Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

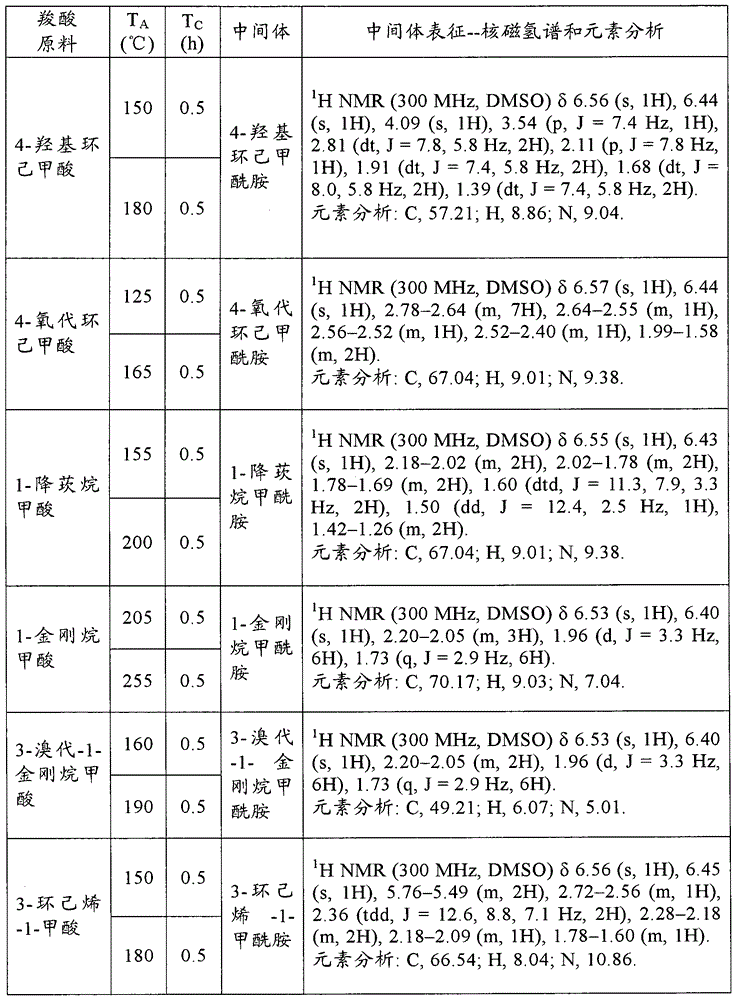

99results about "Cyano group formation/introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

