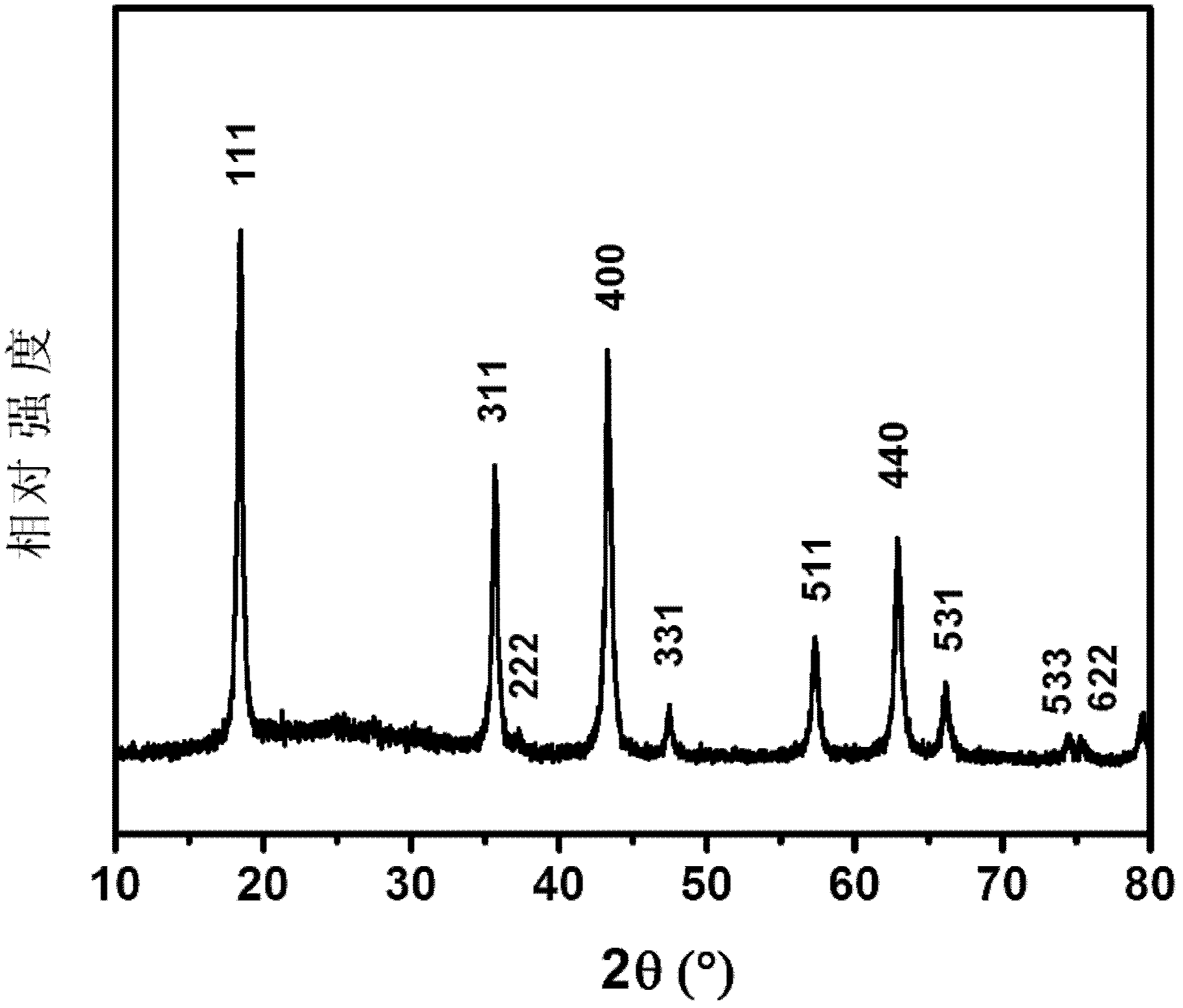

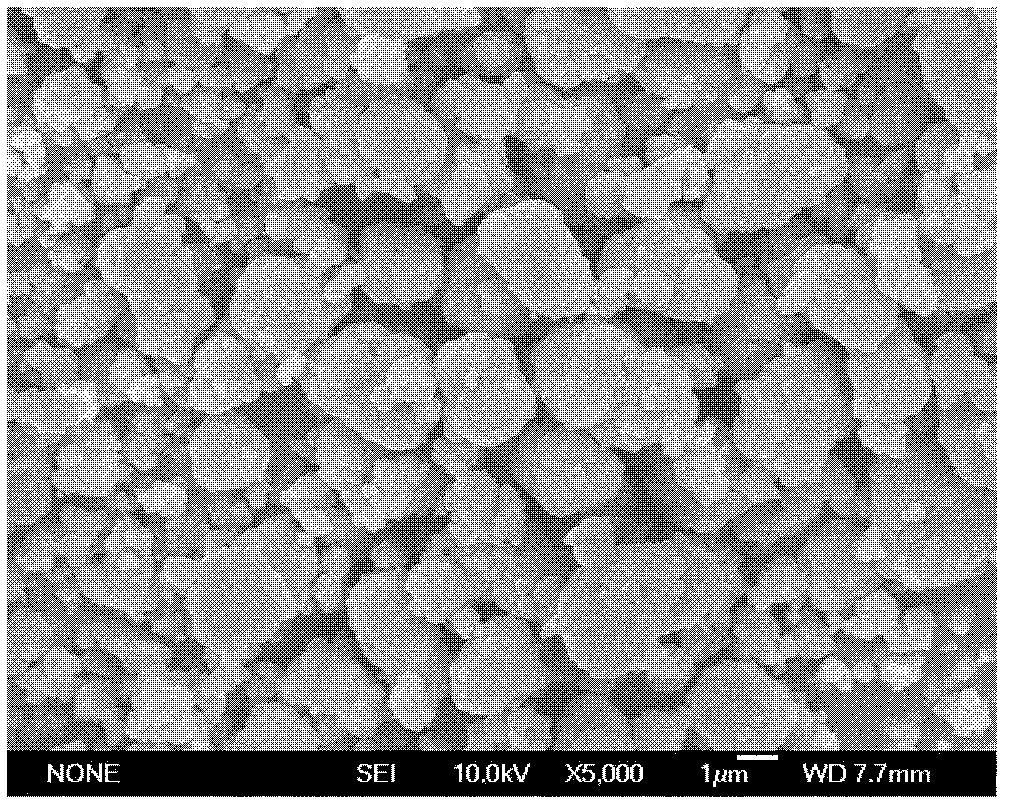

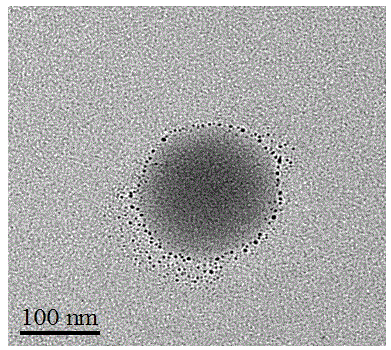

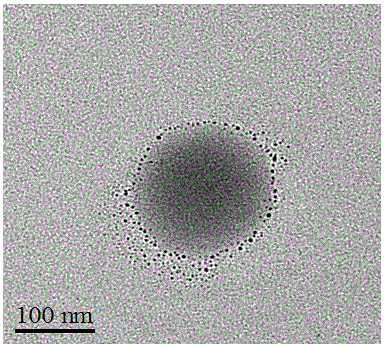

Spherical ferrate having hollow structure and preparation method thereof

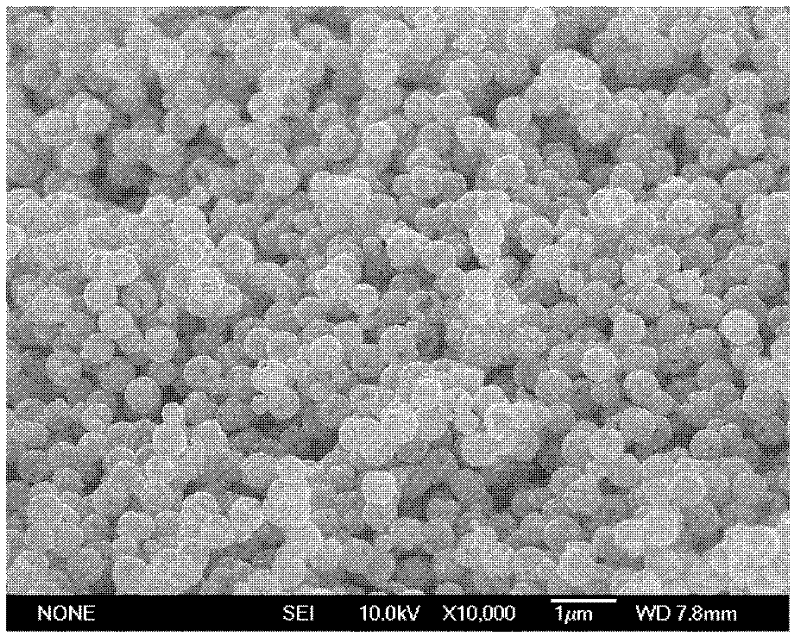

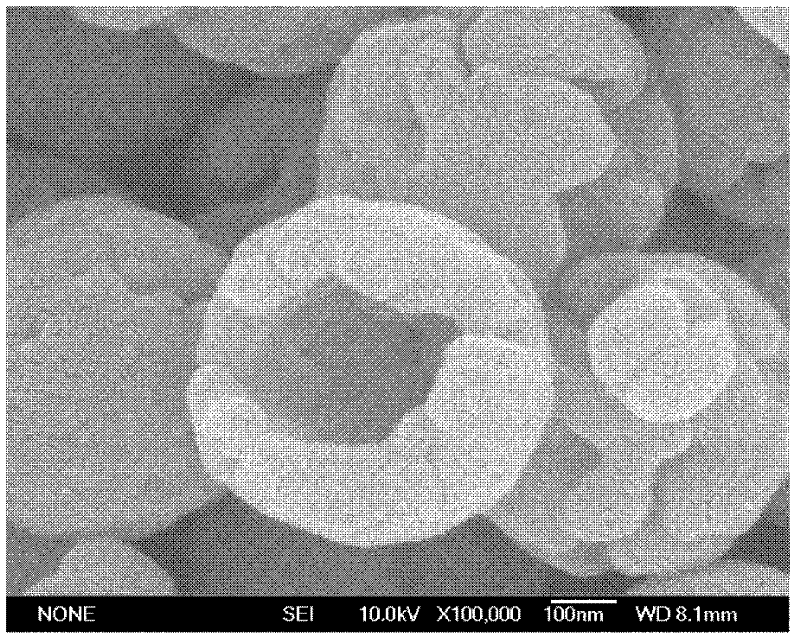

InactiveCN102531066APromote formationHigh viscosityNanotechnologyIron compoundsPhysical chemistryNanocrystal

The invention discloses spherical ferrate having a hollow structure and a preparation method thereof. The ferrate MFe2O4 is of a hollow-structured spherical particle formed by self-assembling of nanocrystals having a particle size of 10-50nm, wherein M is Co, Ni or Zn, the diameter of the particle is 0.1-1mu m, and the thickness of a shell layer is 30-200nm. The spherical ferrate can be used as a negative electrode material of a lithium ion battery.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

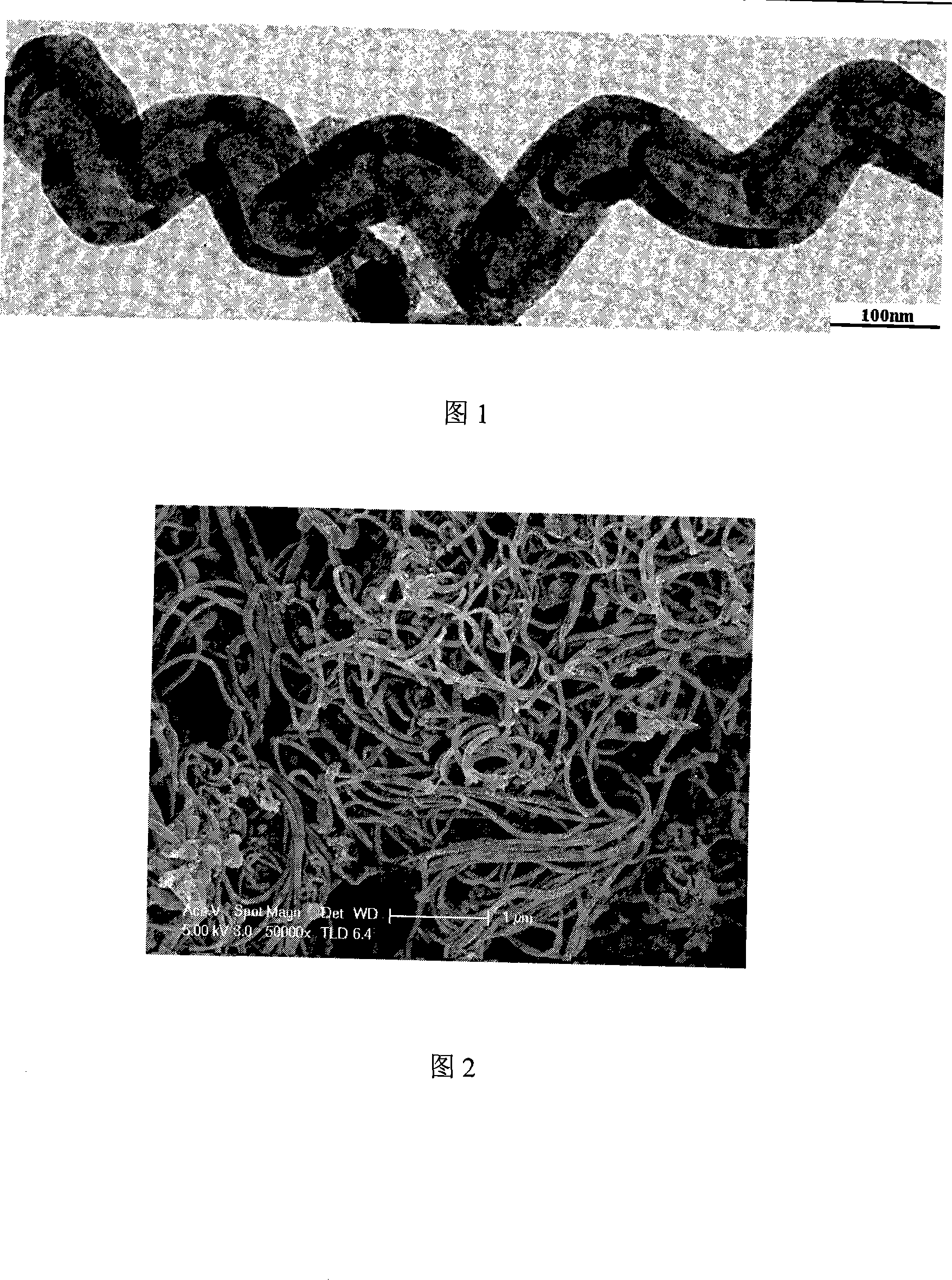

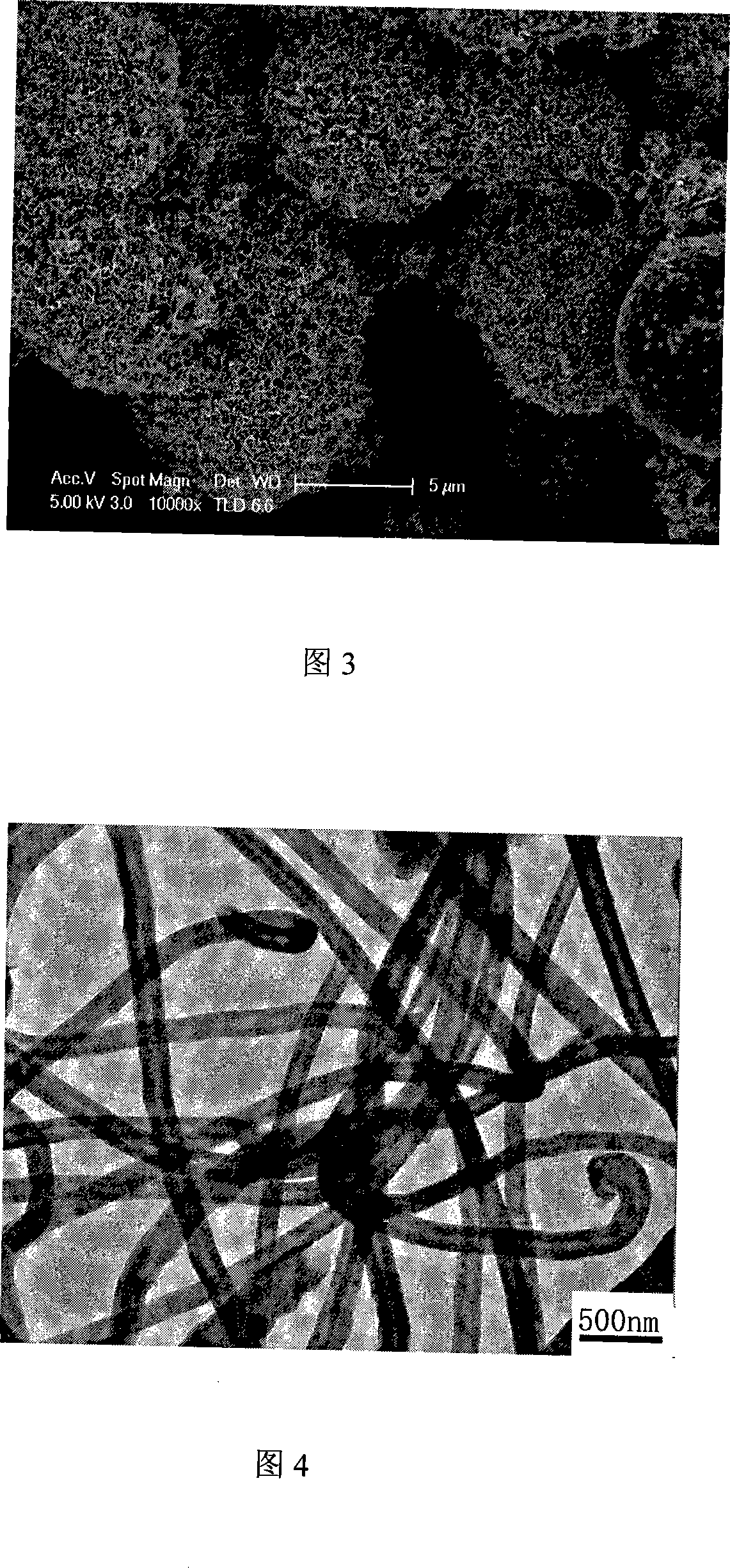

Method of preparing multi-wall carbon nano-tube by using polymer as raw material

InactiveCN101239713AQuick breakdownIncrease growth rateNanostructure manufacturePolymer scienceCarbon nanotube

The present invention provides a method of multi-walled carbon nantubes using polymer as raw material, belonging to inorganic function material synthesizing technology field, in particular: polyethylene or polypropylene, PEMA or polypropylene and catalyst are placed in the sealing container according to a certain proportion, calculated by weight percentage, polyethylene or polypropylene : PEMA or polypropylene : catalyst is 1:0.25-0.5:0.05-0.005; baking 10-25 hour under the temperature 600-850 Celsius, cooling to room temperature, removing reactant, acid washing to remove catalyst, the product is obtained by drying. The invention has a simple operation, high productive rate, lower cost, and is a green method for acquiring carbon nantubes, the multi-walled carbon nantubes have wide application, used as hydrogen storage material, high strength composite field, catalyst carrier etc.

