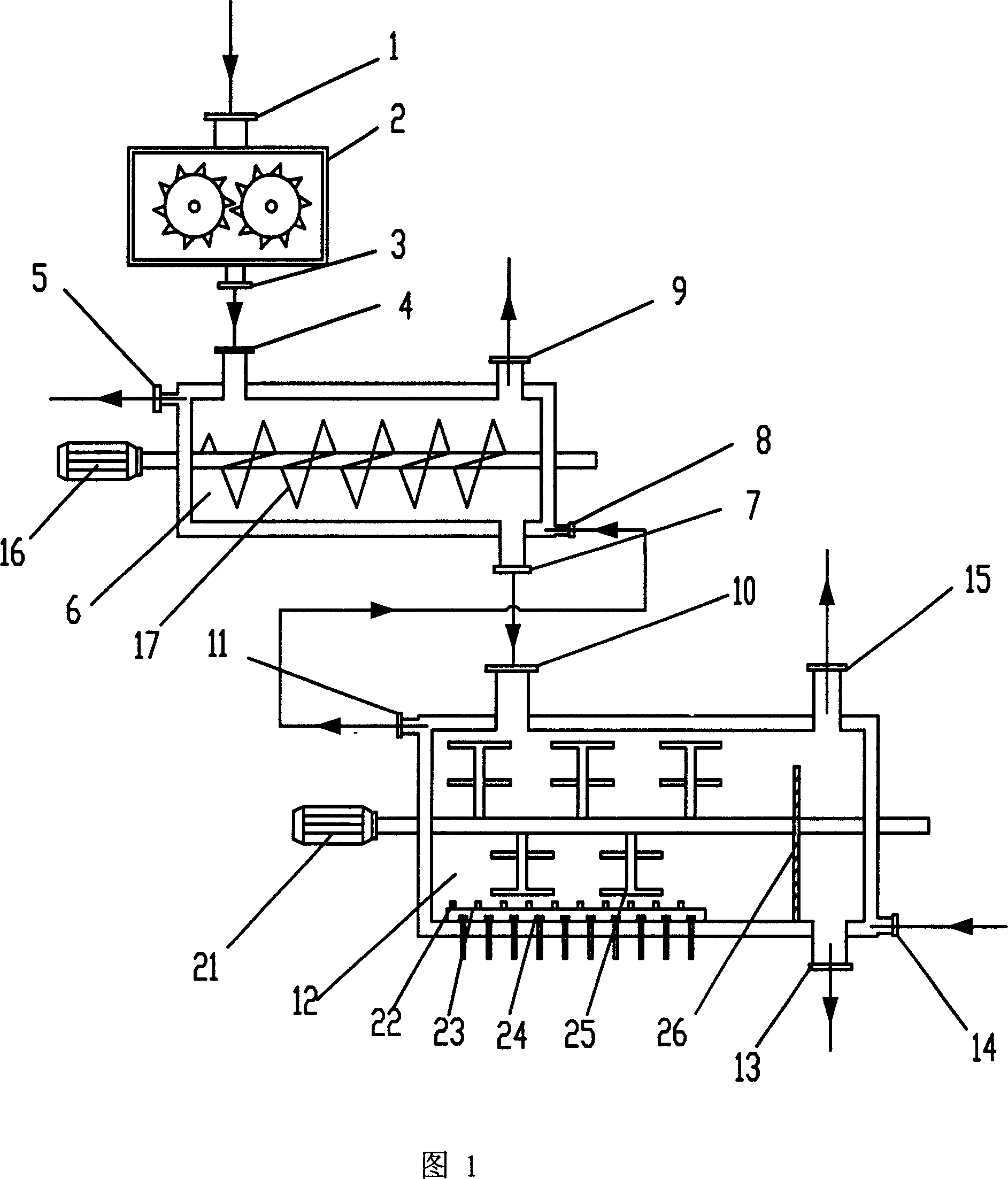

Biomass deep dehydration carbonization continuous processing technology and device thereof

A technology of deep dehydration and treatment process, which is applied in the field of packaging, can solve the problems of low natural biomass charcoal output, low calorific value of combustible gas products, low production efficiency of carbonization system, etc., and achieve easy maintenance, adjustment, and improvement effect of concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

