Hydrogenation reactor apparatus for hydrogenation reaction

A technology of hydrogenation reactor and hydrogenation reaction, applied in chemical/physical/physicochemical process of energy application, chemical instrument and method, chemical/physical/physicochemical process, etc. , unreasonable structural design and other problems, to achieve the effect of increasing catalytic conversion efficiency, reducing reaction temperature, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

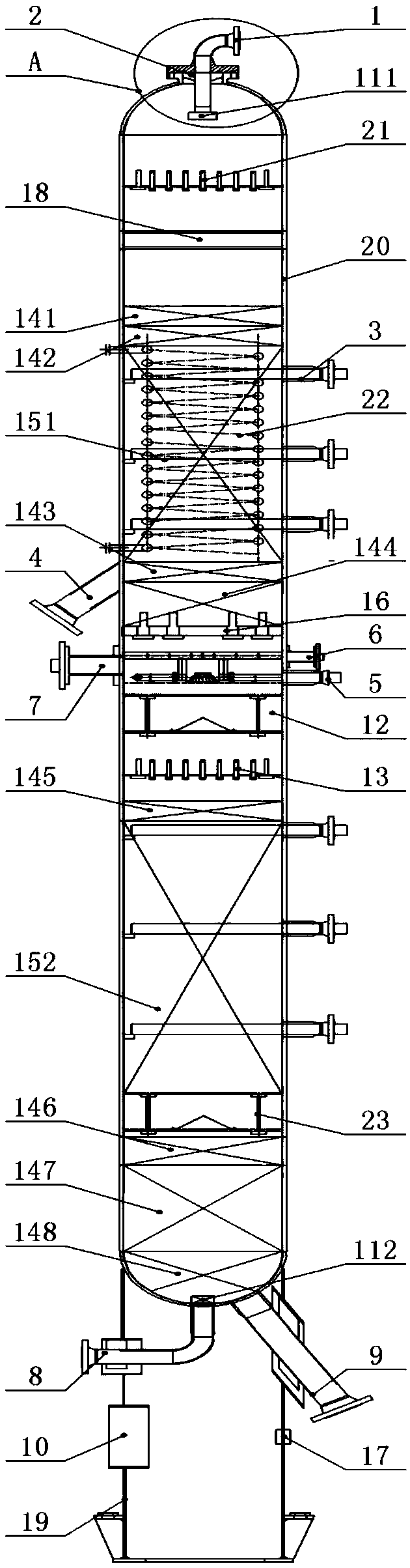

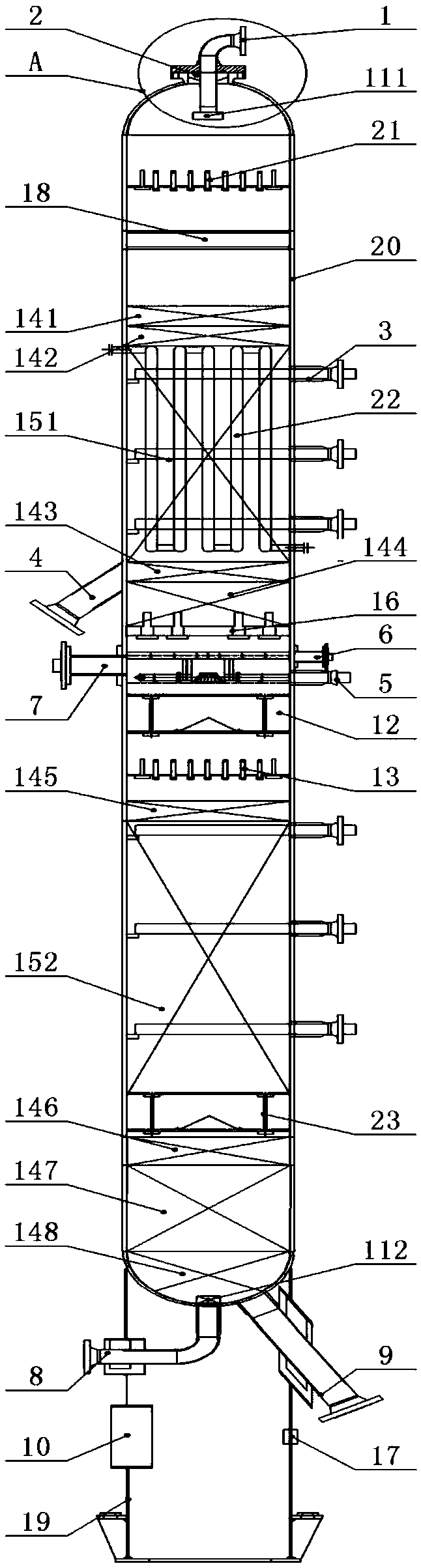

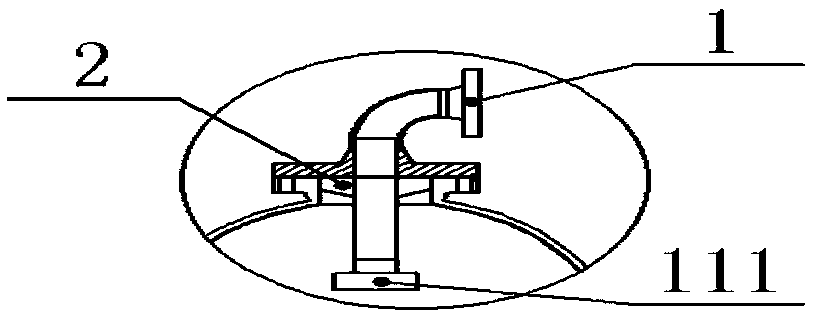

[0032] A hydrogenation reactor device for hydrogenation reaction, comprising a tower shell 20, characterized in that, the body of the tower shell 20 is arranged in a hollow cylindrical structure, and the tower shell 20 The bottom is fixed with a skirt 19, and the bottom of the skirt 19 is installed on the ground through anchor bolts. The skirt 19 is provided with an inspection access hole 10, and the skirt 19 is welded with an orifice 17. The outer surface of the skirt 19 is bound with a wire mesh to lay a fireproof layer through the installation hole plate 17. The upper head of the tower shell 20 is provided with a manhole-2, and the top of the tower shell 20 is equipped with an inlet. Material pipe 1, the feed end of described feed pipe 1 is connected with external material storage equipment, and described feed pipe 1 is positioned at the side setting of described manhole-2, and the discharge end of described feed pipe 1 and The interior of the tower shell 20 is connected, a...

Embodiment 2