Owner:JIANGSU UNIV

Liquefaction catalytic conversion method for producing dimethyl ether with methanol

ActiveCN101152997AImprove mass transfer efficiencyImprove heat transfer efficiencyEther/acetal/ketal group formation/introductionChemical recyclingFixed bedDimethyl ether

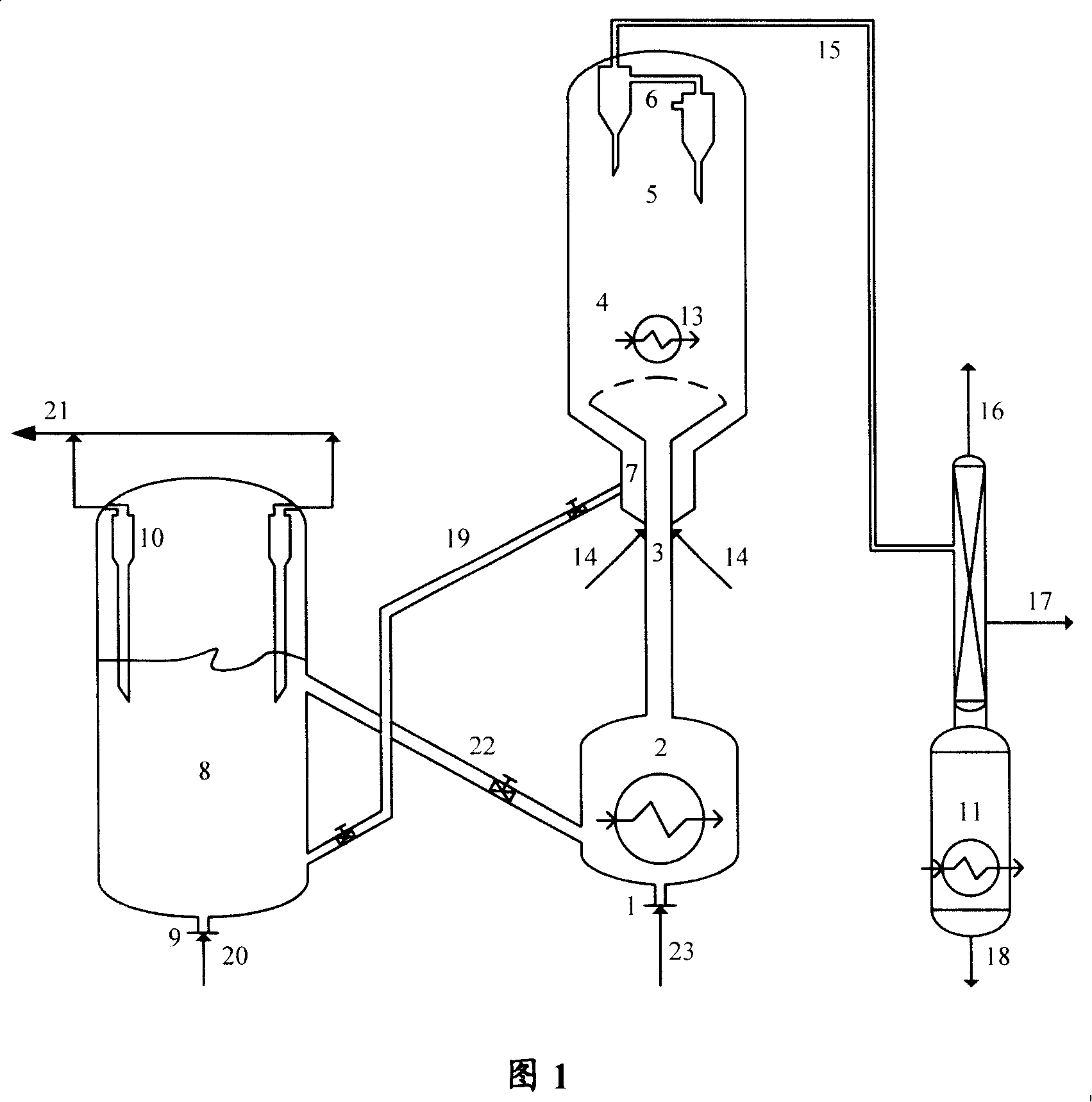

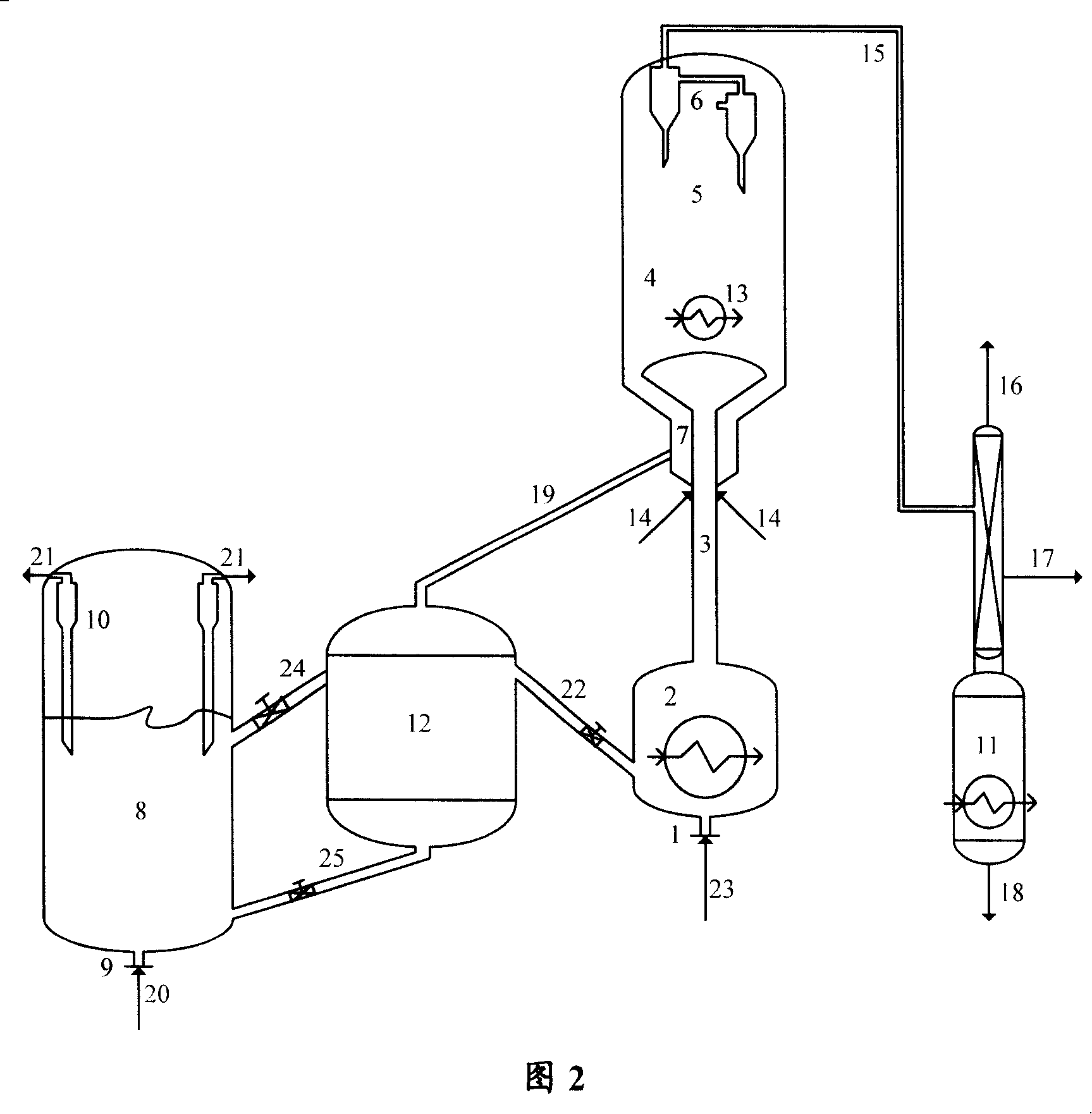

The present invention provides a fluidization and conversion method using methanol to prepare dimethyl ether. The methanol material, cooled regenerated catalyst and pre-lifting medium orderly enter a circulating fluidized bed. At a temperature between 150 and 500 DEG C, under pressure between 0.1MPa and 1.0MPa and at a liquid space-time speed of 0.5 to 4 hours, the -1, catalyst and methanol material react with a weight ratio of 1 to 20. In the reaction process, heat is removed from the circulating fluidized bed; the reaction material flow and catalyst to be generated are separated. Wherein, the target product dimethyl ether can be got by separation of the reaction material flow. The catalyst to be generated is recycled orderly after gas extraction, regeneration and cooling. Compared with a fixed-bed, the circulating fluidized bed of the method provides better gas-solid contact, and has gas-solid phase medium and high heat transfer efficiency. Therefore, the method improves the conversion rate of methanol and the selectivity of dimethyl ether product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Environmentally-friendly cross-linked acrylate polymer emulsion and preparation method thereof

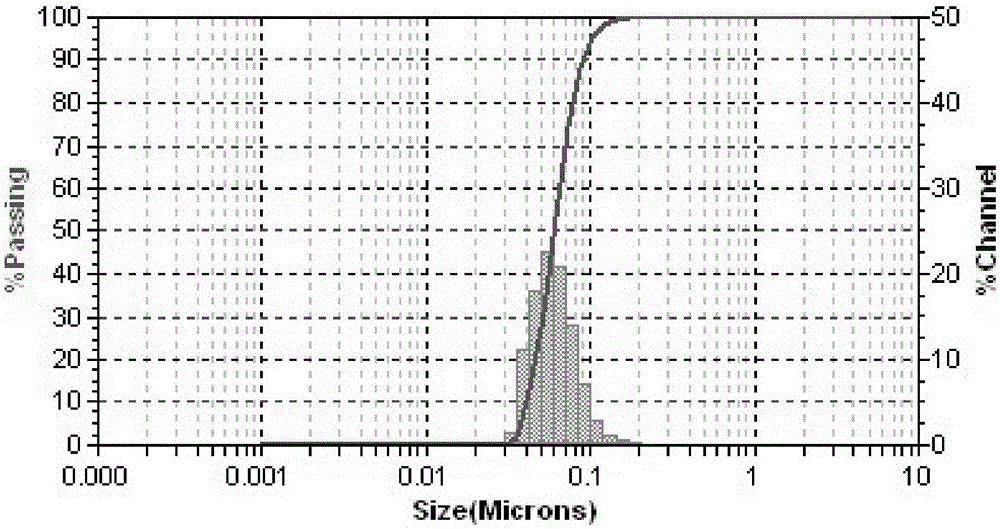

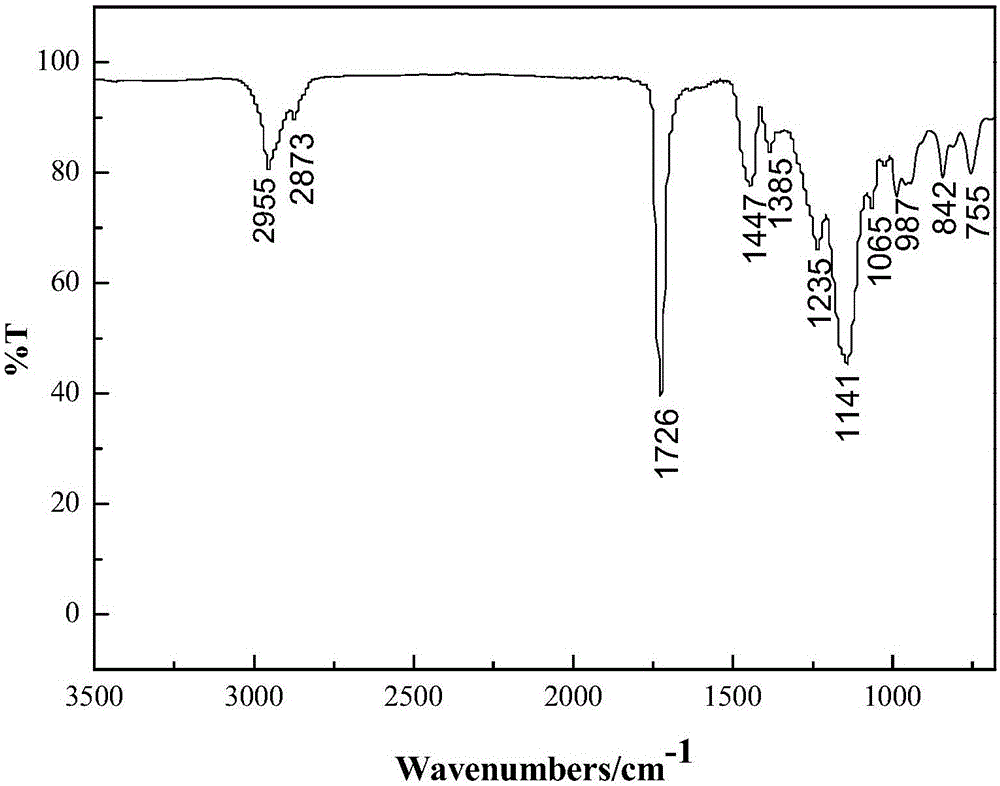

The invention relates to an environmentally-friendly cross-linked acrylate polymer emulsion and a preparation method thereof. The emulsion consists of six main components through semicontinuous seeded emulsion polymerization, is fine and smooth in appearance and is a blue-fluorescent semitransparent emulsion, a pH value is 7.5+ / -0.5, the solid content is 30-50%, the emulsion particle diameter is 50-100 nanometers, and the polymer emulsion has good film-forming property and adhesion after film forming at the 80 DEG C temperature. The environmentally-friendly cross-linked acrylate polymer emulsion has the advantages that due to the fact that an amino acid based anionic surface active agent and an alkyl polyglucoside non-ionic surface active agent both have excellent biodegradability and environmental protection effect and are used for replacing commonly-used alkylphenol polyoxyethylene ether and an alkylbenzene sulfonate surface active agent having poor biodegradability, the environmentally-friendly cross-linked acrylate polymer emulsion is more environmentally-friendly, and the demand for the performances of the emulsion is met.

Owner:新东方油墨有限公司

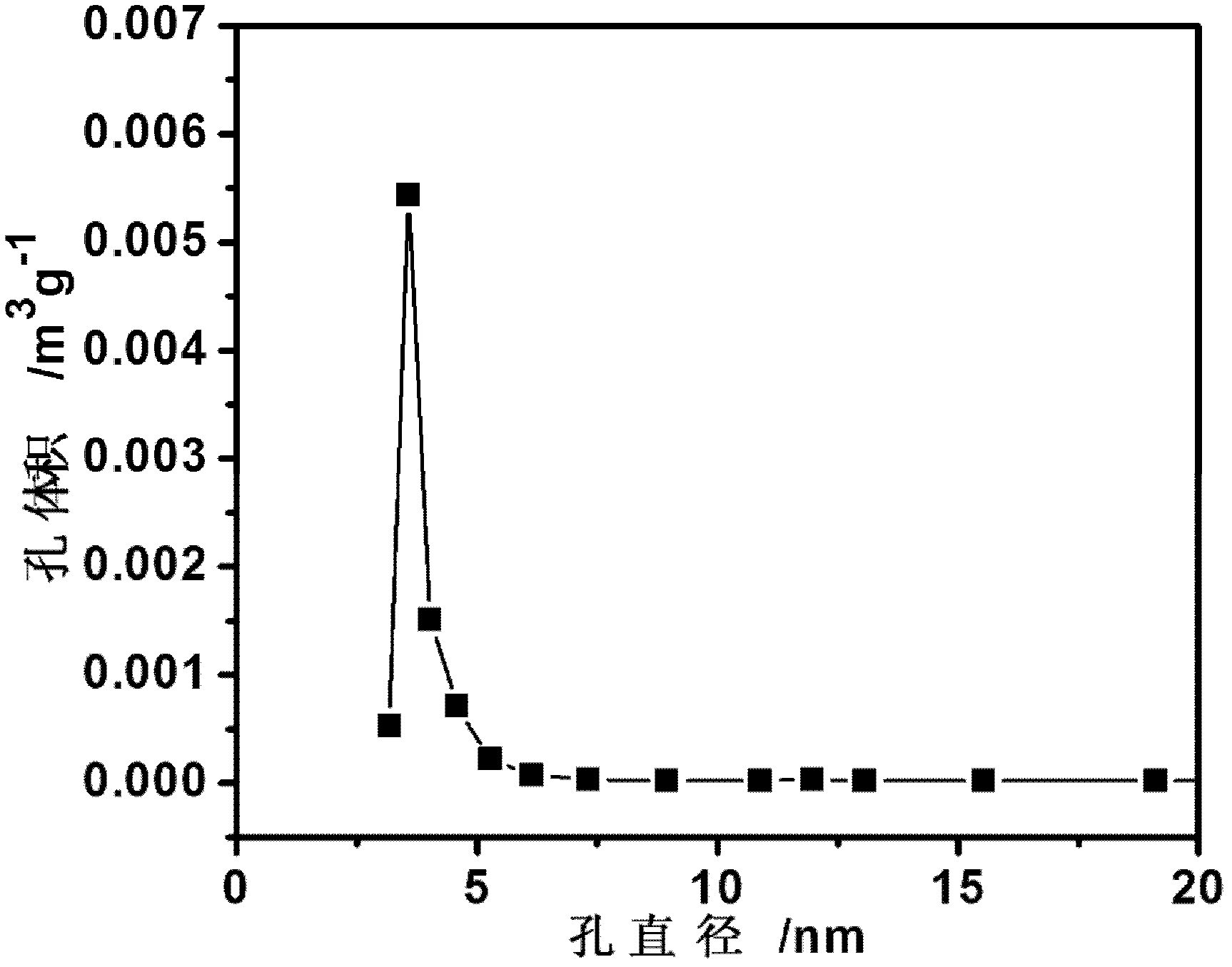

Carbon-coated mesoporous lithium titanate anode material of lithium ion battery and method for preparing carbon-coated mesoporous lithium titanate anode material

ActiveCN102544468APromote hydrolysisPromote migrationCell electrodesTitanium compoundsElectrical batteryPhysical chemistry

The invention discloses a carbon-coated mesoporous lithium titanate anode material of a lithium ion battery and a method for preparing the carbon-coated mesoporous lithium titanate anode material. A particle aggregate with the diameter of 0.1 to 10 mu m is formed by self-assembling nano-crystals with the diameter of 5 to 150 nm. The material has a mesoporous structure, the average pore diameter of the material is 2 to 6 nm, and the carbon content of the material is 0.5 to 5 percent. A lithium titanate sample can serve as an anode material of the lithium ion battery.