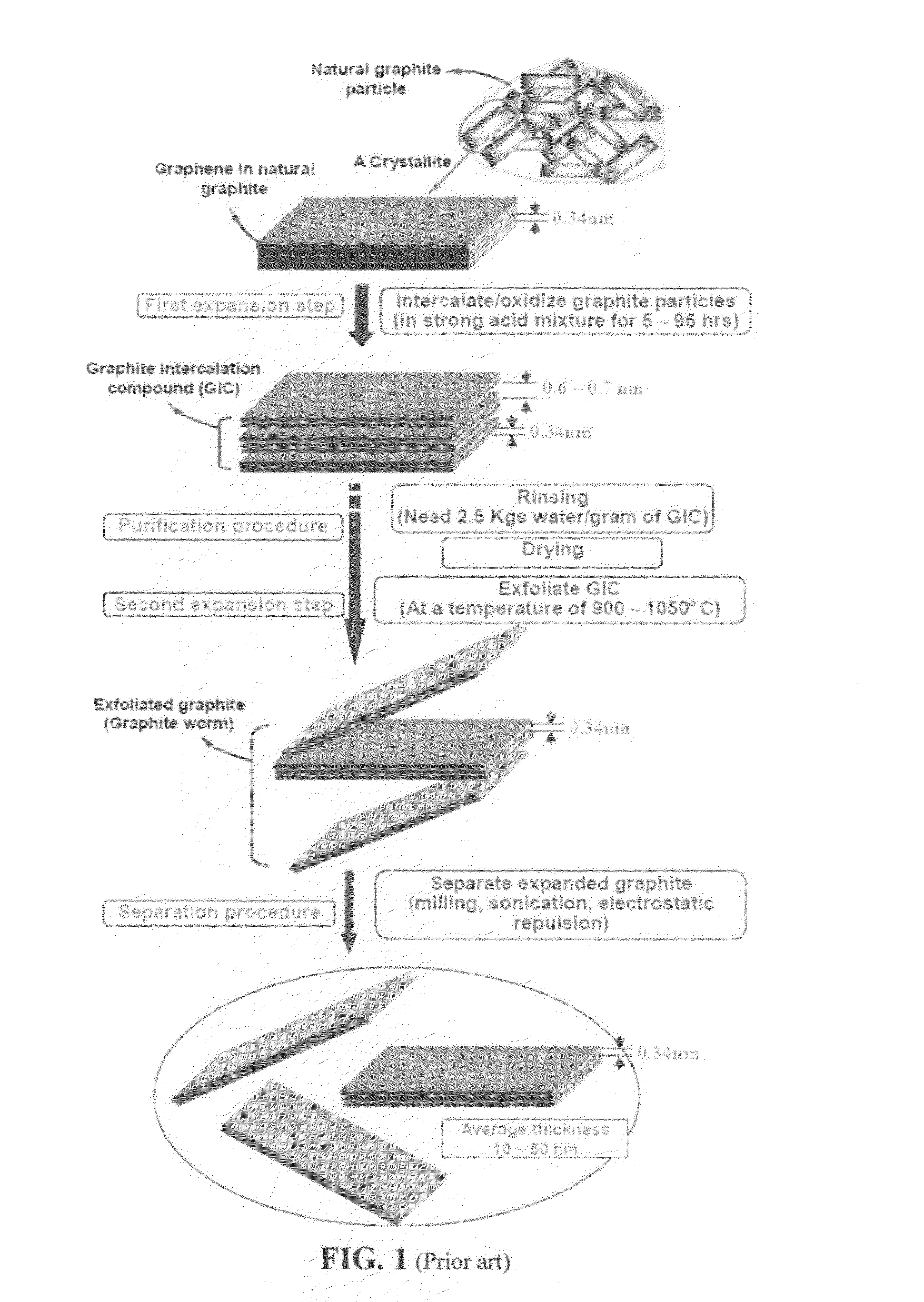

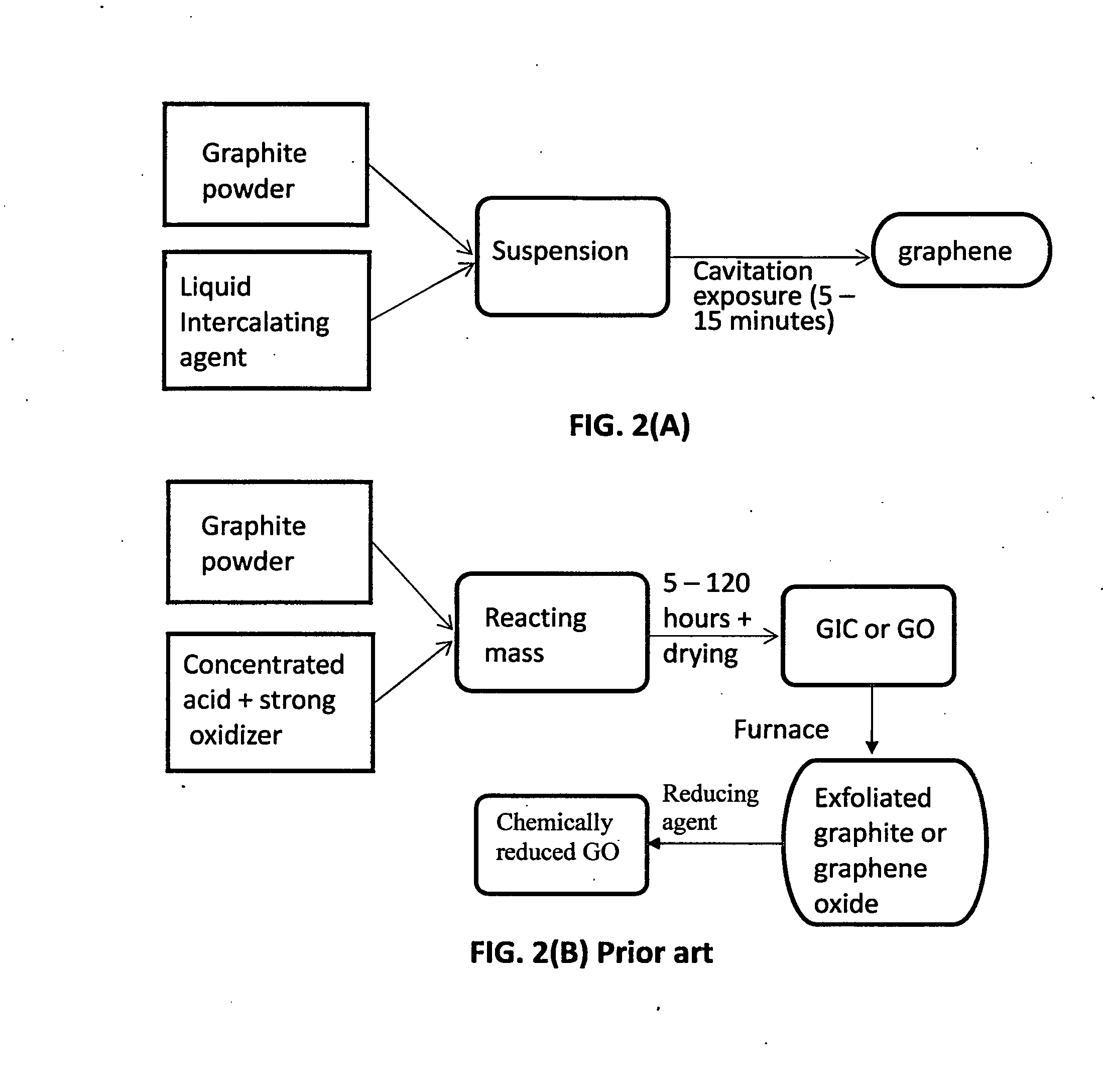

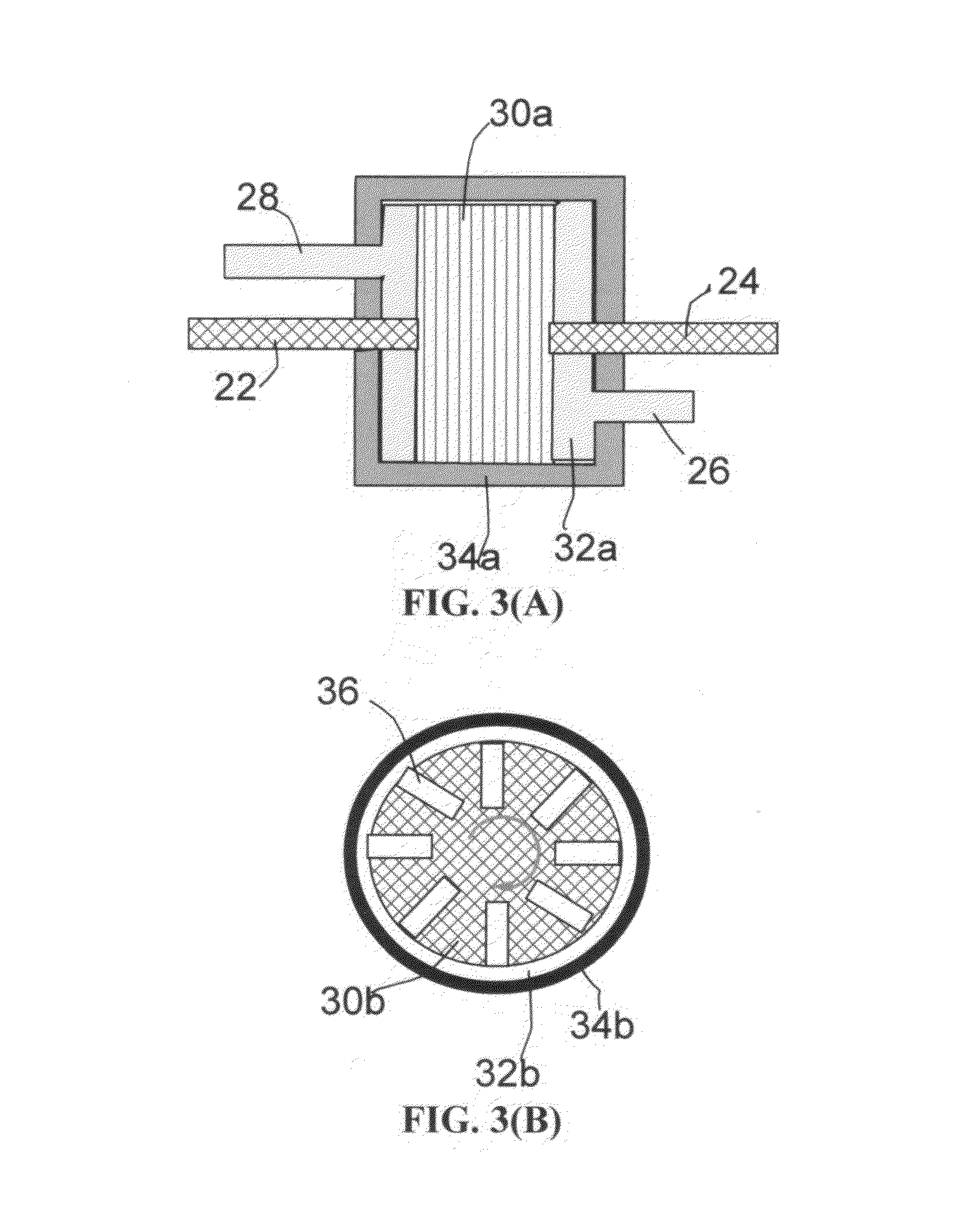

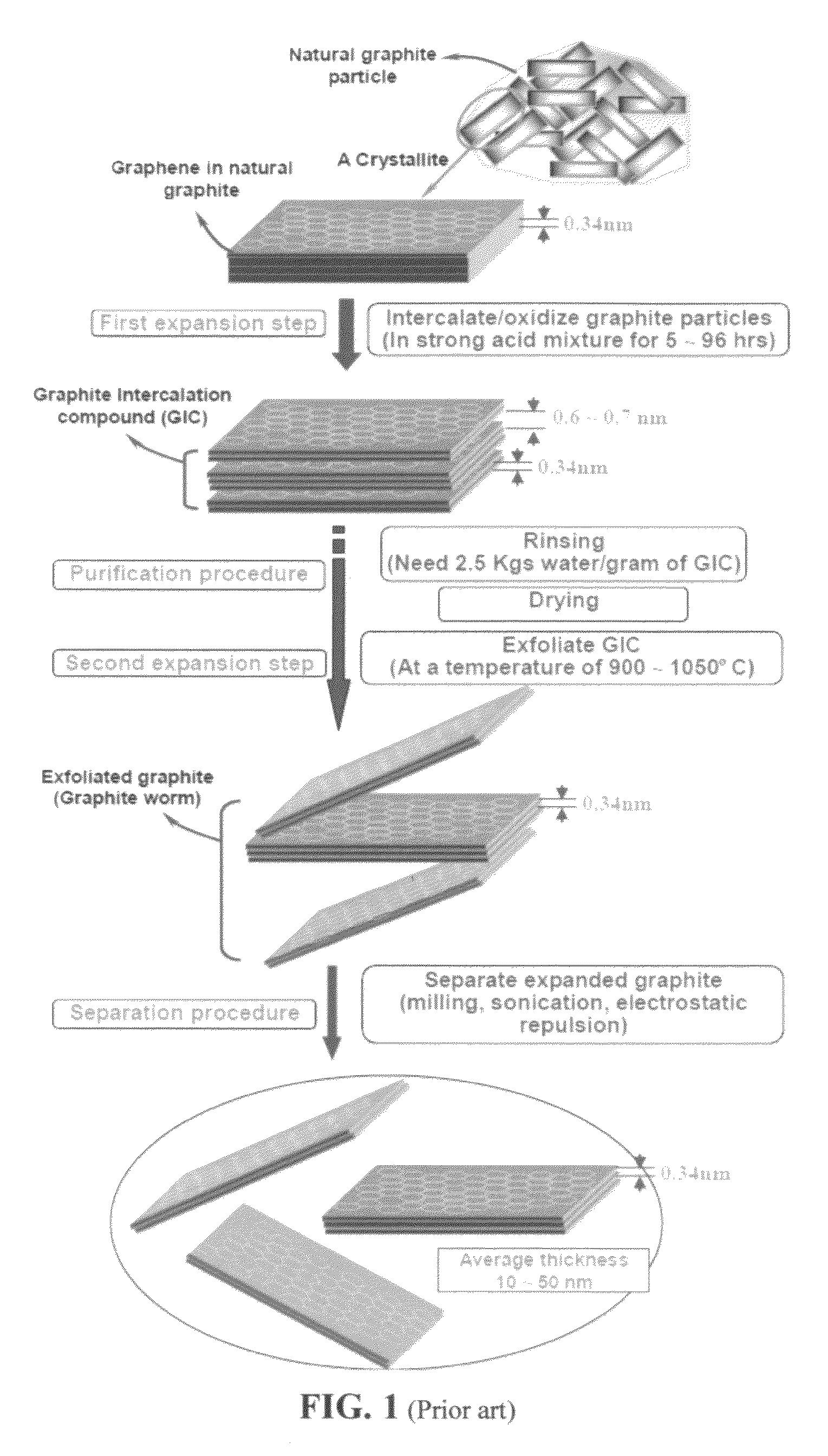

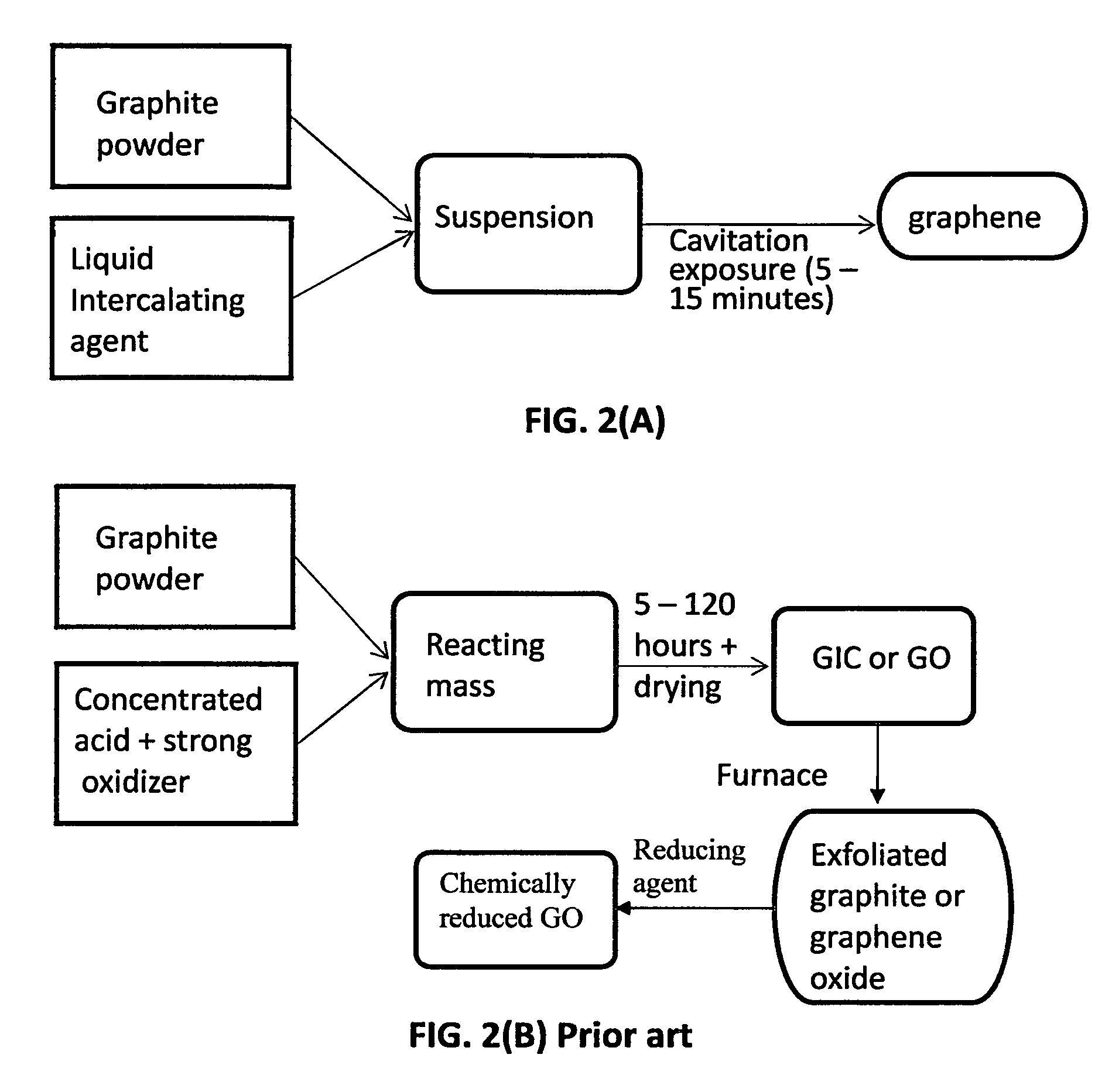

Production of graphene materials in a cavitating fluid

ActiveUS20150239741A1Shorten the timeReduce lossesCarboxylic acid nitrile preparationGraphiteCavitationLiquid medium