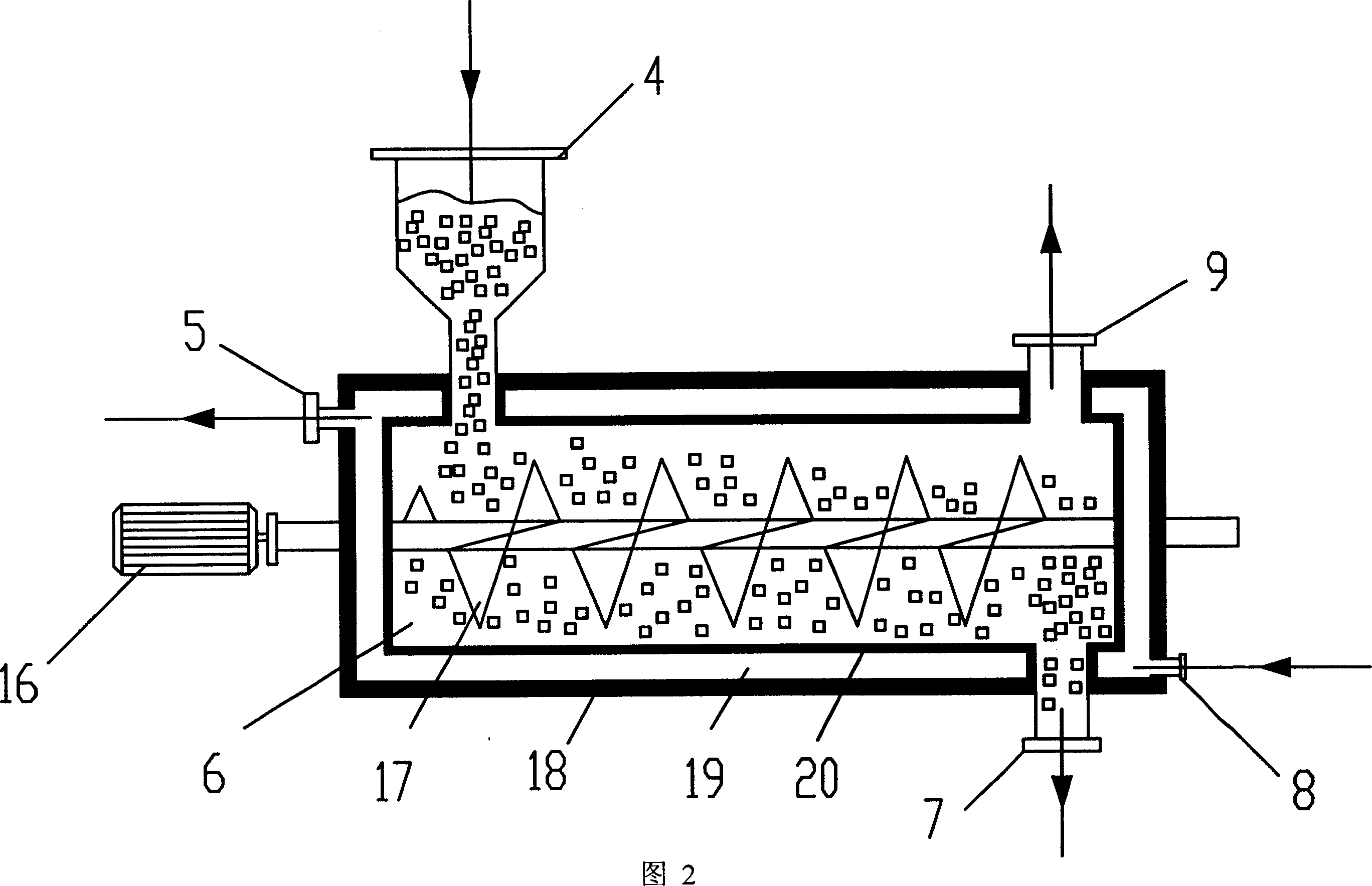

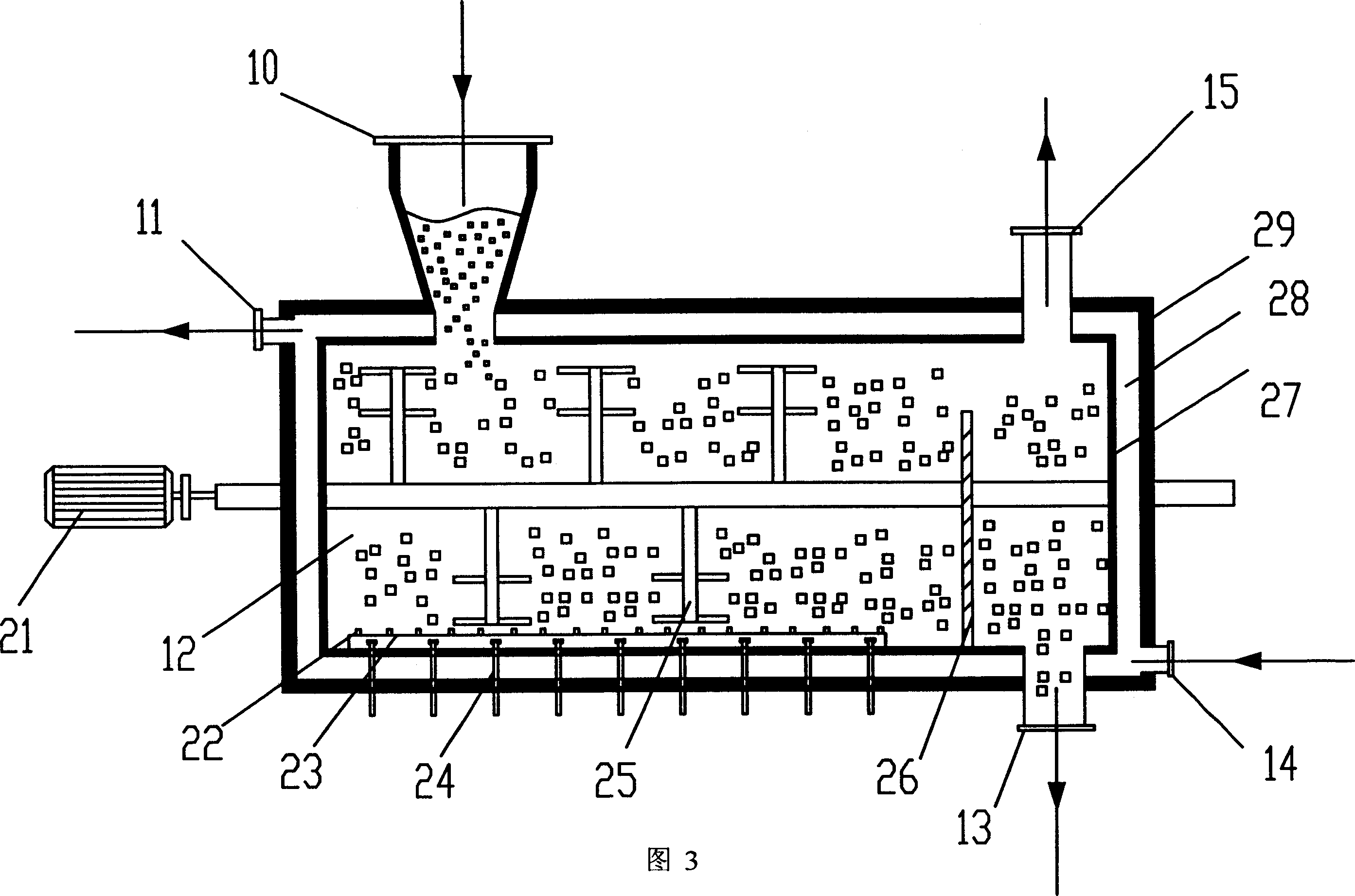

Method used

Image

Examples

Embodiment 1

[0044] Embodiment one: take willow branch as carbonization raw material. The collected willow branches are sorted and cleaned to remove soil and other impurities in the willow branch raw materials, and the raw materials are air-dried until the moisture content of the materials is in the range of 15-20%. The air-dried material is loaded into the cutter, and the material is cut into particles with a particle size of 5-80 mm. The cut material is directly input into the dryer, the motor of the dryer is started, the material is pushed under the action of the screw auger, and at the same time, the hot flue gas is passed into the dryer to heat the dryer, and the temperature of the dryer is kept at 130-150°C. The residence time in the dryer is 700-1000s. The dried material is directly input into the carbonizer, the motor of the carbonizer is started, and the material moves toward the outlet under the action of the stirring paddle, and at the same time, the hot flue gas is passed into...

Embodiment 2

[0045] Embodiment two: the raw material is changed into cotton stalks. The collected cotton stalks are sorted and cleaned to remove soil and other impurities in the cotton stalk raw materials. The raw material is air-dried until the moisture content of the material is in the range of 15-20%. The air-dried material is loaded into the cutter, and the material is cut into particles with a particle size of 5-80mm. Keep the temperature of the drier at 