Owner:重庆中纳科技有限公司

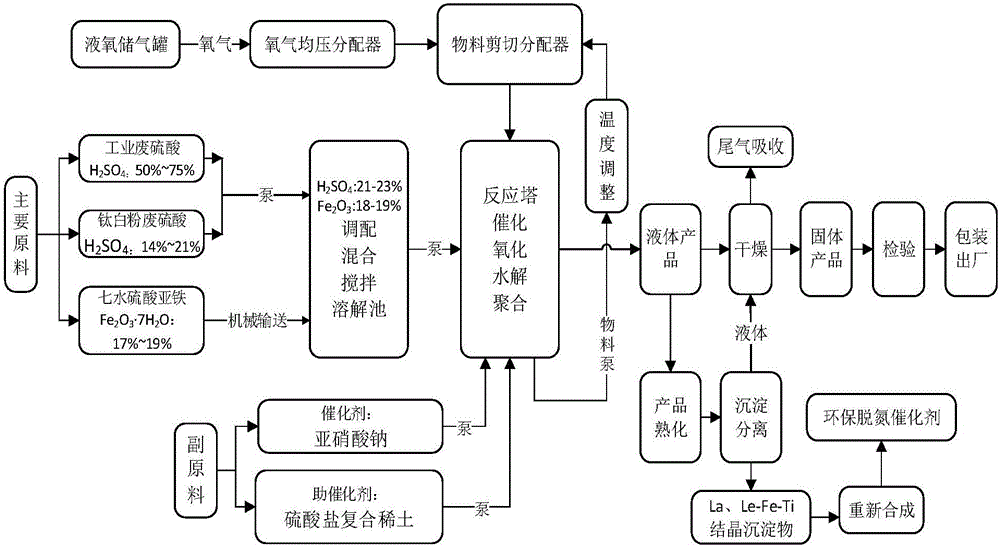

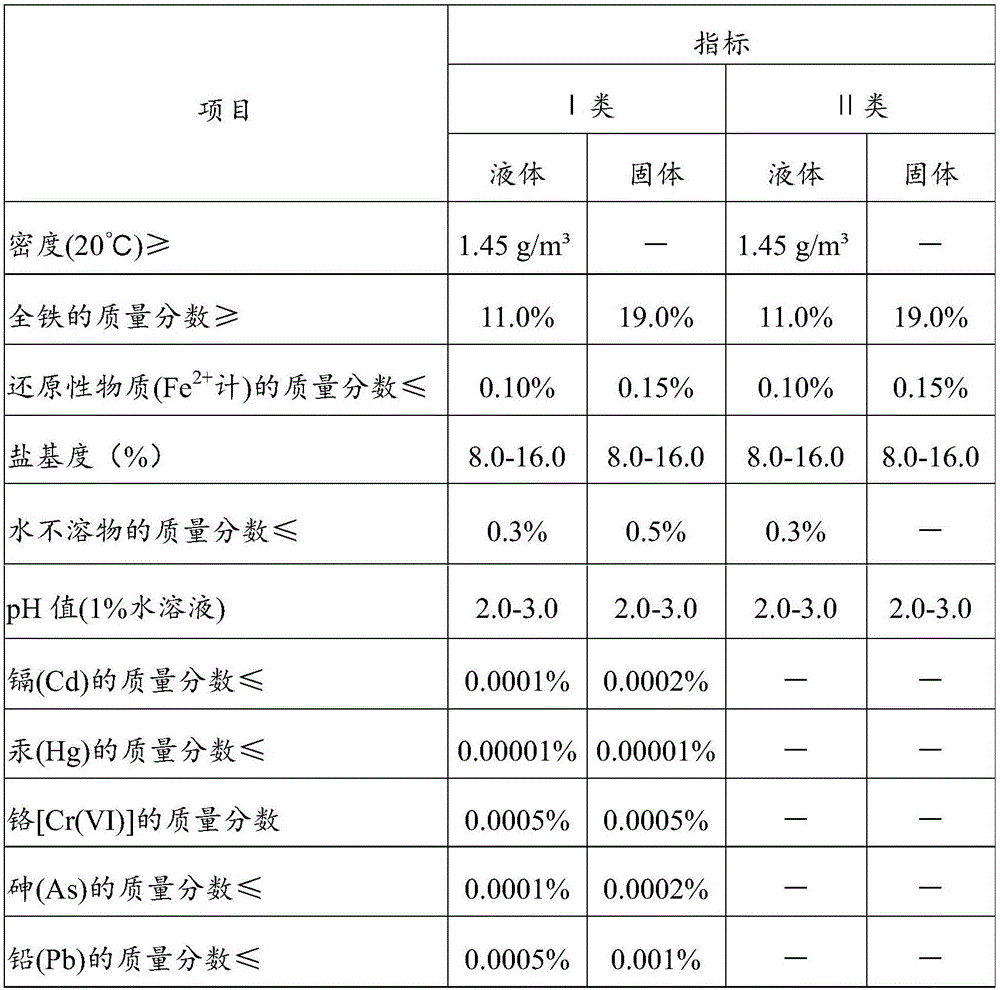

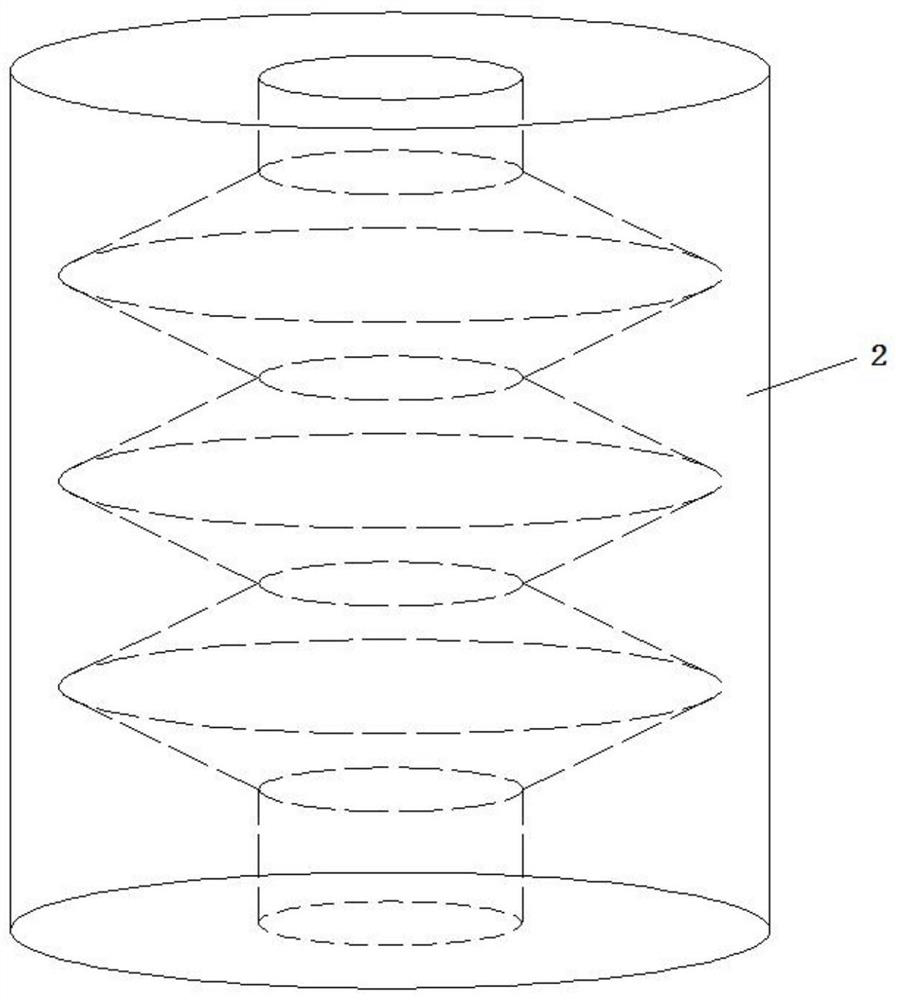

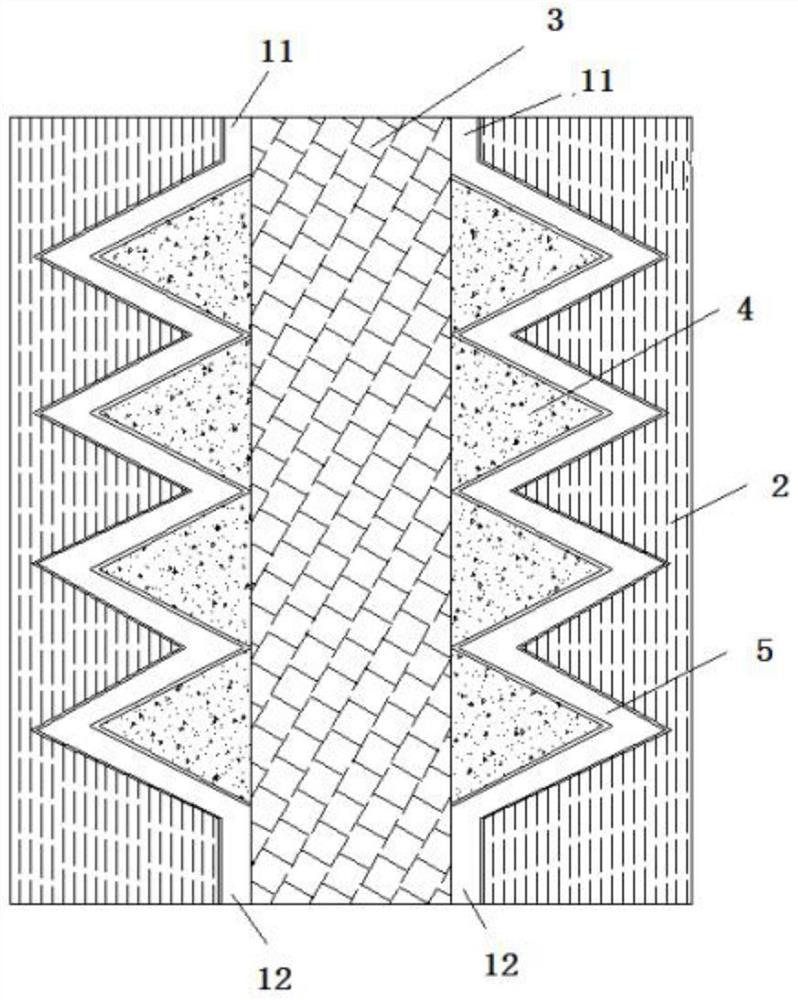

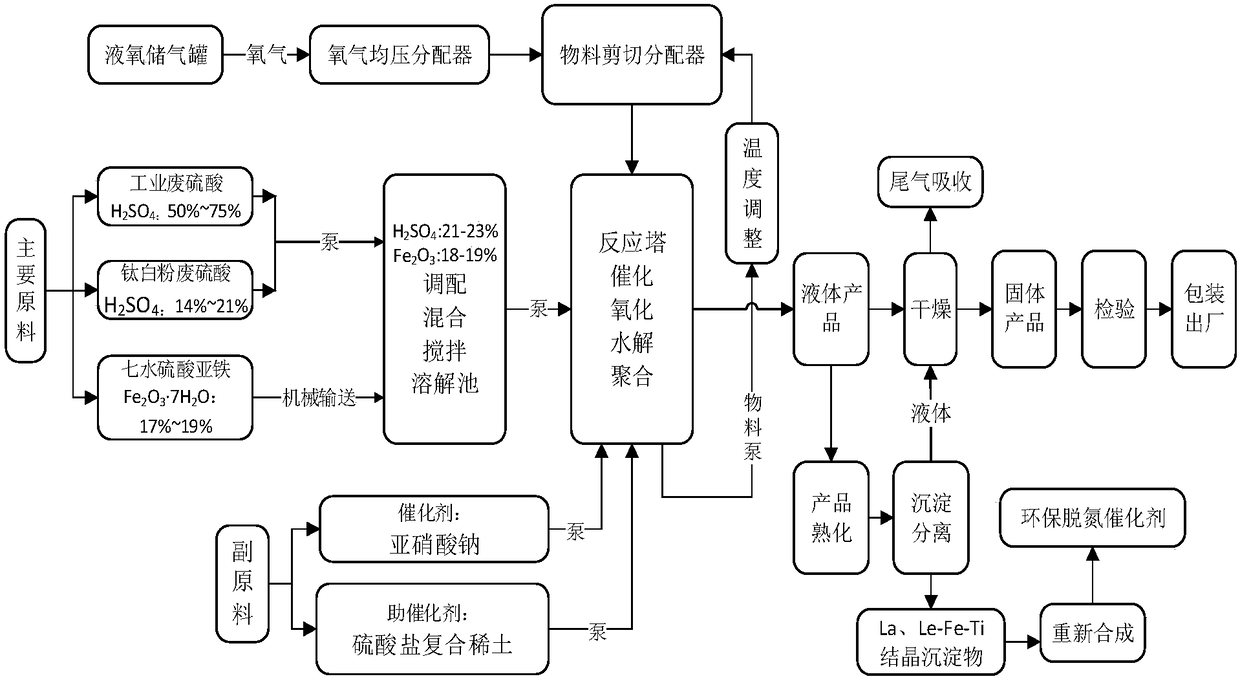

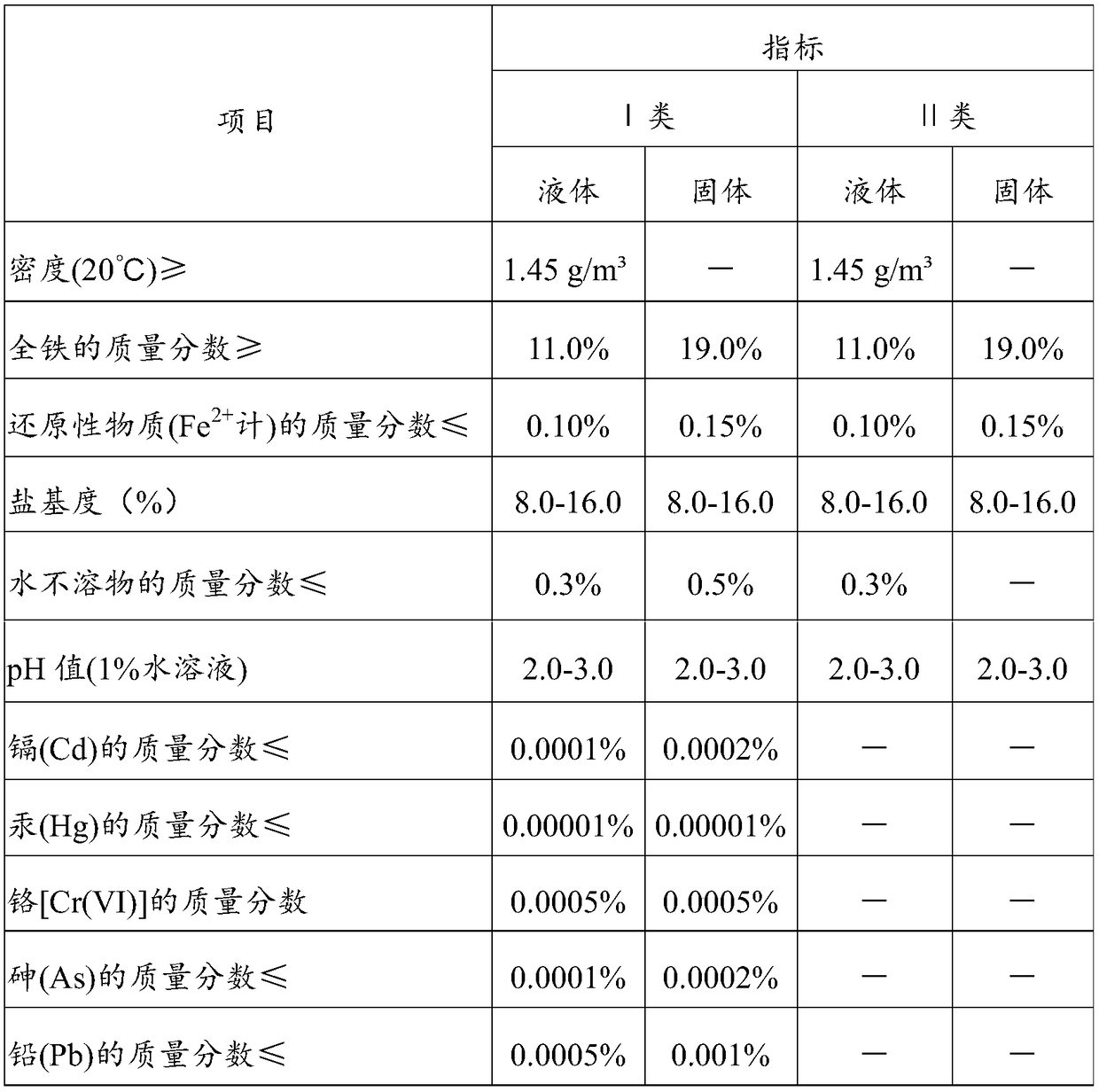

Polyferric sulfate and preparation method of polyferric sulfate

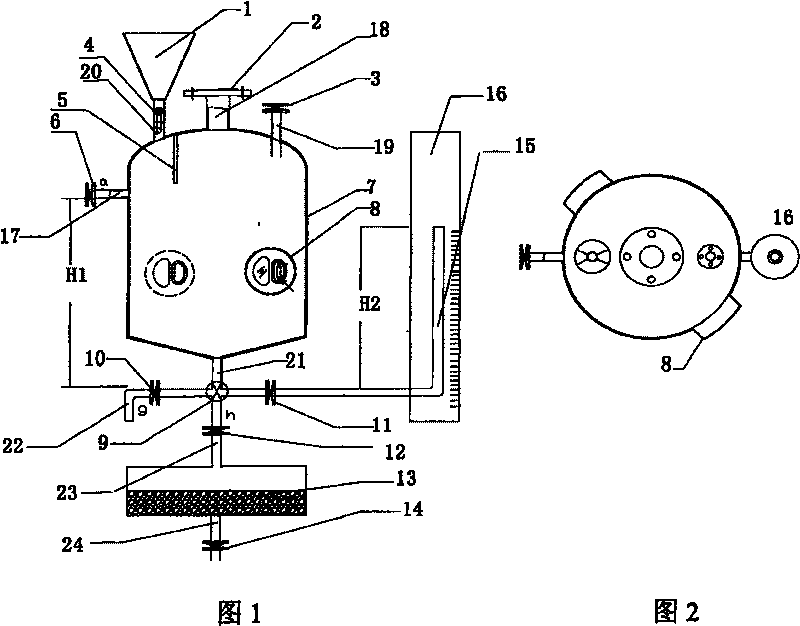

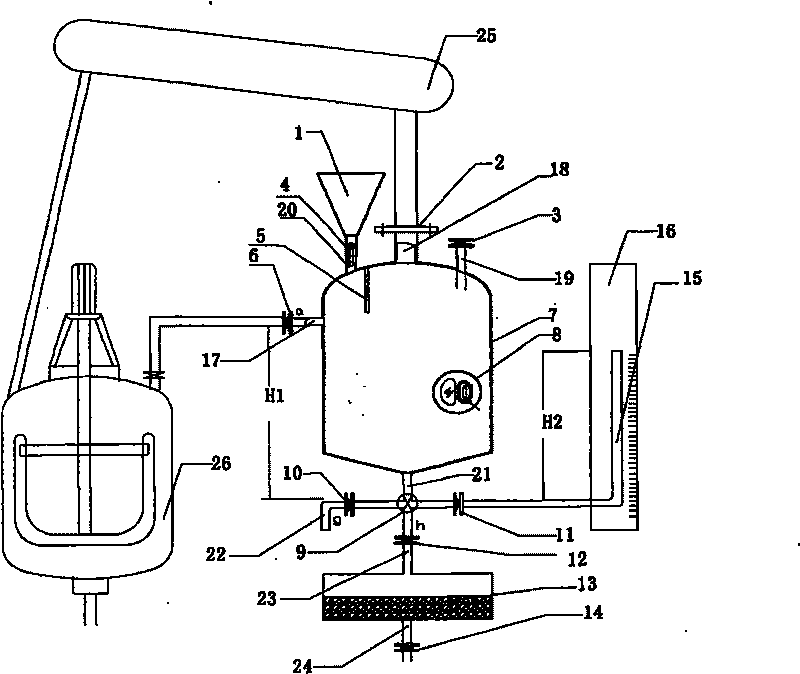

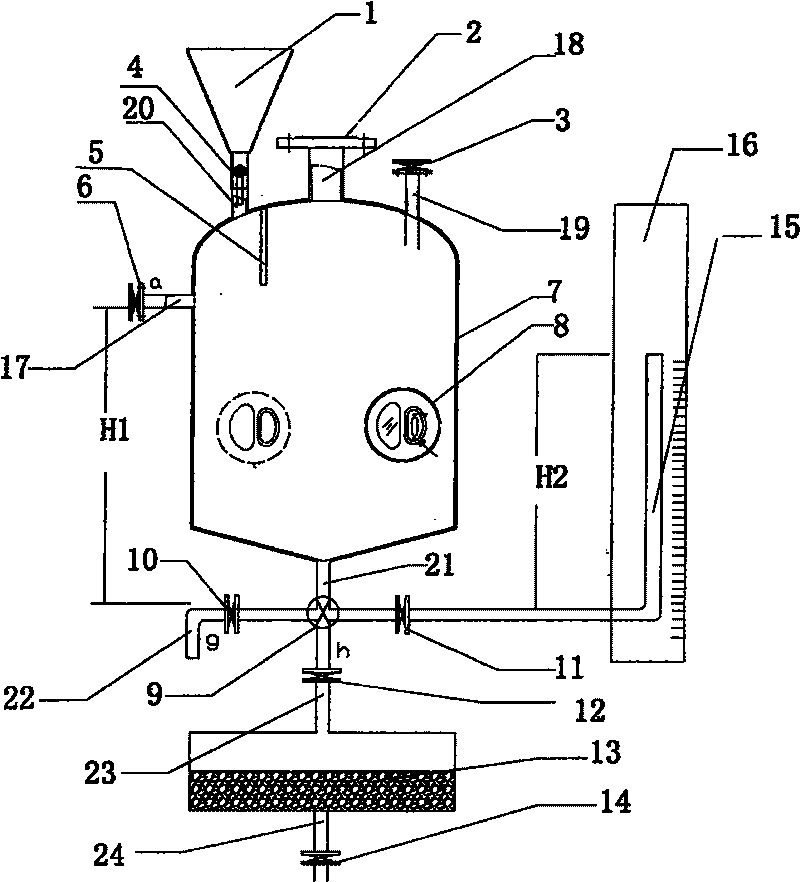

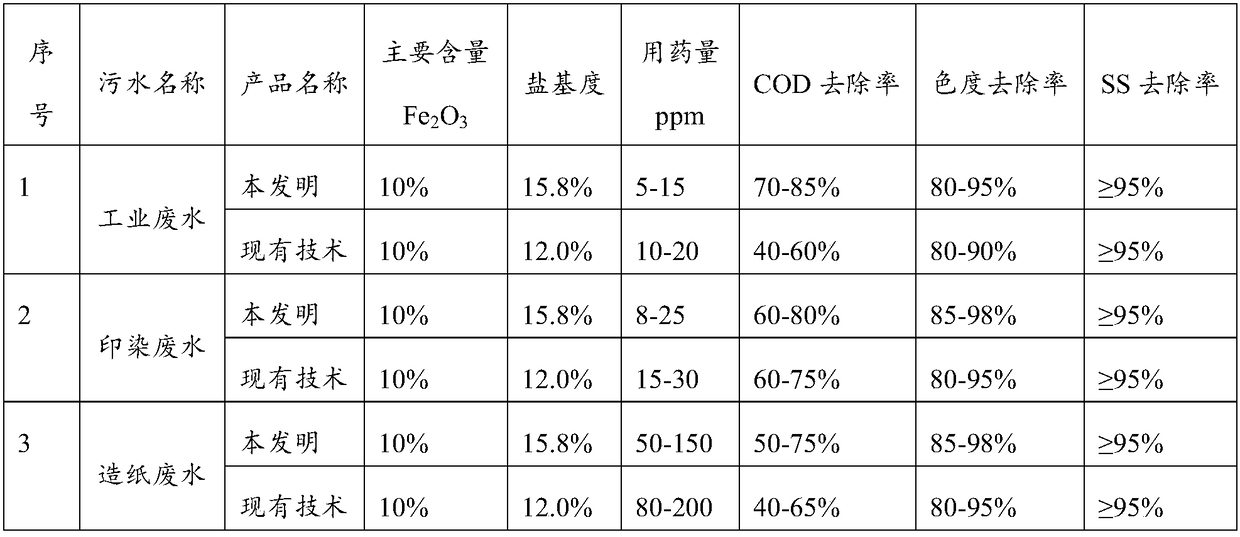

ActiveCN105692717AAdjust the reaction temperatureIncrease acidityIron sulfatesWater/sewage treatment by flocculation/precipitationRare earthIron(III) sulfate

The invention discloses polyferric sulfate as well as a preparation method and a preparation device of the polyferric sulfate. The preparation method comprises the following steps: conveying the following components into a mixing tank in percentage by weight: 40 percent to 50 percent of iron sulfate heptahydrate and 60 percent to 50 percent of titanium dioxide waste sulfuric acid, and blending the materials; adjusting the concentration range of the titanium dioxide waste sulfuric acid H2SO4 to be 21 percent to 23 percent to obtain mixed reaction materials; conveying the reaction materials into a reaction tower, and adding a sulfate composite rare-earth solution as a reaction cocatalyst when conveying the reaction materials into the reaction tower; controlling the temperature in the reaction tower to be 40 DEG C to 60 DEG C; after all the blended materials enter the reaction tower, adding a sodium nitrite solution as a reaction catalyst; continually introducing oxygen gas into the reaction tower so that the oxygen gas and the reaction materials make oxidization, hydrolysis and polymerization reactions under the action of the cocatalyst and the catalyst; after effectively converting Fe<2+> ions in the materials into Fe<3+> ions, obtaining liquid polyferric sulfate. With the adoption of the polyferric sulfate as well as the preparation method and the preparation device of the polyferric sulfate, the production efficiency can be greatly improved, environmental hazards are reduced, and a more prominent water purification and coagulation effect is realized.