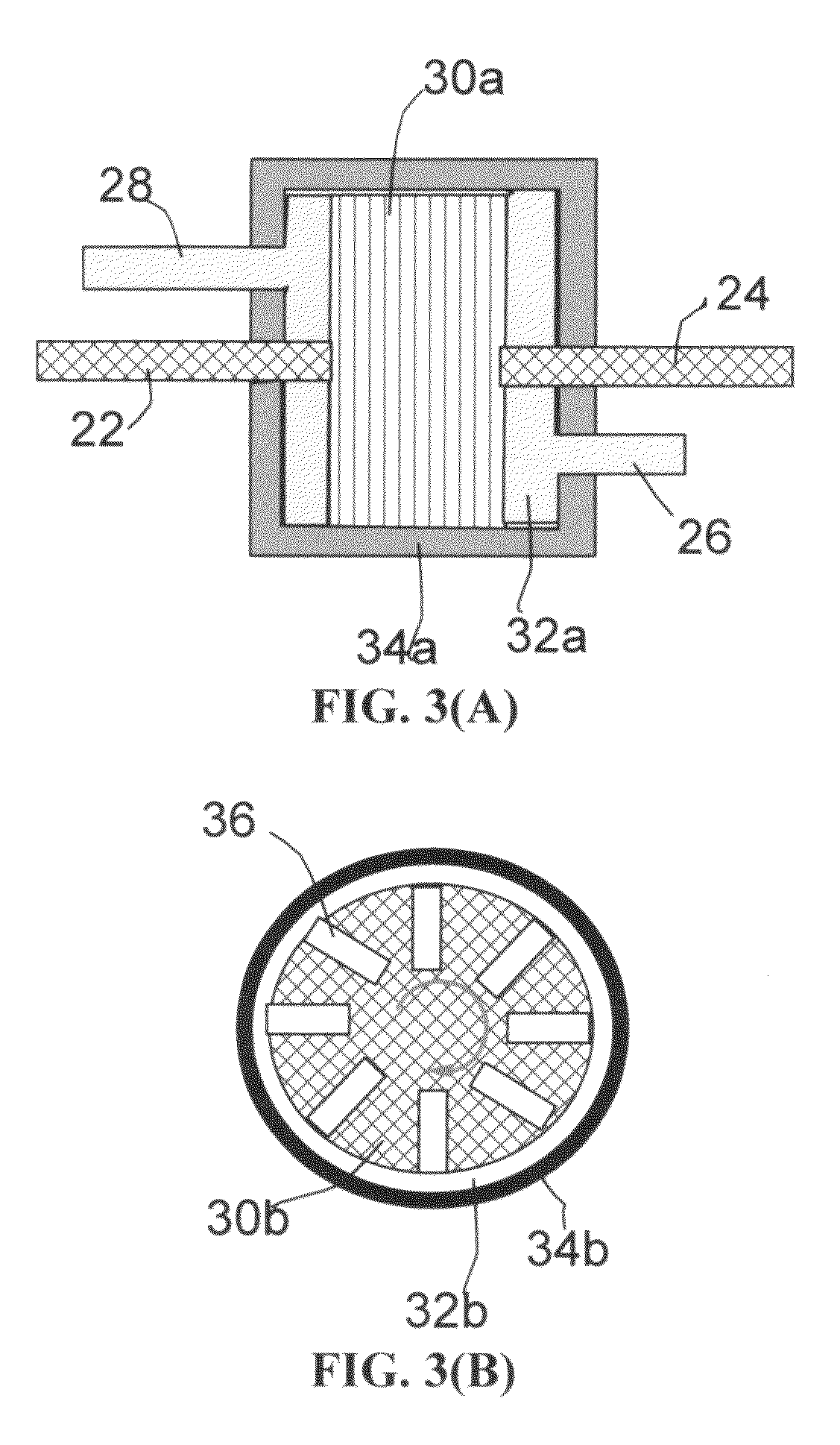

The invention provides a method of producing a graphene material from a starting graphitic material. In an embodiment, the method comprises: (a) dispersing the starting graphitic material in a liquid medium to form a graphite suspension; and (b) introducing the graphite suspension into a hydrodynamic cavitation reactor that generates and collapses cavitation or bubbles in the liquid medium to exfoliate and separate graphene planes from the starting graphitic material for producing the graphene material. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable. The reactor can concurrently perform the functions of graphene production, chemical functionalization, dispersion, and mixing with a polymer to make a composite.

