Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

118results about "Ether/acetal/ketal group formation/introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

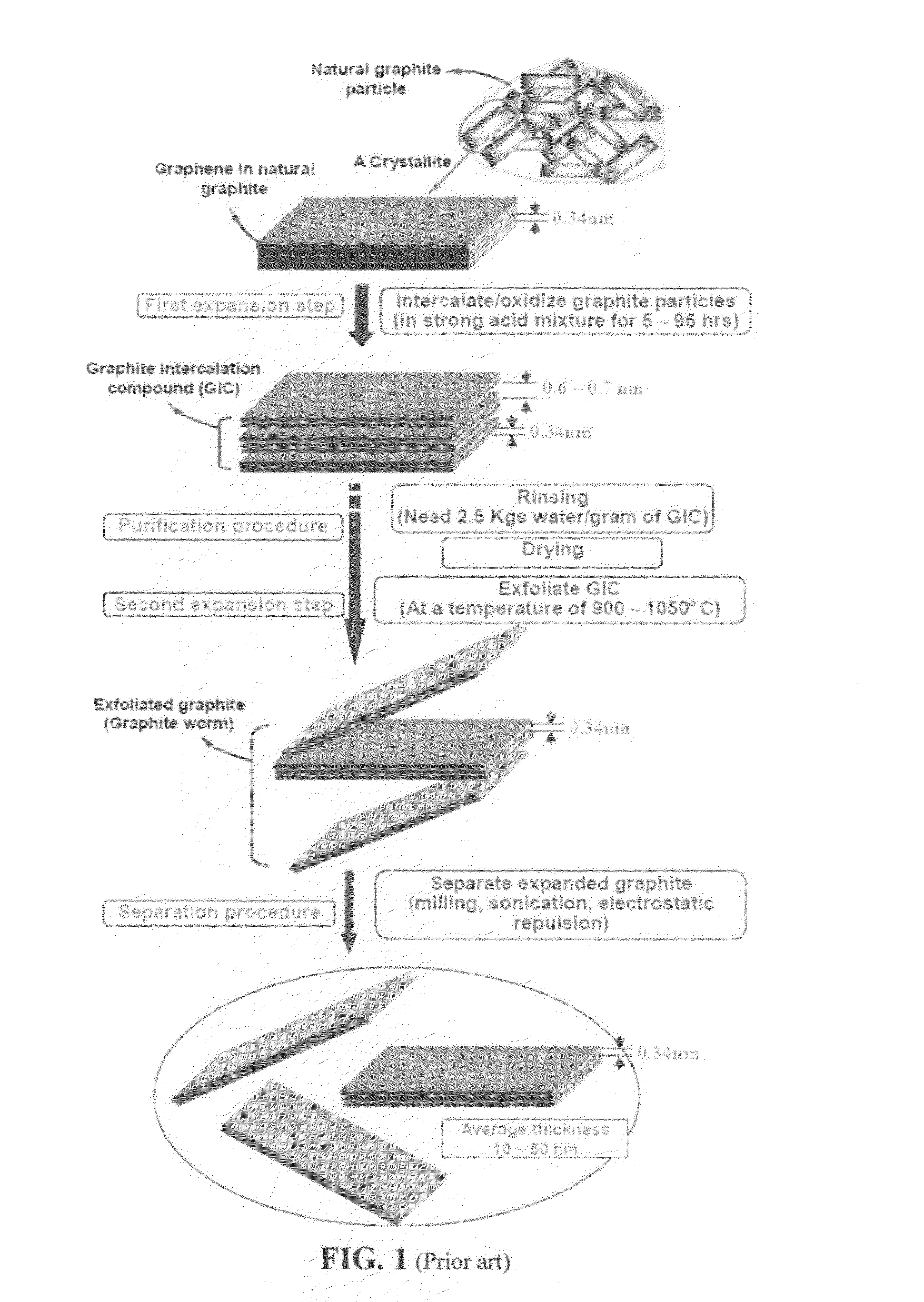

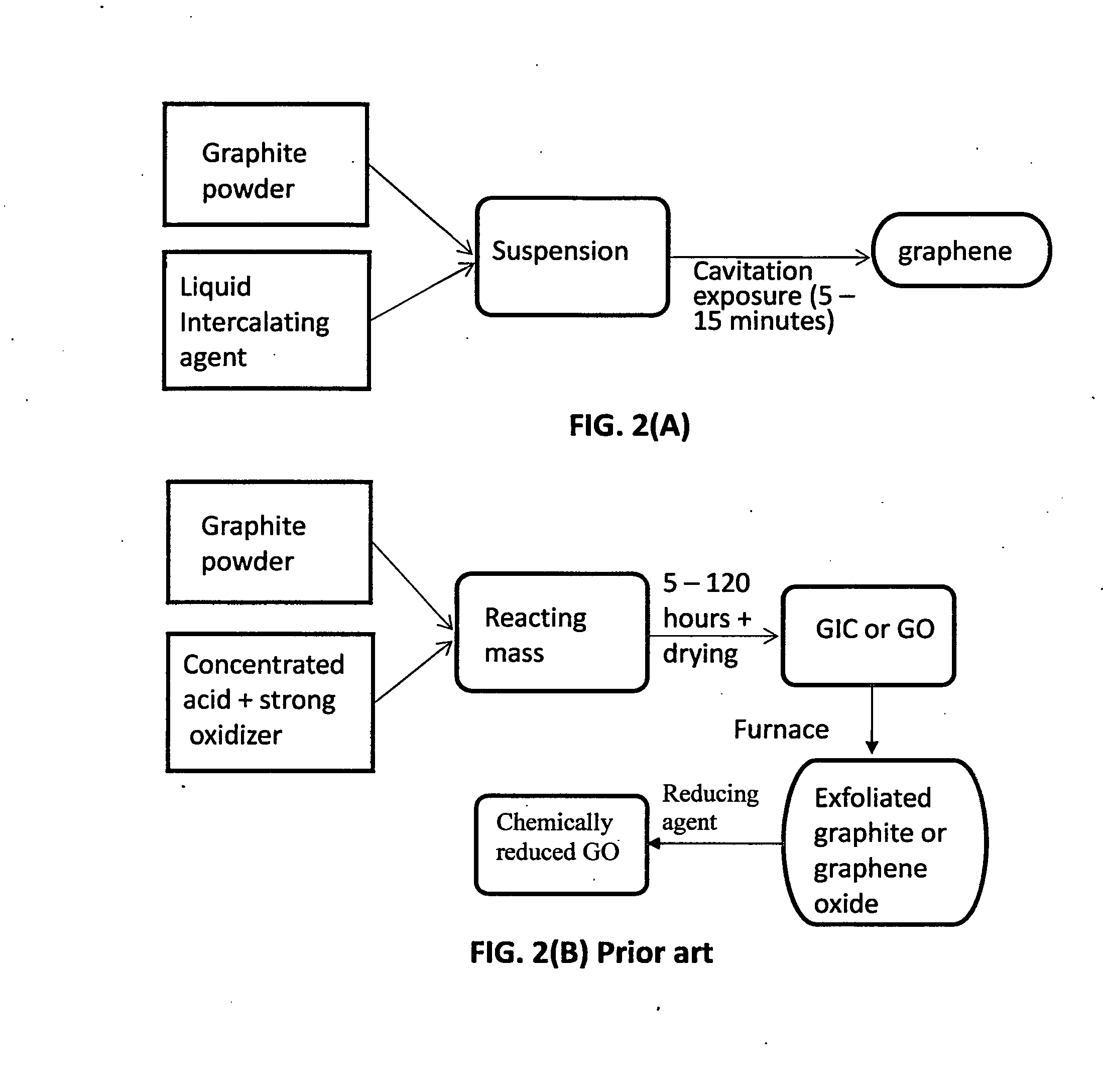

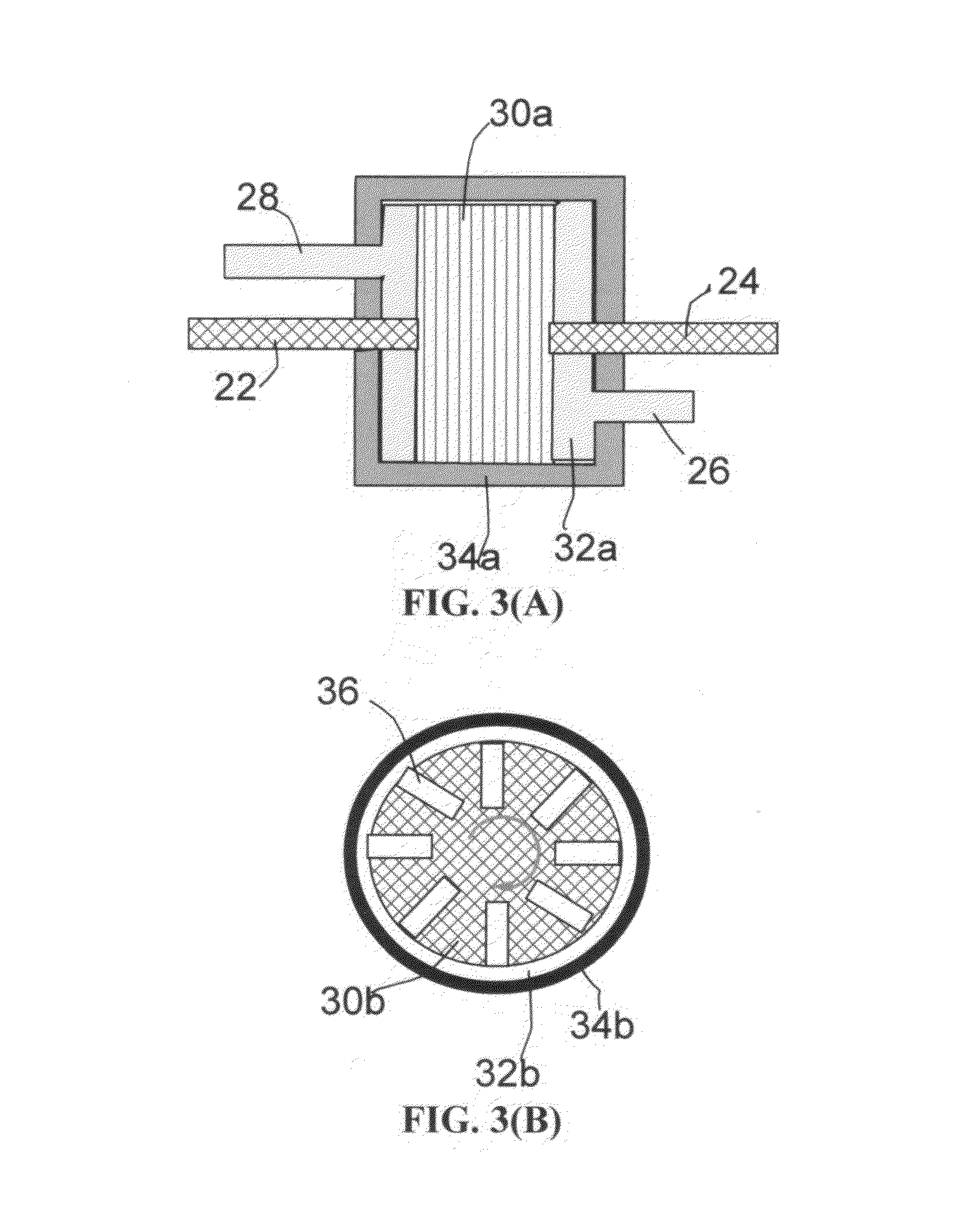

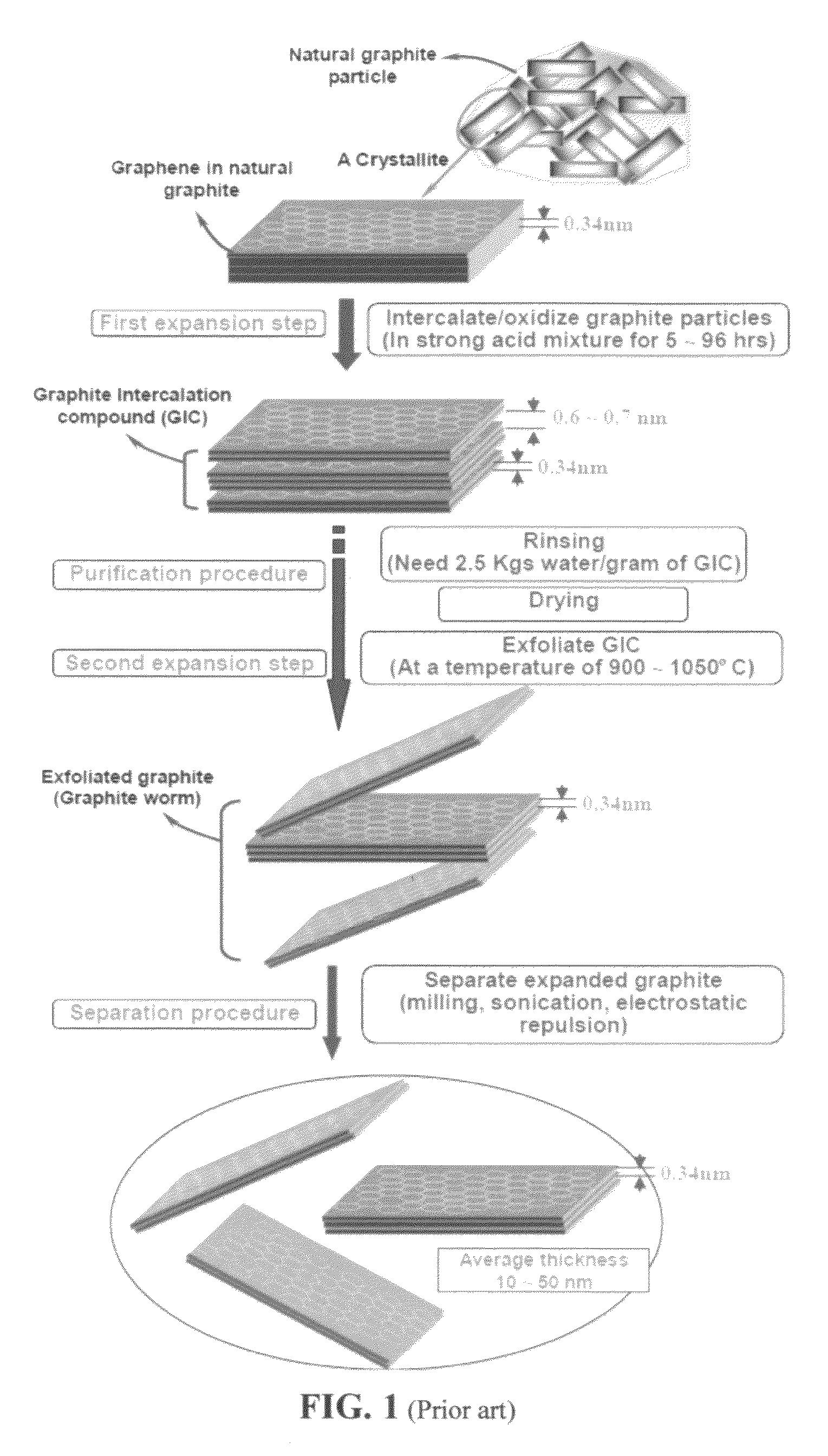

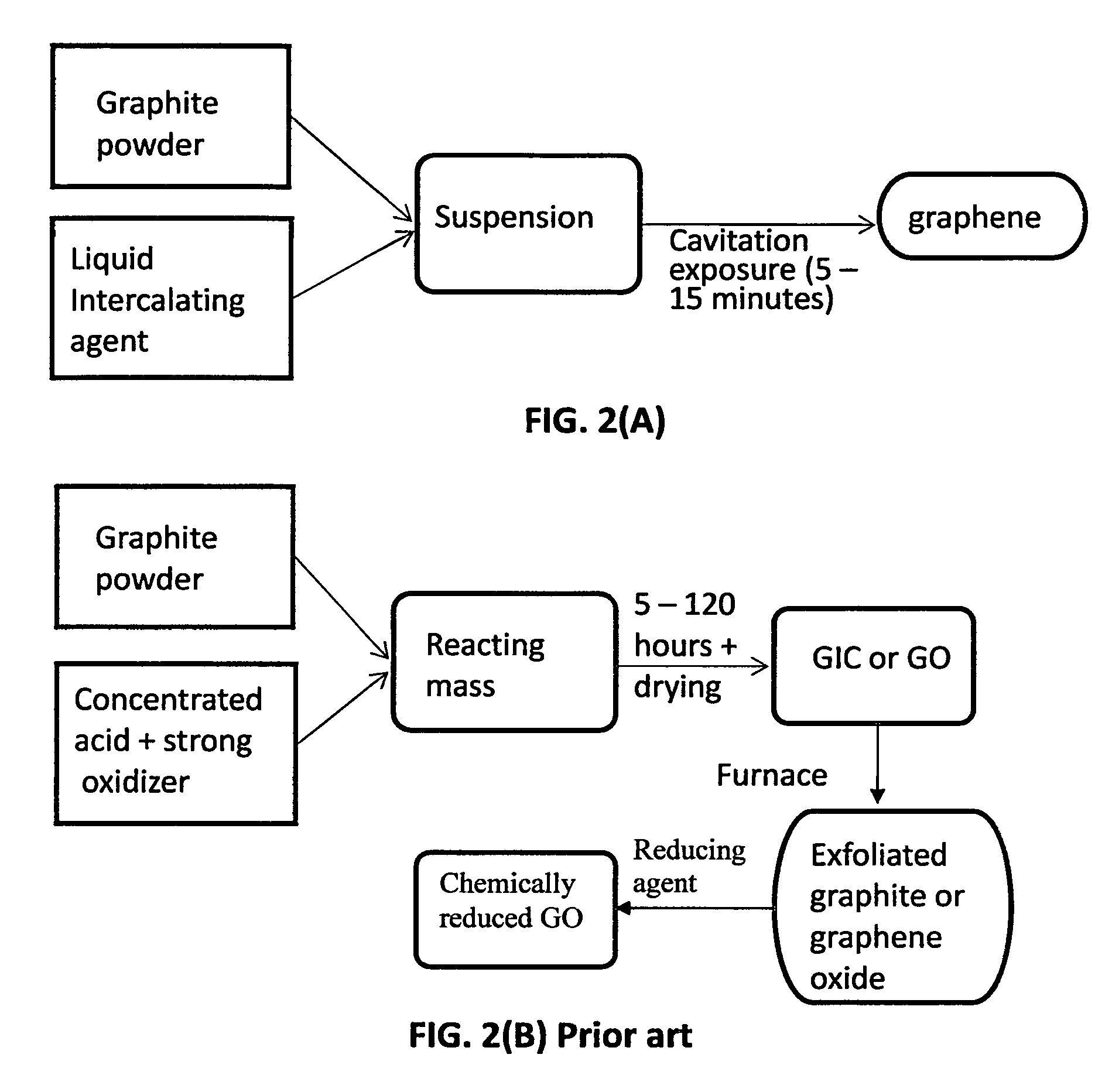

Production of graphene materials in a cavitating fluid

ActiveUS20150239741A1Shorten the timeReduce lossesCarboxylic acid nitrile preparationGraphiteCavitationLiquid medium

The invention provides a method of producing a graphene material from a starting graphitic material. In an embodiment, the method comprises: (a) dispersing the starting graphitic material in a liquid medium to form a graphite suspension; and (b) introducing the graphite suspension into a hydrodynamic cavitation reactor that generates and collapses cavitation or bubbles in the liquid medium to exfoliate and separate graphene planes from the starting graphitic material for producing the graphene material. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable. The reactor can concurrently perform the functions of graphene production, chemical functionalization, dispersion, and mixing with a polymer to make a composite.