140-160°C, and the residence time of the material in the drier is 900-1200s. Keep the temperature of the carbonizer at 300-500°C, and the residence time of the material in the carbonizer is 200-800s. After testing, it is known that for every 1kg of cotton stalks fed, the moisture discharged from the dryer is about 0.1553kg, the charcoal produced is about 0.17kg, the ash is about 0.0263kg, and the pyrolysis gas produced is about 0.6483kg. Calculated by volume percentage, each component in the pyrolysis gas is: H 2 -8.11%, CO2 -10.9...

Embodiment 3

[0046] Embodiment three: the raw material is replaced by corn stalks. The collected corn stalks are sorted and cleaned to remove soil and other impurities in the corn stalks. The raw material is air-dried until the moisture content of the material is in the range of 15-20%. The air-dried material is loaded into the cutter, and the material is cut into particles with a particle size of 5-80mm. Keep the temperature of the drier at 120-140°C, and the residence time of the material in the drier is 600-1000s. Keep the temperature of the carbonizer at 300-500°C, and the residence time of the material in the carbonization process is 400-800s. According to the test, for every 1kg of corn stalks fed, the moisture discharged from the dryer is about 0.052kg, the charcoal produced is about 0.17kg, the ash is about 0.051kg, and the pyrolysis gas produced is about 0.7337kg. Calculated by volume percentage, each component in the pyrolysis gas is: H 2 -9.96%, CO 2 -8.05%, CO - 26.83%, H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com