Owner:GLOBAL GRAPHENE GRP INC

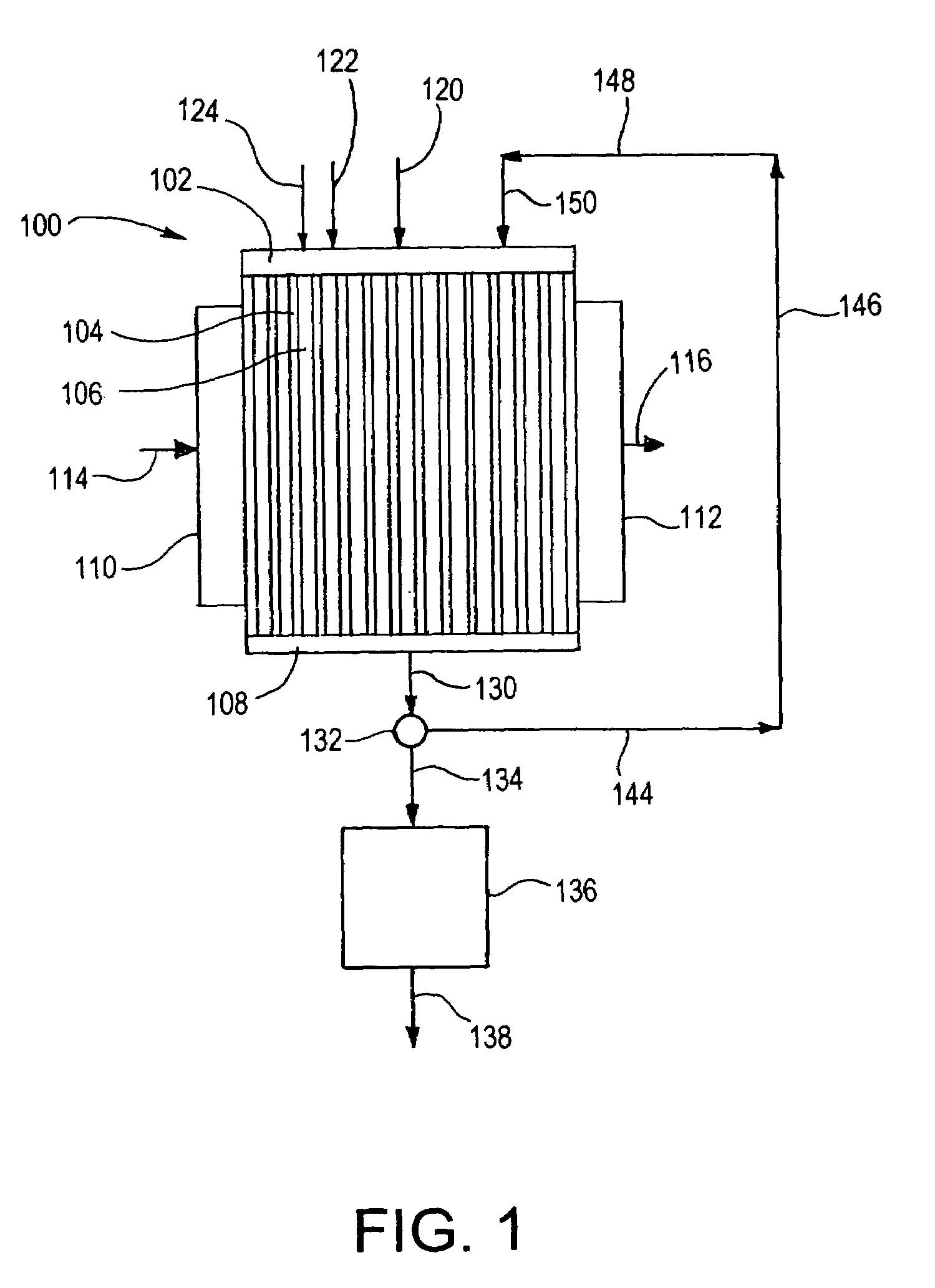

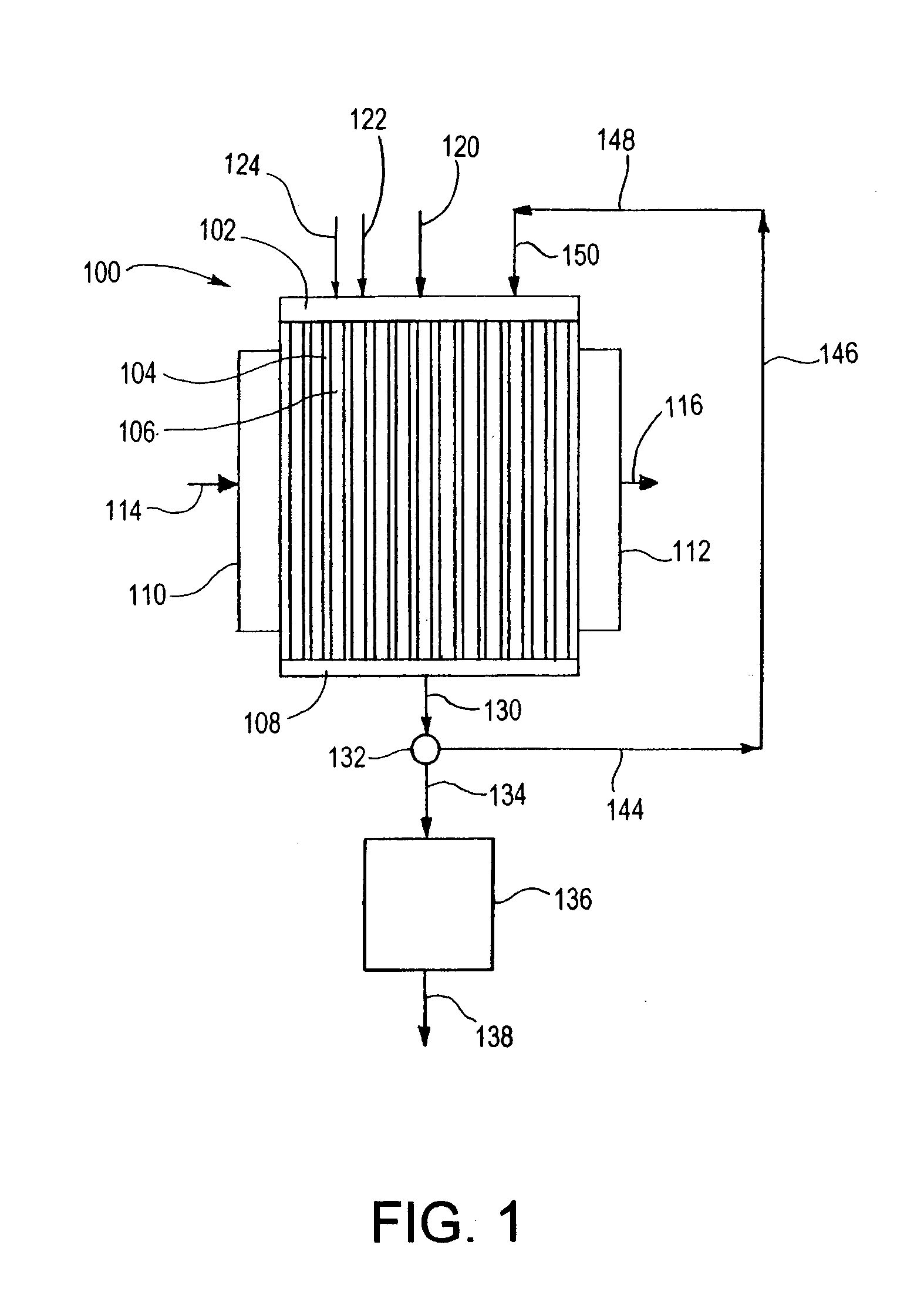

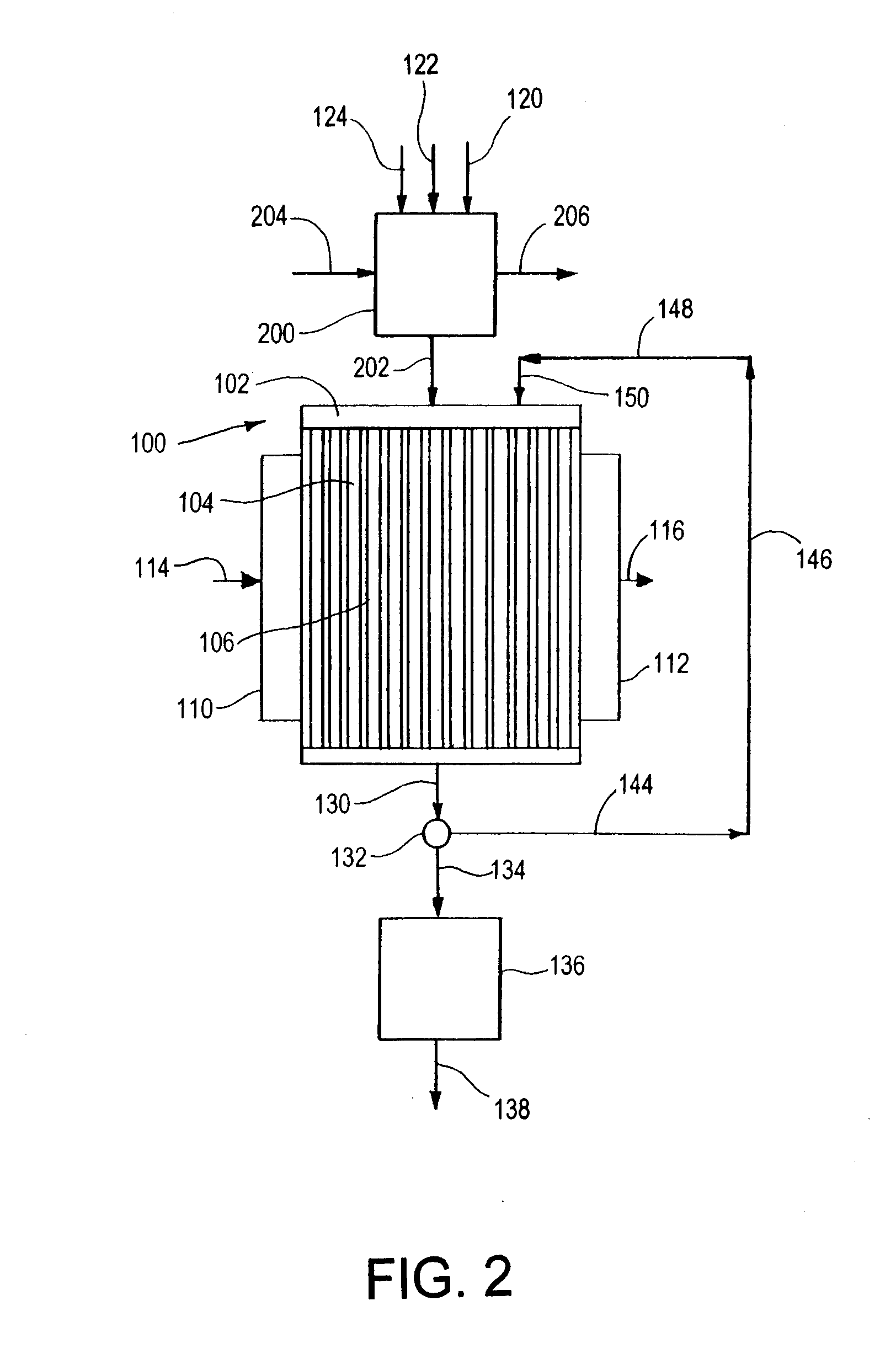

Process for converting a hydrocarbon to an oxygenate or a nitrile

InactiveUS7294734B2Maximize contactOrganic compound preparationCarboxylic acid esters preparationOxygenateOxygen

This invention relates to a process for converting a hydrocarbon reactant to a product comprising an oxygenate or a nitrile, the process comprising: (A) flowing a reactant composition comprising the hydrocarbon reactant, and oxygen or a source of oxygen, and optionally ammonia, through a microchannel reactor in contact with a catalyst to convert the hydrocarbon reactant to the product, the hydrocarbon reactant undergoing an exothermic reaction in the microchannel reactor; (B) transferring heat from the microchannel reactor to a heat exchanger during step (A); and (C) quenching the product from step (A).

Owner:VELOCYS CORPORATION

Process for converting a hydrocarbon to an oxygenate or a nitrile

InactiveUS20080031788A1Maximize contactOrganic compound preparationCarboxylic acid esters preparationHydrocotyle bowlesioidesOxygenate

This invention relates to a process for converting a hydrocarbon reactant to a product comprising an oxygenate or a nitrile, the process comprising: (A) flowing a reactant composition comprising the hydrocarbon reactant, and oxygen or a source of oxygen, and optionally ammonia, through a microchannel reactor in contact with a catalyst to convert the hydrocarbon reactant to the product, the hydrocarbon reactant undergoing an exothermic reaction in the microchannel reactor; (B) transferring heat from the microchannel reactor to a heat exchanger during step (A); and (C) quenching the product from step (A).

Owner:VELOCYS INC

Process for manufacture and use of improved attrition resistant catalyst

A method for manufacturing of an improved attrition resistant catalyst having an oxide-rich surface layer involving forming a slurry comprising; catalyst, catalyst precursor or catalyst support particles (e.g., transition metal oxides), a colloidal oxide sol (e.g., colloidal silica), and a solution of a solvent and solute wherein the solute consist essentially of a precursor of said oxide-rich surface with particle size no greater than 5 nm (e.g., aqueous silicic acid or polysilicic acid) and then spray drying the slurry to form porous microspheres of attrition resistant catalyst; and, calcining the spray dried microspheres. Such a catalyst is particularly useful in oxidation processes wherein the oxidation is performed by an oxidized form of the catalyst and the resulting reduced form of the catalyst is separately regenerated (e.g., two-step vapor phase processes carried out in recirculating solids reactors, transport bed reactors or circulating fluidized bed reactors and the like).