Owner:GLOBAL GRAPHENE GRP INC

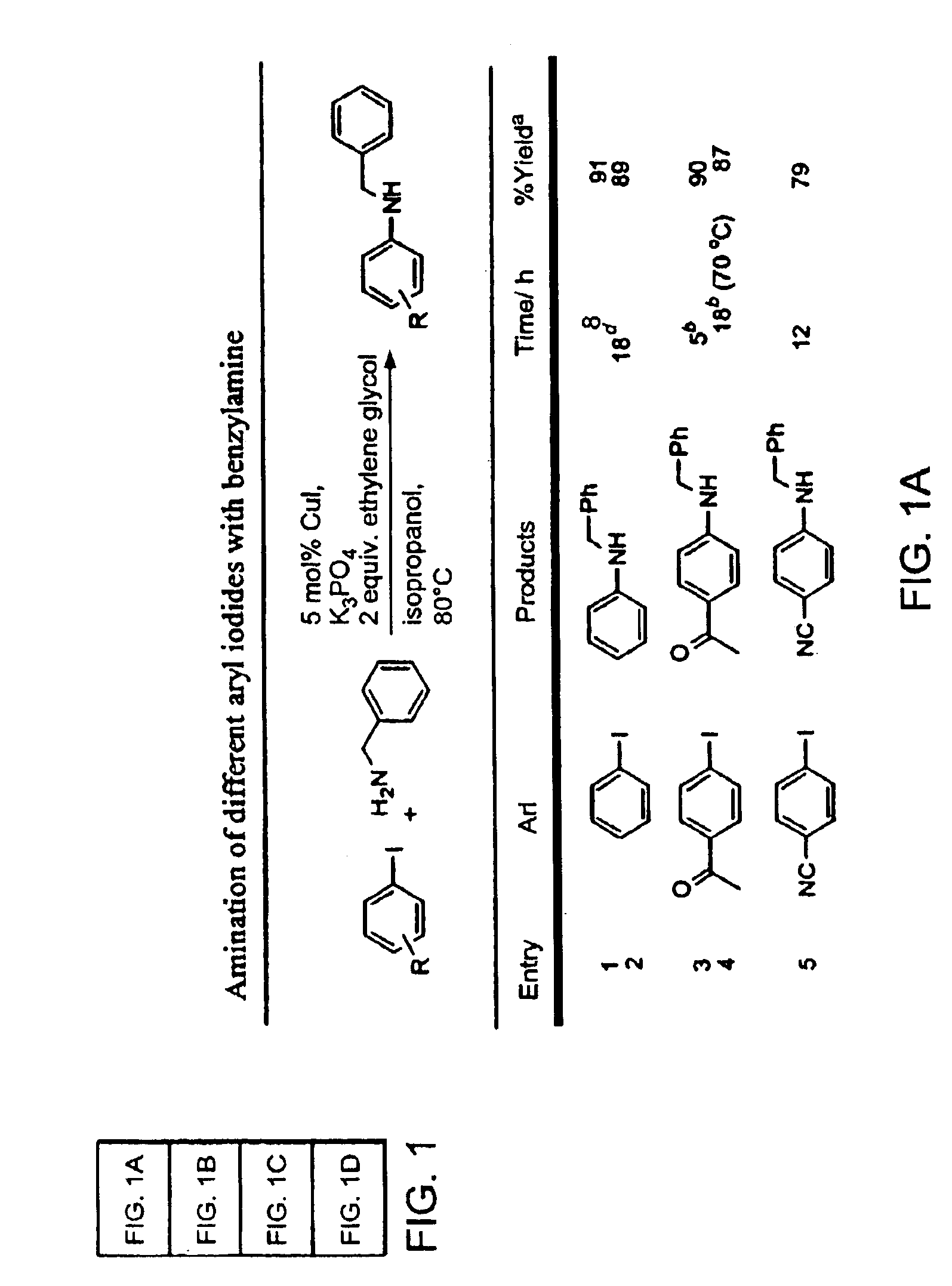

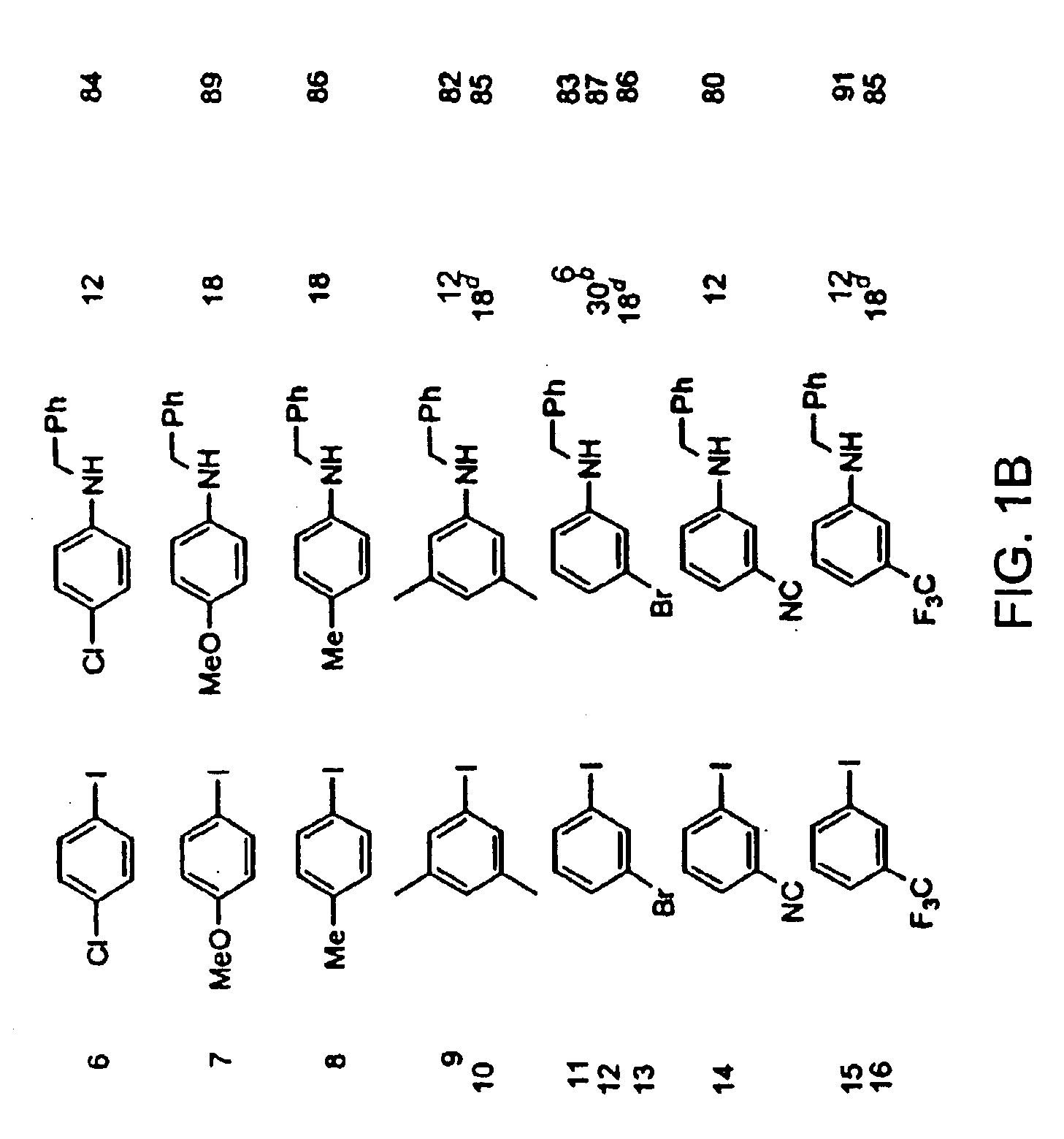

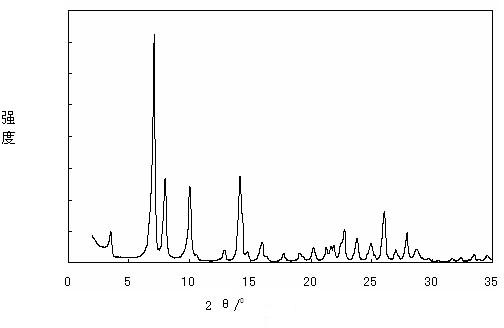

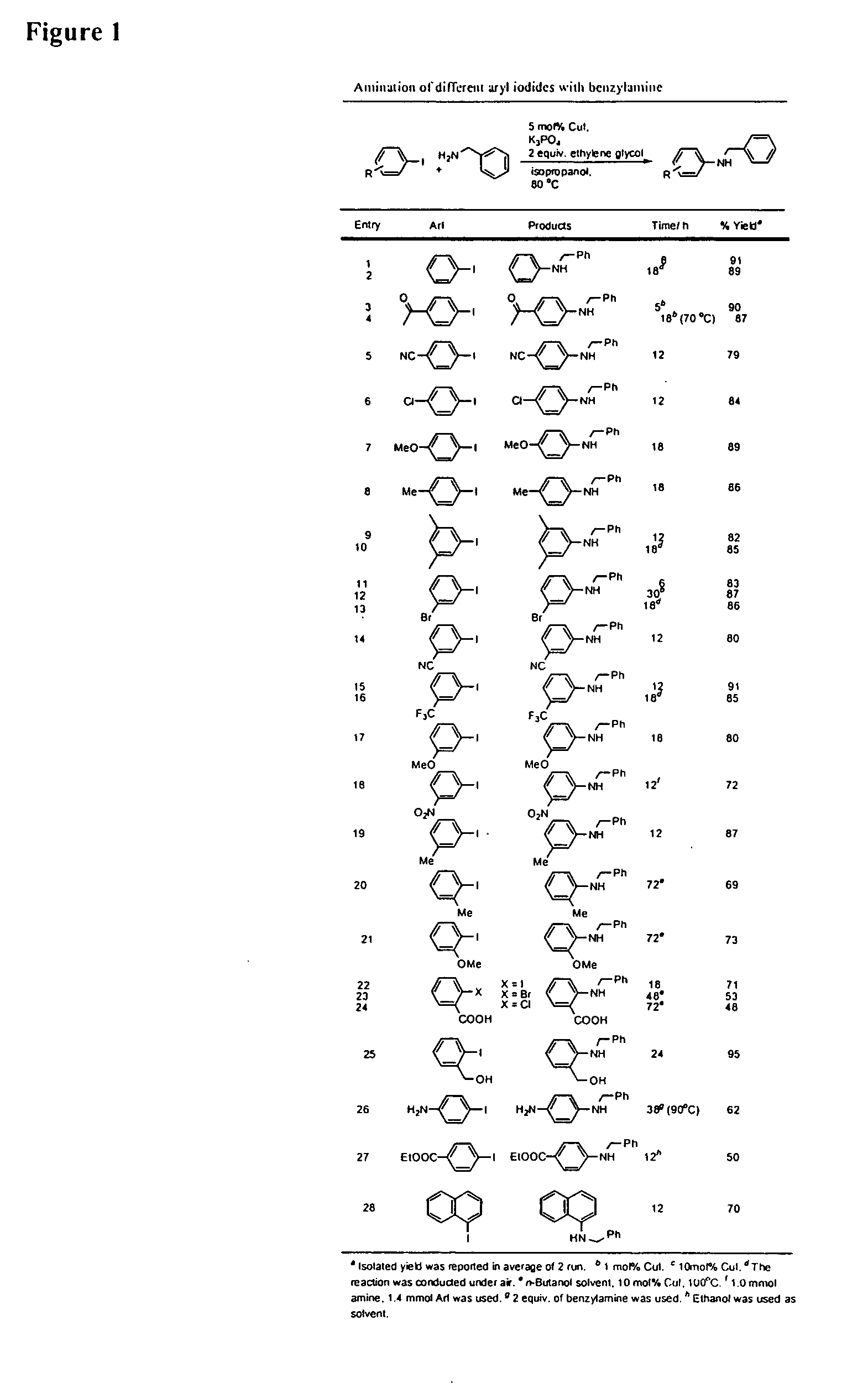

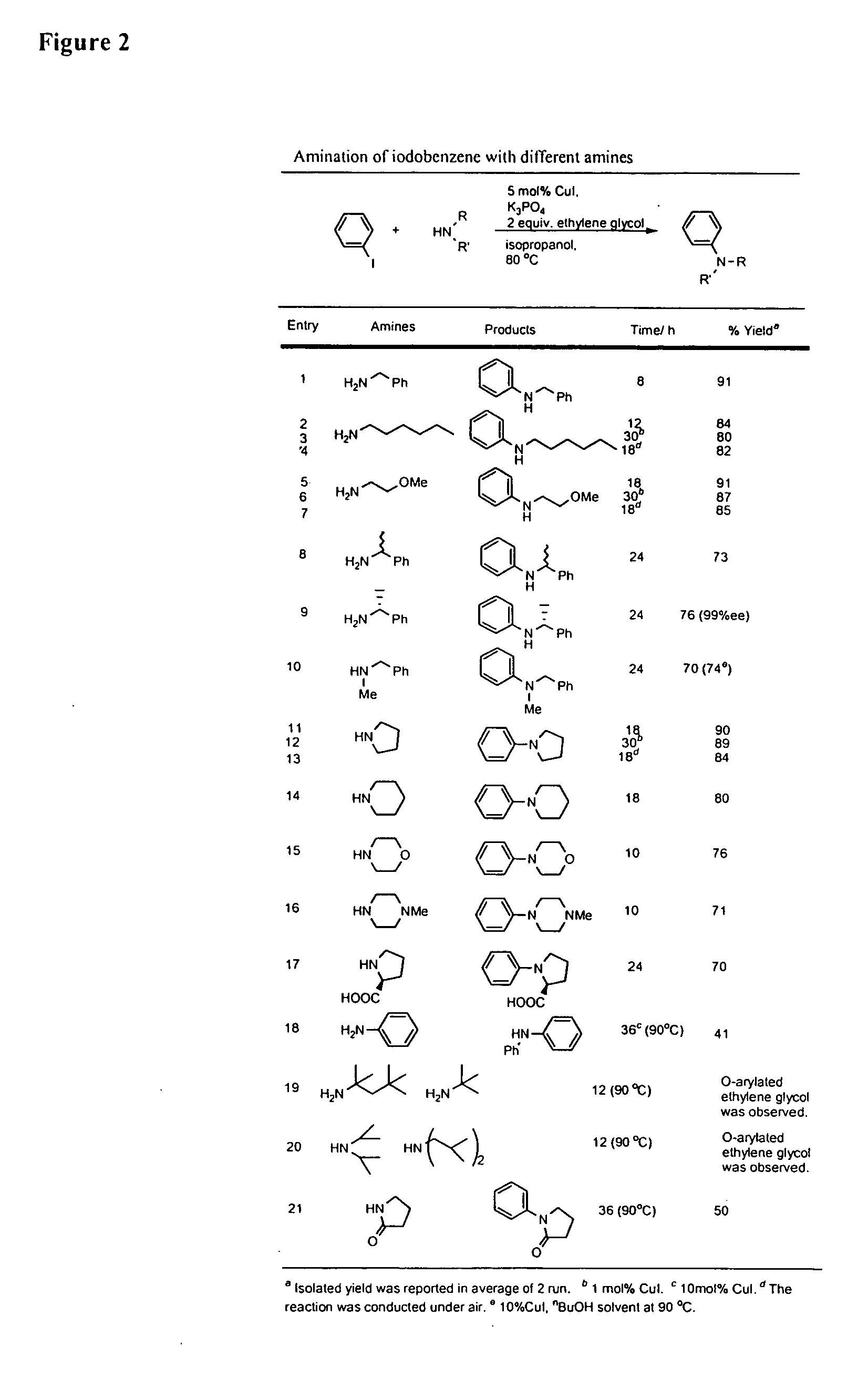

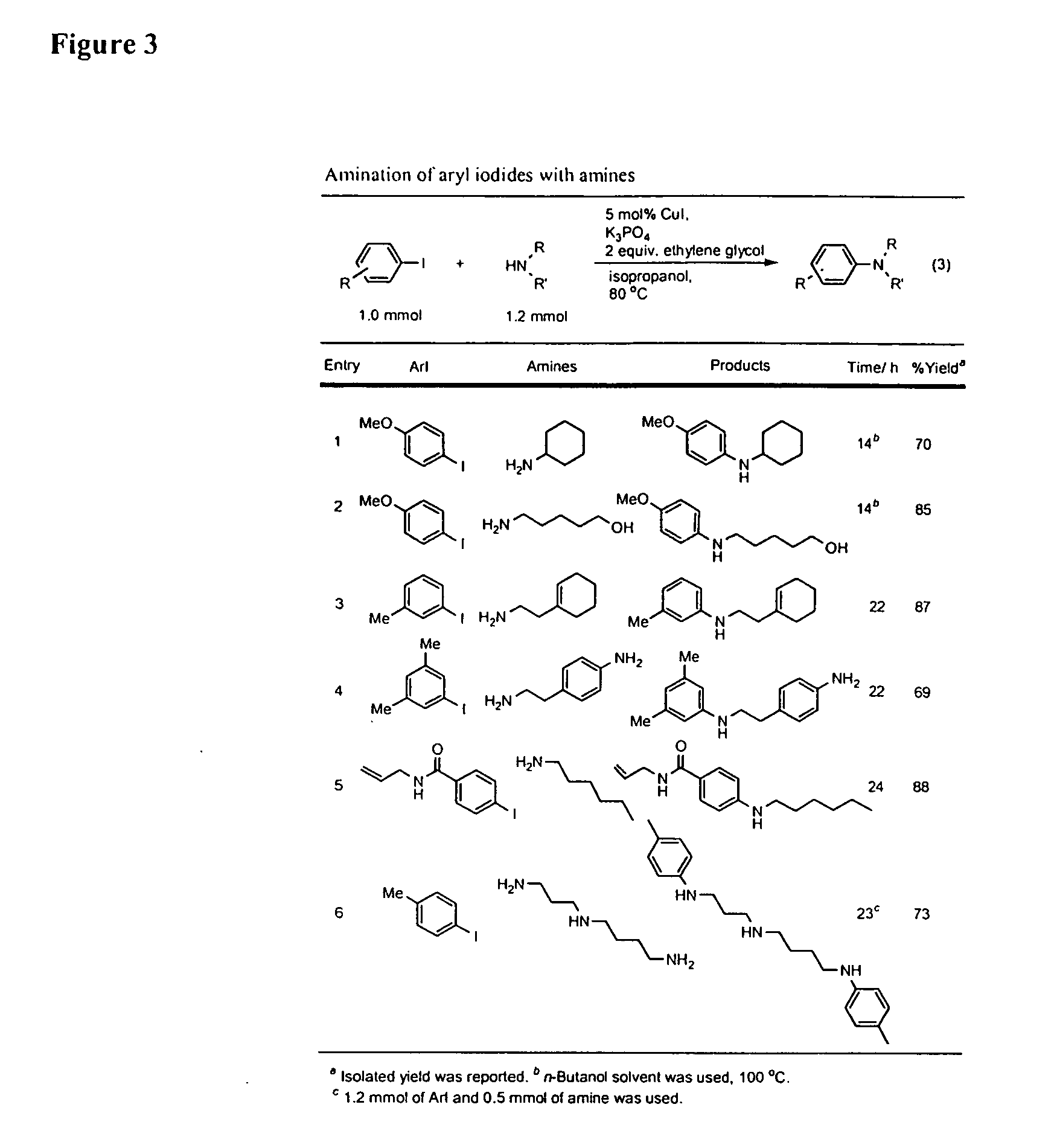

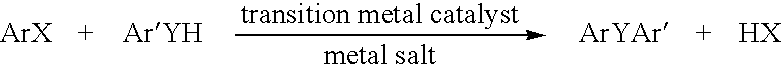

Copper-catalyzed formation of carbon-heteroatom and carbon-carbon bonds

InactiveUS6867298B2Cheap and practicalLow costUrea derivatives preparationCarbamic acid derivatives preparationCarbon–oxygen bondHydrazine compound

The present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide or amine moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In additional embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between a nitrogen atom of an acyl hydrazine and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of a nitrogen-containing heteroaromatic, e.g., indole, pyrazole, and indazole, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-oxygen bond between the oxygen atom of an alcohol and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. The present invention also relates to copper-catalyzed methods of forming a carbon-carbon bond between a reactant comprising a nucleophilic carbon atom, e.g., an enolate or malonate anion, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. Importantly, all the methods of the present invention are relatively inexpensive to practice due to the low cost of the copper comprised by the catalysts.