Owner:广西继禹环保科技有限公司

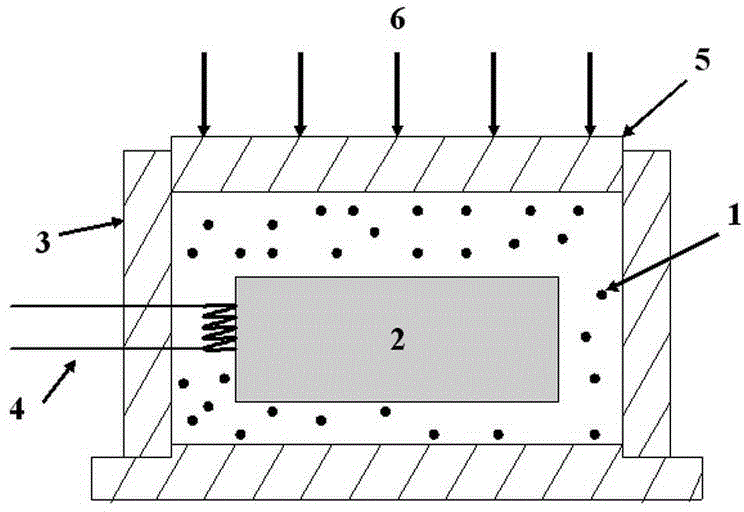

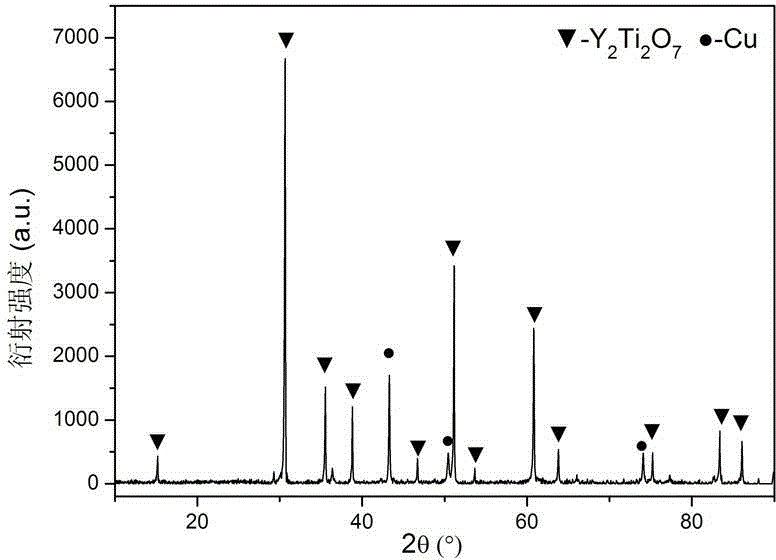

Y2Ti2O7 pyrochlore self-propagating high-temperature synthesis and densification method

InactiveCN104528813AGuaranteed Packet CapacityGuaranteed long-term safetyTitanatesSelf-propagating high-temperature synthesisPyrochlore

The invention discloses a Y2Ti2O7 pyrochlore self-propagating high-temperature synthesis and densification method. The method is characterized in that CuO, Y2O3, Ti and TiO2 powders are adopted as raw materials and are blended according to a certain molar ratio; the mixture is fully ground and well mixed, and is sieved; the mixed material is added into a stainless steel mold, and is pressed into a cylindrical blank; the blank is placed into a self-propagating quasi-isostatic pressing device; the blank is ignited with an ignition tungsten wire; within 5-30s after combustion is finished, a pressure of 50-200MPa is applied by a hydraulic machine and is maintained for 20-100s, such that a Y2Ti2O7 pyrochlore block is obtained. The method has the advantages of high synthesis speed, short production period, high reaction temperature, low energy consumption, controllable synthesis product phase, high product purity, high product density, simple process, and the like. The prepared Y2Ti2O7 pyrochlore is especially suitable for high-level radioactive nuclear waste long-term safe solidification treatment and disposal.

Owner:SOUTHWEAT UNIV OF SCI & TECH

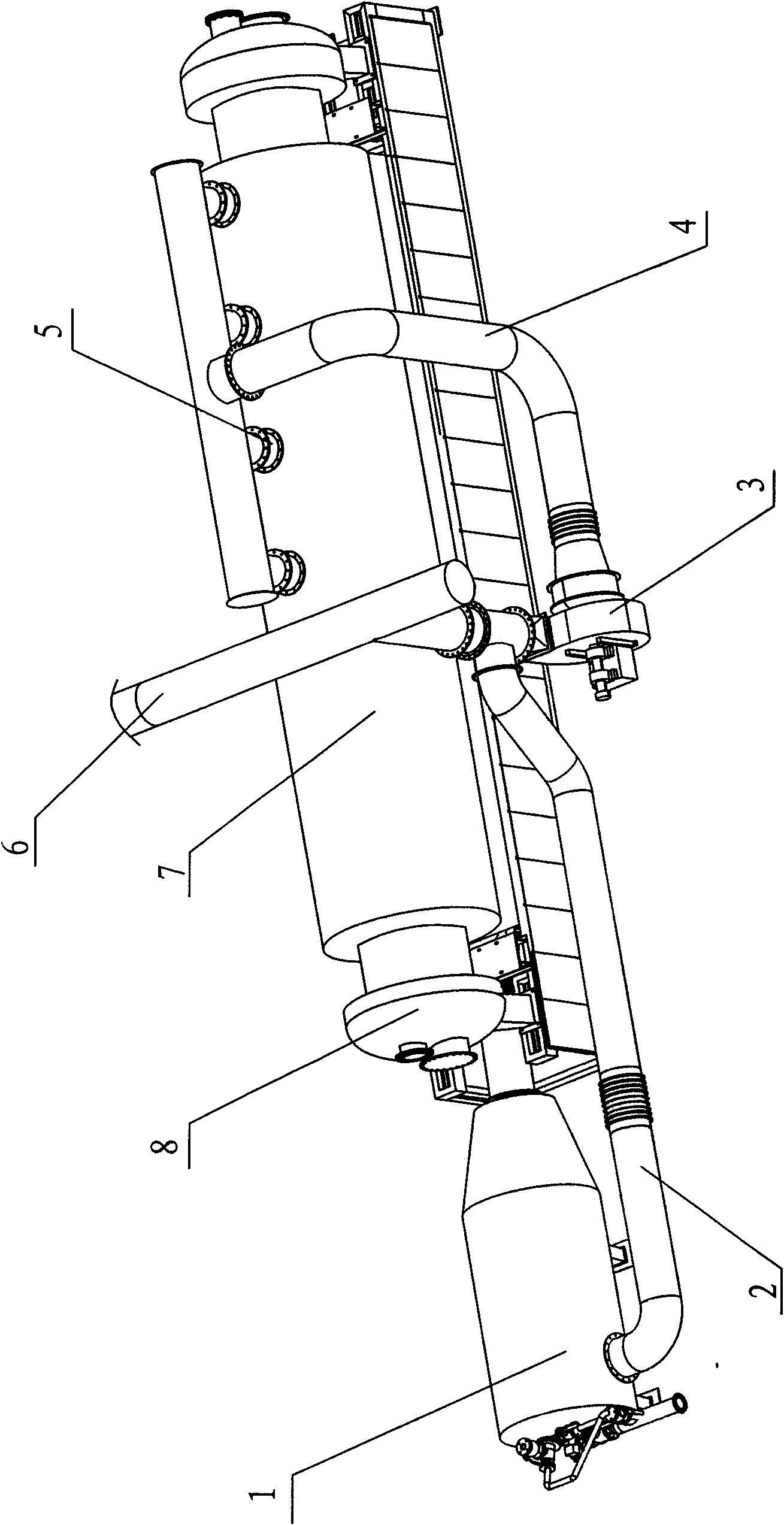

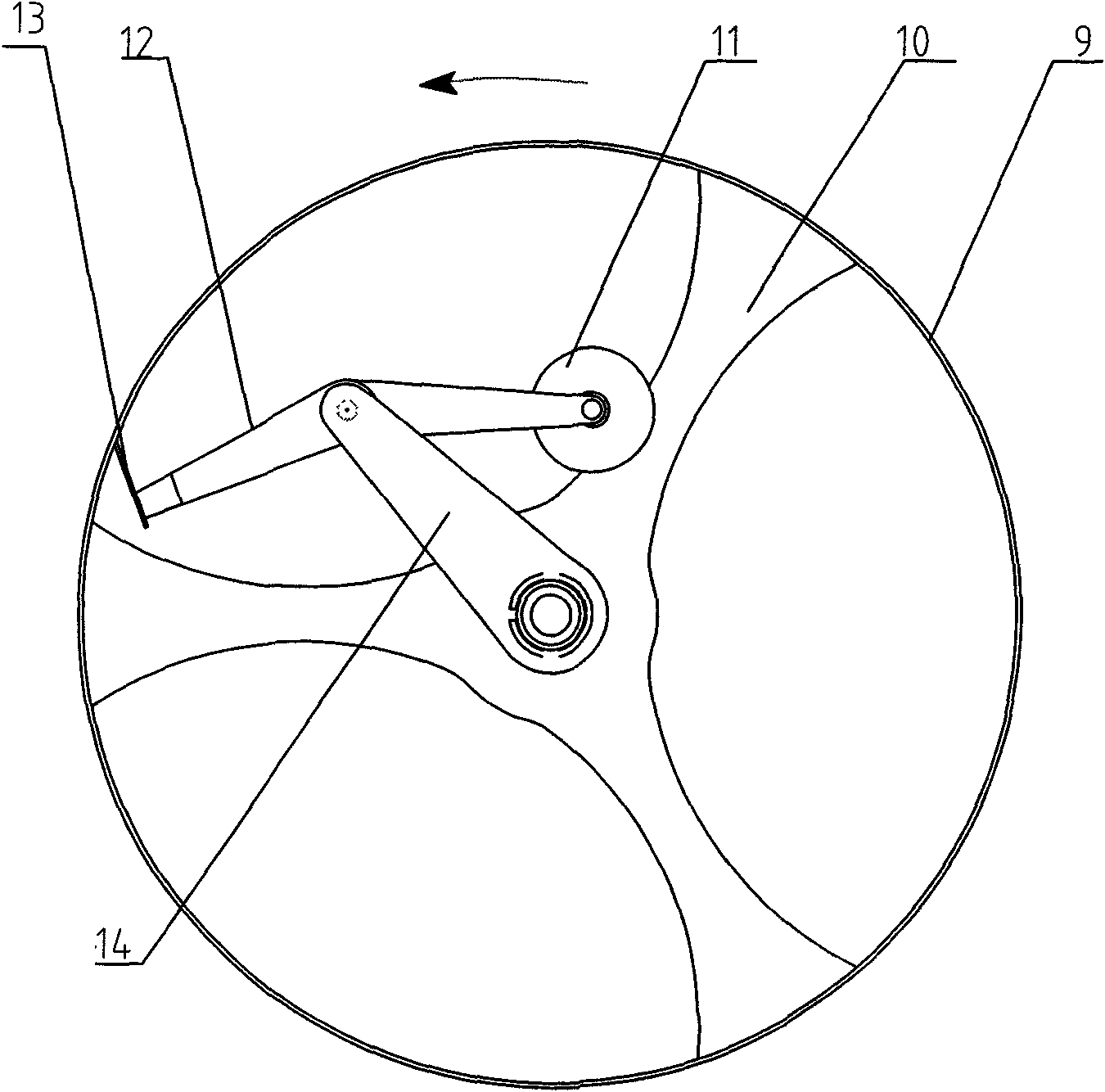

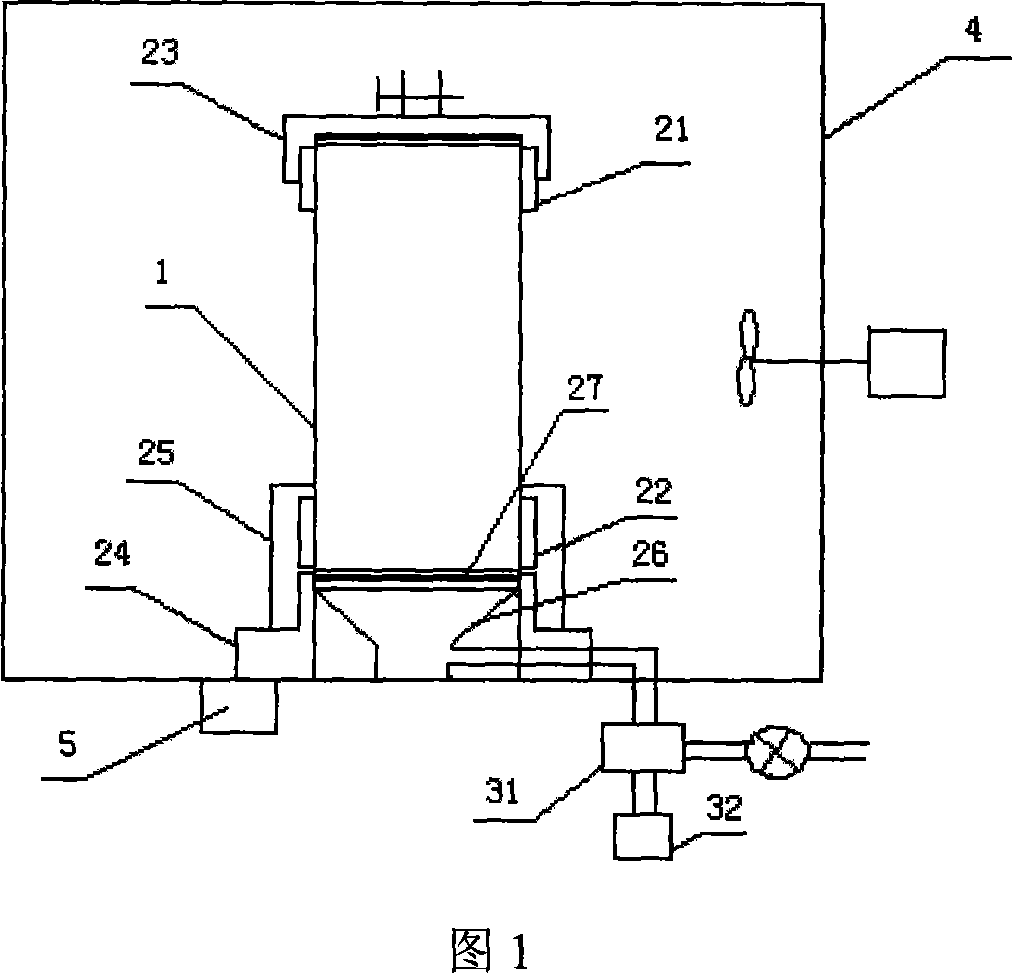

Anti-coking process of oiling device and automatic decoking device

ActiveCN101608130ARealize automatic continuous focus clearingSolve the problem of production scheduleLiquid hydrocarbon mixture productionThermal energyReaction temperature