Owner:EI DU PONT DE NEMOURS & CO

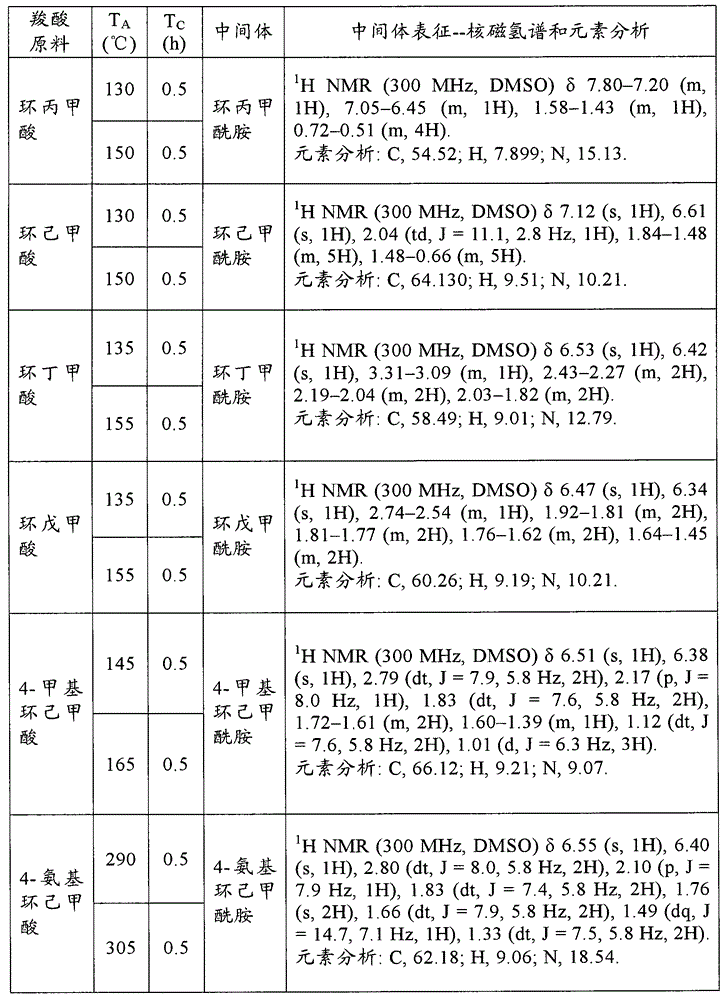

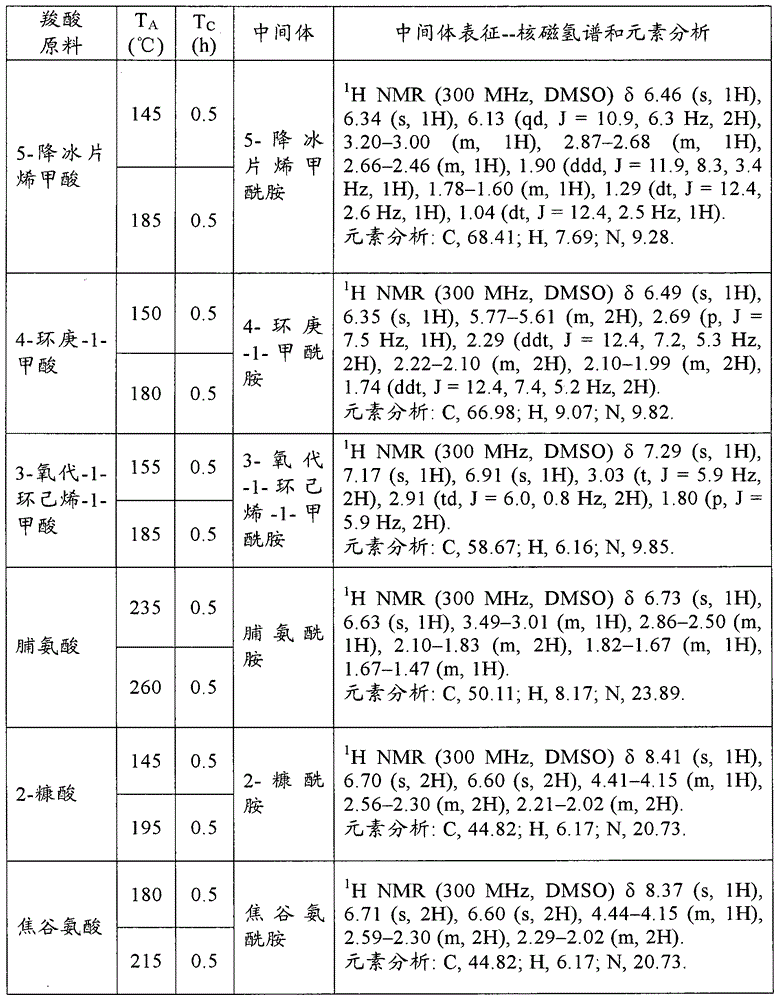

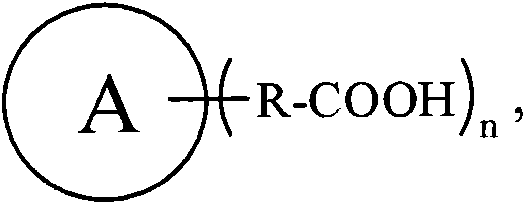

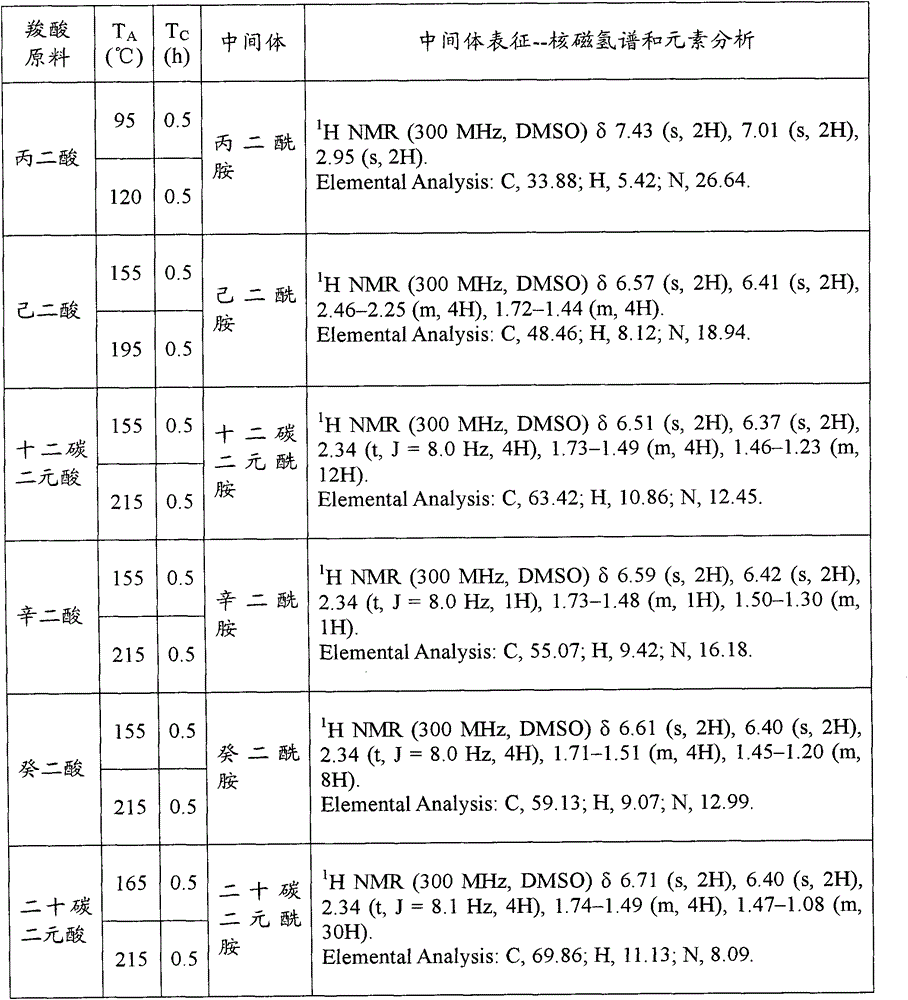

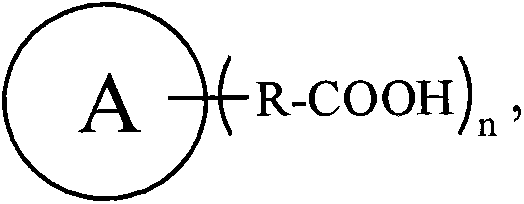

Preparation methods of nitrile and corresponding amine

ActiveCN105016944AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaNitrile

The invention relates to a preparation method of nitrile. Compared with the prior art, the preparation method has the characteristics of obvious reduction of the usage amount of ammonia sources, low environmental pressure, low energy consumption, low production cost, high purity and yields of nitrile products, and the like, and can be used for obtaining nitrile with a more complex structure. The invention also relates to a method for preparing corresponding amine with nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

Manufacturing method of nitrile and corresponding amine thereof

ActiveCN104557357AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaNH3 compound

The invention relates to a manufacturing method of nitrile. Compared with the prior art, the manufacturing method has the characteristics of significantly reduced using amount of an ammonia source, low environmental pressure, low energy consumption, low production cost, high purity and yield of a nitrile product and the like, and nitrile with a more complex structure can be obtained. The invention also relates to a method for manufacturing corresponding amine from nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

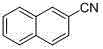

Catalytic preparation process for aromatic nitrile or heteroaromatic nitrile

InactiveCN102898264AMild reaction conditionsThe reaction process is shortPreparation by cyanide reactionCyano group formation/introductionIodideTechnical grade

The invention discloses a catalytic preparation process for aromatic nitrile or heteroaromatic nitrile. According to the process, water is used as a reaction solvent, nanometer cuprous iodide, potassium iodide and N,N'-dimethylethylenediamine are used as a combined catalyst, substituted aryl halide or heteroaryl halide reacts with potassium ferrocyanide at a temperature of 150 to 170 DEG C for 24 to 48 h, and purification is carried out to obtain corresponding aromatic nitrile or heteroaromatic nitrile. Compared with synthetic methods in the prior art, the catalytic preparation process provided by the invention has the following advantages: (1) reaction conditions are mild; (2) reaction process flow is short; (3) a cheap nontoxic cyanated reagent is used, and a wide range of substrates can be used; and (4) industrial-grade aromatic nitrile or heteroaromatic nitrile is easy to use and is more economic and environment-friendly.

Owner:ZHEJIANG UNIV

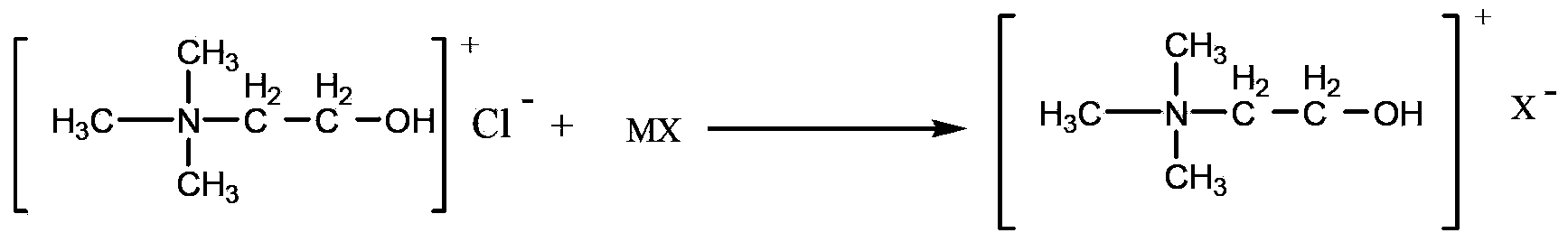

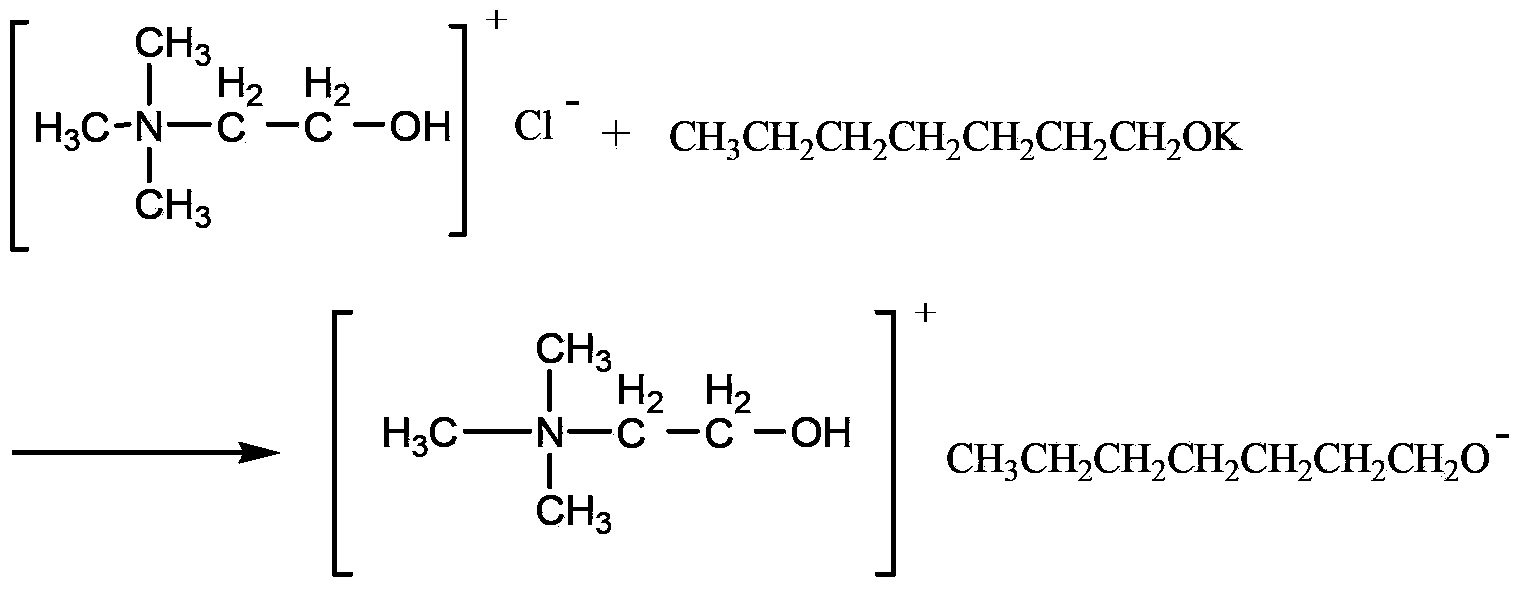

Method for catalyzing Knoevenagel condensation reaction by using function ion liquid

InactiveCN103351270ASpecial featuresSpecial thermodynamic stabilityCarboxylic acid nitrile preparationOrganic compound preparationRoom temperatureIonic liquid

The present invention discloses a method for catalyzing a Knoevenagel condensation reaction by using a function ion liquid. The method comprises that: a choline chloride function ion liquid is adopted as a catalyst, and aromatic aldehyde and an active methylene compound are subjected to a catalysis condensation reaction at a room temperature under a normal pressure to obtain a condensation product. The method has the following characteristics that: operations are simple, a yield is high, the catalysis reaction system has good reusability, reaction conditions are mild, and good industrialization prospects are provided.