Owner:MASSACHUSETTS INST OF TECH

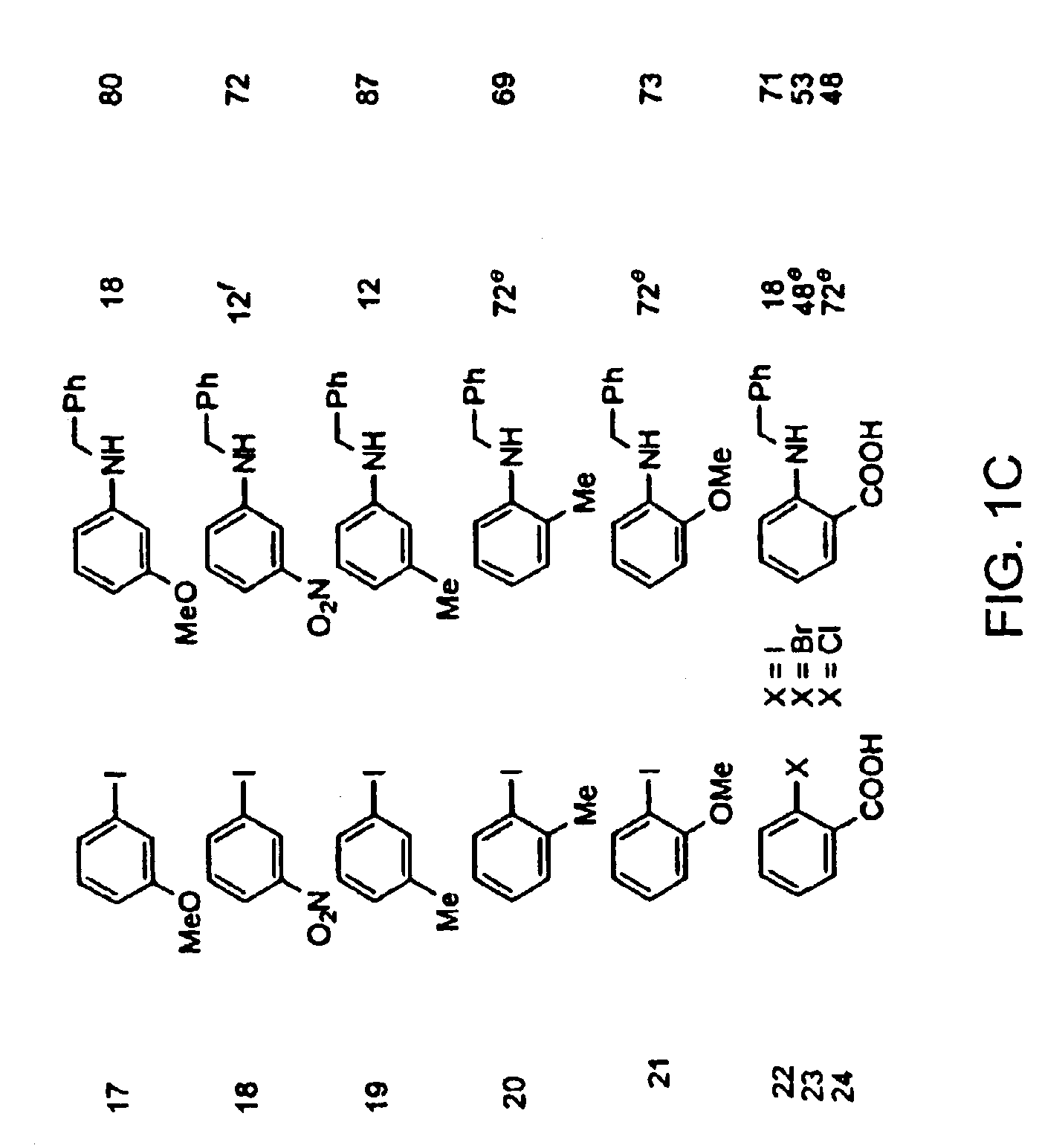

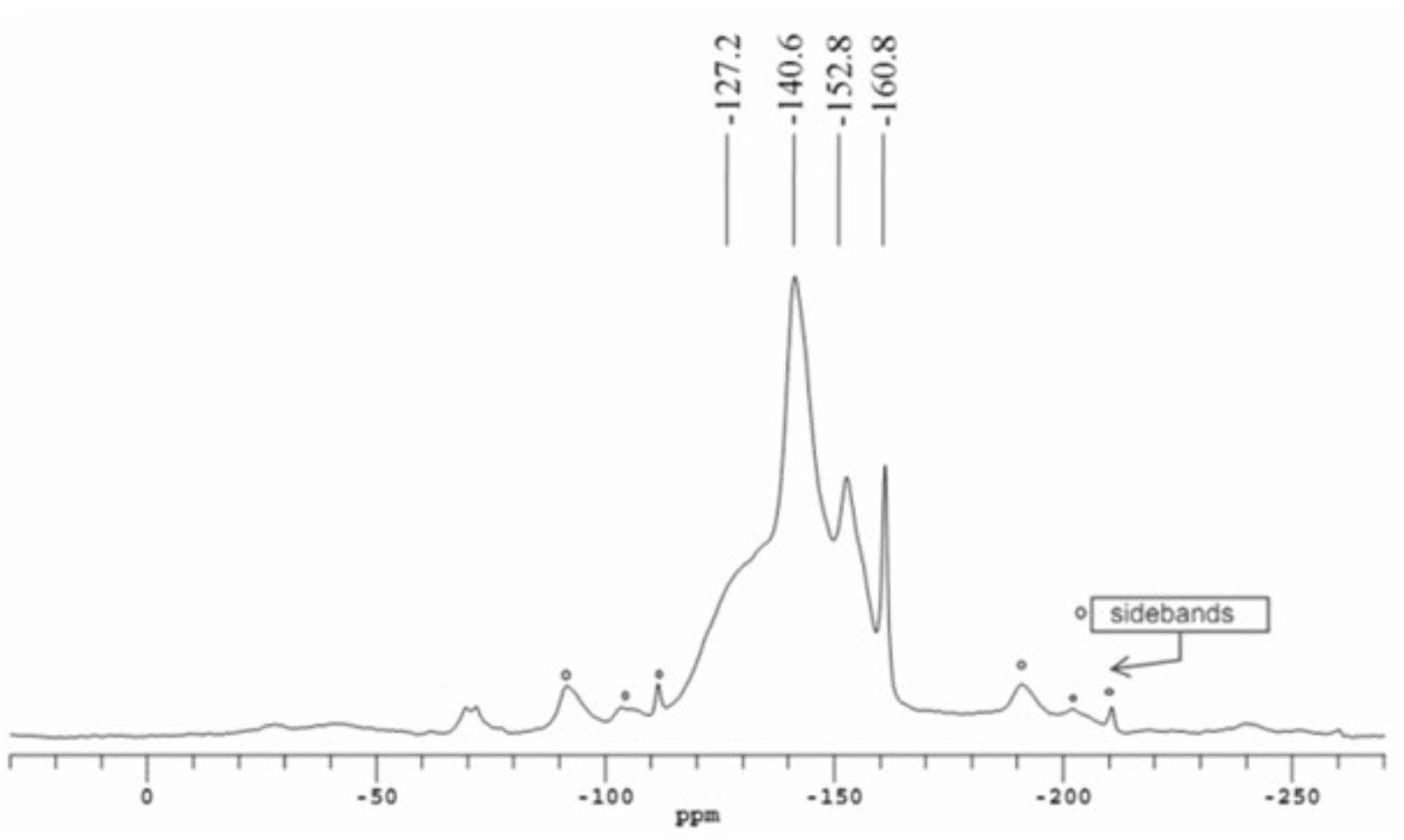

Fluorine-containing titanium-silicon molecular sieve with MWW (Manual Wire Wrap) structure and preparation method and application thereof

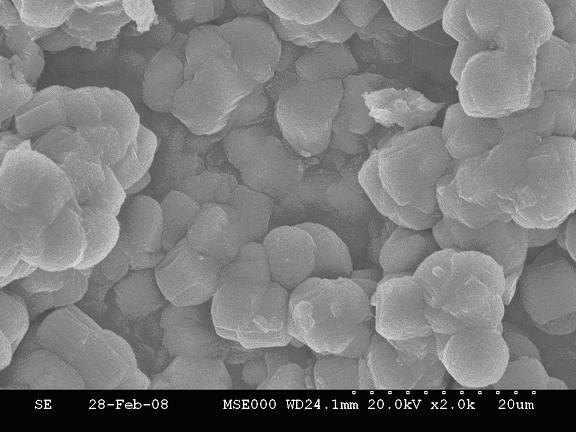

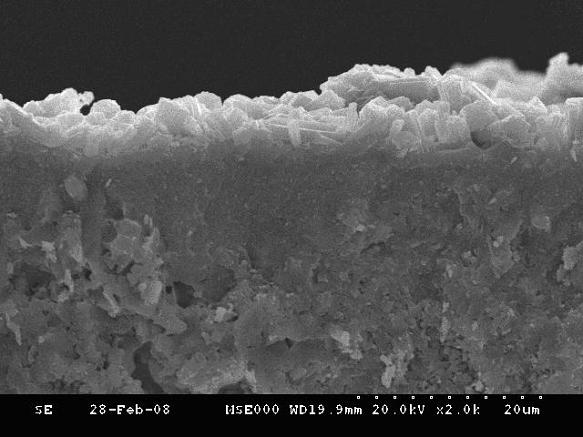

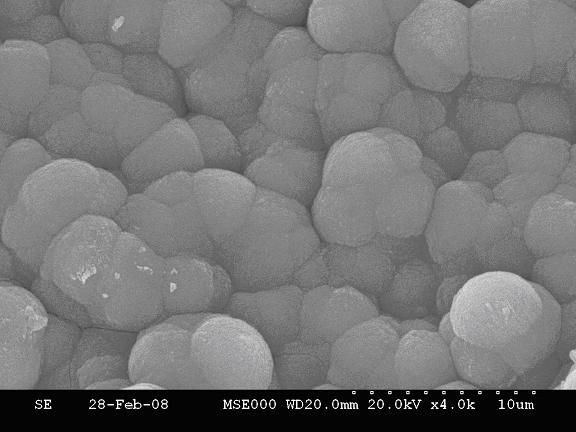

ActiveCN102627291AComplete crystalline structureImprove catalytic oxidation performanceMolecular sieve catalystsEther/acetal/ketal group formation/introductionX-rayCatalytic oxidation

The invention discloses a fluorine-containing titanium-silicon molecular sieve with a MWW (Manual Wire Wrap) structure and a preparation method and an application thereof. In the molecular sieve, a fluorine atom is connected with a framework silicon atom in the form of a chemical bond, an XRD (X-Ray Diffraction) spectrogram contains a characteristic spectral line of the molecular sieve with the MWW structure, and characteristic peaks of -150+ / -5ppm and -143+ / -5ppm appear in a 19FMAS-NMR (19 File Management Assistant For Server-Nuclear Magnetic Resonance) spectrogram; the preparation method comprises the following steps of: synthesizing a boron-containing parent body, post-treating, baking and the like; and the molecular sieve serving as a catalyst is applied to catalytic oxidation reactions of compounds containing carbon-carbon double bonds and at least one other functional group as well as reactions for catalytically synthesizing oxime. The molecular sieve has a complete crystalline state structure; according to the electronic effect of framework fluorine, the molecular sieve and higher catalytic oxidation capability; a preparation process is simple, and is easy for industrial production; synthesis of corresponding epoxides or catalytic synthesis of oxime from compounds containing carbon-carbon double bonds and at least one other functional group can be catalyzed at higher activity and high selectivity; and a reaction process is environmentally-friendly.

Owner:EAST CHINA NORMAL UNIV

Method for preparing ketal in ionic liquid

InactiveCN1858048AReduce usageAvoid harmOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventAlcohol

The present invention relates to new method of preparing ketal. Alcohol and ketone as initial materials produce condensation reaction in acid ionic liquid as catalyst and reaction solvent and in the presence of water absorber to synthesize ketal in high selectivity and high yield. The method is one kind of green synthesis method without using volatile organic solvent and additional catalyst.

Owner:ZHEJIANG UNIV +1

Method for preparing ketal by catalysis of ionic liquid and dehydration of acid-resistant molecular sieve membrane

InactiveCN102584513AHigh yieldHigh degree of greeningOrganic compound preparationEther/acetal/ketal group formation/introductionMolecular sievePtru catalyst

The invention provides a method for preparing ketal by catalysis of an ionic liquid and dehydration of an acid-resistant molecular sieve membrane. According to the method, alcohol and ketone are used as initial raw materials, the acidic ionic liquid is used as a catalyst, water generated by reaction is removed in situ by adopting an acid-resistant molecular sieve membrane pervaporation device, and ketal with high selectivity and high yield is finally obtained. The method integrates the catalysis of the ionic liquid and the dehydration of the acid-resistant molecular sieve membrane, realizes separation while reacting, has the advantages of mild reaction conditions, high reaction selectivity, high product yield and the like; and in the method, waste acid or waste water is not discharged. Thus, the method is an environment-friendly high-efficiency new method for synthesizing ketal.

Owner:JIANGXI NORMAL UNIV

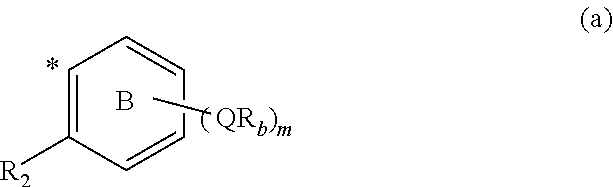

Branched chain-containing aromatic compound

ActiveUS20120059149A1Easy to operatePeptide/protein ingredientsCarboxylic acid amides preparationOperabilityCrystallization

Owner:AJINOMOTO CO INC

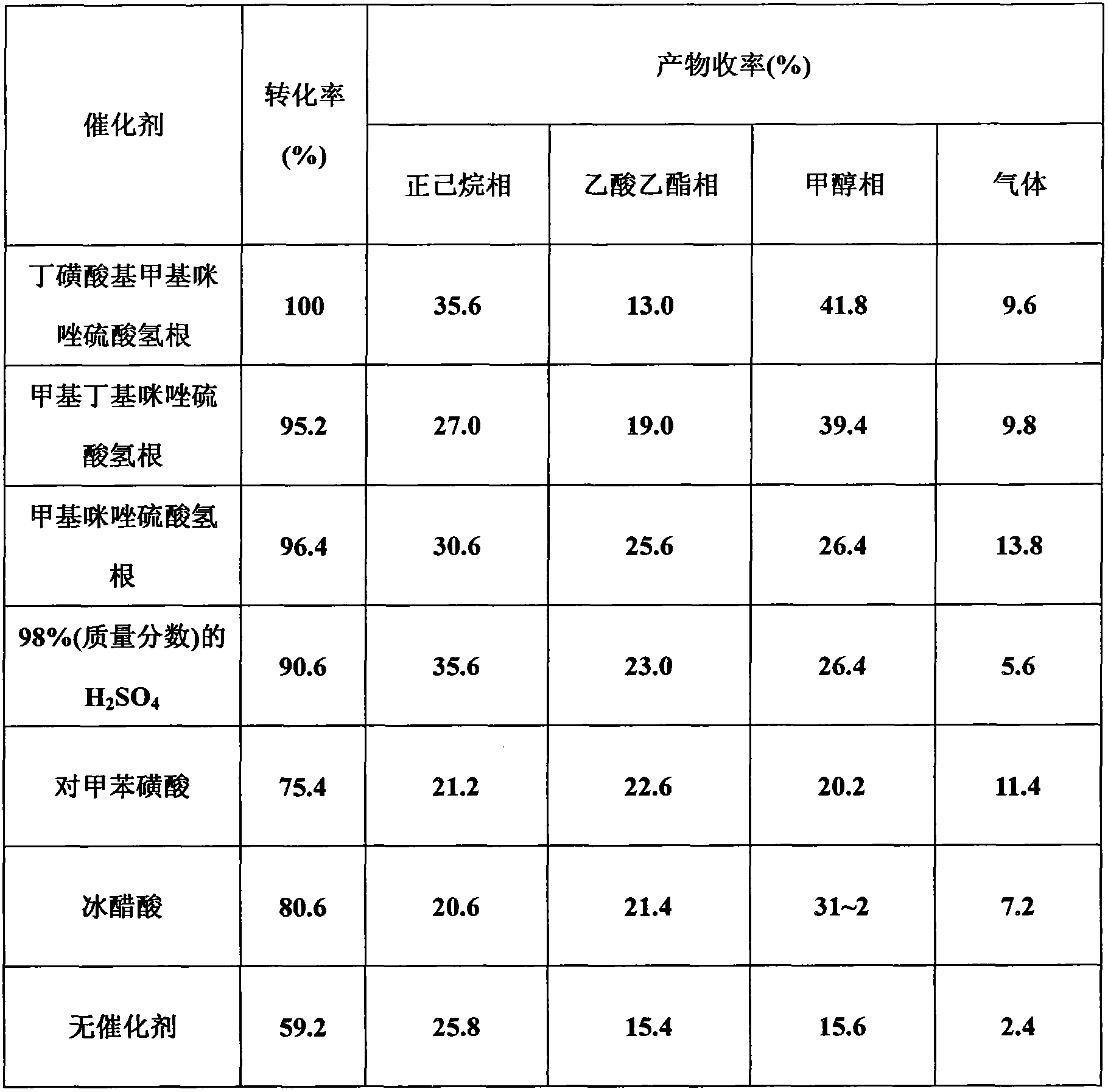

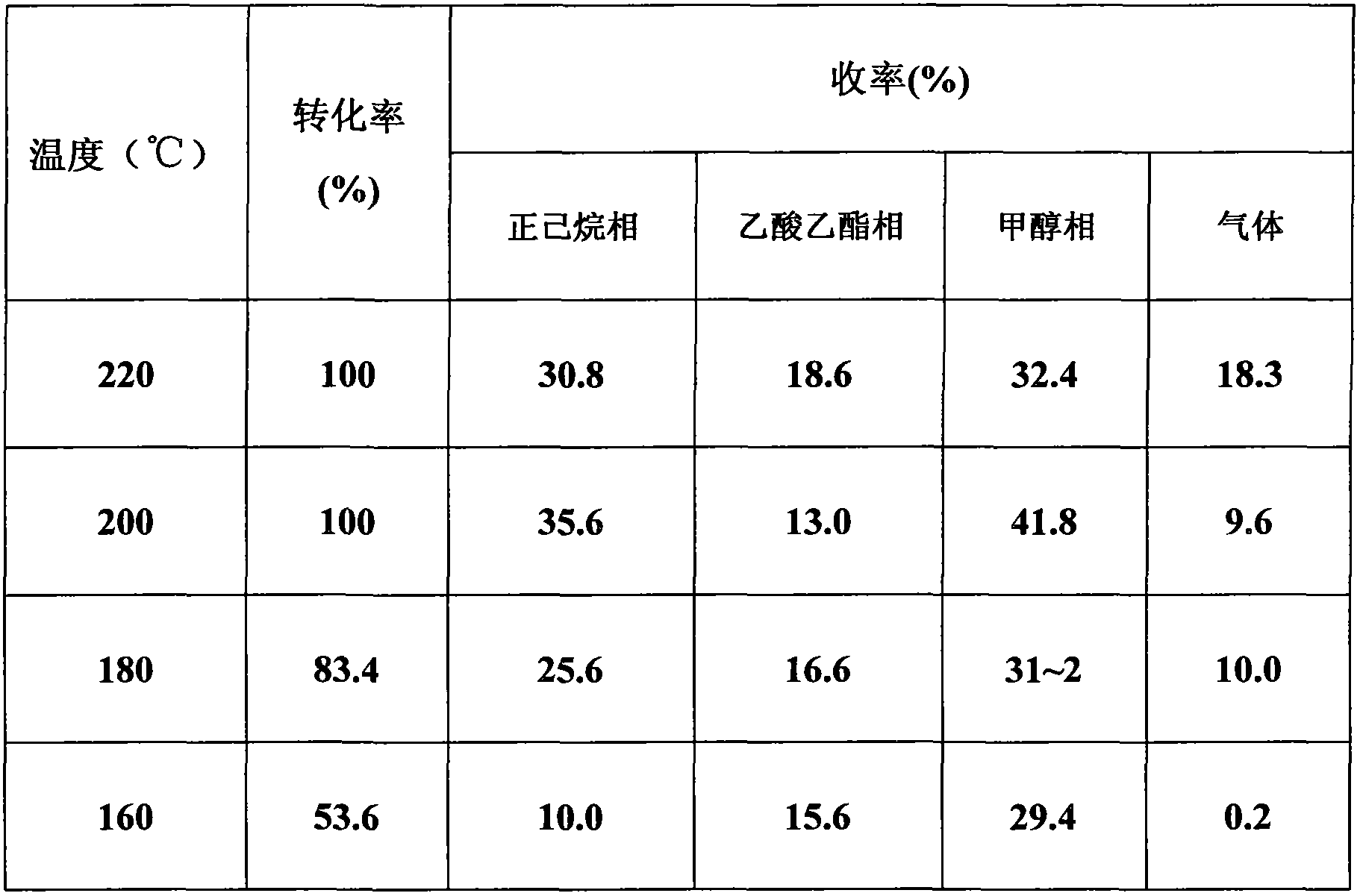

Method for carrying out catalytic conversion with high efficiency on cellulose at low temperature by utilizing compound ion liquid system

InactiveCN102060642AAchieve homogeneous transformationReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIce waterPhysical chemistry

The invention discloses a method for carrying out catalytic conversion with high efficiency on cellulose at low temperature by utilizing a compound ion liquid system, comprising the following steps of: (1) preparation of a compound ion liquid: fully mixing an ion liquid solvent and an acid ion liquid catalyst in ice water bath under the protection of N2 to obtain the compound ion liquid; and (2) catalytic conversion of the cellulose: mixing the compound ion liquid and microcrystalline cellulose, adding a nonpolar solvent, and after N2 replacement, heating, stirring and reacting for 5-75 minutes to obtain a biochemical product. The cellulose is one of main components of biomass, and due to the adoption of the method provided by the invention, the cellulose in the biomass can be converted and prepared into bio-oil and biochemical products so that high-efficiency recycling of the cellulose is realized. The method has the advantages of simple process, mild conditions, small amount of ion liquid and realization of recycling, and the conversion rate of the cellulose under the optimized condition can be up to 100%.

Owner:SOUTH CHINA UNIV OF TECH

Method for synthesis of acetal/ketal in presence of acidic ionic liquid as catalyst?

ActiveCN103193569AEasy to separateHigh purityOrganic compound preparationEther/acetal/ketal group formation/introductionAlcoholKetone

The present invention discloses a method for synthesis of acetal / ketal in presence of acidic ionic liquid as catalyst, including: taking aldehyde / ketone and alcohol as raw materials and cyclohexane as a dehydrating agent, and performing azeotropic dehydration condensation under the catalytic action of the acidic ionic liquid at 80-120 DEG C. The acetal / ketal is obtained by aftertreatment of the reaction liquid after the reaction is completed. The acidic ionic liquid is a 3-(3-sulfonic acid)propyl benzothiazole salt acidic ionic liquid. The alcohol is C2-C4 organic alcohol. The method for synthesis of acetal / ketal catalyzed by the acidic ionic liquid has the advantages that the reaction operation is simple and convenient; separation of the catalyst from the product is easy; product purity and yield are high; and the catalyst can be reused and the catalytic activity thereof is essentially same. Accordingly, the method has broad application prospects.

