Method and device for removing nitrate nitrogen pollutants by intensifying iron-carbon micro-electrolysis through low-intensity magnetic field

A technology of iron-carbon micro-electrolysis and nitrate nitrogen is applied in the field of denitrification to achieve the effects of increasing hydraulic retention time, improving electron donating ability and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

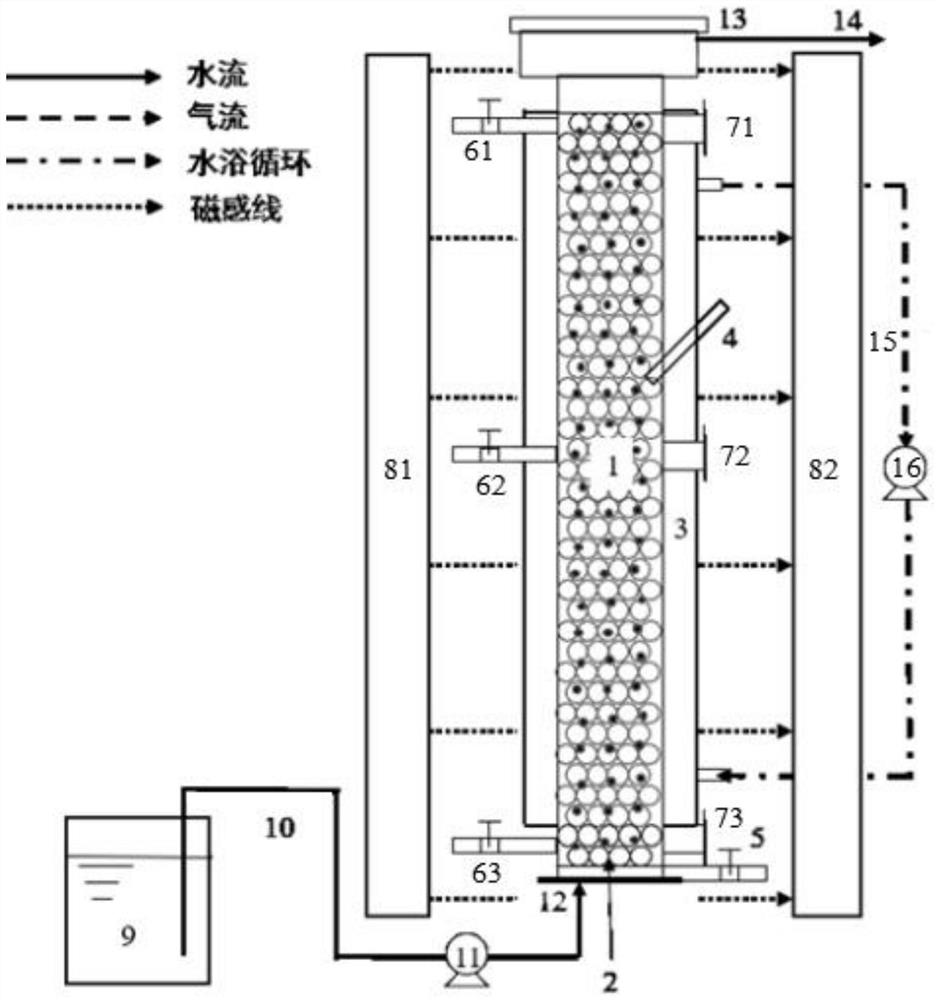

[0048] use figure 1 In the shown device, the iron-carbon carrier is filled on the porous carrier support plate 2 in the reactor 1, and the nitrate nitrogen-containing water to be treated in the water inlet bucket 9 is passed through the water inlet pipeline 10, the water inlet pump 11, and the water inlet 12 enters the reactor 11, inoculates the activated sludge on the iron-carbon carrier, and controls the temperature at 20-30°C through the water bath circulation system and the temperature control sensor 4, and the weak magnet provided by the first permanent magnet 81 and the second permanent magnet 82 Under the condition of magnetic field, the biofilm is cultivated, and the parameters of microorganisms in the biofilm are monitored through the upper mud port 71, the middle mud port 72 and the lower mud port 73. After the carrier is attached to the biofilm, iron-carbon micro-electrolysis autotrophic denitrification is carried out to obtain In addition to nitrate nitrogen efflue...

Embodiment 2

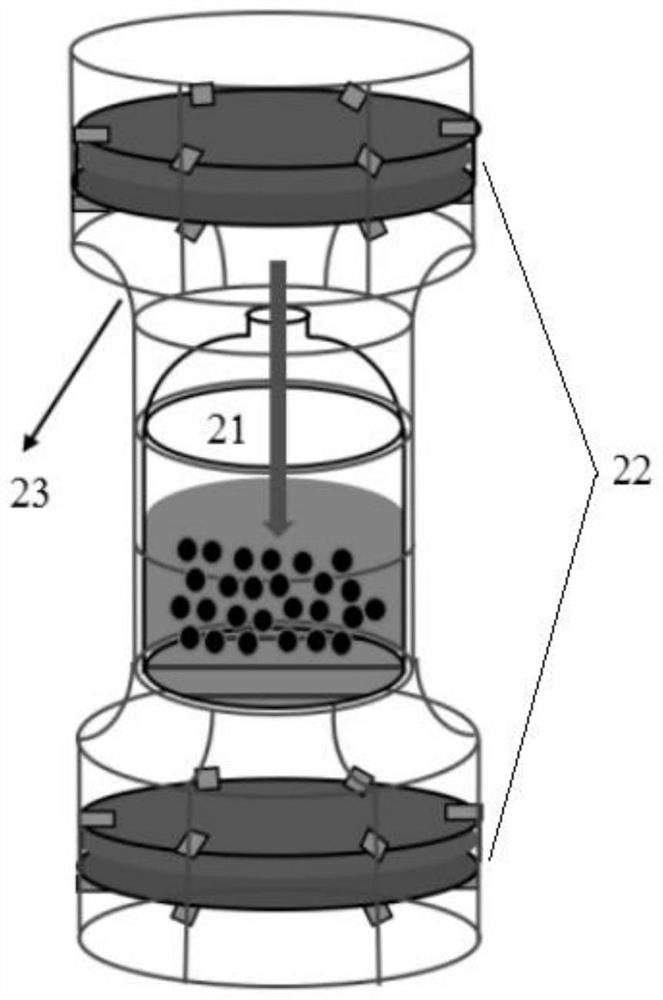

[0050] use figure 2 In the shown device, the iron-carbon carrier is filled in the reactor 21 (the filling volume fraction is 50-60%), and the feed water containing nitrate nitrogen to be treated is added into the reactor, and the distance between the two NdFeB permanent magnets is adjusted. Control the strength of the magnetic field to 20-60mT; inoculate the enriched microorganisms into the reactor 21 and cultivate them at 25-30°C; after the iron-carbon carrier is attached to the biofilm, perform iron-carbon micro-electrolysis autotrophic denitrification to obtain nitrate nitrogen removal effluent; The hydraulic retention time (HRT) is 6h; among them, the influent containing nitrate nitrogen to be treated is the secondary effluent of the municipal sewage treatment plant, NO 3 - -The concentration of N is 20~30mg / L, no organic carbon source is added, and NO is removed from the effluent of nitrate nitrogen 3 - -N and TN removal rates are over 80% and 70% respectively, meetin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com