Owner:TAIZHOU UNIV

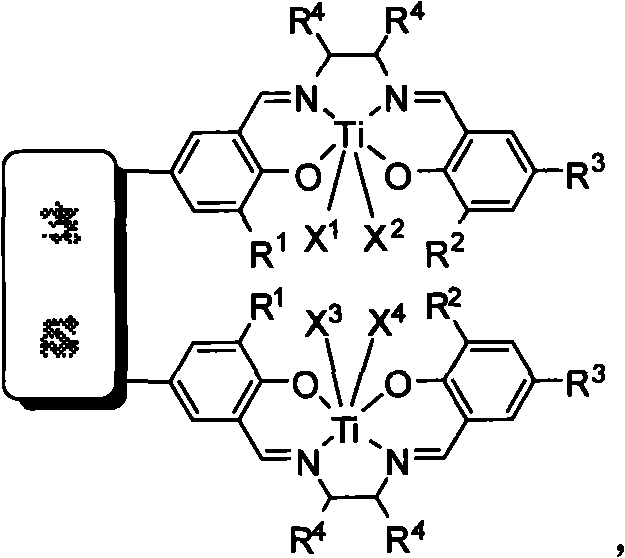

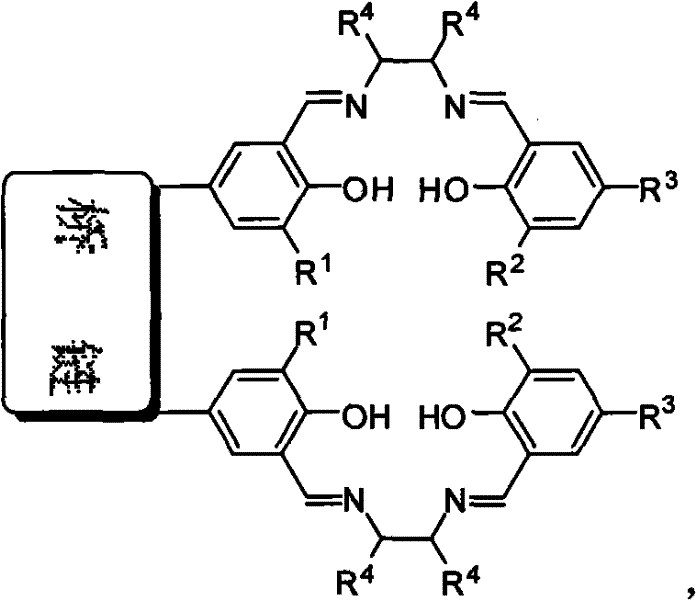

Bridged bis-Schiff-base-titanium complex, and synthesis method and application thereof

InactiveCN102234291AControl of Chiral Inducing EffectsHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSynthesis methodsTitanium

The invention relates to a novel bridged bis-Schiff base ligand, a bridged bis-Schiff-base-titanium complex, a synthesis method of the complex and application of the complex in the cyanidation reaction of various carbonyl compounds. The bridged bis-Schiff-base-titanium complex provided by the invention presents very high catalytic activity and excellent enantioselectivity in the asymmetric cyanidation of aldehydes.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Preparation methods of nitrile and corresponding amine

ActiveCN105016942AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaNitrile

The invention relates to a preparation method of nitrile. Compared with the prior art, the preparation method has the characteristics of obvious reduction of the usage amount of ammonia sources, low environmental pressure, low energy consumption, low production cost, high purity and yields of nitrile products, and the like, and can be used for obtaining nitrile with a more complex structure. The invention also relates to a method for preparing corresponding amine with nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

Preparation methods of nitrile and corresponding amine

ActiveCN105016940AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaNitrile

The invention relates to a preparation method of nitrile. Compared with the prior art, the preparation method has the characteristics of obvious reduction of the usage amount of ammonia sources, low environmental pressure, low energy consumption, low production cost, high purity and yields of nitrile products, and the like, and can be used for obtaining nitrile with a more complex structure. The invention also relates to a method for preparing corresponding amine with nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

Manufacturing method for nitrile and corresponding amine thereof

ActiveCN105001032AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaStereochemistry

The present invention relates to a nitrile manufacturing method, which has characteristics of significantly-reduced ammonia source consumption, low environmental pressure, low energy consumption, low production cost, high nitrile purity, high nitrile yield and the like compared with the method in the prior art, wherein nitrile having a complicated structure can be obtained through the method. The present invention further relates to a method for producing a corresponding amine from the nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

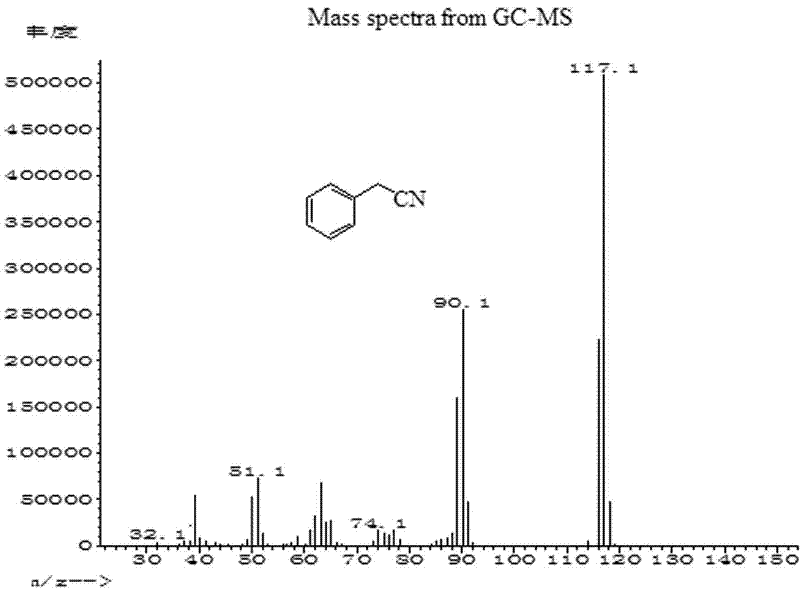

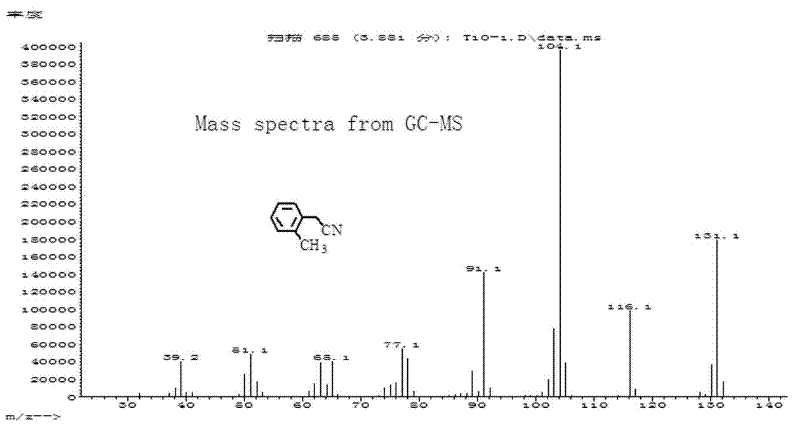

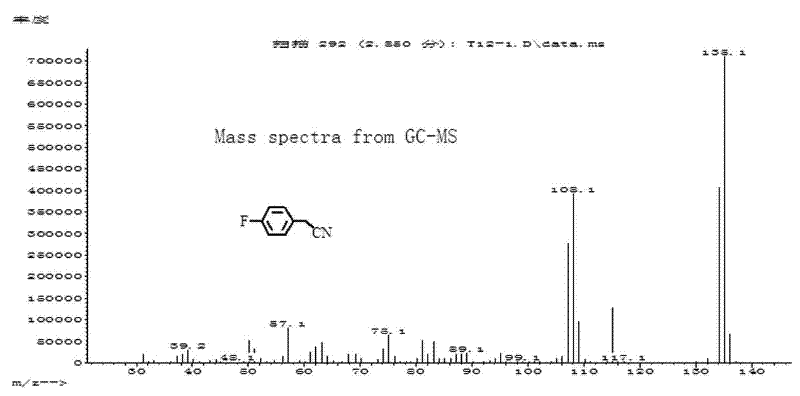

Method for synthesizing benzyl cyanide compound by using benzyl chloride compound

InactiveCN102381918AReduce manufacturing costPreparation by cyanide reactionCyano group formation/introductionCyanideOrganosolv

The invention belongs to the technical field of synthesis of benzyl cyanide compounds and in particular relates to a method for synthesizing a benzyl cyanide compound by using a benzyl chloride compound. The method comprises the following step of: reacting the benzyl chloride compound with potassium ferrocyanide in an organic solvent by using a copper salt as a catalyst to obtain the benzyl cyanide compound. As the less toxic potassium ferrocyanide is used as a cyanide reagent and the inexpensive copper salt is used as the catalyst, the method for synthesizing the benzyl cyanide compound provided by the invention has lower production cost and no highly toxic raw material.

Owner:HENAN UNIV OF SCI & TECH

Manufacturing method of nitrile and corresponding amine thereof

ActiveCN104557356AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationProcess engineeringEnergy consumption

The invention relates to a manufacturing method of nitrile. Compared with the prior art, the manufacturing method has the characteristics of significantly reduced using amount of an ammonia source, low environmental pressure, low energy consumption, low production cost, high purity and yield of a nitrile product and the like, and nitrile with a more complex structure can be obtained. The invention also relates to a method for manufacturing corresponding amine from nitrile.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing cyan aromatic hydrocarbon by using aryl bromide

ActiveCN102875276AReduce pollutionShort synthetic routePreparation by cyanide reactionCyano group formation/introductionArylPtru catalyst

The invention relates to the technical fields of pharmaceutical chemical intermediates and relevant chemicals, in particular to a method for preparing cyan aromatic hydrocarbons by using aryl bromides. The method comprises the following steps of: a, sequentially adding brominated aromatic hydrocarbons, a cyanogen source, palladium catalyst, ligand and alkali into a reactor, adding organic solvent for reaction, controlling reaction temperature to be 50-200DEG C and reaction time to be 24-48h, wherein the molar ratio of the brominated aromatic hydrocarbons to the cyanogen source is 1: (1-2), the molar ratio of the brominated aromatic hydrocarbons to the palladium catalyst is 1: (0.05-0.1), the molar ratio of the ligand to the palladium catalyst is 1: (1-2) and the molar ratio of the brominated aromatic hydrocarbons to the alkali is 1: (1-20); and b, separating the reaction liquid obtained in the step a through a silica gel column to obtain the cyan aromatic hydrocarbons. The method for preparing cyan aromatic hydrocarbons by using aryl bromides has the advantages that the reaction steps are less, the conditions are moderate and the operation is convenient to conduct; the used cyanogen source is cheap and easy to obtain, the toxicity is lower and the prices of the catalyst and the ligand are low; and the preparation cost can be greatly decreased and the pollution to the surrounding environment is reduced.