Owner:临沭县益兴供汽维修服务有限公司

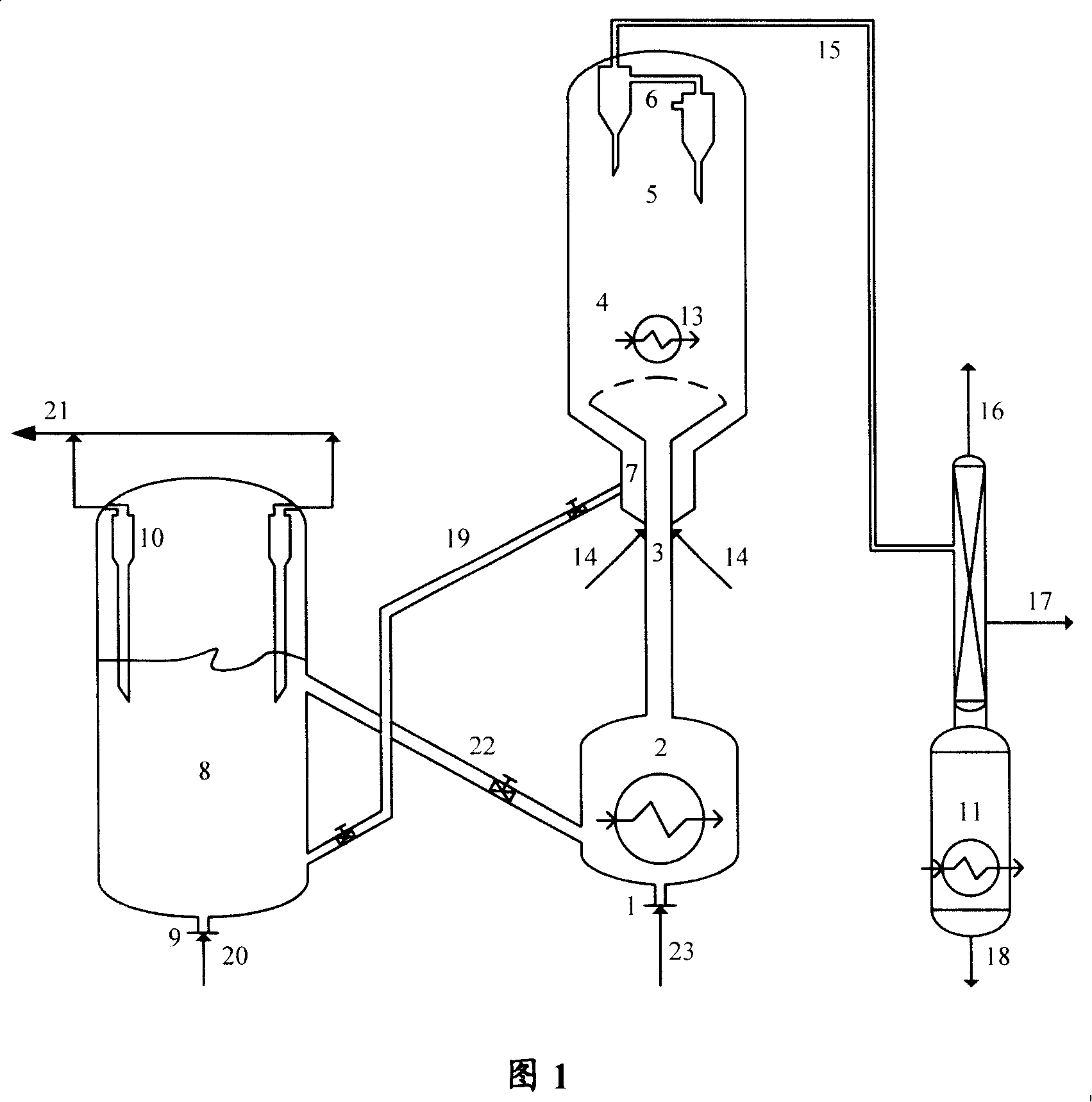

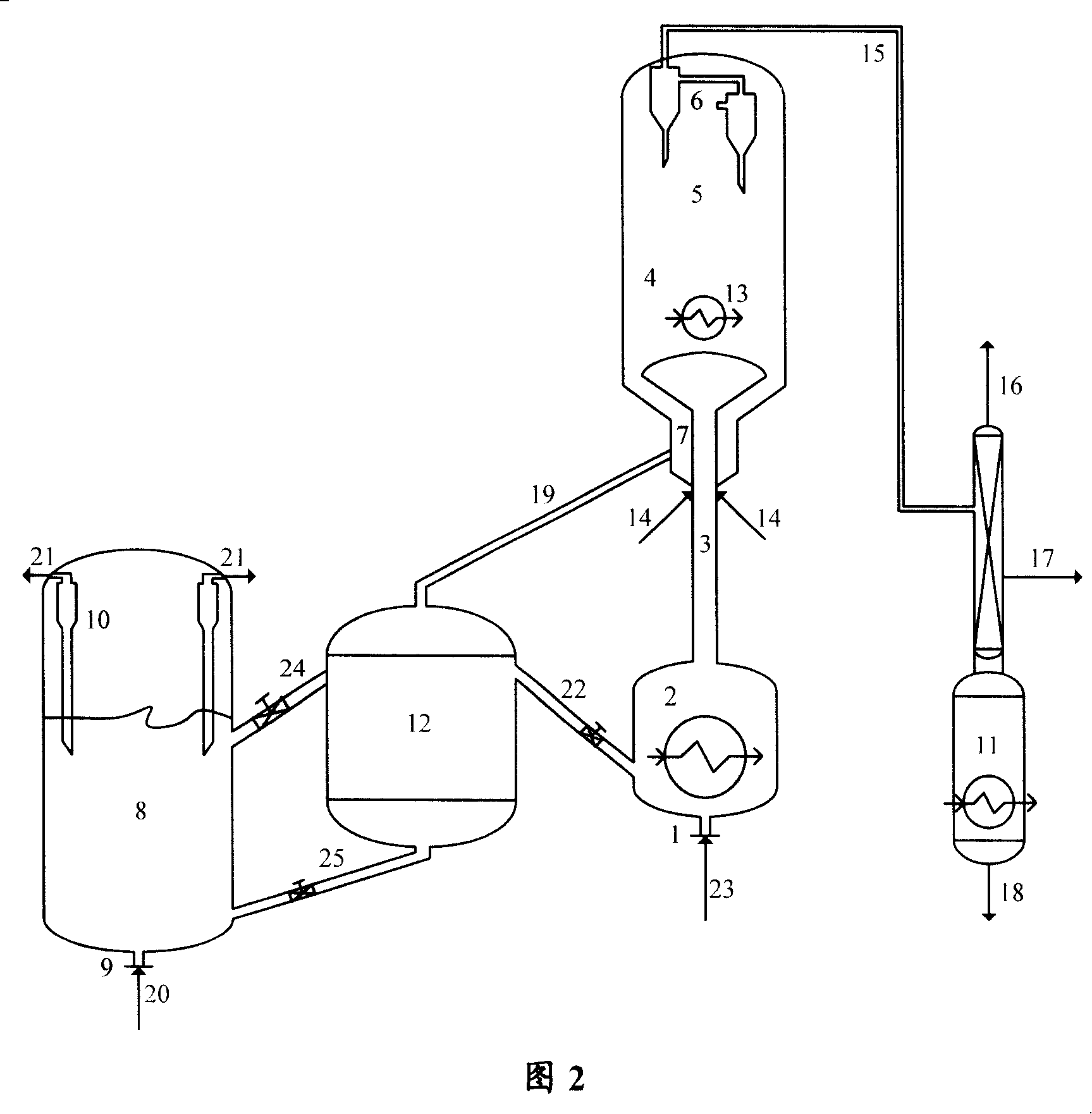

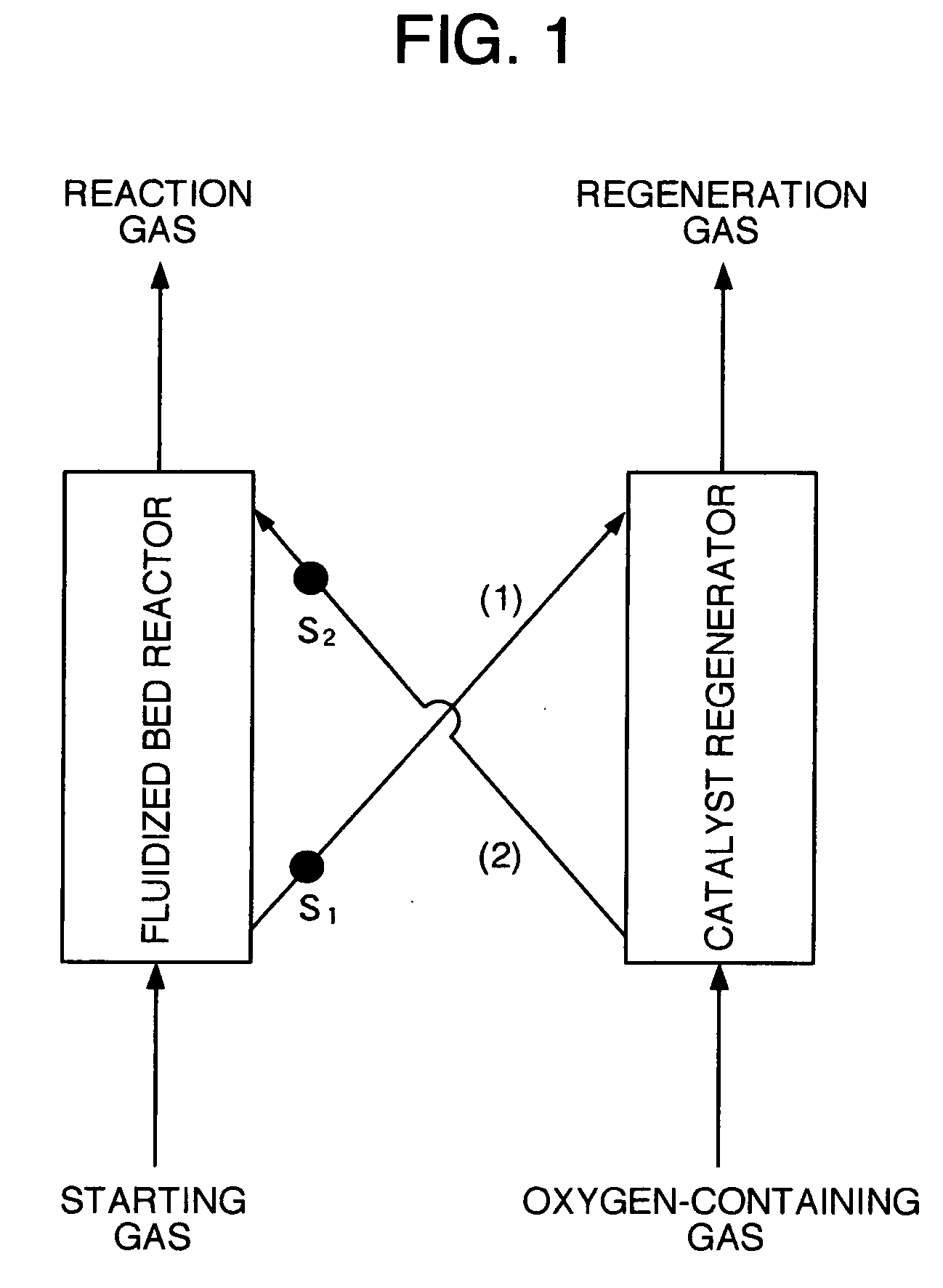

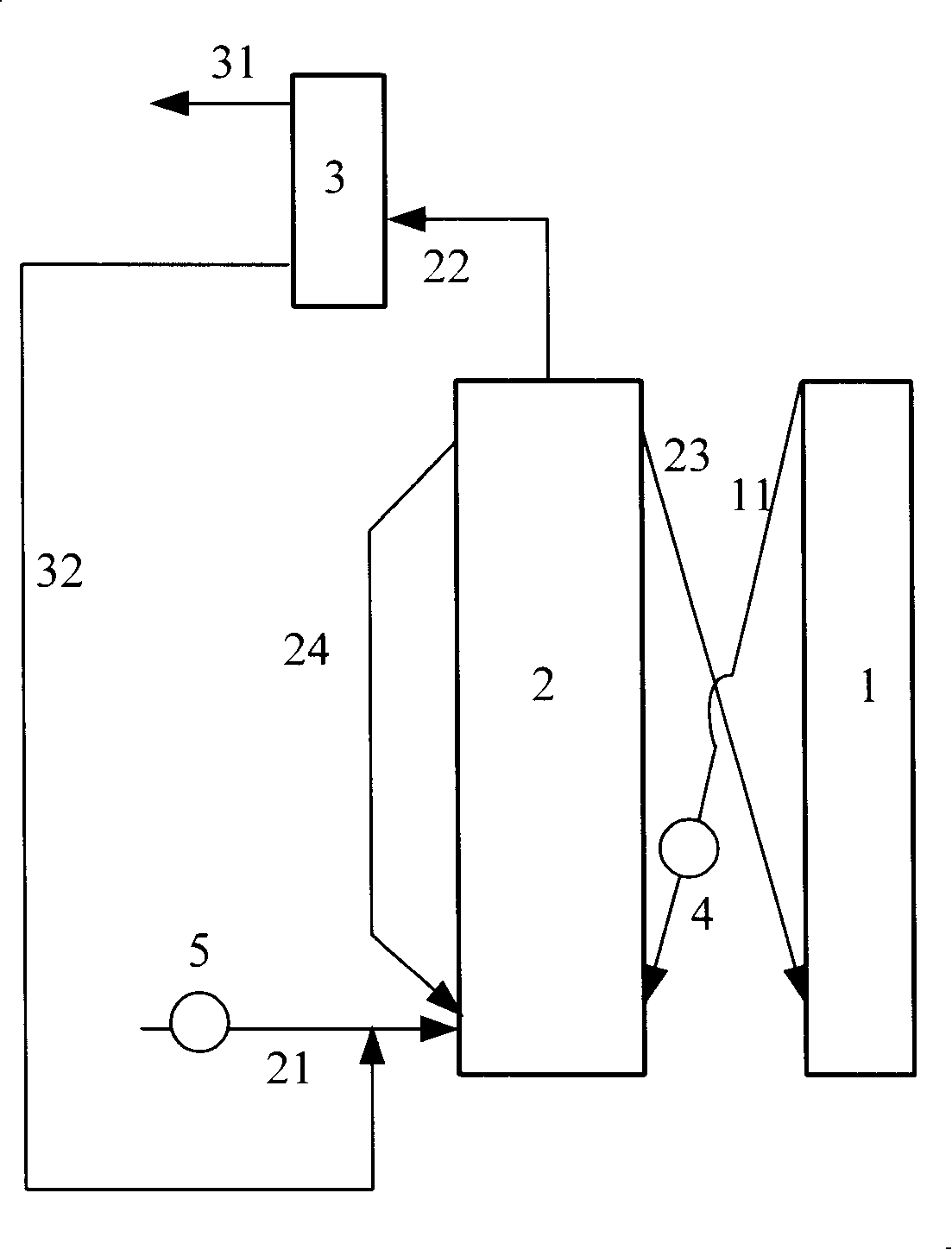

Liquefaction catalytic conversion method for producing dimethyl ether with methanol

ActiveCN101152997AImprove mass transfer efficiencyImprove heat transfer efficiencyEther/acetal/ketal group formation/introductionChemical recyclingFixed bedDimethyl ether

The present invention provides a fluidization and conversion method using methanol to prepare dimethyl ether. The methanol material, cooled regenerated catalyst and pre-lifting medium orderly enter a circulating fluidized bed. At a temperature between 150 and 500 DEG C, under pressure between 0.1MPa and 1.0MPa and at a liquid space-time speed of 0.5 to 4 hours, the -1, catalyst and methanol material react with a weight ratio of 1 to 20. In the reaction process, heat is removed from the circulating fluidized bed; the reaction material flow and catalyst to be generated are separated. Wherein, the target product dimethyl ether can be got by separation of the reaction material flow. The catalyst to be generated is recycled orderly after gas extraction, regeneration and cooling. Compared with a fixed-bed, the circulating fluidized bed of the method provides better gas-solid contact, and has gas-solid phase medium and high heat transfer efficiency. Therefore, the method improves the conversion rate of methanol and the selectivity of dimethyl ether product.

Owner:CHINA PETROLEUM & CHEM CORP +1

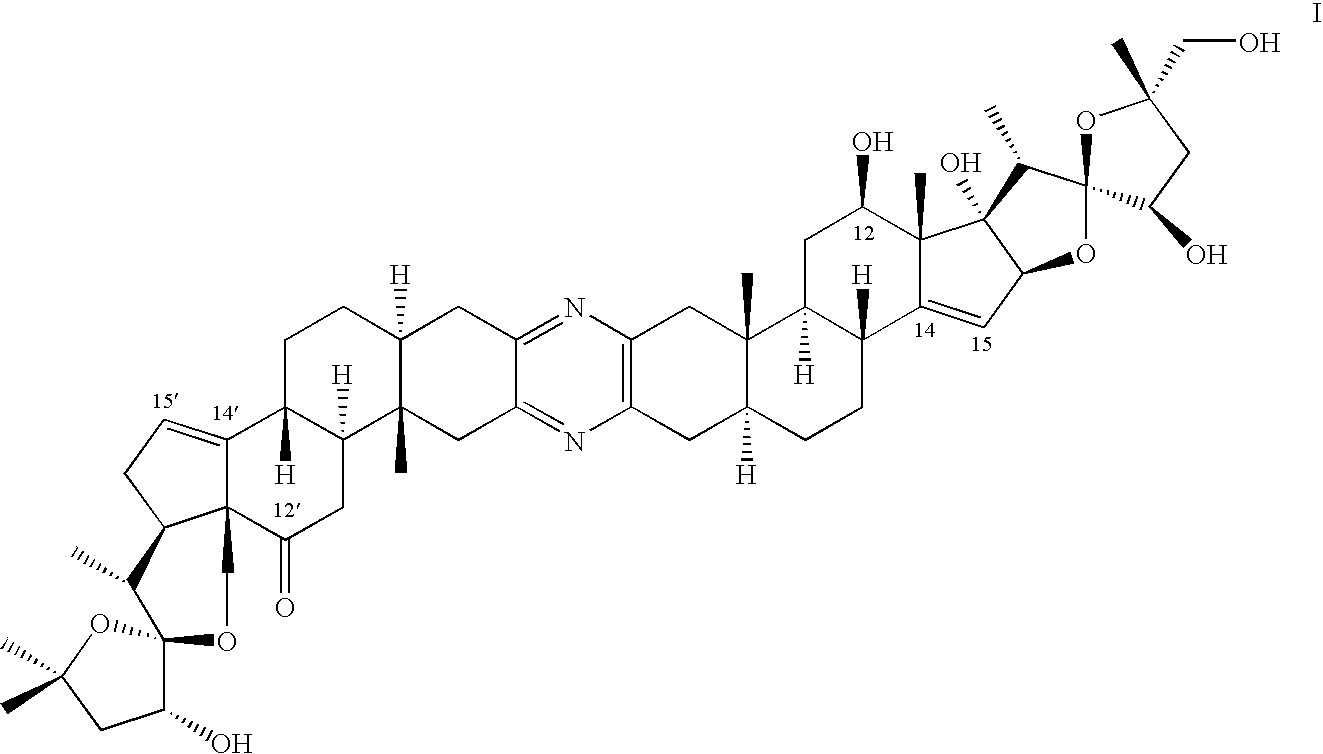

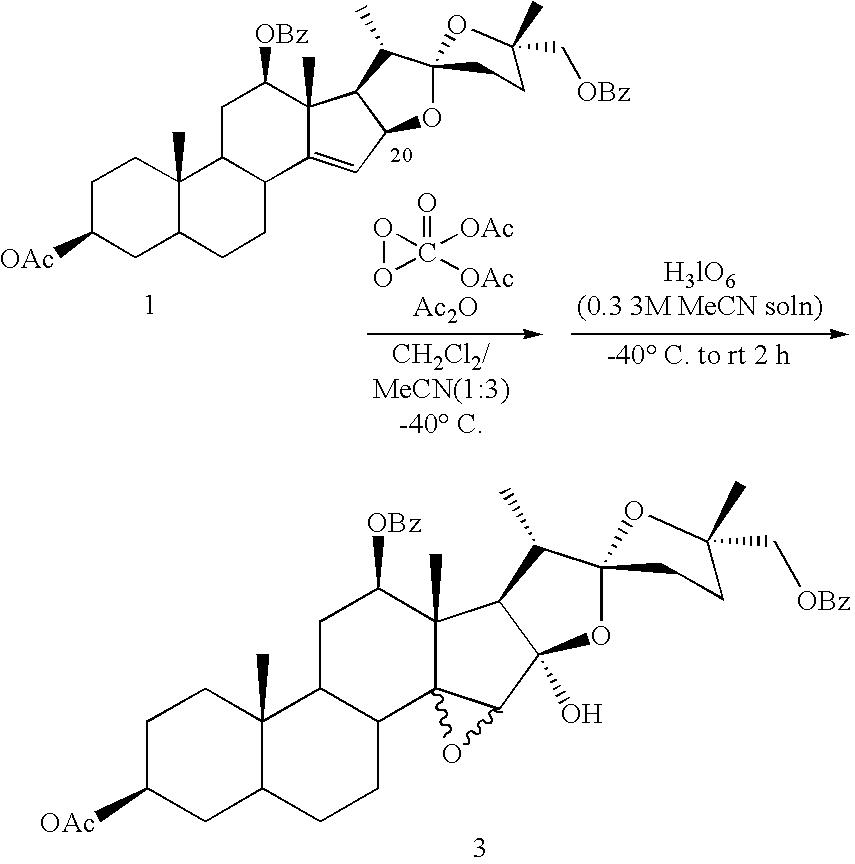

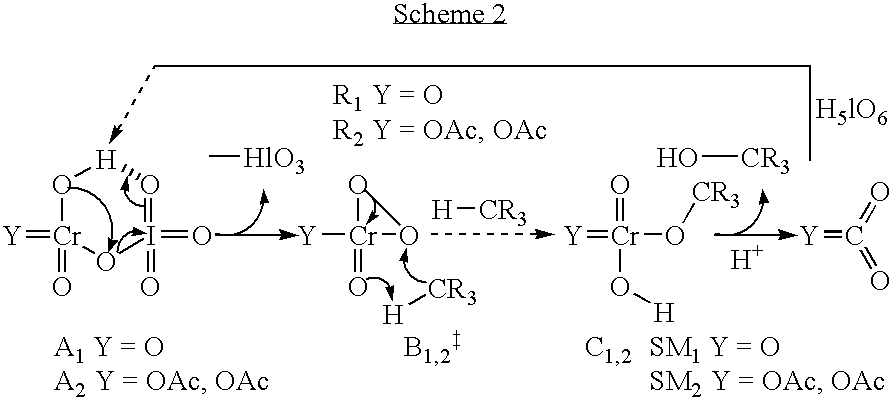

Catalytic oxidation of C-H bonds

InactiveUS20040087820A1Increase productionLow yieldOxygen-containing compound preparationPreparation by oxidation reactionsHemiacetalAlcohol

The invention provides a catalytic, chemospecific and stereospecific method of oxidizing a wide variety of substrates without unwanted side reactions. Essentially, the method of the instant invention, under relatively mild reaction conditions, catalytically, stereospecifically and chemospecifically inserts oxygen into a hydrocarbon C-H bond. Oxidation (oxygen insertion) at a tertiary C-H bond to form an alcohol (and in some cases a hemiacetal) at the tertiary carbon is favored. The stereochemistry of an oxidized tertiary carbon is preserved. Ketones are formed by oxidizing a secondary C-H bond and ring-cleaved diones are formed by oxidizing cis tertiary CH bonds.