The invention relates to an energy-saving anti-coking process in an oiling device, in particular to a process for reducing temperature difference for reaction by using a heat energy recycling system and setting a special decoking device in a cracker. The process is realized by mixing hot air exhausted in the decoking process with high-temperature hot air to be sent to the cracker before entering the cracker to reduce the temperature difference in the cracker. By adopting the process, the invention fully utilizes waste heat in the cracker, regulates the reaction temperature in the whole decoking process, greatly reduces the temperature difference so as to prevent coking phenomenon caused by great temperature difference in the reaction process; besides, as the special decoking device is assistantly used, the invention completely solves the coking problem in a cracking reactor, improves the reaction efficiency, reduces the load of the device, prolongs the service life of the device, reduces the production cost and decreases the energy consumption.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

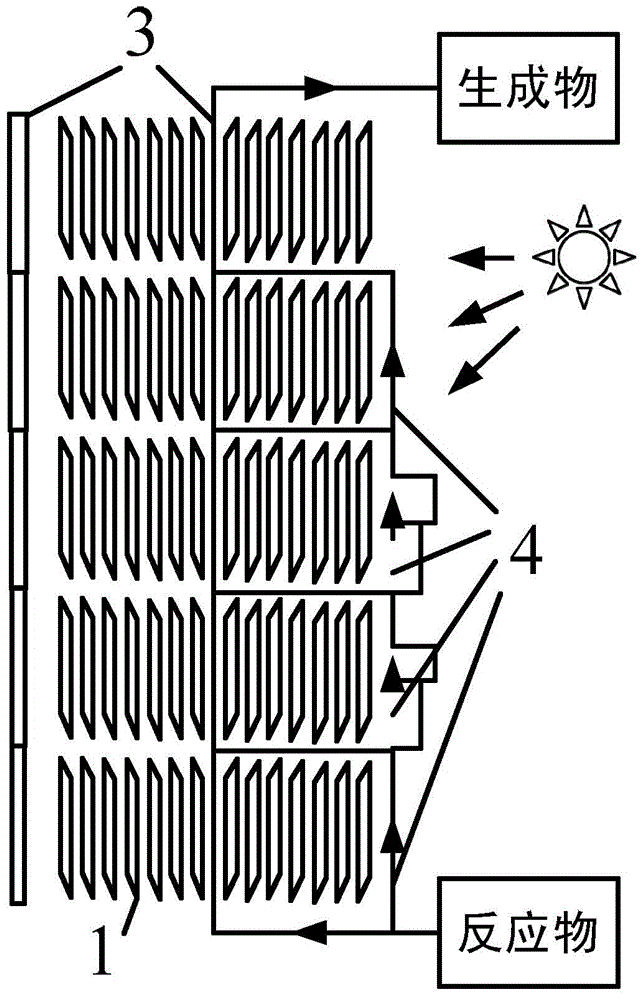

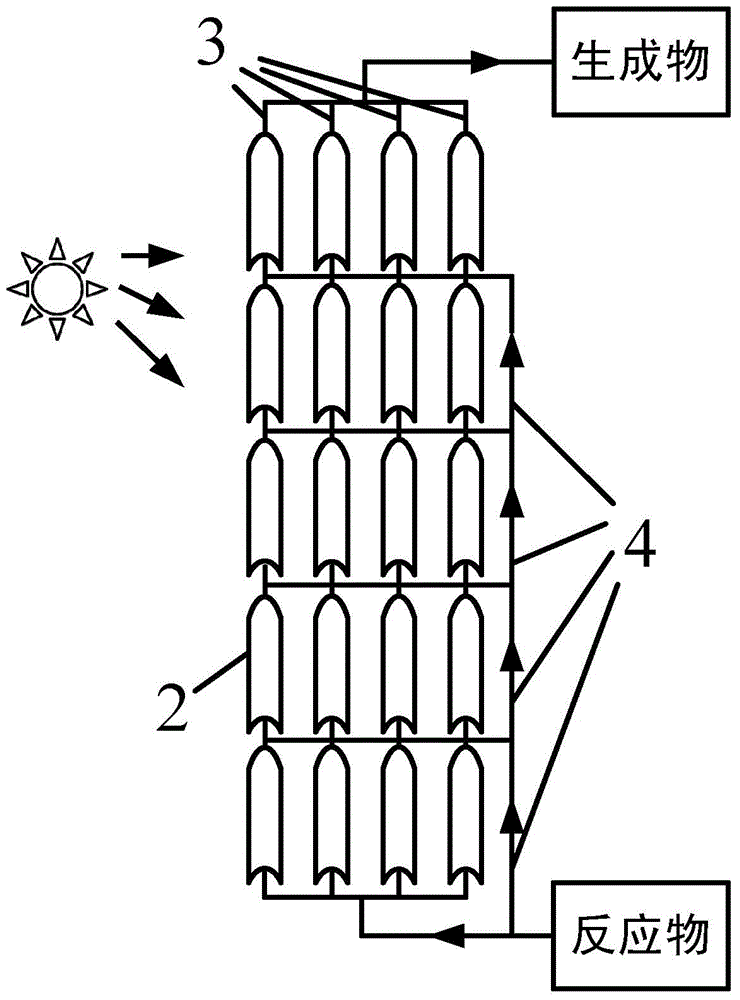

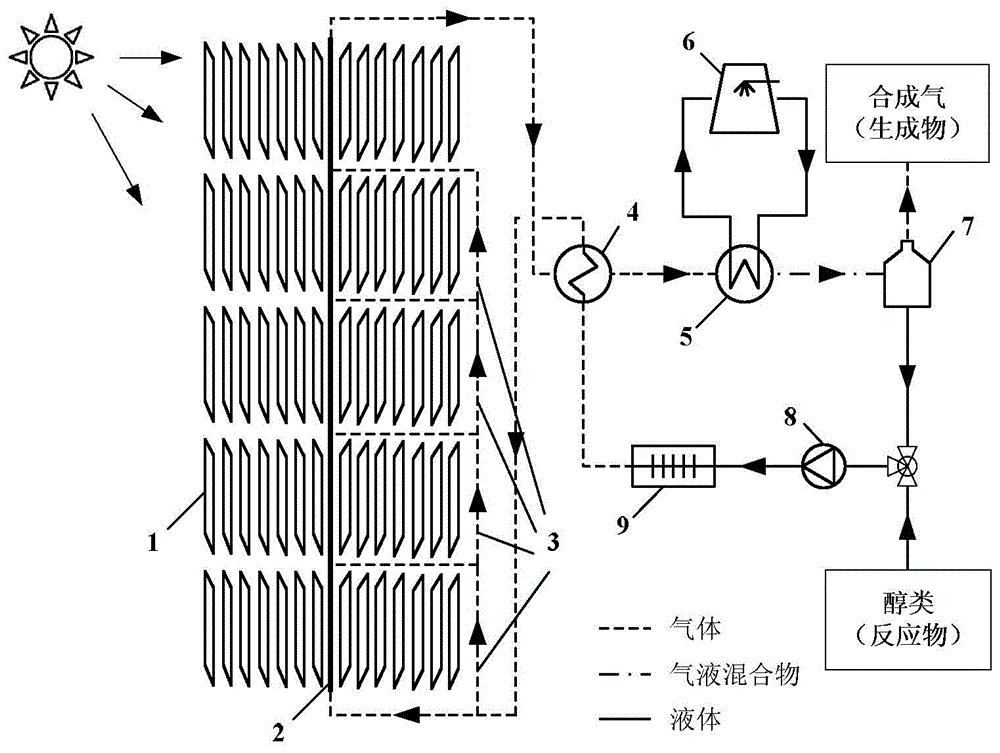

Multi-stage injection-type line focus solar absorption reactor

ActiveCN104826569ARelative partial pressure does not decrease significantlyDoes not significantly reduce the reaction rateHydrogenEnergy inputEnergy transferWorking fluid

The invention discloses a multi-stage injection-type line focus solar absorption reactor for middle and low temperature solar thermochemistry. The reactor includes a line focus reflective mirror array, variable diameter absorption reaction tubes and an injection pipe. The variable diameter absorption reaction tubes are arranged in a plurality of mirrors among the reflective mirror array; part of the reactant enters the absorption reaction tubes from the inlets on the ends of the reaction tubes, and the remaining reactant is injected into the absorption reaction tubes in a multi-stage way through the injection pipe along the tube; after entrance into the reaction tubes, the reactant is heated by the solar focused by the line focus reflective mirror array, and generates endothermic reaction under the catalyst condition, so as to convert solar energy into chemical energy of the resultant and improve response reactant grade. The invention improves the chemical processes and apparatus, so that the structure reasonably matches the parameters such as specific reaction characteristics and working fluid status in the absorption reaction tubes. The reactor achieves the efficient energy transfer and transformation, improves the overall reaction efficiency and reduces the overall energy consumption.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Feed method for coal tar hydrogenating unit

The invention relates to a feed method for coal tar. After the pressure of a coal tar raw material is boosted by a hydrogenation reaction raw material booster pump, the coal tar raw material enters a hydrogenation reactor without any indirect heat exchange; and before the pressure of the coal tar raw material is boosted, the coal tar raw material can be hot stream from a fractionating tower. The method can avoid a high-pressure heat-exchange temperature-rise process of the coal tar, eliminate the problem of fouling of high-pressure coal tar heat exchangers, reduce the hydrogenation catalyst bed pressure drop, slow down the coking, and prolong the operation cycle.

Owner:何巨堂

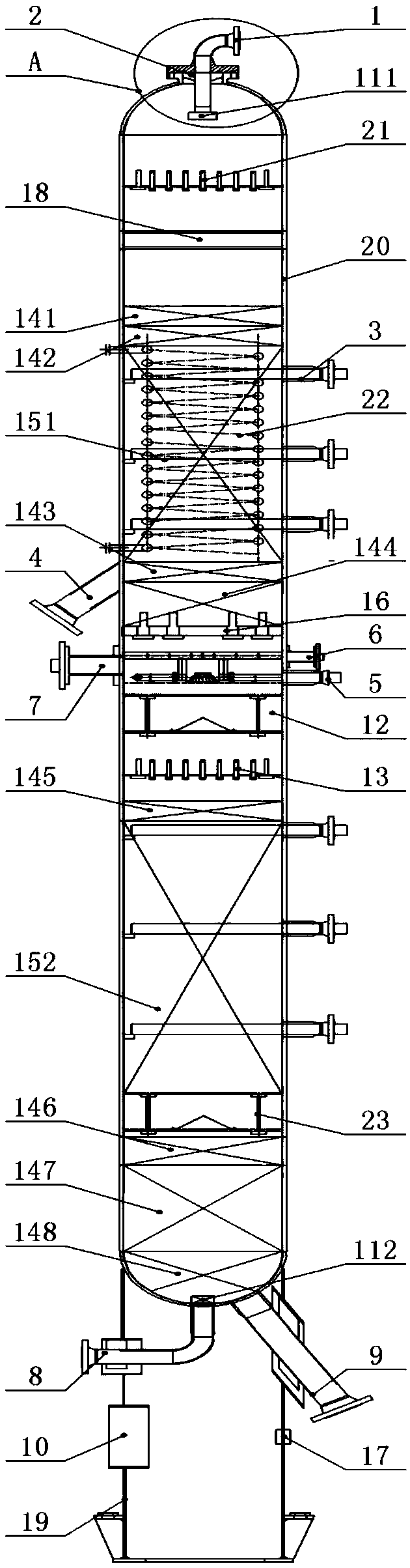

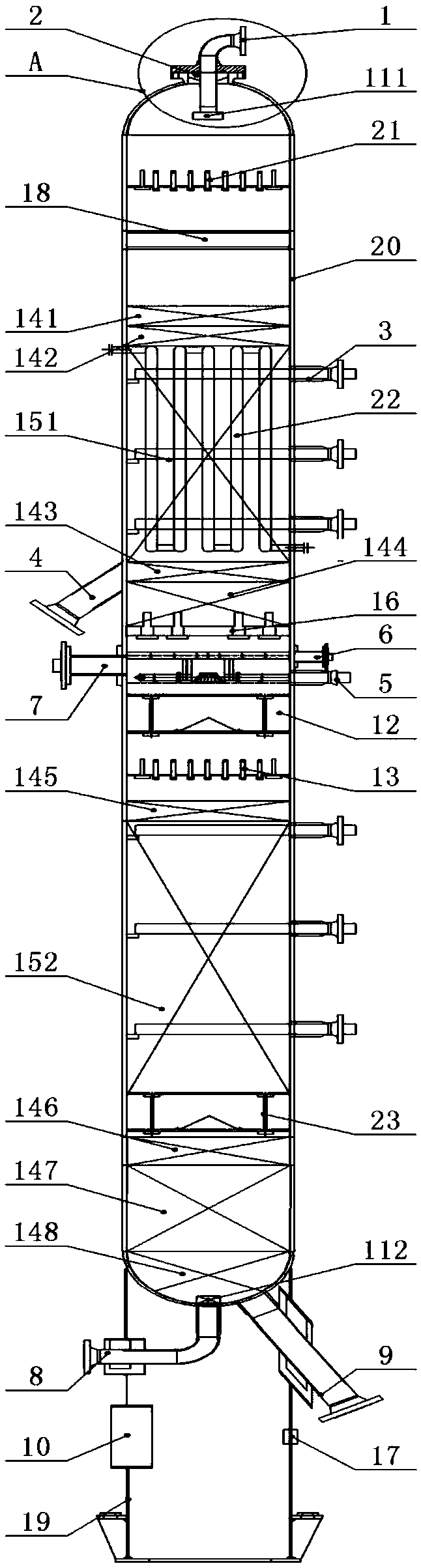

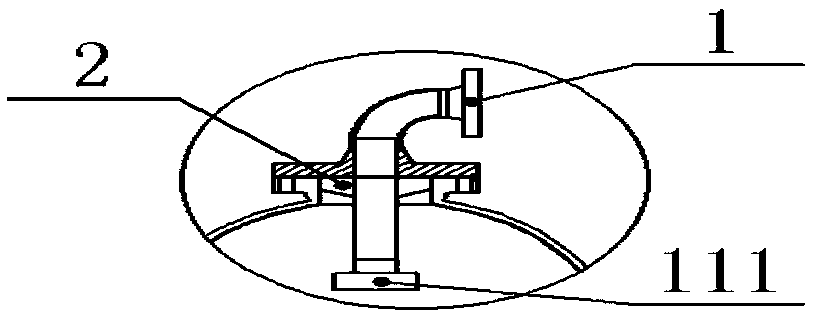

Hydrogenation reactor apparatus for hydrogenation reaction

PendingCN109304133AMonitor temperature in real timeAdjustable temperatureEnergy based chemical/physical/physico-chemical processesHydrogenation reactionReaction temperature

The invention relates to a hydrogenation reactor apparatus for hydrogenation reaction. The hydrogenation reactor apparatus comprises a tower shell, and is characterized in that a barrel body of the tower shell is of a hollow cylinder structure, and the bottom of the tower shell is provided with a discharging pipe. According to different production conditions, the reaction temperature and the reaction pressure in the tower shell can be monitored in real time, so that the reaction temperature and reaction pressure in the tower shell can be adjusted, so as to control the hydrogenation reaction, and by arranging an air blowing apparatus I, an air blowing apparatus II and an upper cooling apparatus, the reaction temperature is effectively reduced; by arranging an inlet diffuser, a distributor,a ceramic ball layer I, a ceramic ball layer II, a ceramic ball layer III, a ceramic ball layer IV, a ceramic ball layer V, a ceramic ball layer VI, a ceramic ball layer VII, a ceramic ball layer VIIIand a re-distributor, the uniform liquid supply can be realized; and by arranging an illumination light source, the illumination catalytic reaction is realized, and the catalytic conversion efficiency can be improved.

Owner:ARSD TIANJIN ENERGY TECH CO LTD

Preparation method of structured lipid with long carbon chain and low calorie

The invention relates to a preparation method of a structured lipid with a long carbon chain and low calorie. The preparation method is mainly characterized by comprising the steps of dissolving glycerin and rice bran wax (of which the mol ratio is (2:1)-(7:1)) into isooctane and tert-amyl alcohol solvents (of which the volume ratio is 7:3) in a concentration of 10%; placing on a magnetic stirrer with a speed of 200rpm / min; heating at 50-70 DEG C, and stirring until substrates are uniformly mixed; adding 4-10% of lipase in percentage by weight, and reacting for 6-36 hours; after completing reaction, removing lipase in a product by virtue of filtration, removing organic solvents by virtue of rotary evaporation, then removing unreacted glycerin by virtue of water washing, and performing vacuum drying to obtain a powdered solid product. The preparation method disclosed by the invention is low in cost and simple in experimental operation, can be used for respectively obtaining triglyceride, diglyceride and monoglyceride by controlling different reaction conditions, and can be used for determining applications of the product according to the characteristics of melting points.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for recovering multiple components through dilute ethylene

InactiveCN107739628AReduce loadReduce energy consumptionGaseous fuelsLiquid hydrocarbon mixtures productionChemistryFuel oil

The invention relates to a method for recovering multiple components through dilute ethylene. The method sequentially comprises the following steps of after water washing catalytic cracking dry gas containing ethylene with the concentration of 15 to 25V percent, desorbing residual ethanol amine to enable the ammonia nitrogen content in the raw material dry gas to be smaller than 100ppm; after preliminarily preheating cold dry gas through a first heat exchanger, continuously preheating through a second heat exchanger, then entering a raw material heating furnace for heating to the reaction trigger temperature, and entering a catalytic reactor for reacting to generate a fuel oil component and a liquefied petroleum gas component; feeding a reaction product into the second heat exchanger for preheating the raw material dry gas for the second time, carrying out fractionation on the cooled reaction product, pumping fractionated heavy fuel oil components out from a tower bottom of a fractionating tower, cooling through a first cooler, then feeding into a heavy fuel oil storage tank through an oil pump, and storing; distilling off a fractionated oil gas component from a gas phase outlet ofthe fractionating tower on the top part of the fractionating tower, and entering a hot side of the first heat exchanger for preheating the raw material dry gas for the first time. The method can be used for directly recovering fuel oil components, liquefied petroleum gas and other components.