Owner:DALIAN UNIV OF TECH

Manufacturing method for nitrile and corresponding amine thereof

ActiveCN105001033AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaStereochemistry

The present invention relates to a nitrile manufacturing method, which has characteristics of significantly-reduced ammonia source consumption, low environmental pressure, low energy consumption, low production cost, high nitrile purity, high nitrile yield and the like compared with the method in the prior art, wherein nitrile having a complicated structure can be obtained through the method. The present invention further relates to a method for producing a corresponding amine from the nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

Production of graphene materials in a cavitating fluid

ActiveUS9315388B2Shorten the timeReduce lossesGraphiteHydroxy group formation/introductionLiquid mediumCavitation

The invention provides a method of producing a graphene material from a starting graphitic material. In an embodiment, the method comprises: (a) dispersing the starting graphitic material in a liquid medium to form a graphite suspension; and (b) introducing the graphite suspension into a hydrodynamic cavitation reactor that generates and collapses cavitation or bubbles in the liquid medium to exfoliate and separate graphene planes from the starting graphitic material for producing the graphene material. The process is fast (minutes as opposed to hours or days of conventional processes), environmentally benign, and highly scalable. The reactor can concurrently perform the functions of graphene production, chemical functionalization, dispersion, and mixing with a polymer to make a composite.

Owner:GLOBAL GRAPHENE GRP INC

Preparation methods of nitrile and corresponding amine

ActiveCN105016945AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationAmmoniaNitrile

The invention relates to a preparation method of nitrile. Compared with the prior art, the preparation method has the characteristics of obvious reduction of the usage amount of ammonia sources, low environmental pressure, low energy consumption, low production cost, high purity and yields of nitrile products, and the like, and can be used for obtaining nitrile with a more complex structure. The invention also relates to a method for preparing corresponding amine with nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

Preparation methods of nitrile and corresponding amine

ActiveCN105016941AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationState of artAmmonia

The invention relates to a preparation method of nitrile. Compared with the prior art, the preparation method has the characteristics of obvious reduction of the usage amount of ammonia sources, low environmental pressure, low energy consumption, low production cost, high purity and yields of nitrile products, and the like, and can be used for obtaining nitrile with a more complex structure. The invention also relates to a method for preparing corresponding amine with nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

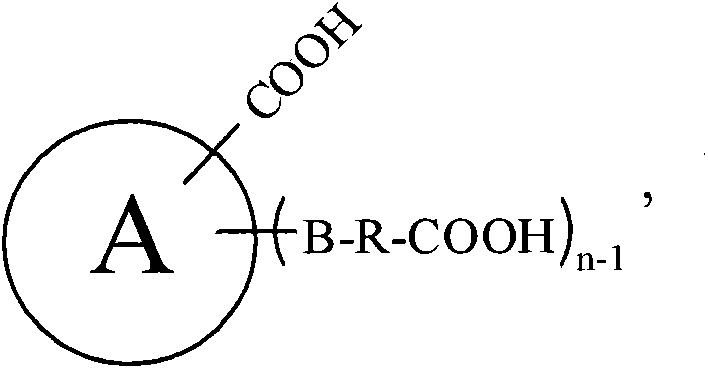

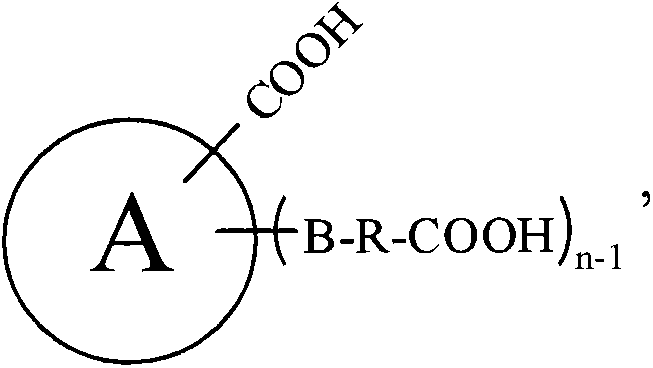

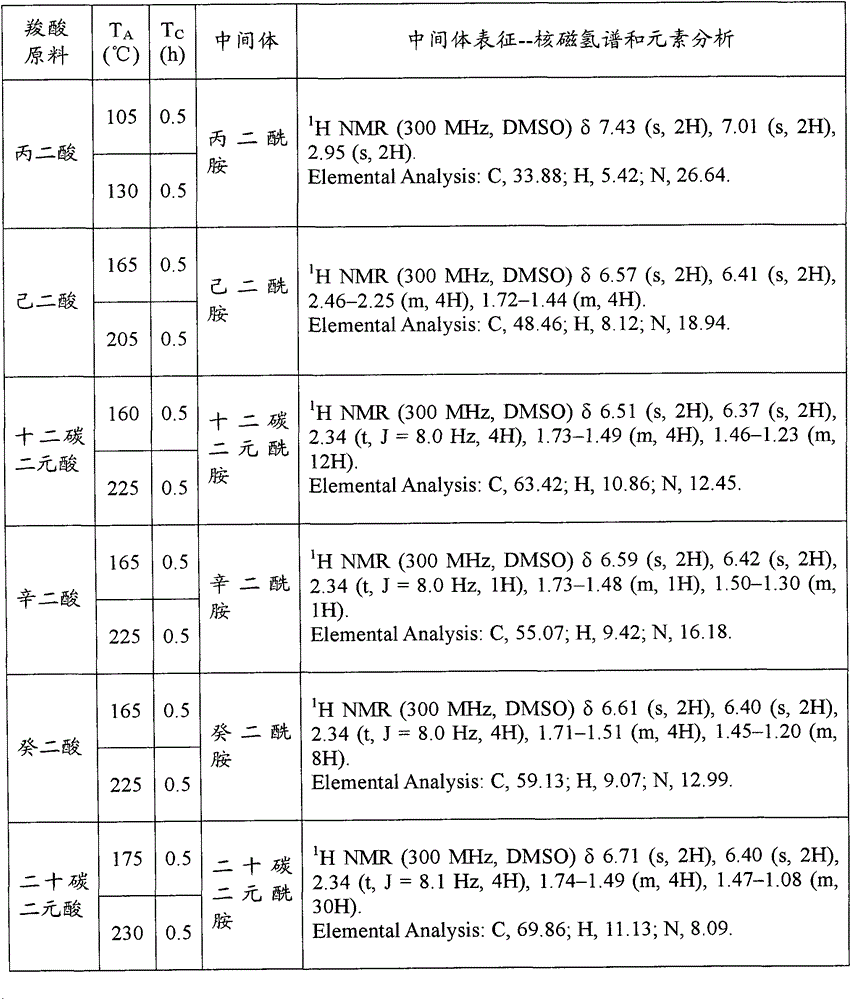

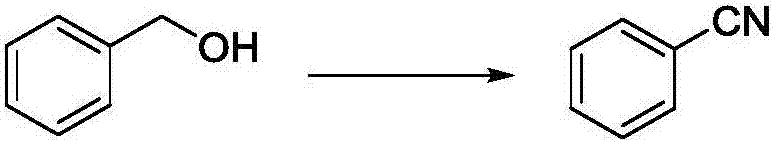

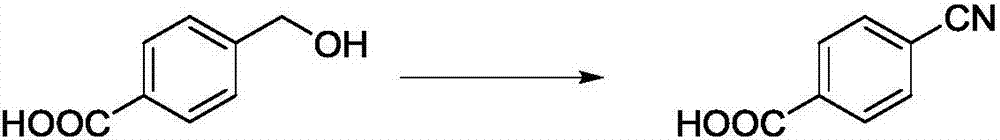

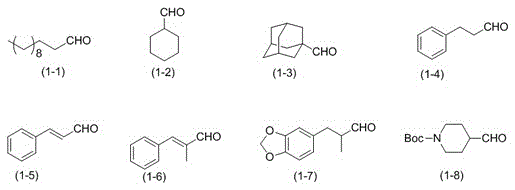

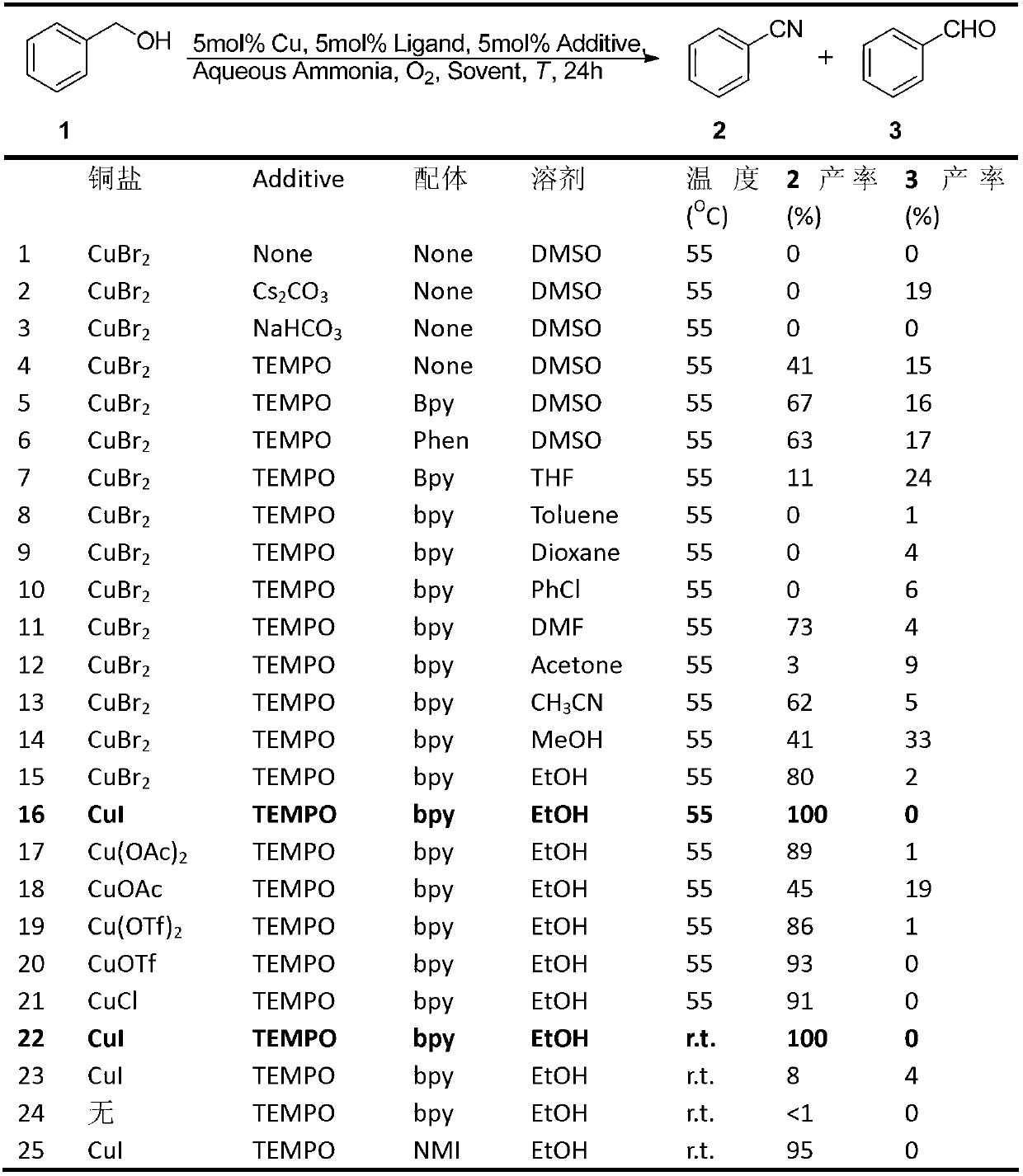

Method for preparing nitrile from primary alcohol

InactiveCN106866326ARaw materials are cheap and easy to getHigh reaction conversion rateCarboxylic acid nitrile preparationOrganic compound preparationNitrogen oxidesCatalytic oxidation