Owner:PURDUE RES FOUND INC

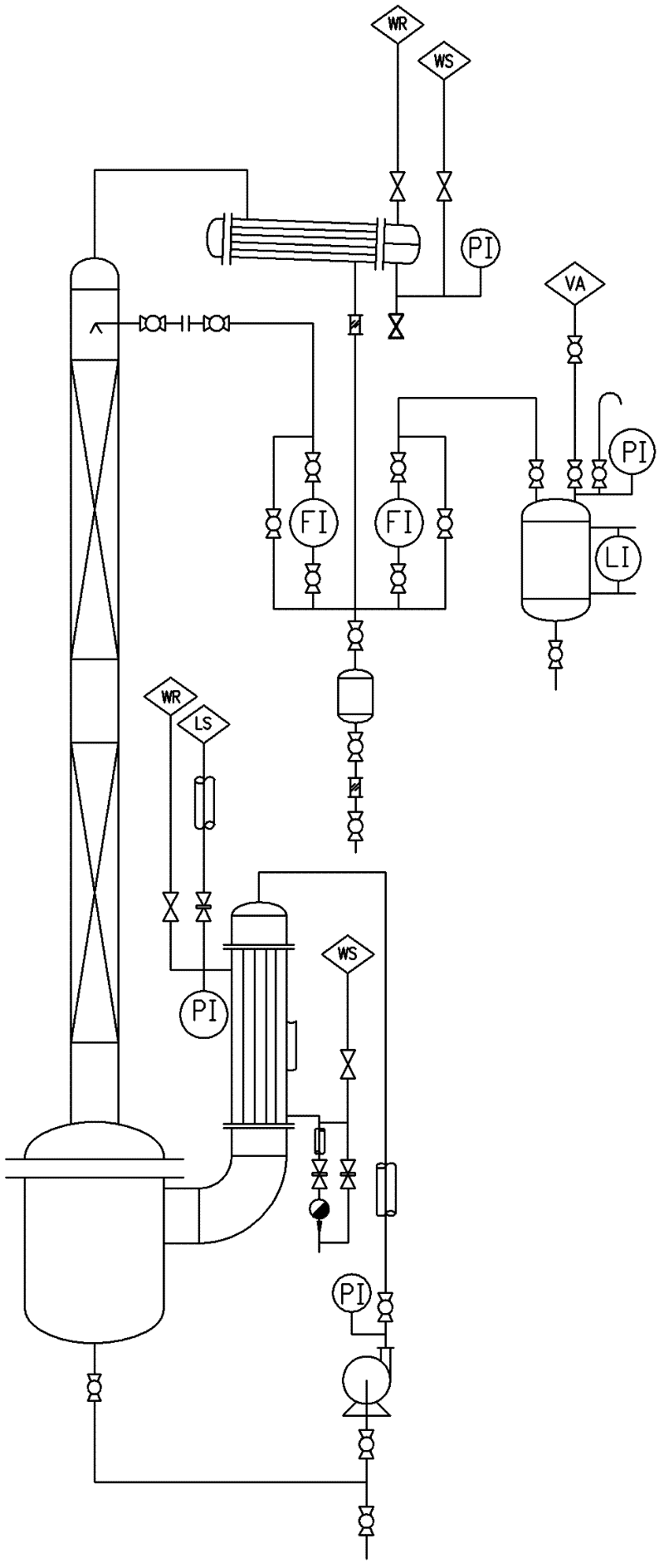

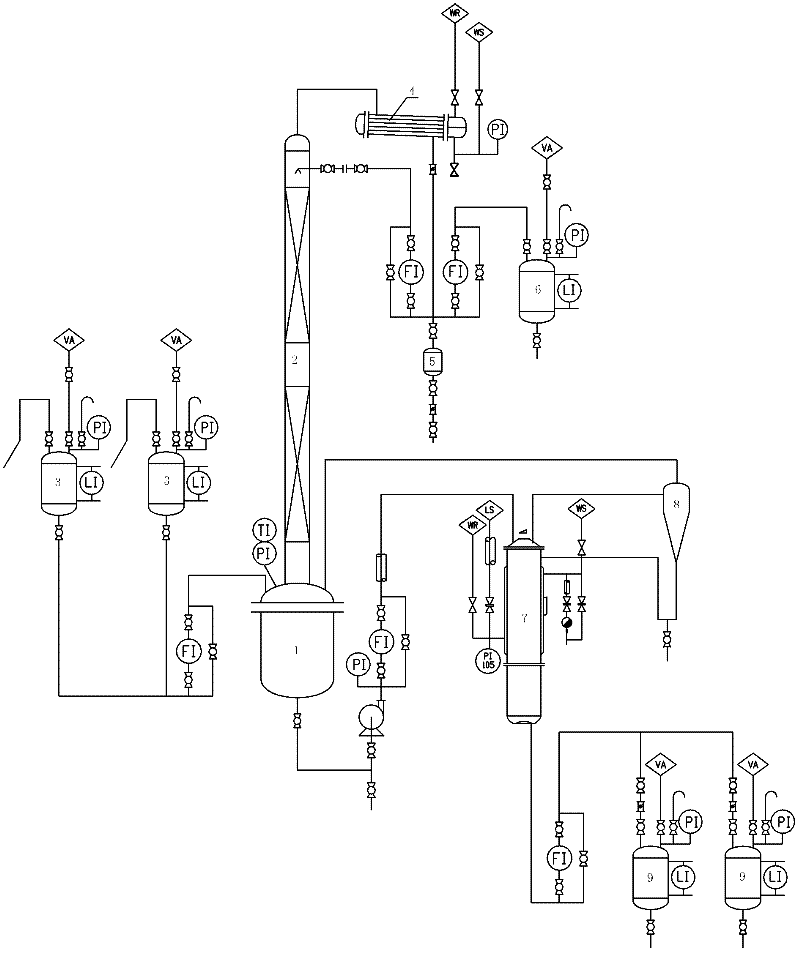

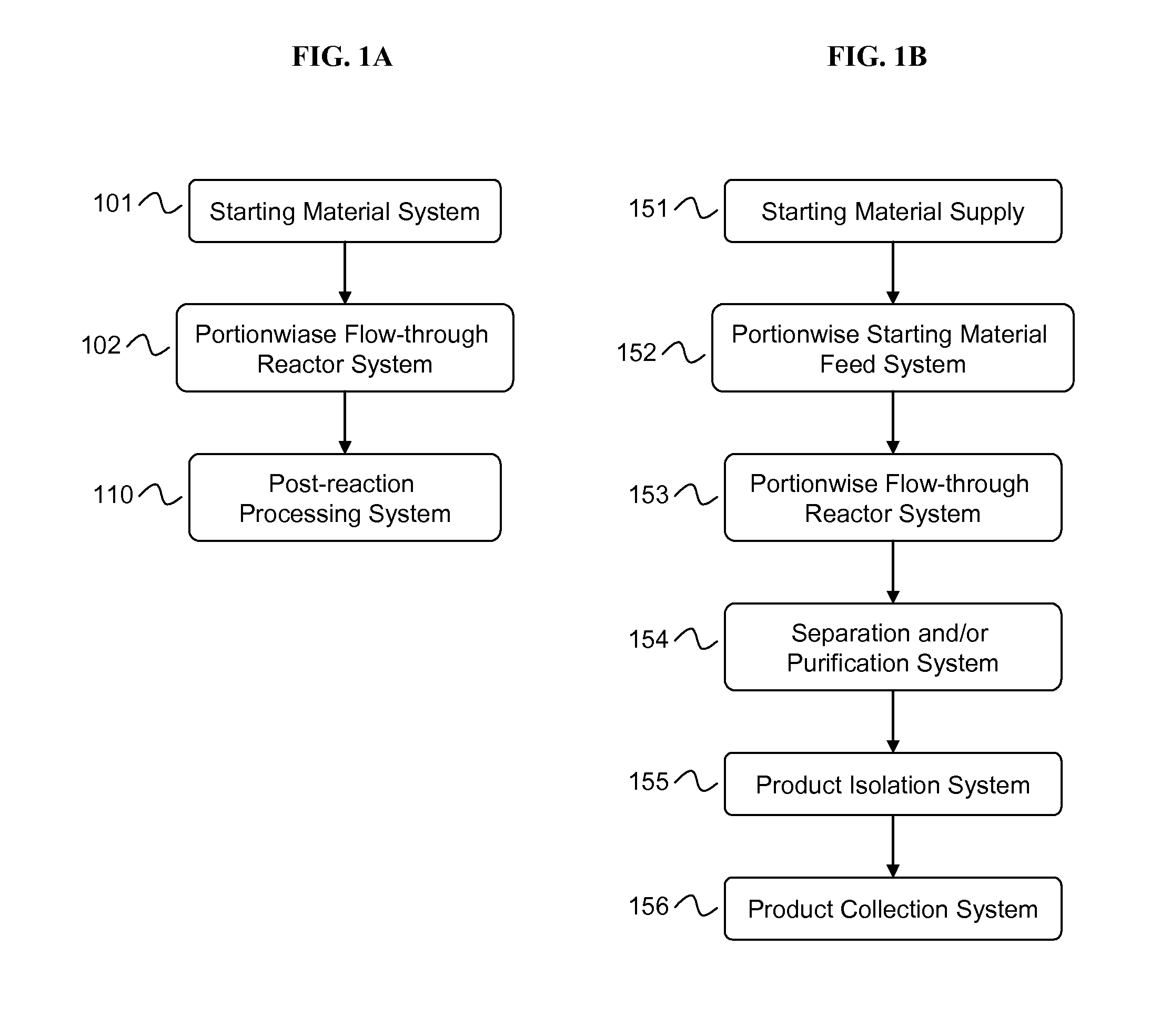

Continuous reaction method

ActiveCN102557849AIncrease production capacityEliminate time spent on non-productive operationsOrganic compound preparationCarboxylic acid esters preparationPhysical chemistryProcess engineering

The invention discloses a continuous reaction method. The conventional intermittent reaction is almost balanced reaction, conversation rate is low, the proportion of nonproductive time in the total production time is small, and unit capacity of equipment is low. The continuous reaction method comprises the following steps of: feeding raw materials for reaction into a reaction kettle, feeding the raw materials flowing out of the bottom of the reaction kettle into reaction heating equipment, starting the reaction heating equipment and heating, feeding vapor and liquid mixture flowing out of the top of the reaction heating equipment into vapor-liquid separation equipment, feeding raw material vapor obtained from the top of the vapor-liquid separation equipment into a reaction kettle, wherein a rectifying column arranged on the reaction kettle is stably in a refluxing state, and feeding light components flowing out of the top of the rectifying column into a light component collection tank; and feeding liquid flowing out of the bottom of the vapor-liquid separation equipment into the reaction heating equipment again, and feeding liquid flowing out of the bottom of the reaction heating equipment into a product tank. Common intermittent reaction is improved to continuous reaction, and unit capacity of equipment is improved.

Owner:ZHEJIANG NHU CO LTD

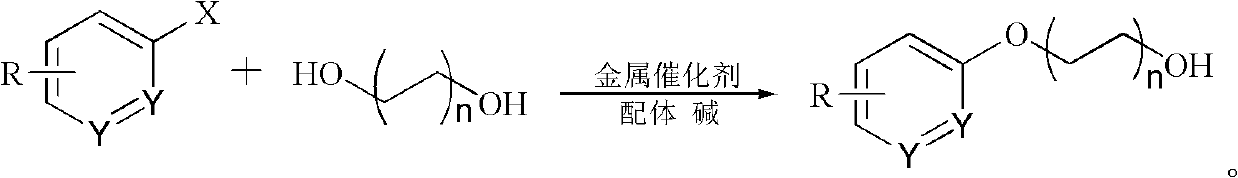

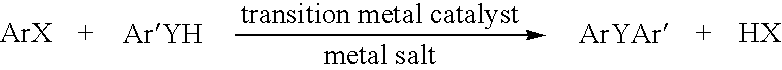

Synthetic method of diol phenylate compounds

InactiveCN102617257ANot corrosiveEasy to manufactureOrganic compound preparationEther/acetal/ketal group formation/introductionOrganic solventChemical reaction

The invention relates to a synthetic method of diol phenylate compounds, which is characterized in that raw material comprises aromatic compounds, diol, metal salt catalysts, alkali, reaction promoting ligand and reaction solvent; the raw material is added in a reactor and stirred for 1 to 72 hours under the temperature ranging from 50 to 220 DEG C; the raw material is extracted through organic solvent and concentrated through a rotary evaporator, and then the diol phenylate compounds are obtained through column passing; a chemical reaction equation is shown in a patent specification; the synthetic method achieves high efficiency; in addition, metal salt is adopted as the catalysts, so that non-corrosiveness can be achieved, and the synthetic method is convenient to prepare and use.

Owner:CHANGZHOU UNIV +1

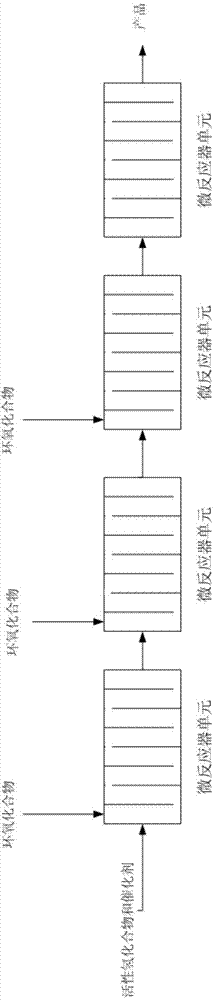

Method for performing alkoxylation reaction in microreactor

InactiveCN104725169AReduce contentLight colorOrganic compound preparationCarboxylic acid esters preparationMicroreactorHydrogen

The invention relates to a method for performing alkoxylation reaction in a microreactor, which comprises the following steps: adding a composite system composed of an active-hydrogen-containing compound, an epoxy compound and a catalyst into the microreactor, and carrying out alkoxylation reaction, wherein the microreactor is provided with a plurality of microchannels of which the cross section equivalent diameter is 0.001-10mm. The method can save resources and enhance the control safety in the alkoxylation reaction process, and is stable in process control. The obtained alkoxylation product has the advantages of light color, narrow distribution and low epoxy compound content.

Owner:LIAONING OXIRANCHEM INC

Copper-catalyzed formation of carbon heteroatom and carbon-carbon bonds

InactiveUS20050215794A1Cheap and practicalLow costUrea derivatives preparationCarbamic acid derivatives preparationCarbon–oxygen bondHydrazine compound

The present invention relates to copper-catalyzed carbon-heteroatom and carbon-carbon bond-forming methods. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of an amide or amine moiety and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In additional embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between a nitrogen atom of an acyl hydrazine and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In other embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-nitrogen bond between the nitrogen atom of a nitrogen-containing heteroaromatic, e.g., indole, pyrazole, and indazole, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. In certain embodiments, the present invention relates to copper-catalyzed methods of forming a carbon-oxygen bond between the oxygen atom of an alcohol and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. The present invention also relates to copper-catalyzed methods of forming a carbon-carbon bond between a reactant comprising a nucleophilic carbon atom, e.g., an enolate or malonate anion, and the activated carbon of an aryl, heteroaryl, or vinyl halide or sulfonate. Importantly, all the methods of the present invention are relatively inexpensive to practice due to the low cost of the copper comprised by the catalysts.

Owner:MASSACHUSETTS INST OF TECH

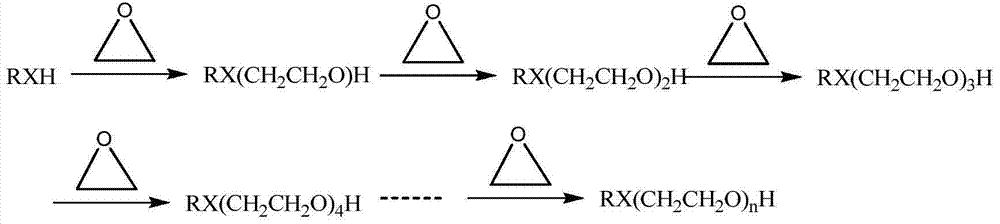

Method for preparing polyether polyol

ActiveCN101974149AReduce usageMeet the needs of productionSugar derivativesEther/acetal/ketal group formation/introductionAlkaline catalystVegetable oil

The invention provides a method for preparing polyether polyol which is prepared by the reaction between co-initiators and oxidized olefins under the action of an alkali catalyst. The method comprises the steps of: adding vegetable oil polyol and polyol or an amine compound or the mixture of the two in a reactor as the co-initiators; adding the catalyst and the oxidized olefin in the reactor; and reacting the co-initiators with the oxidized olefins in the presence of the catalyst under certain temperature and pressure to obtain the polyether polyol. The method for preparing the polyether polyol has the advantages of cheap and available raw materials, stable product quality and favorable usability; and the polyurethane foam plastic prepared by the method has good degradability.