[0042] A hydrogenation reactor device for hydrogenation reaction, comprising a tower shell 20, characterized in that, the body of the tower shell 20 is arranged in a hollow cylindrical structure, and the tower shell 20 The bottom is fixed with a skirt 19, and the bottom of the skirt 19 is installed on the ground through anchor bolts. The skirt 19 is provided with an inspection access hole 10, and the skirt 19 is welded with an orifice 17. The outer surface of the skirt 19 is bound with a wire mesh to lay a fireproof layer through the installation hole plate 17. The upper head of the tower shell 20 is provided with a manhole-2, and the top of the tower shell 20 is equipped with an inlet. Material pipe 1, the feed end of described feed pipe 1 is connected with external material storage equipment, and described feed pipe 1 is positioned at the side setting of described manhole-2, and the discharge end of described feed pipe 1 and The interior of the tower shell 20 is connected, a...

Embodiment 3

[0052] A hydrogenation reactor device for hydrogenation reaction, comprising a tower shell 20, characterized in that, the body of the tower shell 20 is arranged in a hollow cylindrical structure, and the tower shell 20 The bottom is fixed with a skirt 19, and the bottom of the skirt 19 is installed on the ground through anchor bolts. The skirt 19 is provided with an inspection access hole 10, and the skirt 19 is welded with an orifice 17. The outer surface of the skirt 19 is bound with a wire mesh to lay a fireproof layer through the installation hole plate 17. The upper head of the tower shell 20 is provided with a manhole-2, and the top of the tower shell 20 is equipped with an inlet. Material pipe 1, the feed end of described feed pipe 1 is connected with external material storage equipment, and described feed pipe 1 is positioned at the side setting of described manhole-2, and the discharge end of described feed pipe 1 and The interior of the tower shell 20 is connected, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com