Owner:CHINA PETROLEUM & CHEM CORP +1

Basolan wool processing technology

ActiveCN102535179BAdjust the reaction temperatureAdjust the pH value of the reactionDry-cleaning apparatus for textilesAnimal materialReaction temperatureEngineering

The invention relates to a basolan wool processing technology. According to the basolan wool processing technology designed by the invention, a basolan processor is used for processing wool; the usage of a basolan auxiliary is increased to be 4-6% of the weight of the wool; the PH value is 4-5; the water temperature is 20-25 DEG C; the liquid rate is 100%; after the wool is processed by using a basolan DCCA (Drying Control Chemical Additive) penetrating agent in the basolan processor, the wool remains in a remaining tank for 6-10 minutes and the temperature in the remaining tank is kept at 25 DEG C; and then five tank-washing processes are performed, thereby finishing the technology. The basolan DCCA auxiliary is adopted in the basolan wool processing technology, so that the handling capacity for the wool is 4-6%, the reaction time is prolonged to 6-10 minutes, the reaction temperature is adjusted, the reaction PH value is adjusted and the softening agent is adjusted. The processed and obtained basolan wool finally reaches the machine washable standard of the international wool bureau; a balanced joint point at the aspects of the products, such as looseness, dyeing vividness, felting contraction resistance, and the like, is obtained; and the basolan wool fully meets the market requirement.

Owner:浙江新中和羊毛有限公司

Fluidized-bed reactor for powder material

InactiveCN101073760AKeep abreast of the bonding situationHigh strengthDrying solid materials with heatChemical/physical processesFluidized bedReaction temperature

The invention is concerned with the boiling bed reaction equipment for the powder material, includes: the glass main reactor (-), the combination tie-in, the gas heating system, the heating constant temperature system (-), the shaking equipment (-), the combination tie-in sealing glass main reactor (-), the heating constant temperature system (-) provides the constant temperature reaction environment for the glass main reactor (-), the shaking equipment (-) sets at the bottom of the heating constant temperature system (-). The equipment is easy for observing the reaction process, realizing felt of the powder material in order to adjust the reaction temperature, improve the molecular weight of the production and the intensity of the product.

Owner:DONGHUA UNIV

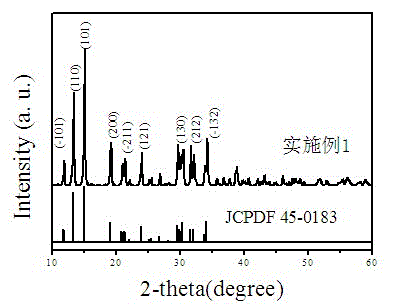

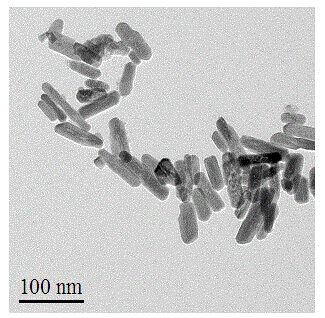

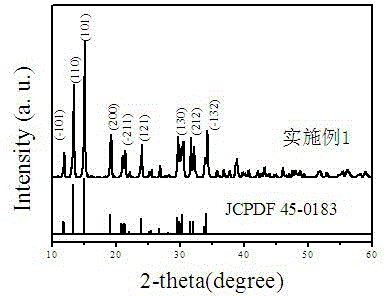

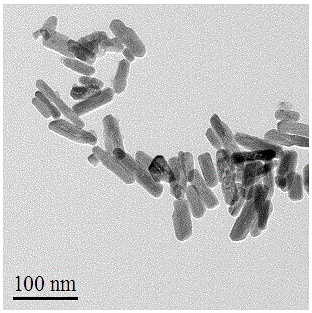

Synthesis method of nanorod-shaped AlPO4-15

ActiveCN104528754AExtended reaction timePromote formationMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesUreaAluminium

The invention discloses a synthesis method of nanorod-shaped AlPO4-15, and belongs to the field of nanomaterials. The method comprises the following steps: 1, dissolving an aluminum salt in water to prepare an aluminum salt solution with the concentration of 0.8-3mol / L; 2, adding urea to the aluminum salt solution according to a molar ratio of the aluminum salt to urea of 4:1-15:1, and stirring for 10-60min; 3, adding phosphate to a solution obtained in step 2 according to a molar ratio of Al:P of 1:1, and stirring for 10-60min; and 4, transferring a solution obtained in step 3 to a hydrothermal reaction kettle, reacting at 130-160DEG C for 30-72h, filtering after the reaction ends, washing the obtained filter cake, and drying to obtain nanorod-shaped AlPO4-15 powder. AlPO4-15 nanorods are formed through self-assembling under hydrothermal synthesis conditions by changing the content of urea, prolonging the reaction time and adjusting the reaction temperature.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

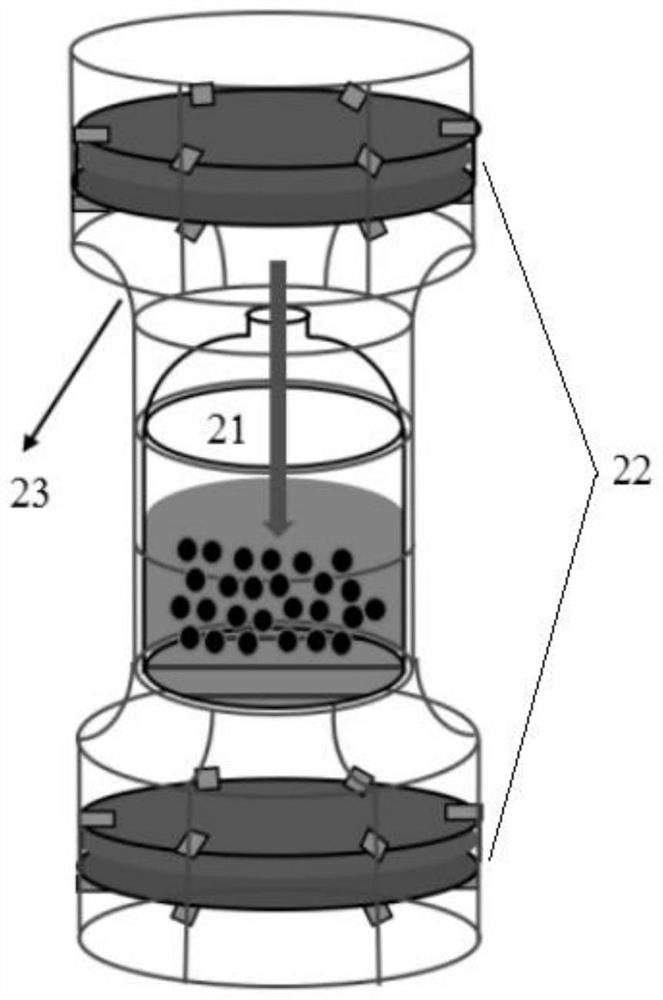

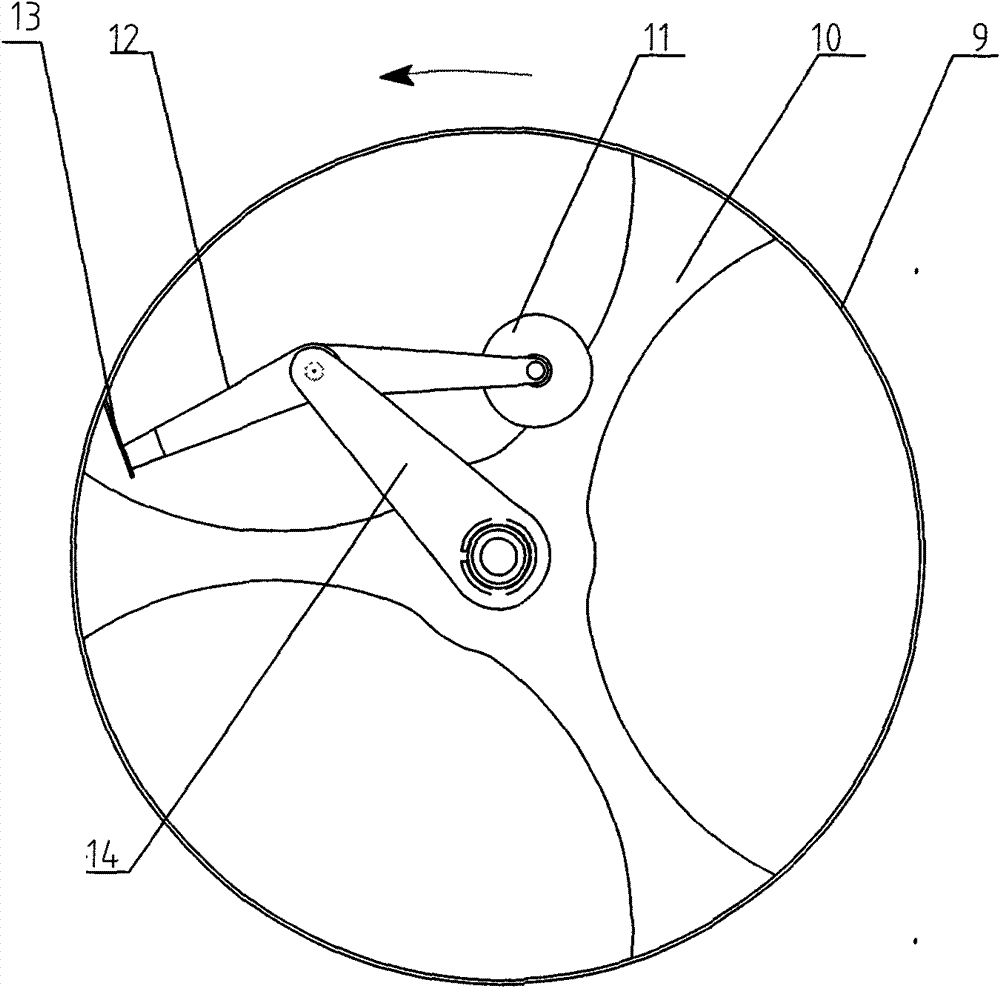

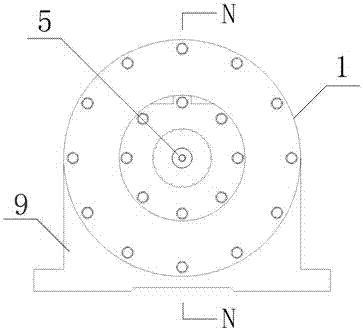

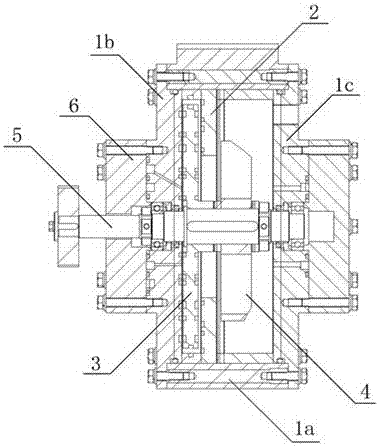

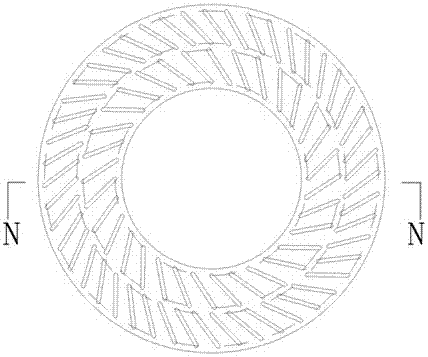

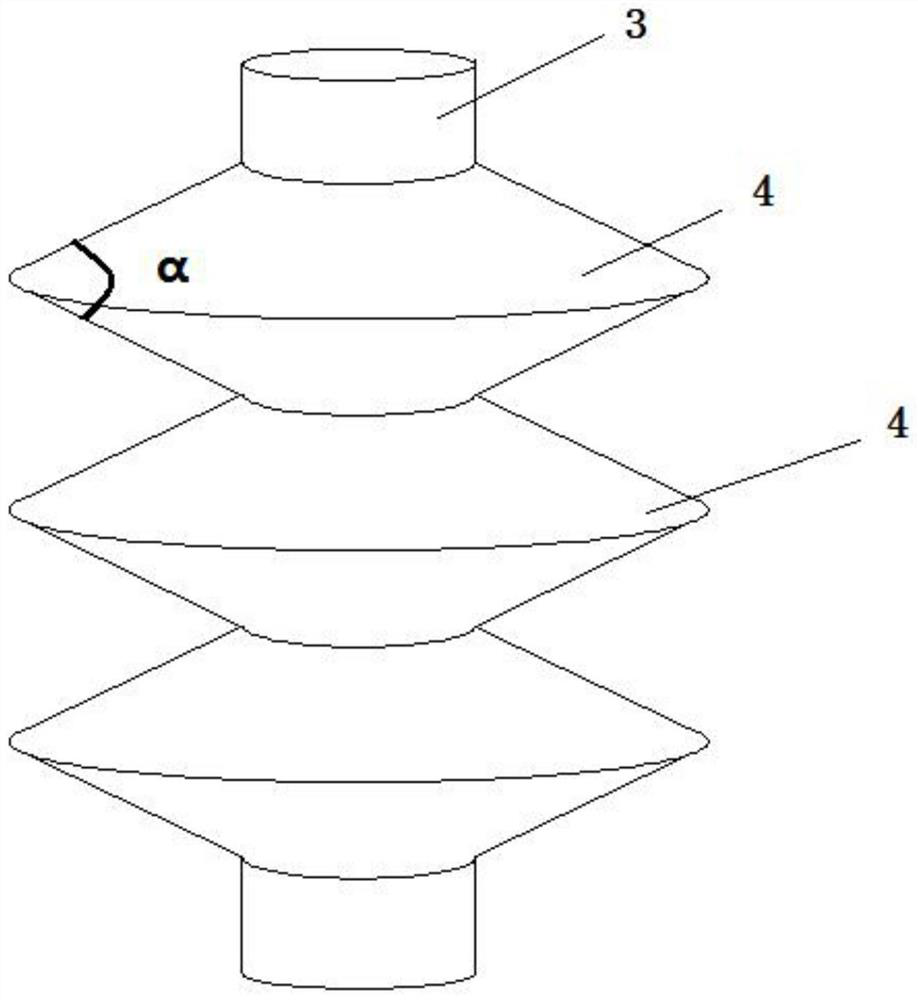

Multi-layer rotating disc thin-layer chemical reactor and using method thereof

ActiveCN111495301AIncrease the reactive surface areaExtended reaction timeDispersed particle separationLiquid solutions solvent extractionPhysicsReaction timing

The invention discloses a multi-layer rotating disc thin-layer type chemical reactor and a using method thereof. The chemical reactor comprises a shell; an outer fixed disc is fixedly arranged in theshell; at least one discharge hole is formed, a rotating shaft is arranged in the center of an inner cavity of the outer fixed disc, a plurality of layers of inner rotating discs are fixed on the rotating shaft, the inner rotating discs are gap type cavities which are consistent with the inner rotating discs and the rotating shaft in shape, and the outer fixed disc inner cavity and the inner rotating discs are used for mixing materials of all phases and have narrow gaps; the upper surface and the lower surface of the inner rotating disc are both inclined faces inclining outwards from the rotating shaft. The inner rotating disc and the outer fixed disc are matched to form a narrow zigzag cavity to form a Z-shaped or S-shaped mixing chamber, so that the reaction surface area is increased, the reaction time is prolonged, the mass transfer rate is increased, and the reaction rate is increased; according to the invention, two operation modes of forward flow and reverse flow can be realized,especially under the condition of large specific gravity difference, the reverse flow operation can be realized, and the separation or reaction efficiency is improved.

Owner:宁波巨谷智能装备有限公司

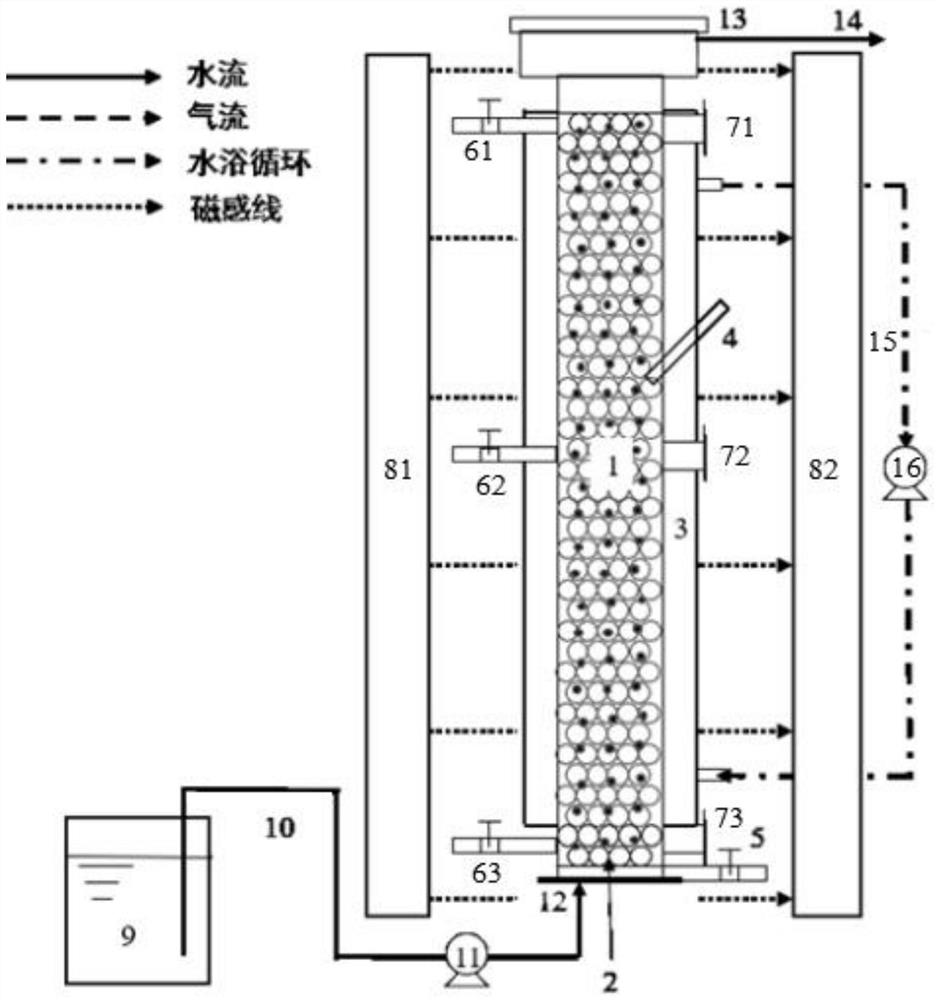

Method and device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through low-intensity magnetic field

InactiveCN113620413AIncrease the reflux ratioReduce corrosion potentialWater treatment parameter controlTreatment by combined electrochemical biological processesMicrobial inoculationMagnetic field gradient

The invention provides a method and a device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through a low-intensity magnetic field, and belongs to the technical field of denitrification. Under the action of a low-intensity magnetic field, microorganisms are inoculated on an iron-carbon carrier, nitrate-nitrogen-containing inlet water is introduced, iron-carbon micro-electrolysis corrosion hydrogen evolution and iron-carbon micro-electrolysis autotrophic denitrification are carried out, and nitrate-nitrogen-removed outlet water is obtained. Iron-carbon micro-electrolysis autotrophic denitrification is carried out under the condition of a low-intensity magnetic field, the activity of microorganisms and related enzymes can be improved, the corrosion potential of an iron-carbon carrier can be reduced, the iron-carbon micro-electrolysis corrosion hydrogen evolution rate is increased, the precipitation position and the precipitate attribute can be changed through the Lorentz force and the magnetic field gradient force effect, therefore, the formation of an iron-carbon carrier passivation film is relieved, and the nitrate nitrogen removal effect of microorganisms is effectively improved.