Owner:JURONG NINGWU NEW MATERIAL CO LTD BY SHARES

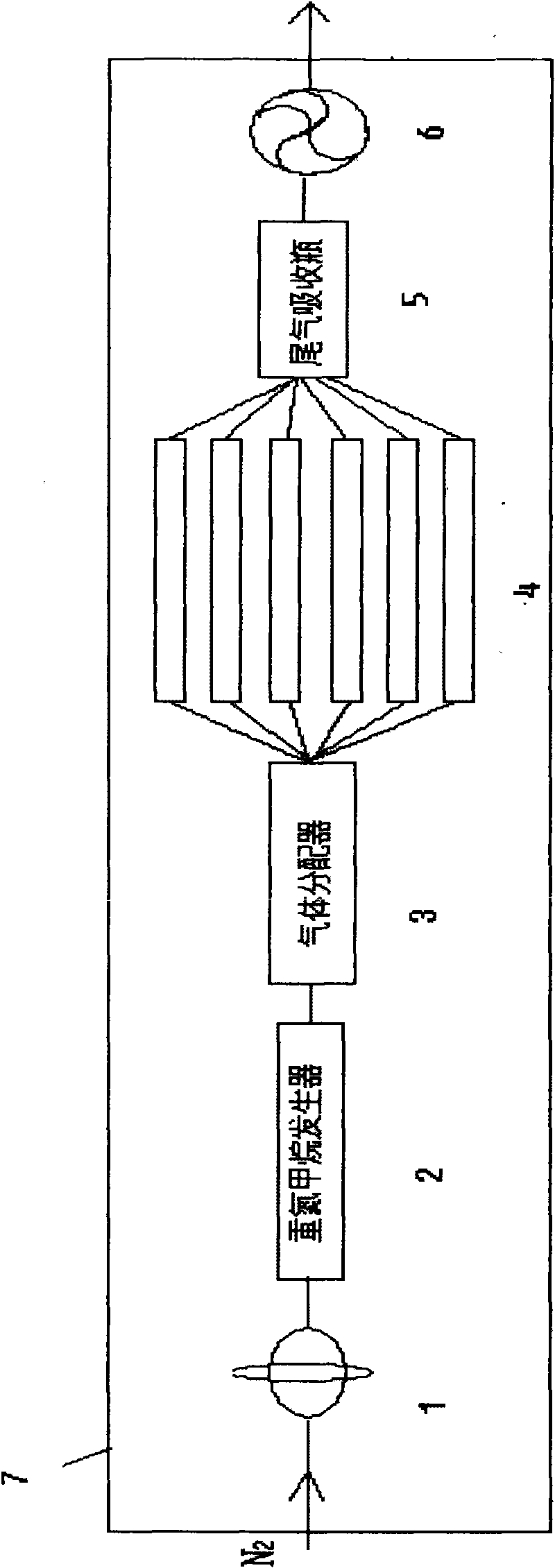

Diazomethane on-line deriving method

InactiveCN101704702AImprove securityEasy to operateOrganic compound preparationCarboxylic acid esters preparationMethaneChemistry

The invention relates to a diazomethane on-line deriving method, which comprises the following steps of: (1) a step of generating diazomethane; and (2) a step of deriving the diazomethane. The method can be realized under the action of N2. The method also comprises a tail gas absorption step after the step of deriving the diazomethane, wherein absorbent used in the tail gas absorption step for absorbing excessive diazomethane can be aether. The method also comprises a N2 flow rate control step before the step of generating the diazomethane and also comprises a diazomethane gas distribution step between (1) the step of generating the diazomethane and (2) the step of deriving the diazomethane. The method can be carried out in sealed environment. The diazomethane on-line deriving method can also comprise a step of exhausting the exhaust gas generated in the reaction from the sealed environment. The method organically integrates the preparation and the derivation of the diazomethane and has the characteristics of safety and high efficiency.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

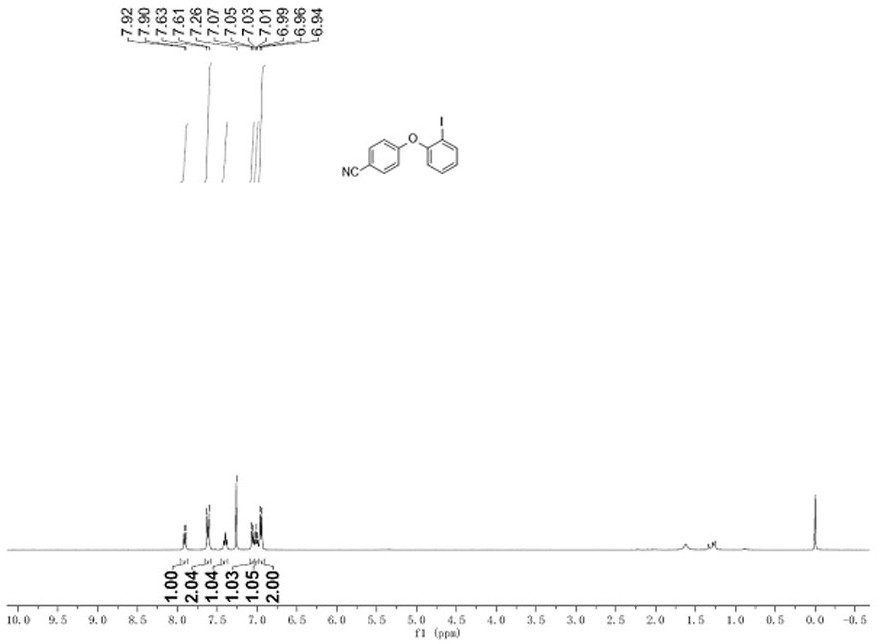

Method for preparing 2-iodo aryl ether under action of alkali metal hydride

ActiveCN112979400AImprove compatibilitySolve the problem that the reaction needs to be carried out at a higher temperatureCarboxylic acid nitrile preparationOrganic compound preparationArylPtru catalyst

The invention discloses a method for preparing 2-iodo aryl ether under the action of alkali metal hydride, which comprises the following steps: adding alkali metal hydride and phenol into a solvent, then adding 1, 2-diiodo aromatic hydrocarbon, and reacting at 0-100 DEG C to obtain a 2-iodo aryl ether product. In the coupling process, no transition metal catalyst needs to be added, so that metal pollution to the product is avoided; the method provided by the invention can be carried out at room temperature, has high functional group compatibility, and solves the problem that the existing metal-catalyzed coupling aryl ether reaction needs to be carried out at a relatively high temperature.

Owner:SUZHOU UNIV

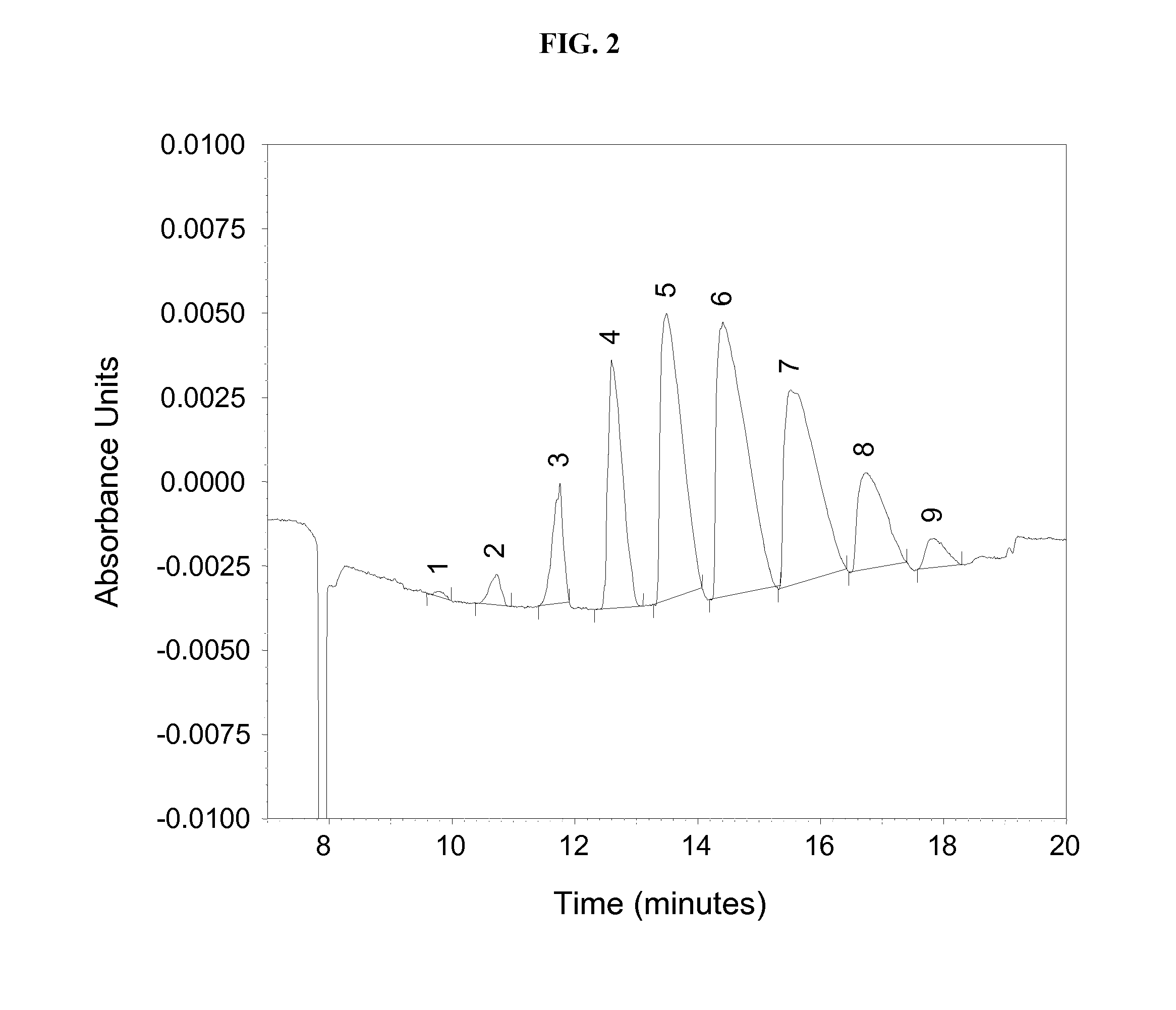

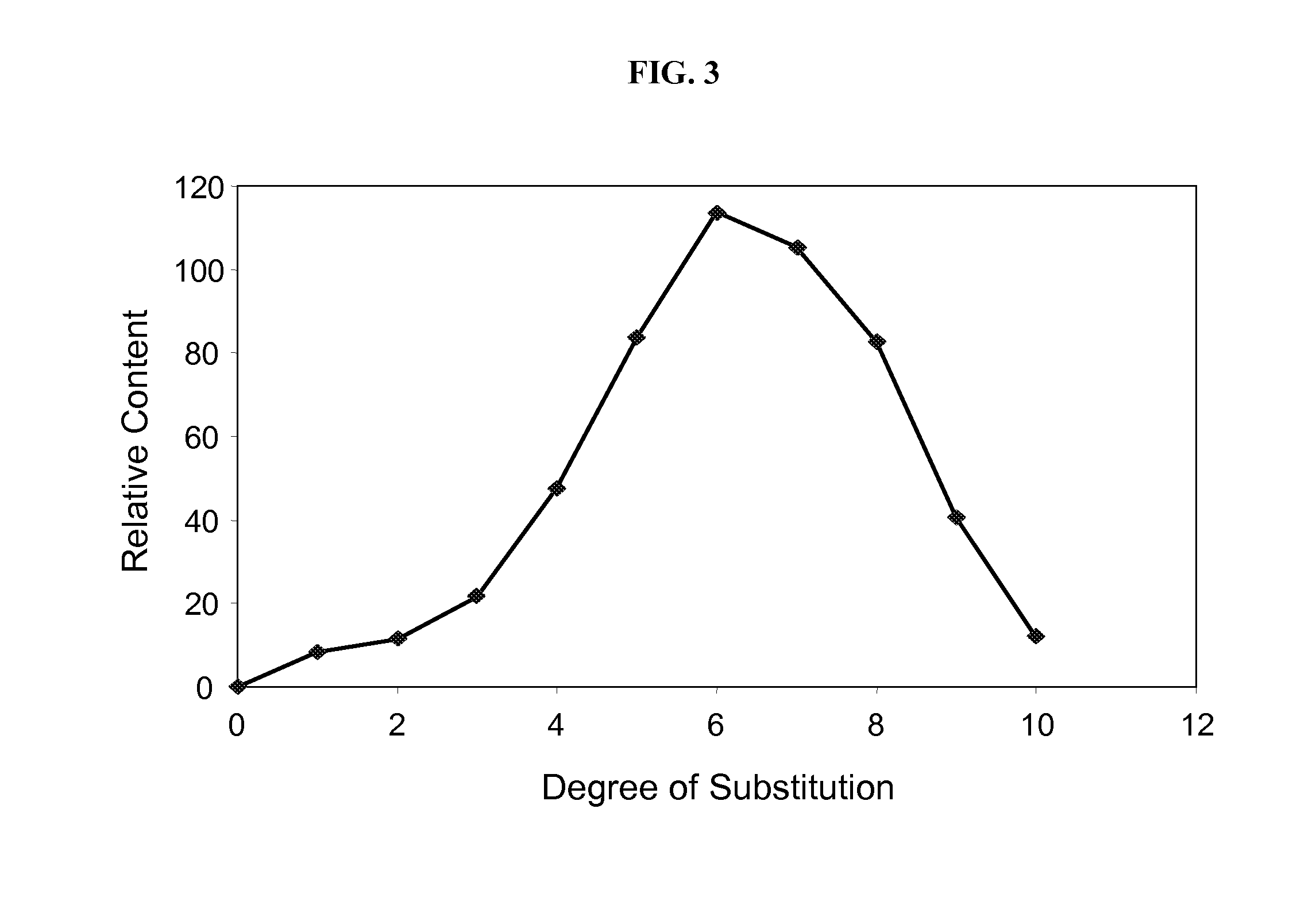

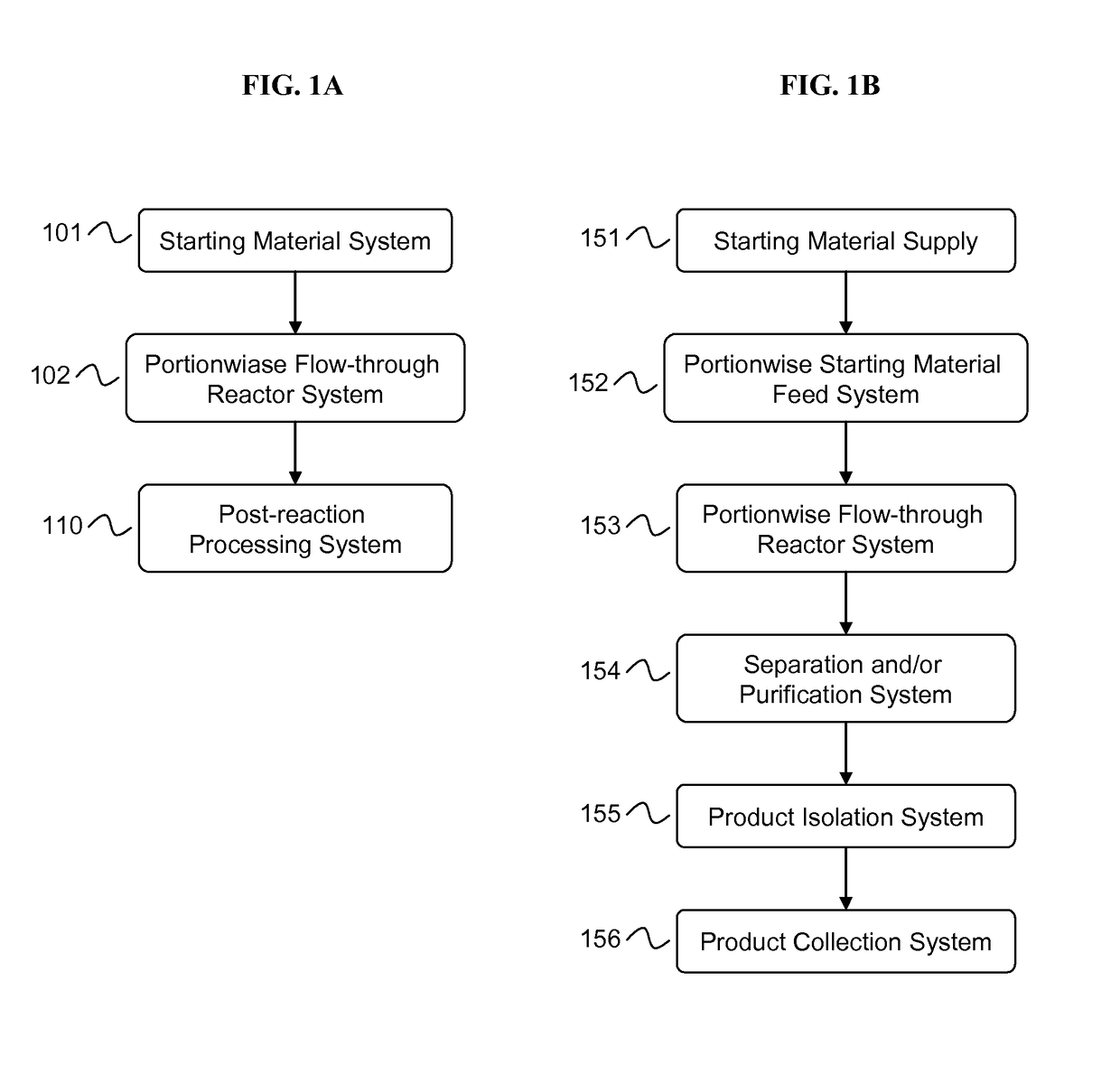

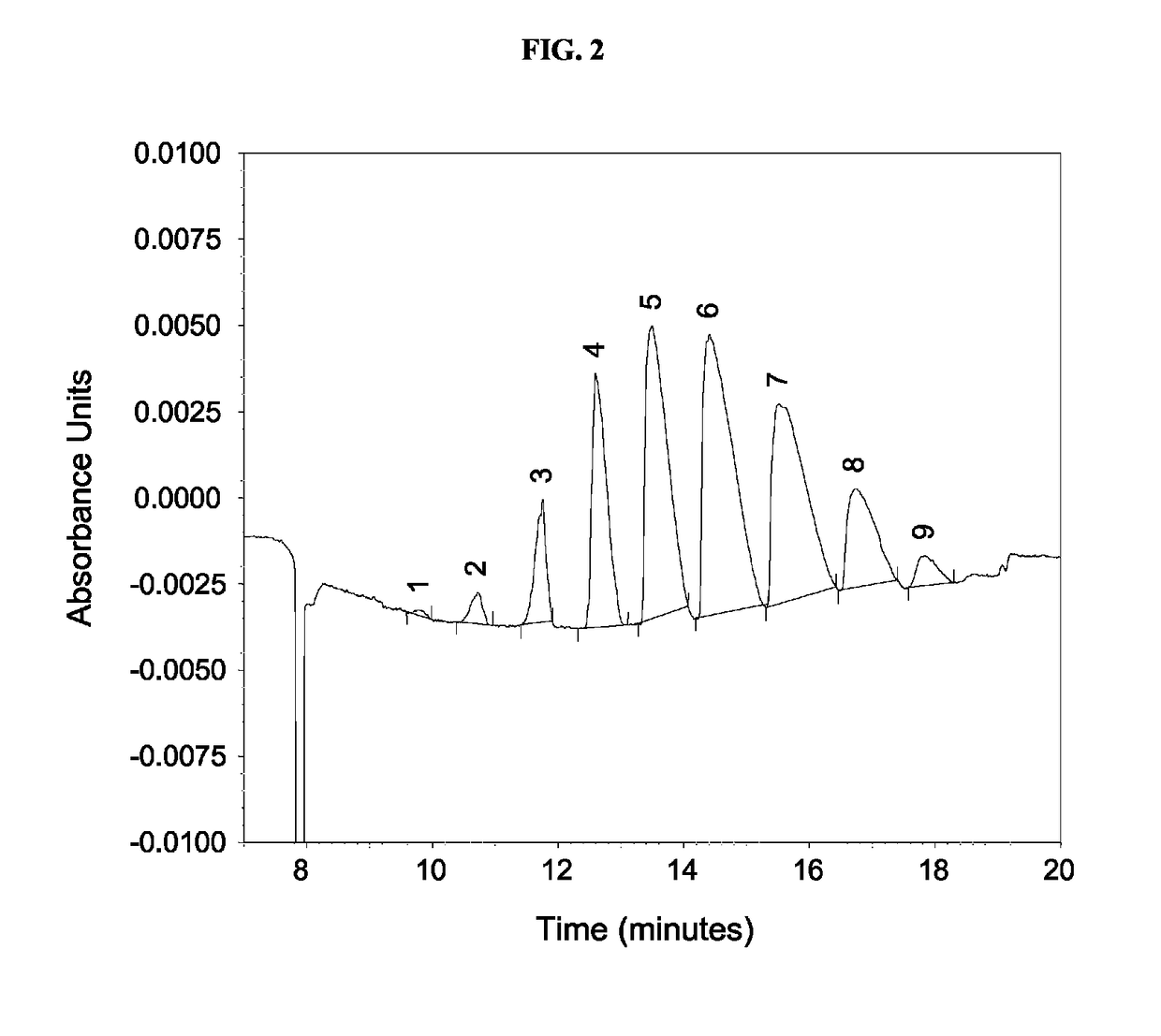

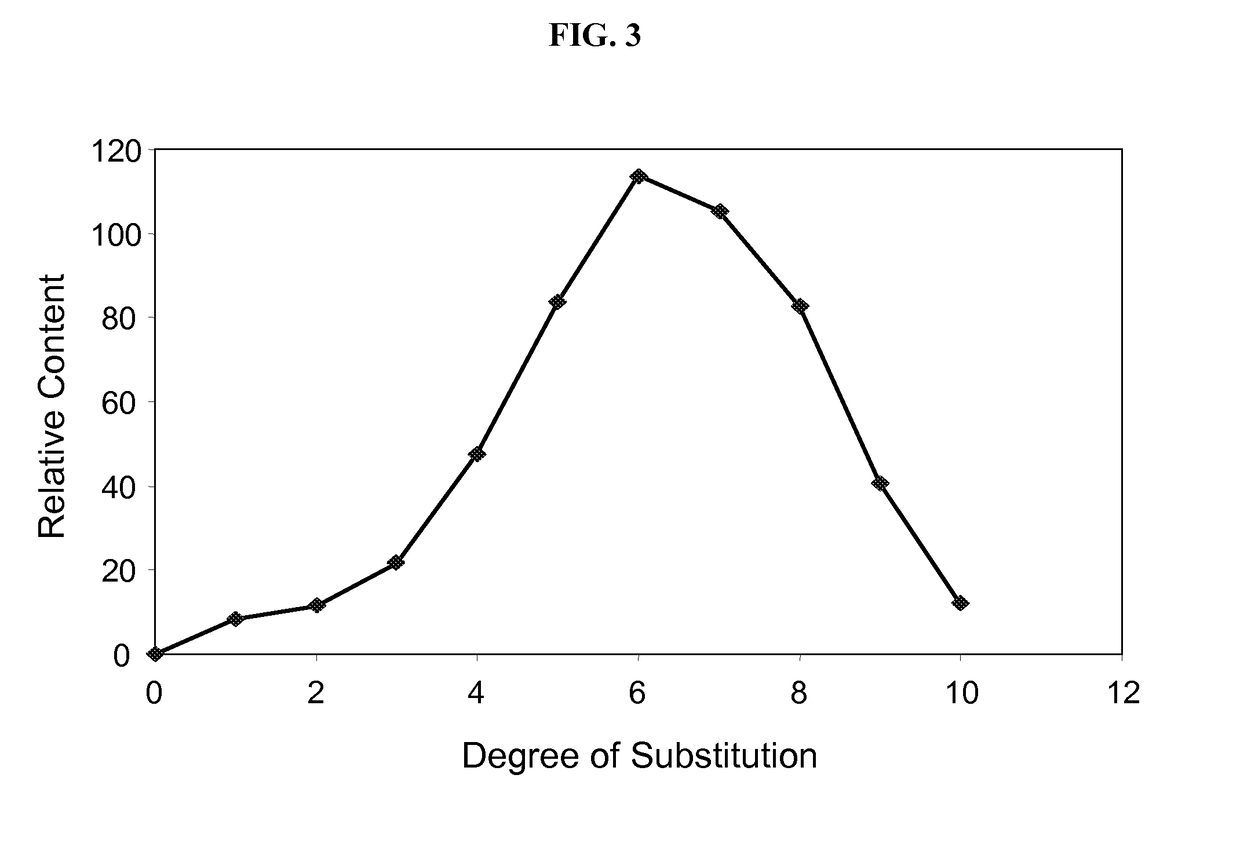

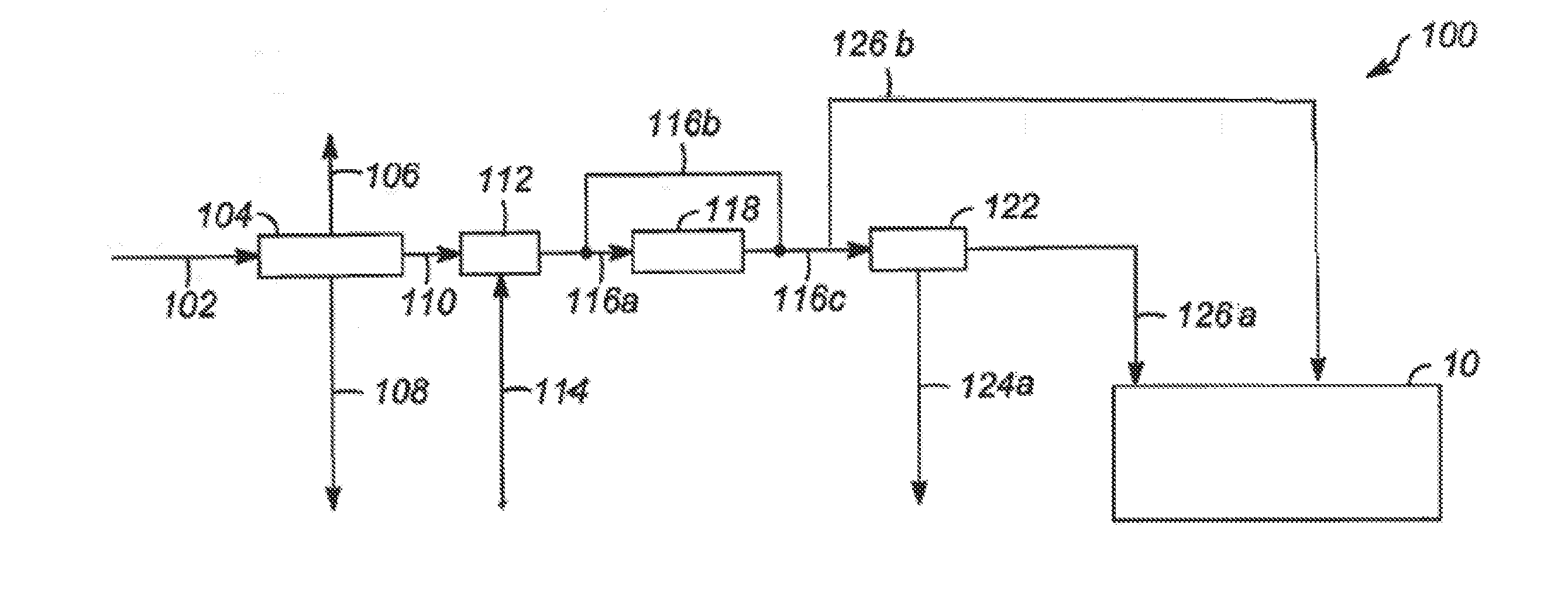

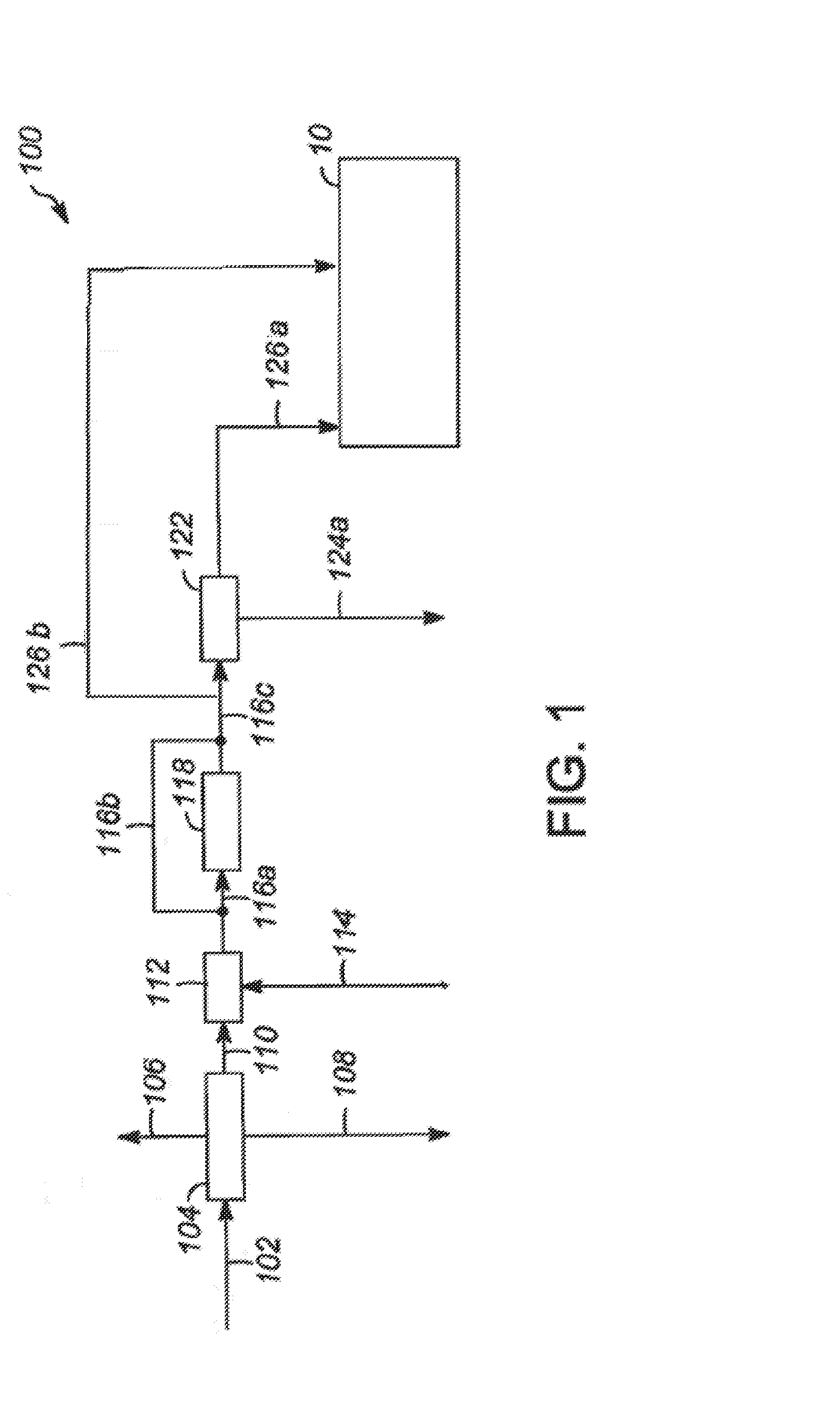

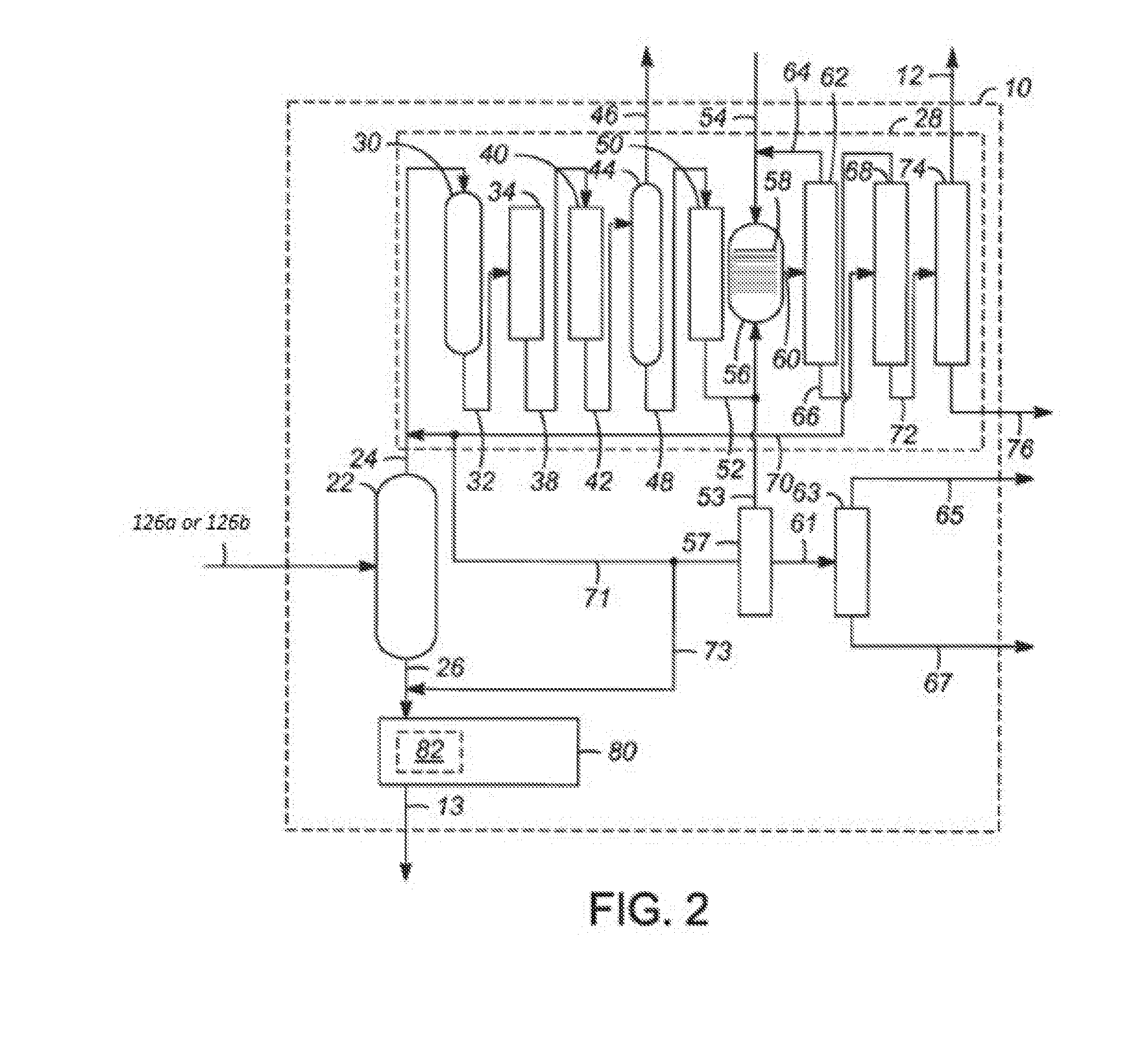

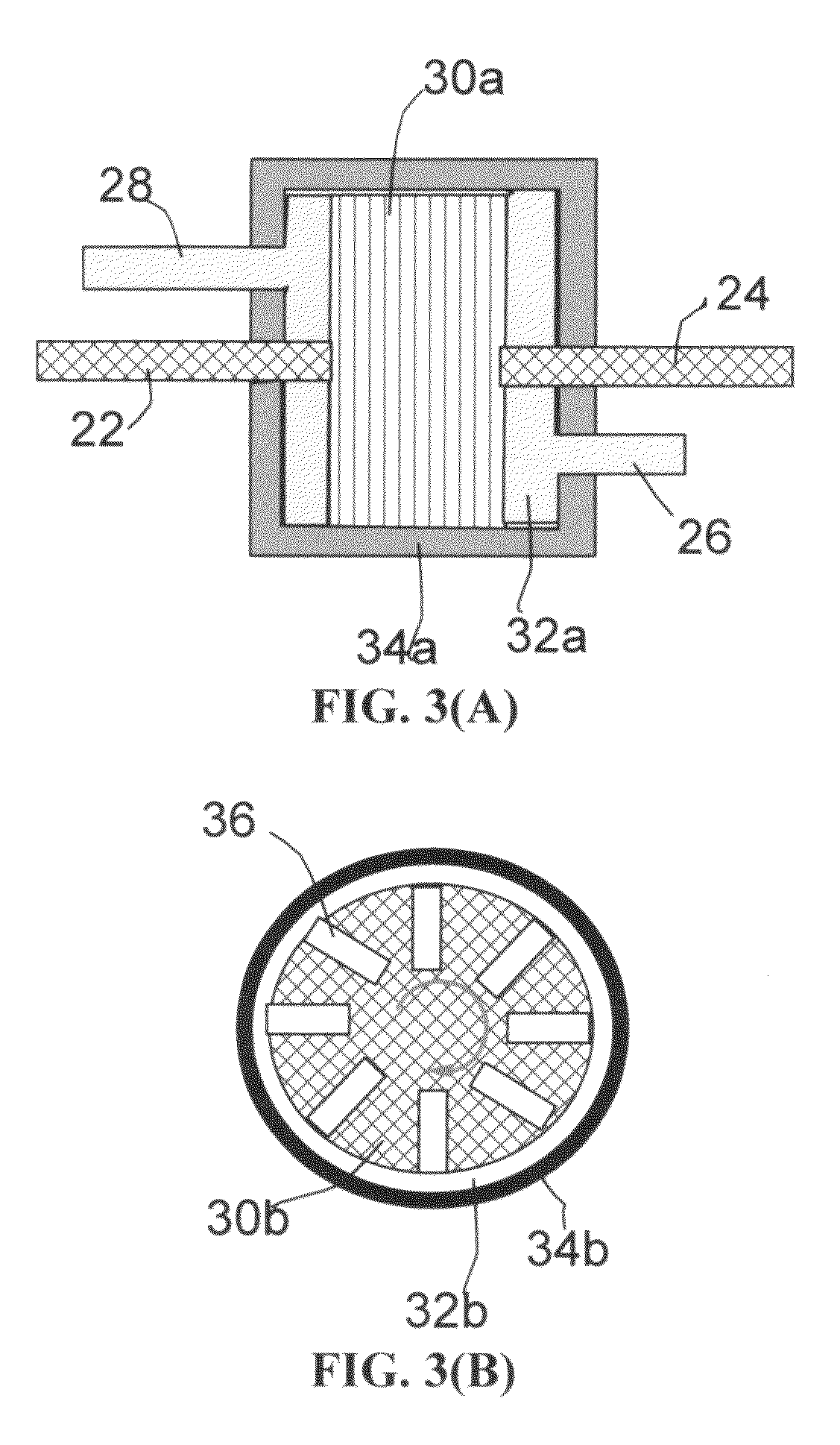

Manufacturing process for cyclodextrin derivatives

ActiveUS20160009826A1Rapid responseMinimize formationEther/acetal/ketal group formation/introductionSulfo/sulfonyldioxy group formation/introductionCyclodextrin DerivativesSide product

A process and equipment assembly for reacting a substituent precursor with a cyclodextrin starting material to provide a raw product comprising a cyclodextrin derivative and 1% or less of an initial amount of the substituent precursor is provided, The process of the present invention provides cyclodextrin derivatives in substantially shorter time and with fewer side products than previous processes that utilize substantially the same starting materials.

Owner:CYDEX PHARMACEUTICALS INC

Process for producing alcohol and/or ketone

ActiveUS20060173220A1High selectivitySelectivityPreparation by oxidation reactionsOrganic compound preparationAlcoholGas phase

The present invention relates to a method for producing an alcohol and / or a ketone from a corresponding alkene(s) in a gas phase in the presence of water vapor by the use of an oxide catalyst. According to the present invention, there is provided a method for producing an alcohol and / or a ketone by bringing a starting material containing an alkene(s), as a gas phase into contact with an oxide catalyst in the presence of water vapor to carry out the reaction, wherein the oxide catalyst satisfies the following requirements: (a) it comprises an oxide(s) of molybdenum and / or tin, and (b) the amount of carbonaceous substances accumulated on the oxide catalyst is controlled to be within a range of 0.1 to 10% by mass, during the reaction.

Owner:MARUZEN PETROCHEMICAL CO LTD

Diaryl ether condensation reactions

InactiveUS20050054882A1Efficient synthesisDramatic effectCarboxylic acid nitrile preparationOrganic compound preparationLeaving groupDiaryl ether

One aspect of the present invention relates to novel reaction conditions that allow the efficient synthesis of diaryl ethers from arenes bearing a leaving group and arenols under relatively mild conditions. Another aspect of the present invention relates to the dramatic effects of acidic activators on Ullmann-type couplings involving electron-poor and / or relatively insoluble substrates.

Owner:MARCOUX JEAN FRANCOIS

Manufacturing process for cyclodextrin derivatives

ActiveUS9751957B2Rapid responseMinimize formationEther/acetal/ketal group formation/introductionSulfo/sulfonyldioxy group formation/introductionCyclodextrin DerivativesSide product

A process and equipment assembly for reacting a substituent precursor with a cyclodextrin starting material to provide a raw product comprising a cyclodextrin derivative and 1% or less of an initial amount of the substituent precursor is provided. The process of the present invention provides cyclodextrin derivatives in substantially shorter time and with fewer side products than previous processes that utilize substantially the same starting materials.

Owner:CYDEX PHARMA INC

Method for producing dimethyl ether from methanol

InactiveCN101152999AContinuous conversionEffective control of reaction temperatureEther/acetal/ketal group formation/introductionChemical recyclingReaction temperatureCarbon deposit

The present invention provides a production method of dimethyl ether from methanol. The methanol material and catalyst containing Y-series zeolite contact and react in a reactor where the catalyst can be fluidized; the reaction materials are separated to get carbon deposit catalyst and target product dimethyl ether; part of or all of the carbon deposit catalyst enter a regenerator to be burnt and regenerated. The regenerated catalyst returns into the reactor to contact the methanol material. The method can effectively control the reaction temperature of bed layers, ensures the continuous transformation of methanol into dimethyl ether; the conversion rate of methanol is generally more than 80 per cent; the selectivity of dimethyl ether is more than 98 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparation of a mixture of alcohols and ketones by liquid phase oxidation of higher alkanes

InactiveUS20060094905A1Preparation by oxidation reactionsOrganic compound preparationHigher alkanesDiketone

The present invention provides a process for the production of a mixture of alcohols and ketones by the liquid phase oxidation of higher alkanes using a catalyst system consisting of transition group metal such as palladium and support such as alumina, silica, carbon, preferably carbon in the presence of alkyl hydroperoxide as oxygen carrier, under stirring conditions at a temperature range of 10°-120° C. and at atmospheric pressure in a stirred glass reactor for a period of 1-30 h. The present invention produces a mixture of alcohols and ketones with high selectivity (preferably 60-90%) along with other byproducts such as diketones and acids.

Owner:COUNCIL OF SCI & IND RES

Methods for producing alkylbenzenes, paraffins, olefins and oxo alcohols from waste plastic feedstocks

ActiveUS20170044465A1Broad representationHydrocarbon by dehydrogenationSulfonyl/sulfinyl group formation/introductionOxo alcoholParaffin oils

The present invention relates generally to methods for producing detergent compounds from waste plastic feedstocks. More specifically, the invention relates to methods for producing detergent intermediates, including alkylbenzenes, paraffins, olefins, oxo alcohols, and surfactant derivatives thereof from waste plastic feedstock.

Owner:THE PROCTER & GAMBLE COMPANY

Method for producing oxygen-containing compound

InactiveUS20060173221A1Promote recoveryEasy to reusePreparation by oxidation reactionsOrganic compound preparationSelenium CompoundDouble bond

It is provided that a method for producing an oxygen-containing compound, characterized in that an olefin compound having a carbon-carbon double bond which is bonded to a methyl or methylene group is reacted with an organic hydroperoxide in the presence of an ionic liquid and a selenium compound.