Owner:BEIJING JIAOTONG UNIV

Water diversion recovering device for polycarboxylic acids series dehydragent macromer preparation

InactiveCN101249317BApplicable preparationAvoid joiningNon-miscible liquid separationMolecular sieveWater discharge

The invention relates to a water separation recovery device for preparing a polycarboxylic acid type water-reducer macromonomer, including a water separator, a liquid mixing pipe, a return pipe and adischarge pipe, the discharge pipe is arranged at the bottom part of the water separator, the liquid mixing pipe is arranged at the top part of the water separator, the return pipe is arranged at theupper-middle position of the water separator, the lower part of the discharge pipe is connected with a material discharging three-way valve, the material discharging three-way valve is respectively connected with a solvent recovery pipe, an automatic water drainage pipe and a water discharge pipe, the other end of the solvent recovery pipe is connected with a dehydration molecular sieve device, the other end of the automatic water drainage pipe is connected with a water collecting barrel, a solvent recovery valve, an automatic water drainage valve and a water discharge valve are respectively arranged on the solvent recovery pipe, the automatic water drainage pipe and the water discharge pipe, and the lower part of the dehydration molecular sieve device is connected with a solvent dischargepipe and a solvent discharge valve. The device is visible and convenient in operation and comprises the solvent recovery and recycling device, which has higher production efficiency.

Owner:NINGBO QIHANG ASSISTANT

Anti-coking process of oiling device and automatic decoking device

ActiveCN101608130BSolve cokingAdjust the reaction temperatureLiquid hydrocarbon mixture productionReaction temperatureProcess engineering

The invention relates to an energy-saving anti-coking process in an oiling device, in particular to a process for reducing temperature difference for reaction by using a heat energy recycling system and setting a special decoking device in a cracker. The process is realized by mixing hot air exhausted in the decoking process with high-temperature hot air to be sent to the cracker before entering the cracker to reduce the temperature difference in the cracker. By adopting the process, the invention fully utilizes waste heat in the cracker, regulates the reaction temperature in the whole decoking process, greatly reduces the temperature difference so as to prevent coking phenomenon caused by great temperature difference in the reaction process; besides, as the special decoking device is assistantly used, the invention completely solves the coking problem in a cracking reactor, improves the reaction efficiency, reduces the load of the device, prolongs the service life of the device, reduces the production cost and decreases the energy consumption.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

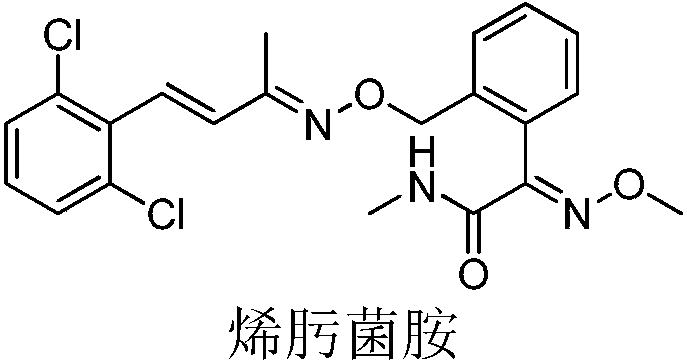

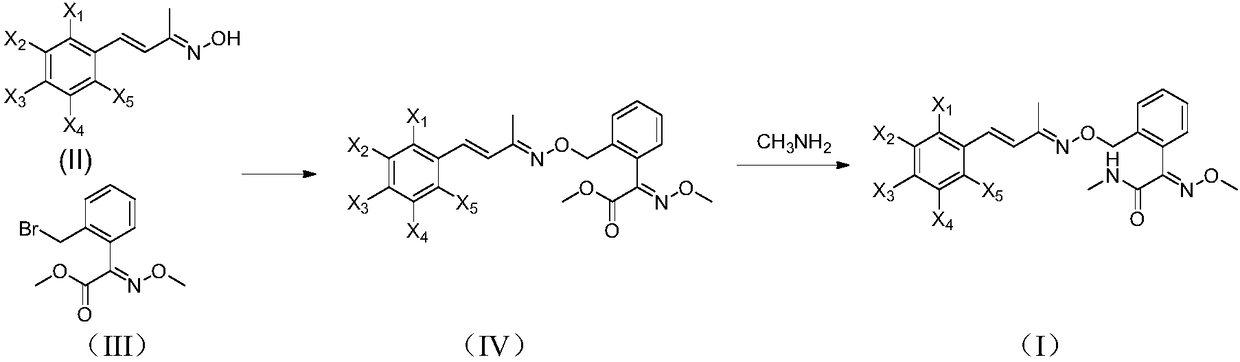

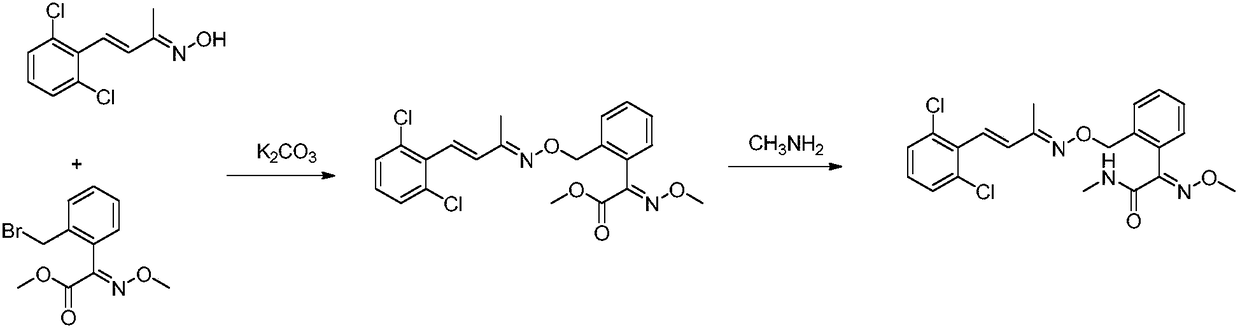

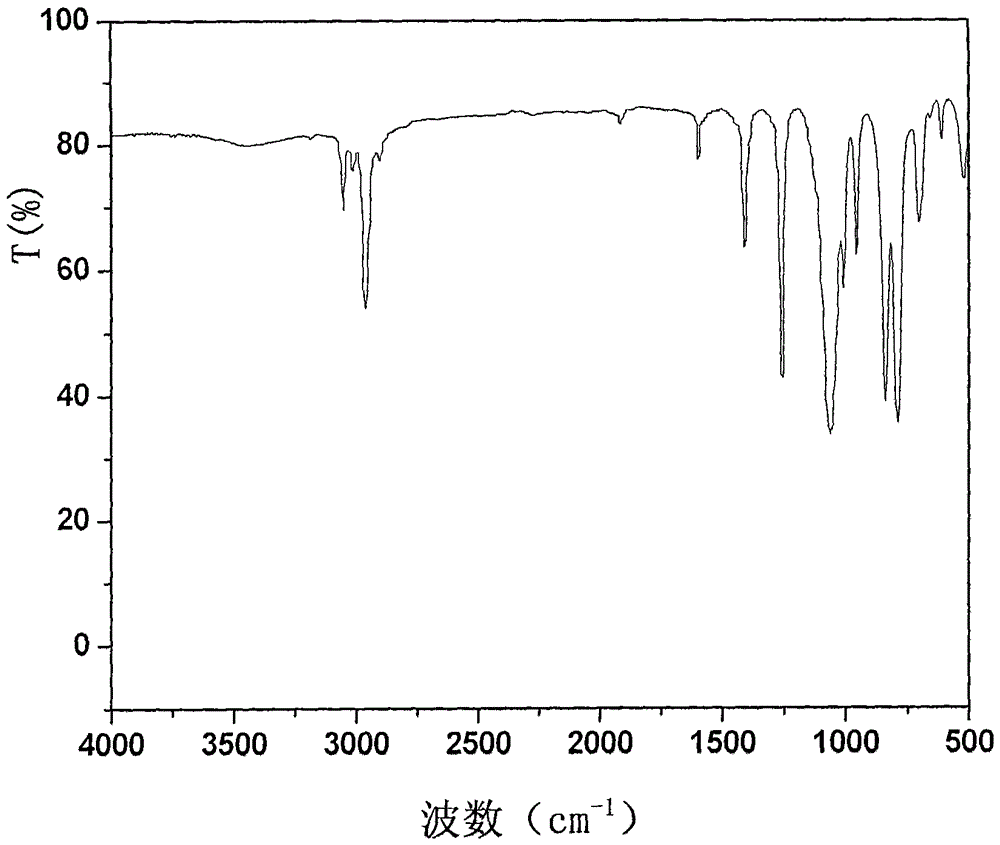

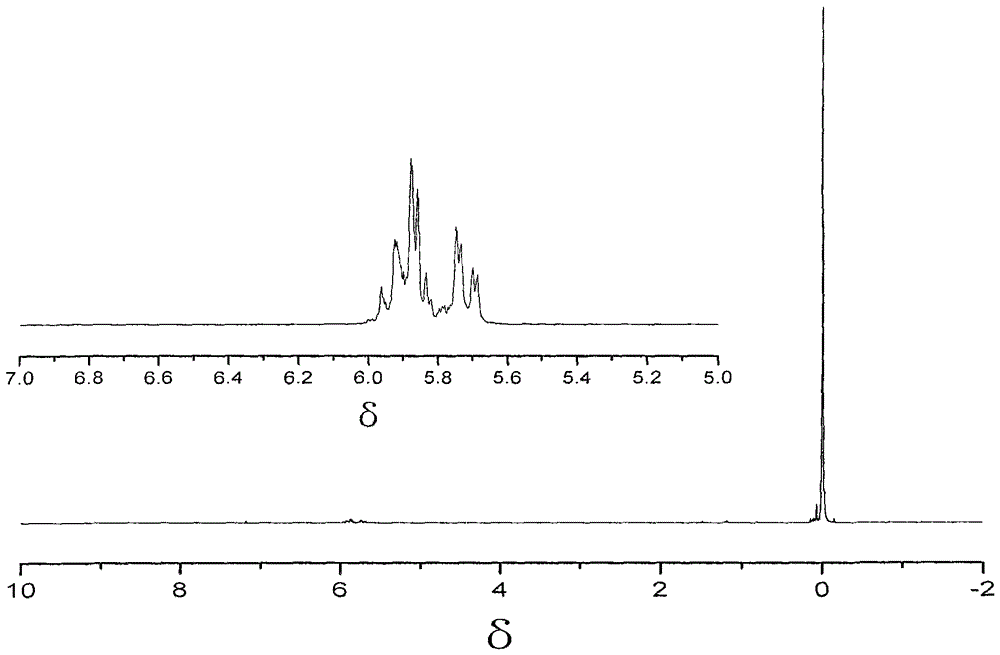

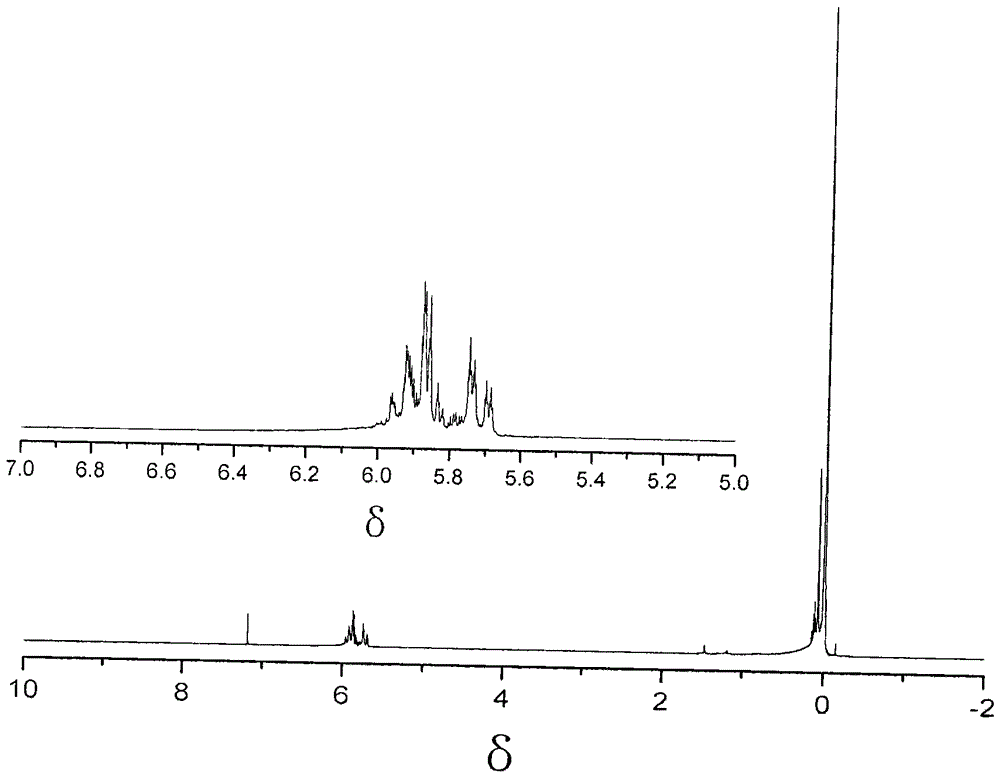

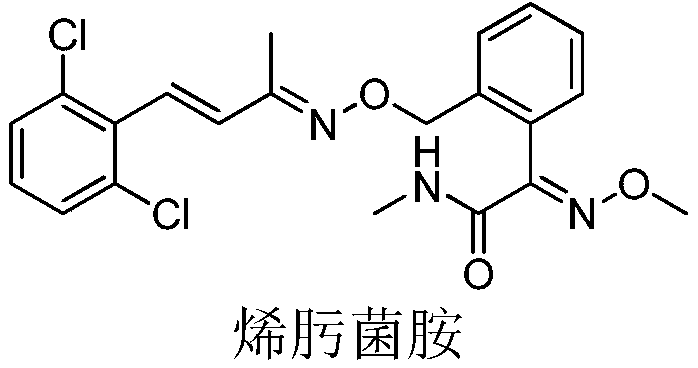

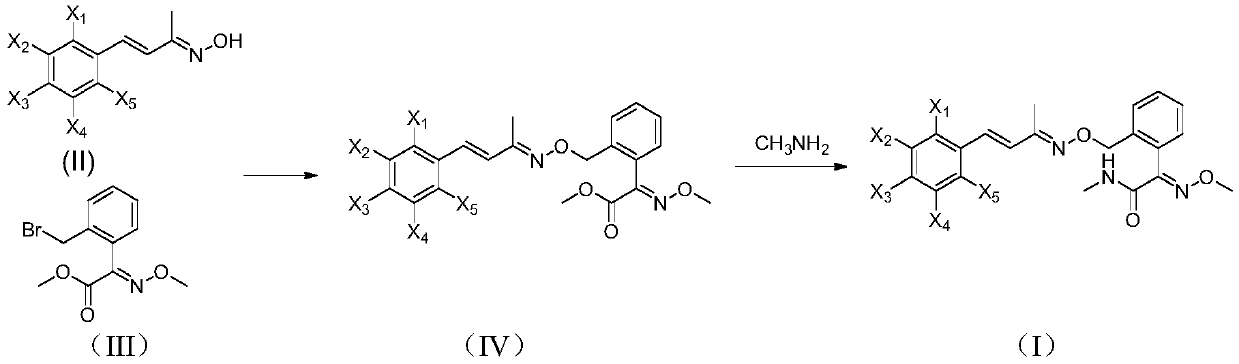

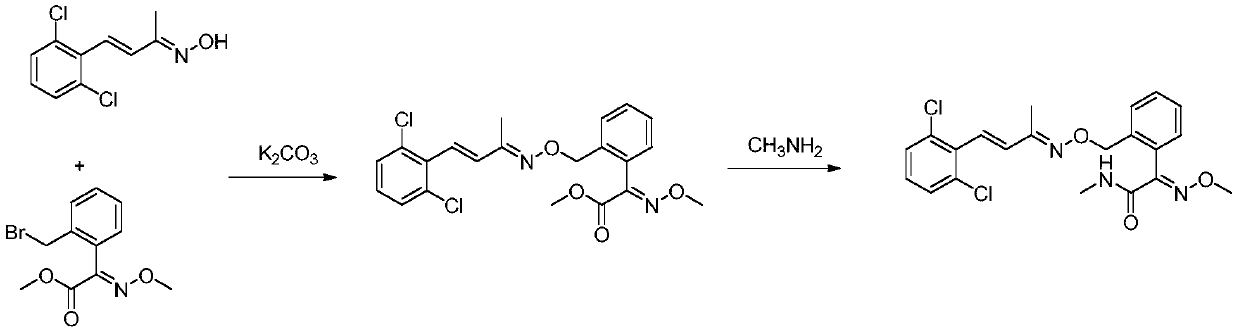

Unsaturated oxime ether compound preparation method

ActiveCN108191709AHigh reaction yieldHigh bactericidal activityOximes preparationKetone solventsCompounded preparations

The invention relates to an unsaturated oxime ether compound (I) preparation method, wherein the reaction formula is defined in the specification, and each group in the formula is defined in the specification. According to the present invention, with the method, styryl methyl ketone oxime (II) and bromo oxime ether (III) are subjected to a reaction in a ketone solvent by using a carbonate as an alkali to prepare a high-yield oxime ether compound (IV), and further the unsaturated oxime ether compound (I) is prepared through aminolysis under the action of methylamine.

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

A kind of preparation method of specific vinyl content polysiloxane

ActiveCN104031267BAdjust the reaction temperatureIncrease or decrease reaction timePolymer scienceEnd-group

The invention relates to a preparation method of polysiloxane with a specific content of vinyl groups. The preparation method concretely comprises the following steps: adding 50-300mg of a dewatered hexamethylcyclotrisioxane monomer and 100-1000m of 1,3,5-trivinyl-1,3,5-trimethylsiloxane monomer to a 5ml new distilled tetrahydrofuran solvent, add 10 drops of an n-butyl lithium solution, reacting at 40DEG C for 20h, adding frozen anhydrous methanol for end group termination, allowing a polymer to precipitate, centrifuging, and carrying out rotary evaporation on the obtained precipitate to obtain polysiloxane with special content of vinyl groups. The polymerization process can be controlled through a controllable anionic ring opening polymerization reaction by changing a monomer feeding ratio, adjusting the reaction temperature, increasing or decreasing the reaction time and adding a chain termination agent in order to realize the regulation and control of the monomer conversion rate, the molecular weight and the vinyl group content.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

A nanorod-shaped alpo 4 Synthetic method of -15

ActiveCN104528754BPromote formationExtended reaction timeMaterial nanotechnologyMolecular-sieve and base-exchange phosphatesPhosphateSynthesis methods

The invention discloses a synthesis method of nanorod-shaped AlPO4-15, and belongs to the field of nanomaterials. The method comprises the following steps: 1, dissolving an aluminum salt in water to prepare an aluminum salt solution with the concentration of 0.8-3mol / L; 2, adding urea to the aluminum salt solution according to a molar ratio of the aluminum salt to urea of 4:1-15:1, and stirring for 10-60min; 3, adding phosphate to a solution obtained in step 2 according to a molar ratio of Al:P of 1:1, and stirring for 10-60min; and 4, transferring a solution obtained in step 3 to a hydrothermal reaction kettle, reacting at 130-160DEG C for 30-72h, filtering after the reaction ends, washing the obtained filter cake, and drying to obtain nanorod-shaped AlPO4-15 powder. AlPO4-15 nanorods are formed through self-assembling under hydrothermal synthesis conditions by changing the content of urea, prolonging the reaction time and adjusting the reaction temperature.