Owner:SUMITOMO CHEM CO LTD

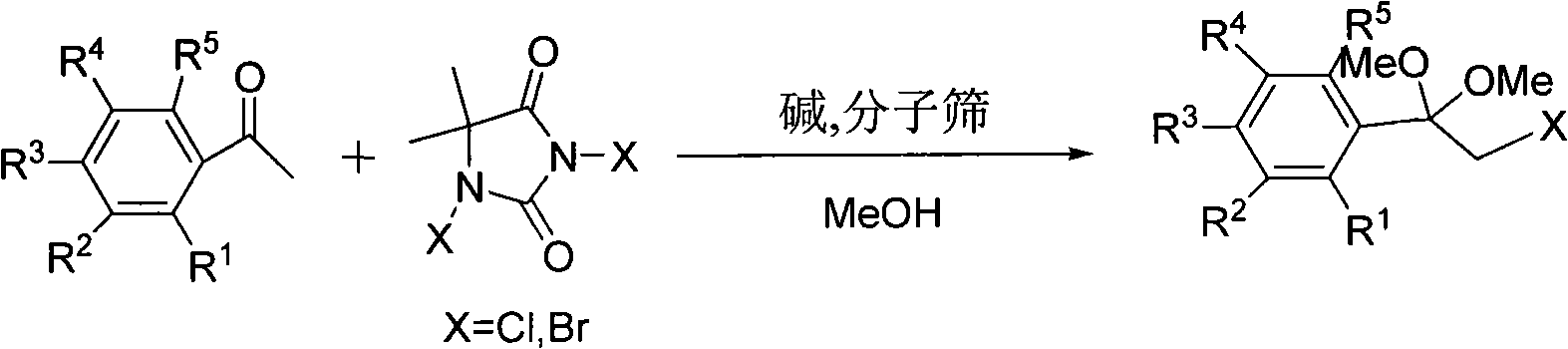

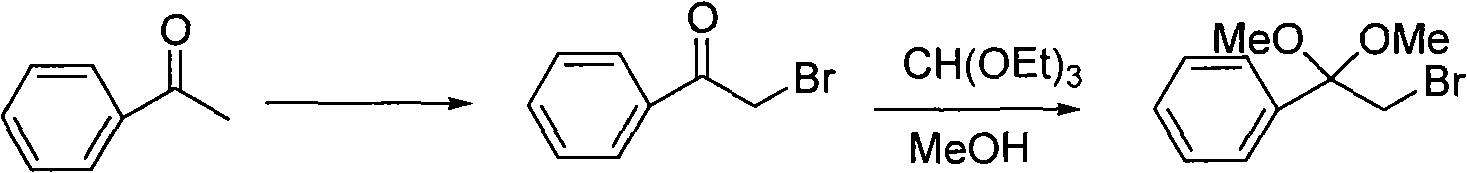

One-step method for preparing alpha-halo acetophenone dimethyl ketal compounds

InactiveCN101624321AMild reaction conditionsHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationBromineSolvent

The invention discloses a one-step method for preparing alpha-halo acetophenone dimethyl ketal compounds, and the method takes carbonyl compounds as reactants, takes a base as a catalyst, takes a dihalogenated hydantoin as a halogenating agent and takes methanol as a solvent for simultaneously carrying out alpha-site halogenating reaction and condensation reaction of the methanol in one step in the presence of a dewatering agent, thereby obtaining the alpha-halo acetophenone dimethyl ketal compounds. The method uses a variety of acetophenone compounds and 1,3-dichloro (bromo)-5,5-dimethyl hydantoin and adopts the one-step method to directly obtain the corresponding alpha-halo acetophenone dimethyl ketal which can be generally obtained by two steps of reaction, the reaction conditions are mild, and the yield is high, thereby having better industrial prospects.

Owner:EAST CHINA NORMAL UNIV

Method for preparing diphenyl ether compound

ActiveCN103012027ACarboxylic acid nitrile preparationOrganic compound preparationAluminium chlorideSilica gel

The invention relates to a method for preparing a diphenyl ether compound. The method is characterized by comprising the following technical steps of: (1) adding a halogenated benzene derivative and a bis(pinacolato)diboron into a reaction vessel, adding copper chloride or aluminum chloride and 1,2-bi(diphenylphosphine) ethane as a catalyst, then adding alkaline and an organic solvent, and reacting at 25-160 DEG C for 6-24 hours; and (2) after extracting a reaction solution obtained from the step (1) by using ethyl acetate, purifying by a 200-300 meshes silica gel column, pre-eluting the silica gel column by using 20-50 mL of normal hexane, eluting by adopting an eluent at a flow speed of 1-2 mL / min for 3-6 hours, and removing the solvent to obtain the diphenyl ether compound. The method for preparing the diphenyl ether compound, disclosed by the invention, no only overcomes the disadvantage of the use of phenolic substances in a reaction process, but also has the advantages of mild reaction condition and high yield.

Owner:JIANGNAN UNIV

Production of graphene materials in a cavitating fluid

ActiveUS9315388B2Shorten the timeReduce lossesGraphiteHydroxy group formation/introductionLiquid mediumCavitation

The invention provides a method of producing a graphene material from a starting graphitic material. In an embodiment, the method comprises: (a) dispersing the starting graphitic material in a liquid medium to form a graphite suspension; and (b) introducing the graphite suspension into a hydrodynamic cavitation reactor that generates and collapses cavitation or bubbles in the liquid medium to exfoliate and separate graphene planes from the starting graphitic material for producing the graphene material. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable. The reactor can concurrently perform the functions of graphene production, chemical functionalization, dispersion, and mixing with a polymer to make a composite.

Owner:GLOBAL GRAPHENE GRP INC

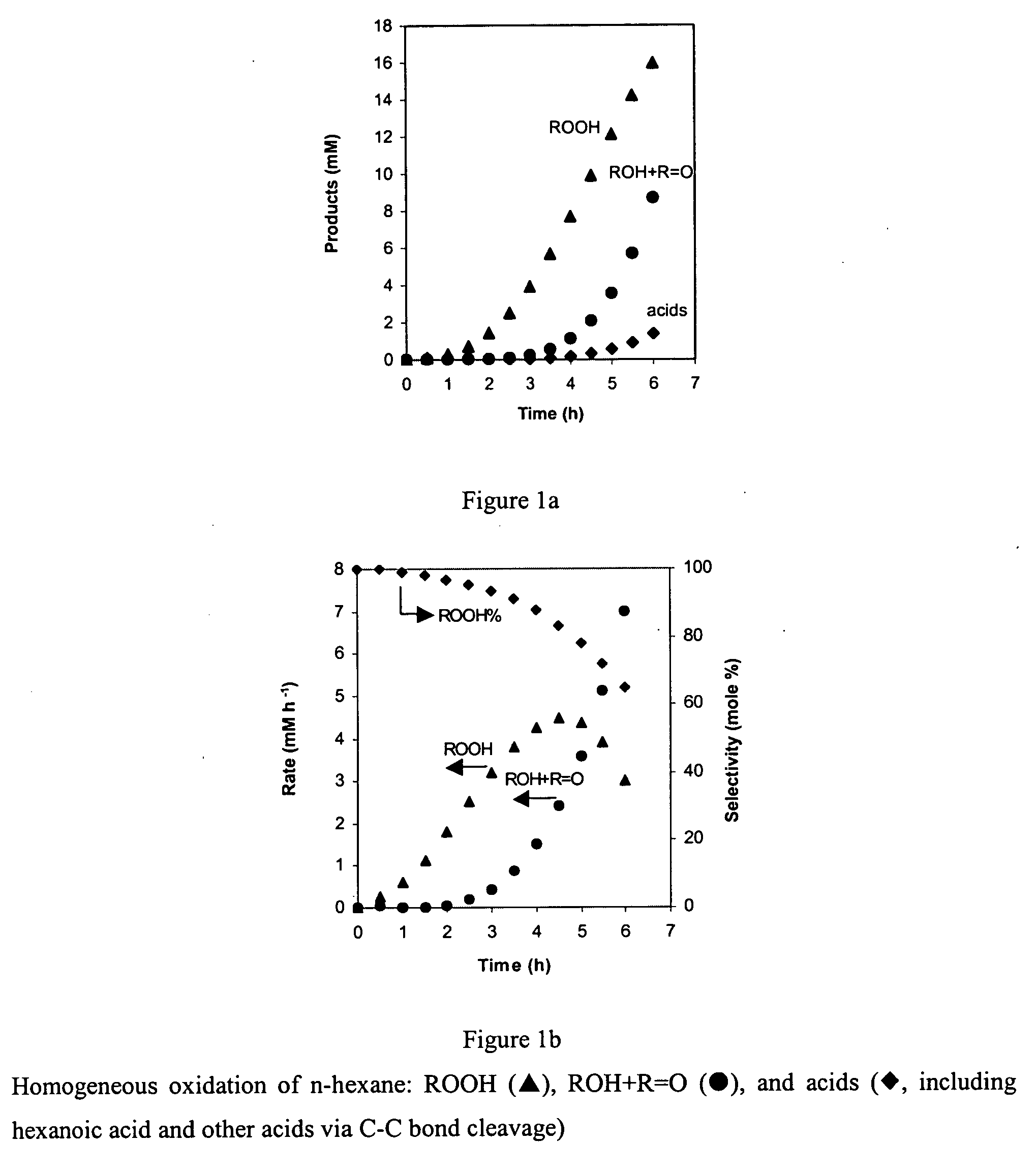

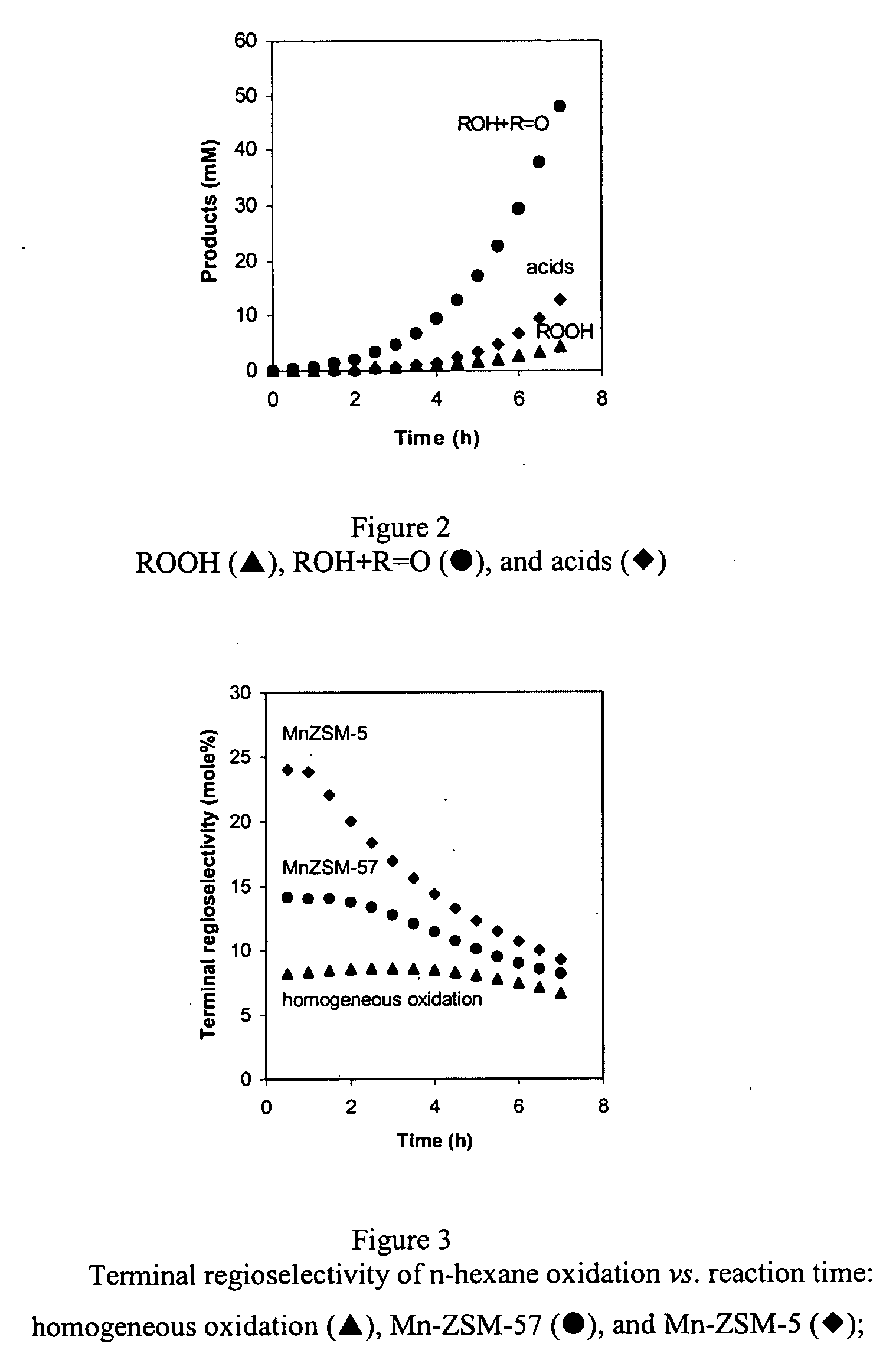

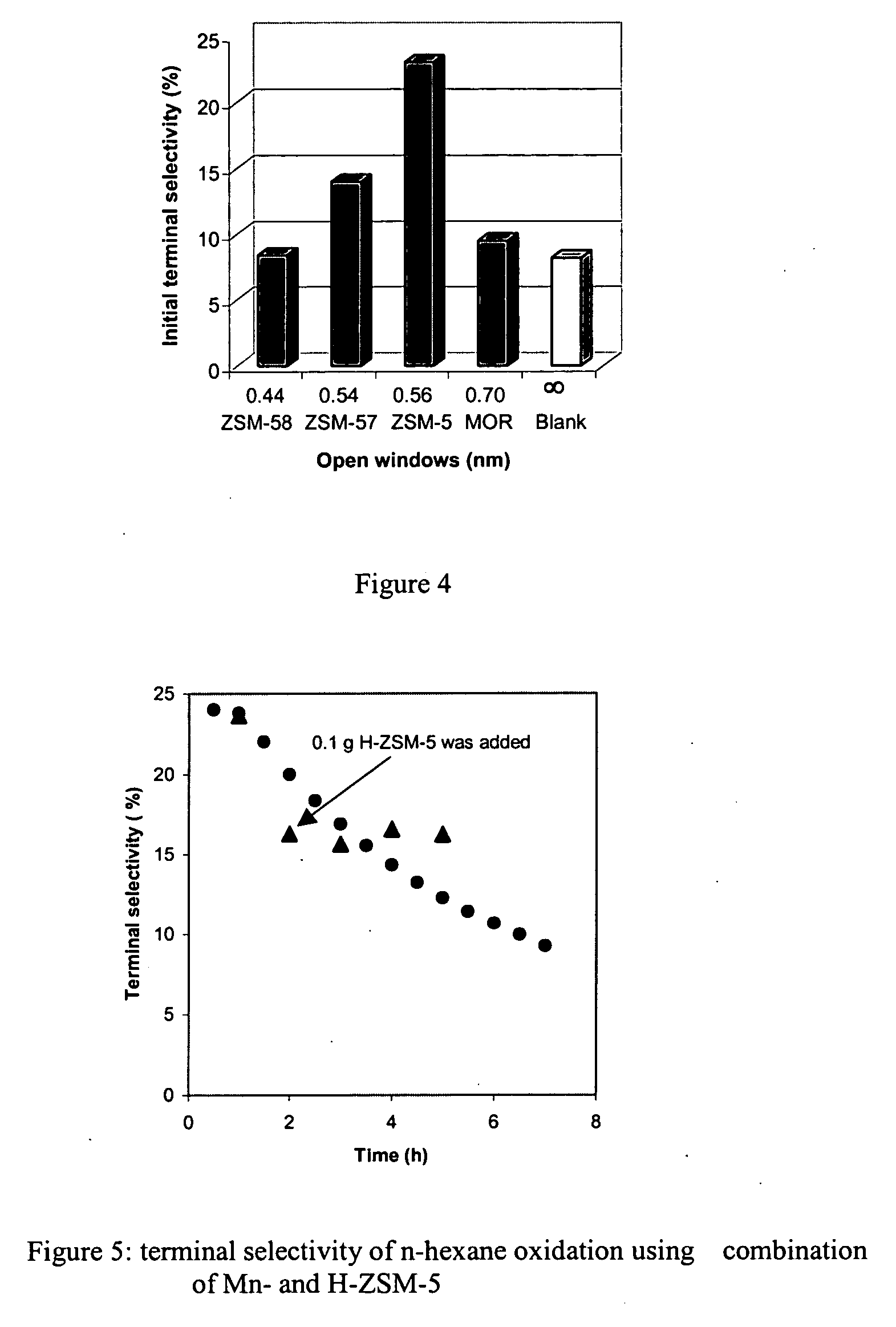

Process and catalyst for oxidation of hydrocarbons

A process for the oxidation of hydrocarbons comprises contacting the hydrocarbon with an oxygen-containing gas in the presence of a catalyst comprising a microporous solid support, preferably a zeolite, having from 8- to 12-ring open windows and comprising non-framework metal cations selected from manganese, iron, cobalt, vanadium, chromium, copper, nickel, and ruthenium, and mixtures thereof, providing that the oxygen-containing gas does not contain significant amounts of added hydrogen. The catalyst is novel and forms part of the invention. The process may be used for oxidation of alkanes, cycloalkanes, benzene and alkylbenzenes, and is suitable for use in regioselective terminal oxidation of straight chain alkanes and for selective oxidation / separation of p-dialkylbenzenes from an alkylbenzene mixture, for example, p-xylene from an isomeric mixture of xylenes.

Owner:RGT UNIV OF CALIFORNIA +1

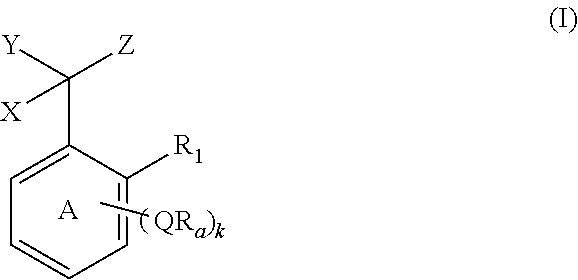

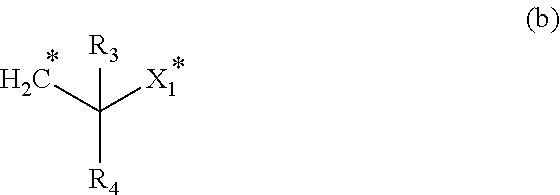

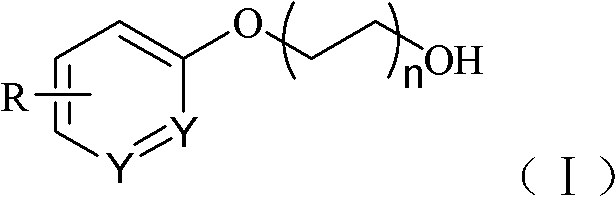

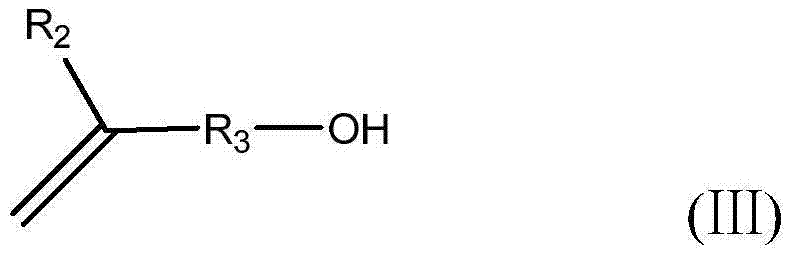

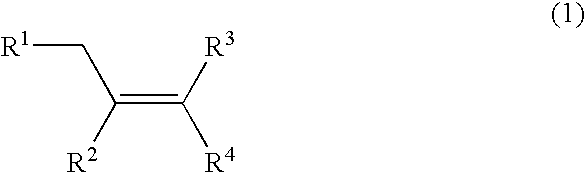

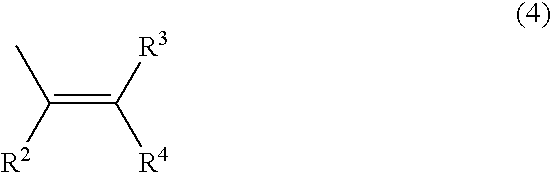

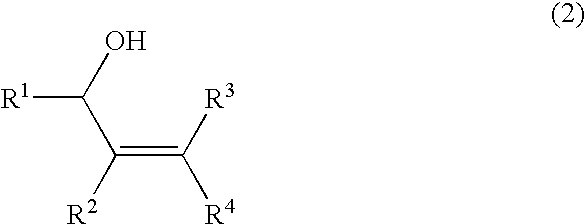

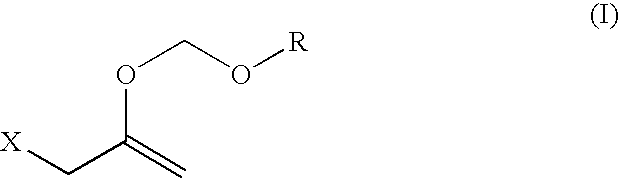

Hydroxy-protecting reagent and method of protecting hydroxy with the same

InactiveUS20070155983A1Solve low usageSatisfy safety performance requirementsOrganic compound preparationEther/acetal/ketal group formation/introductionHydrogen atomProtecting group

The present invention relates to a method of protecting a hydroxyl group, which includes reacting a hydroxyl group-containing compound with a compound represented by the formula (I): wherein R is a phenyl group optionally having substituent(s), an alkyl group optionally having substituent(s) or a benzyl group optionally having substituent(s), and X is a halogen atom, in the presence of an acid catalyst to substitute the hydrogen atom of the hydroxyl group of the hydroxyl group-containing compound with a protecting group represented by the formula (II): wherein R is as defined above. The present invention provides a method capable of introducing an acetal type protecting group into a hydroxyl group under mild conditions, and a protecting reagent therefor and a method of producing the protecting reagent.

Owner:SUMITOMO CHEM CO LTD

Popular searches

Hydroxy compound preparation Amino group formation/introduction Cyano group formation/introduction Ketenes preparation Oxygen compounds preparation by hydrocarbon oxidation Graphene Amino compound preparation Carboxylic preparation by oxidation Preparation by cyanide reaction Sulfonic acid amide preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com