Owner:SHANDONG YUHUANG NEW ENERGY TECH +1

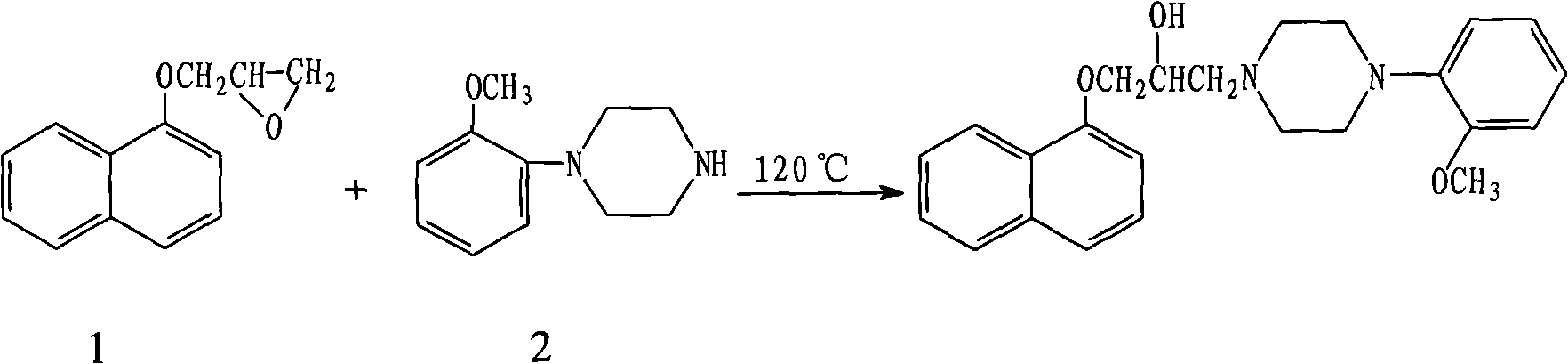

Preparation method of Naftopidil

ActiveCN101671317BAdjust the reaction temperatureRefining process optimizationOrganic chemistryPiperazine hydrobromidePotassium carbonate

The invention provides a preparation method of Naftopidil. In the presence of reaction solvent, a reflux reaction is carried out between 3-(1-naphthoxy)-1,2-propylene epoxide and o-methoxyphenyl piperazine hydrobromide, and then refined processing is carried out after the reaction, wherein, the reaction solvent is trichloromethane or dichloromethane; and the alkali matter is potassium carbonate water solution. The method in the invention improves the yield, improves the reaction yield to about 80% from the original 55-65%; and the refined products are white or almost white crystals, and the product quality accords with the medicinal requirement.

Owner:蚌埠丰原涂山制药有限公司

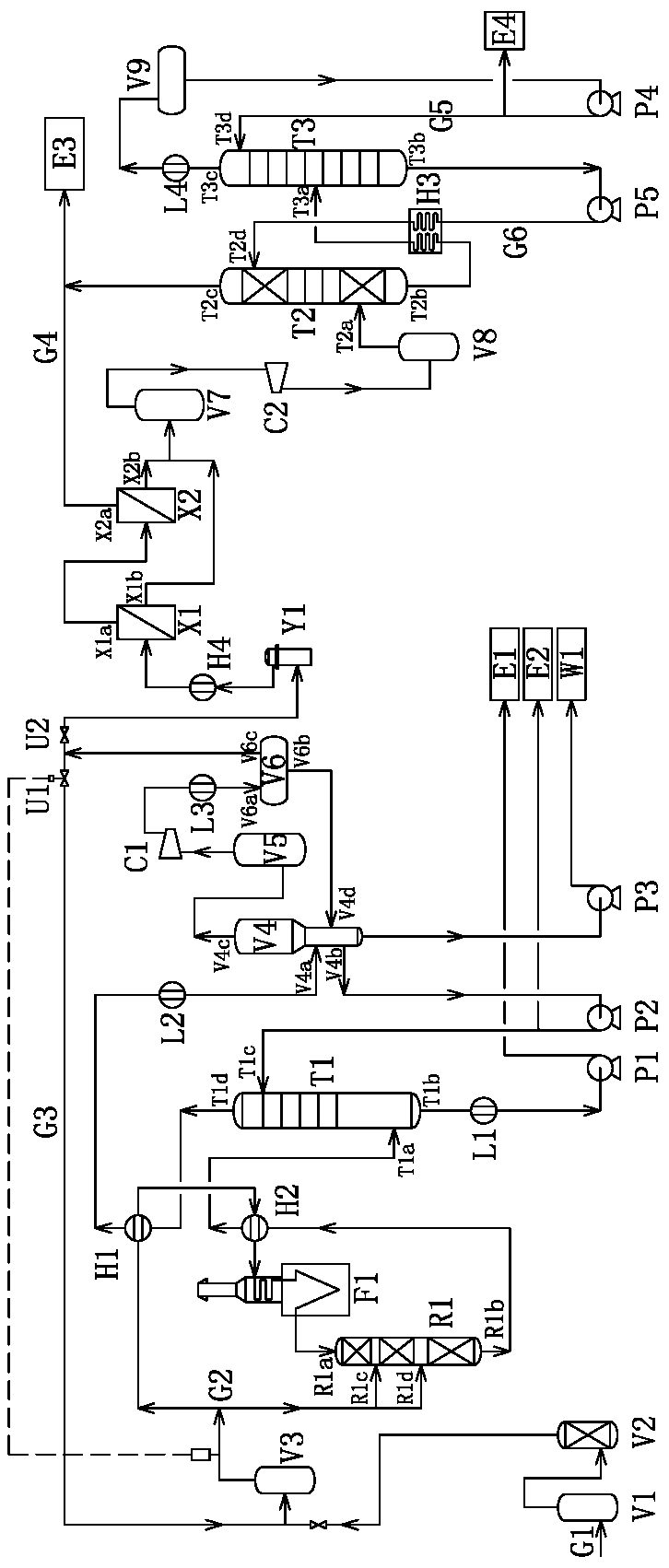

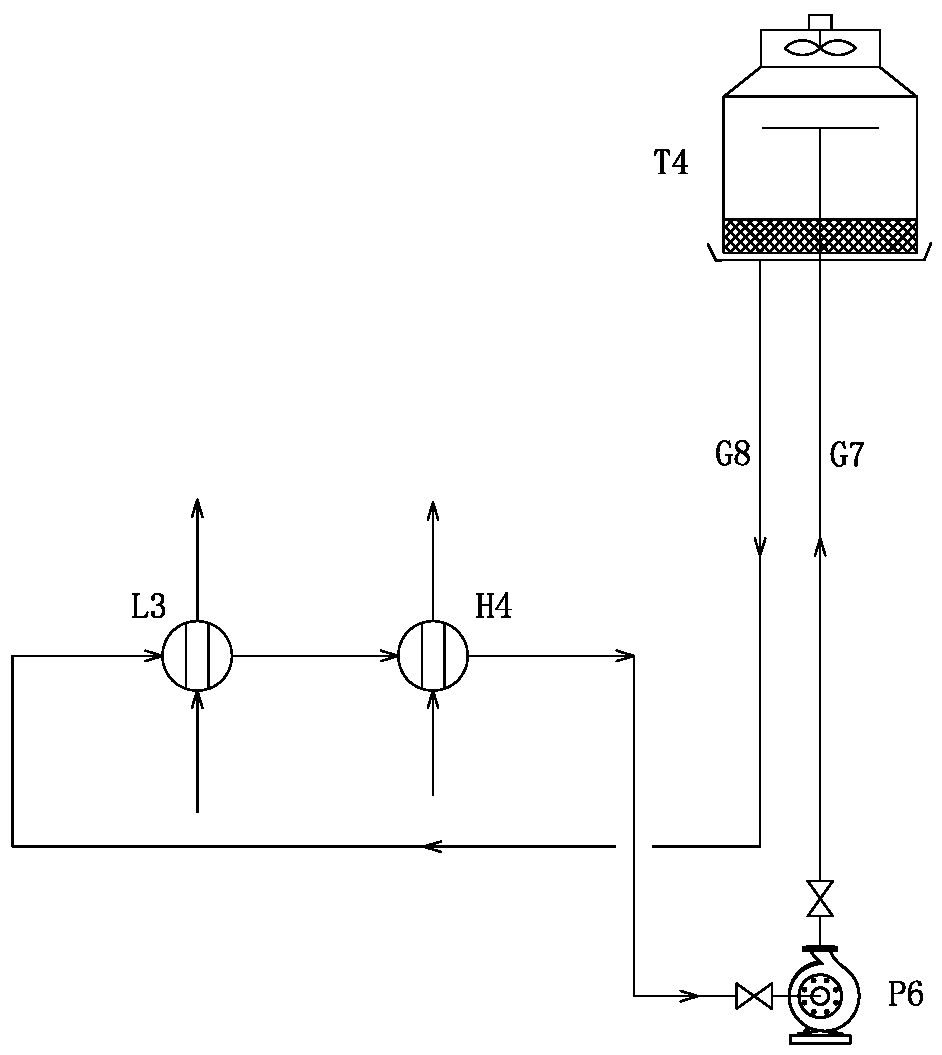

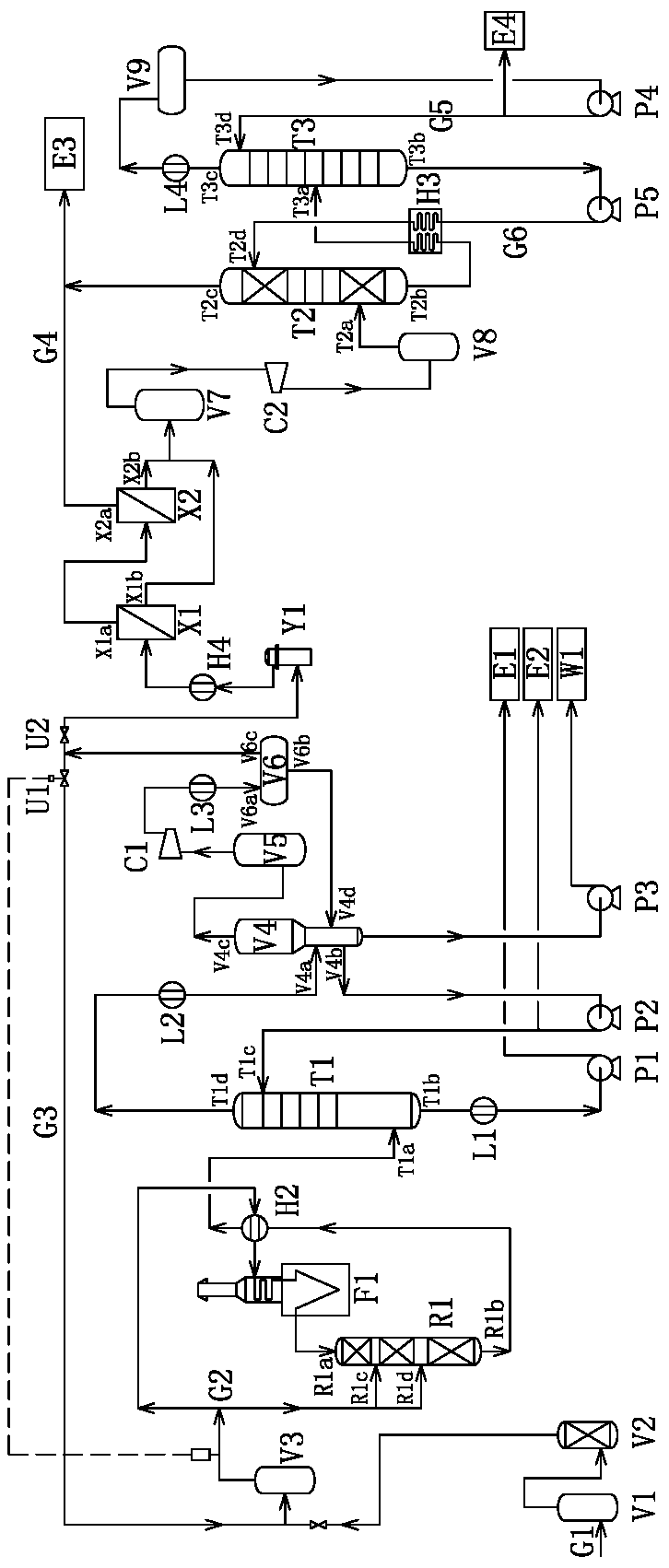

Hexamethylenediamine production system

PendingCN112337409AEvenly distributedReduce mechanical wear and tearAmino compound purification/separationOrganic compound preparationVapor–liquid separatorPtru catalyst

A hexamethylenediamine production system comprises at least two hydrogenation reactors, a gas-liquid separator and a gas-liquid separator, wherein the hydrogenation reactors are gas-liquid-solid three-phase fixed bed reactors, a heat exchange interlayer is arranged on the side wall of each hydrogenation reactor, and a heat exchange coil is arranged in each hydrogenation reactor; wherein the top ofeach hydrogenation reactor is connected with an adiponitrile source through a first feeding pipe, a first valve is arranged on each first feeding pipe, the bottom of each hydrogenation reactor is connected with a hydrogen source through a second feeding pipe, and a second valve is arranged on each second feeding pipe; the side wall of the hydrogenation reactor located at the high position is connected with a liquid-phase material source through a third feeding pipe and connected with the side wall of the hydrogenation reactor located at the low position through an overflow pipe, and the gas-liquid separator is arranged at the top of the corresponding hydrogenation reactor. The hexamethylenediamine production system is simple in structure and convenient to operate, can effectively reduce the mechanical loss of the catalyst, is convenient for enterprises to control the reaction temperature, and is beneficial to production of high-quality hexamethylenediamine products.

Owner:CHONGQING HUAFON CHEM

A kind of method for preparing unsaturated oxime ether compound

A preparation method of unsaturated oxime ether compound (I), the reaction formula is as follows: the definition of each group in the formula can be found in the description. The method reacts styryl methyl ketoxime (II) with bromoxime ether (III), and under the condition of carbonate as base, in a ketone solvent, the oxime ether compound ( IV), further reacting methylamine with aminolysis to obtain unsaturated oxime ether compound (I).

Owner:SHENYANG SINOCHEM AGROCHEMICALS R&D CO LTD

A single-phase or multi-phase reaction device that effectively improves mixing intensity and mass transfer rate

ActiveCN106111037BLarge specific surface areaIncrease mixing intensityChemical/physical/physico-chemical stationary reactorsImpellerDrive shaft

The invention relates to a single-phase or multi-phase reaction device capable of effectively improving the mixing intensity and the mass transfer rate and belongs to the technical field of chemical equipment. A shell of the single-phase or multi-phase reaction device consists of a feed end cover, a discharge end cover and a barrel and is fixed on a base; a transmission shaft penetrates through the barrel and is fixed by two bearing pedestals; an isolation ring disc divides the shell into two intervals, namely a mixing chamber and a separation chamber; the mixing chamber consists of the feed end cover, a mass transfer disc and the isolation ring disc; a feed through hole is formed in the feed end cover and is connected with the mixing chamber; the separation chamber consists of the isolation ring disc, an impeller and the discharge end cover; the mass transfer disc and the impeller are fixed on the transmission shaft and rotate along with the transmission shaft; reaction fluid enters the separation chamber and is centrifugally separated by the impeller fixed on the transmission shaft, a heavy phase is thrown to the outer ring of the shell, and a light phase is extruded to the periphery of the transmission shaft by the heavy phase; a light-phase discharge through hole is formed in a position, close to the transmission shaft, on the surface of the discharge end cover; a heavy-phase discharge through hole is formed outside the surface of the discharge end cover. The device can effectively improve the mixing intensity and the mass transfer efficiency.

Owner:宁波巨谷智能装备有限公司

A multi-layer rotating disk thin-layer chemical reactor and its application method

ActiveCN111495301BIncrease the reactive surface areaIncrease mass transfer rateDispersed particle separationLiquid solutions solvent extractionRotational axisChemical reactor

The invention discloses a multi-layer rotating disc thin-layer chemical reactor and a method for using the same. The chemical reactor includes a shell, an outer fixed plate is fixed inside the shell, and at least one discharge port is provided. The center of the inner cavity of the fixed plate is provided with a rotating shaft, and several layers of inner turntables are fixed on the rotating shaft. There are gap-shaped cavities with narrow gaps for mixing the materials of each phase; the upper and lower surfaces of the inner turntable are slopes inclined from the rotation axis to the outside. The present invention increases the reaction surface area and prolongs the reaction time by coordinating the inner rotating disk and the outer fixed disk to form a narrow zigzag cavity to form a Z or S-shaped mixing chamber, thereby enhancing the mass transfer rate and increasing the reaction rate; the present invention can also Realize both forward and countercurrent operation modes, especially in the case of large specific gravity difference, countercurrent operation can be realized to improve separation or reaction efficiency.

Owner:宁波巨谷智能装备有限公司

A kind of polyferric sulfate and preparation method thereof

ActiveCN105692717BAdjust the reaction temperatureIncrease acidityIron sulfatesWater/sewage treatment by flocculation/precipitationIron sulfateRare earth

The invention discloses polyferric sulfate as well as a preparation method and a preparation device of the polyferric sulfate. The preparation method comprises the following steps: conveying the following components into a mixing tank in percentage by weight: 40 percent to 50 percent of iron sulfate heptahydrate and 60 percent to 50 percent of titanium dioxide waste sulfuric acid, and blending the materials; adjusting the concentration range of the titanium dioxide waste sulfuric acid H2SO4 to be 21 percent to 23 percent to obtain mixed reaction materials; conveying the reaction materials into a reaction tower, and adding a sulfate composite rare-earth solution as a reaction cocatalyst when conveying the reaction materials into the reaction tower; controlling the temperature in the reaction tower to be 40 DEG C to 60 DEG C; after all the blended materials enter the reaction tower, adding a sodium nitrite solution as a reaction catalyst; continually introducing oxygen gas into the reaction tower so that the oxygen gas and the reaction materials make oxidization, hydrolysis and polymerization reactions under the action of the cocatalyst and the catalyst; after effectively converting Fe<2+> ions in the materials into Fe<3+> ions, obtaining liquid polyferric sulfate. With the adoption of the polyferric sulfate as well as the preparation method and the preparation device of the polyferric sulfate, the production efficiency can be greatly improved, environmental hazards are reduced, and a more prominent water purification and coagulation effect is realized.

Owner:广西继禹环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com