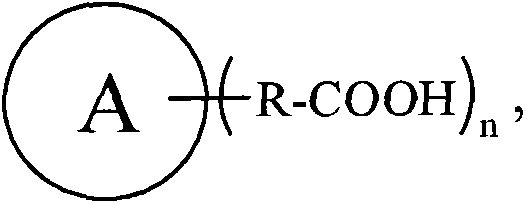

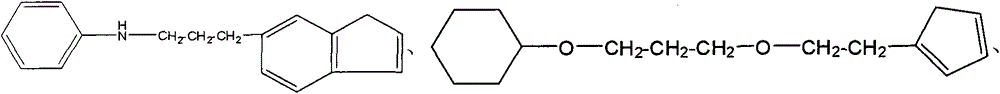

The invention discloses a method for preparing nitrile from primary alcohol through catalytic oxidation. The method comprises the following steps: taking primary alcohol shown in Formula (I) or Formula (III) as a raw material, copper salt as a catalyst, air as an oxidizer, TEMPO (2,2,6,6-tetramethyl piperidine oxynitride) as an oxidizing aid and ammonia water as a cocatalyst and solvent, reacting at 80-120 DEG C for 15-30 hours, and performing posttreatment on the reaction solution after the reaction is completed to obtain the nitrile shown in Formula (II) or Formula (IV).The method disclosed by the invention is high in reaction conversion rate and yield, convenient to operate, low in cost and safe in reaction; and the whole process is environment-friendly and causes no pollution. The formulas are shown in the specification.

Owner:ZHEJIANG UNIV OF TECH

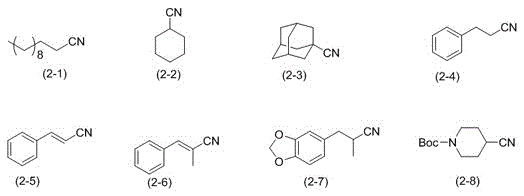

Aliphatic nitrile catalytic oxidation synthesis method

ActiveCN105481624ASimple and safe operationLow costPreparation by hydrocarbon ammoxidationCyano group formation/introductionSynthesis methodsCatalytic oxidation

The invention discloses an aliphatic nitrile catalytic oxidation synthesis method. With aliphatic aldehyde serving as reaction substrate, 2, 2, 6, 6-tetramethylpiperidine-1-oxygen radical (TEMPO), alkali metal salt and tert-butyl nitrite (TBN) as catalysts, hexamethyl-disilazane (HMDS) as the nitrogen source and oxygen as an oxidizing agent, the reaction substrate is reacted in organic solvent at normal pressure at the temperature of 25-50 DEG C, and aftertreatment is performed after reaction to obtain the aliphatic nitrile. The method is easy and safe to operate, and environment cost is lowered.

Owner:邳州市润宏实业有限公司

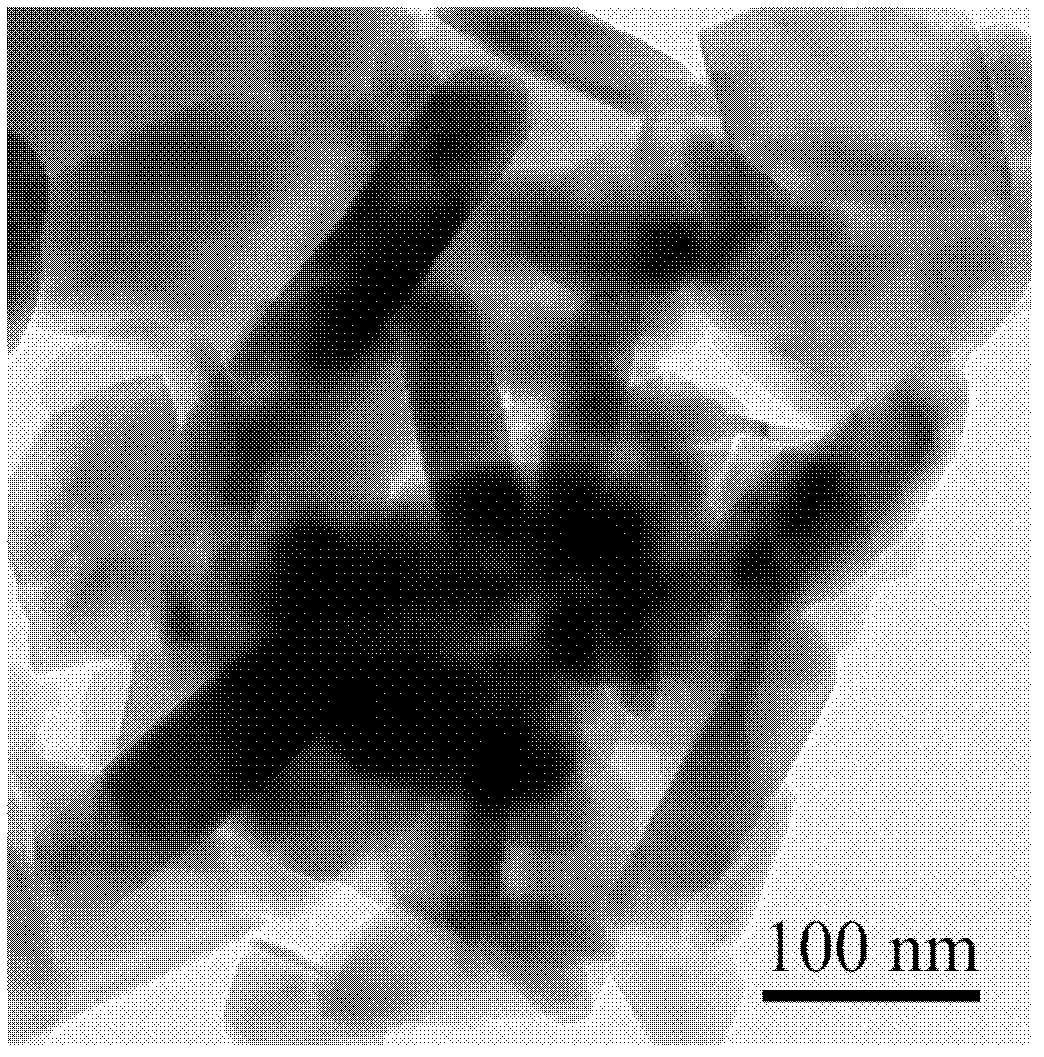

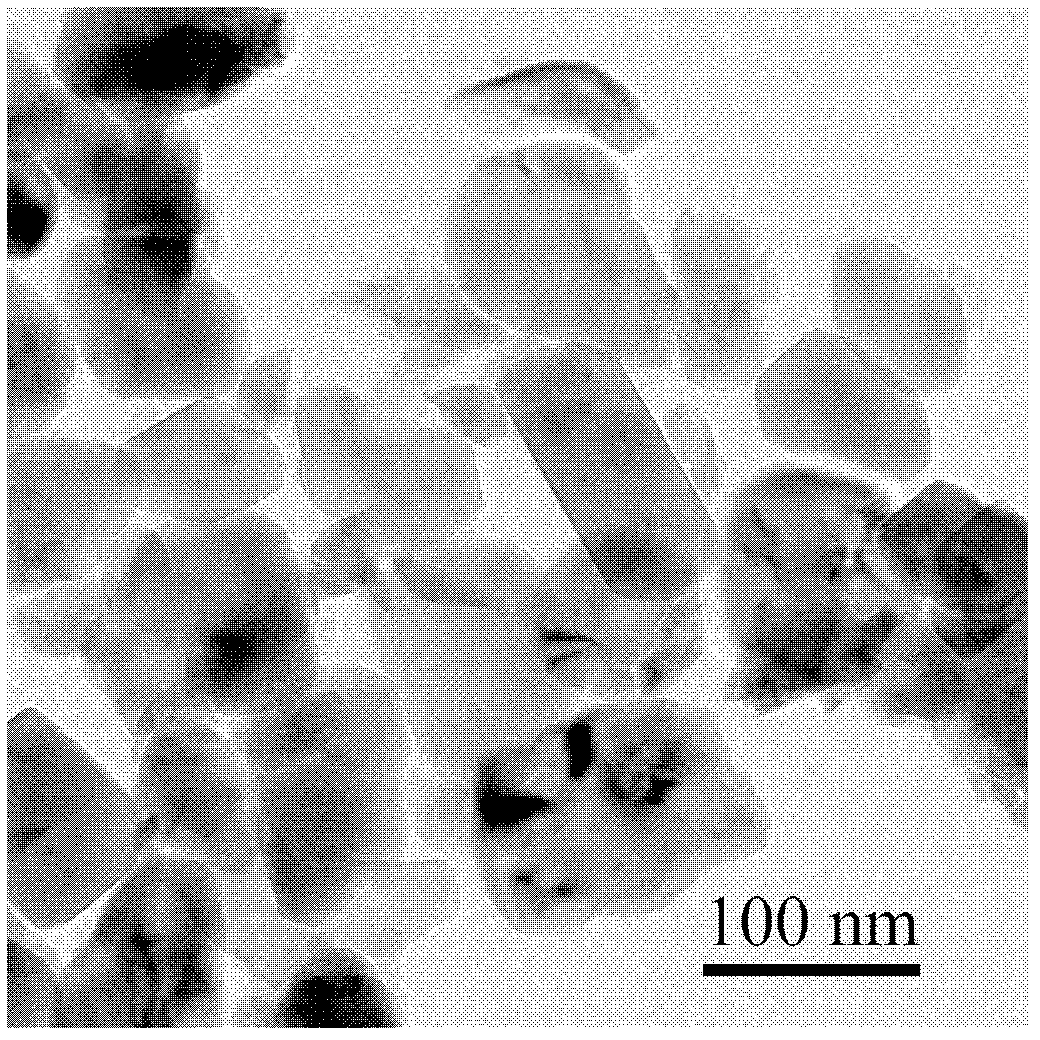

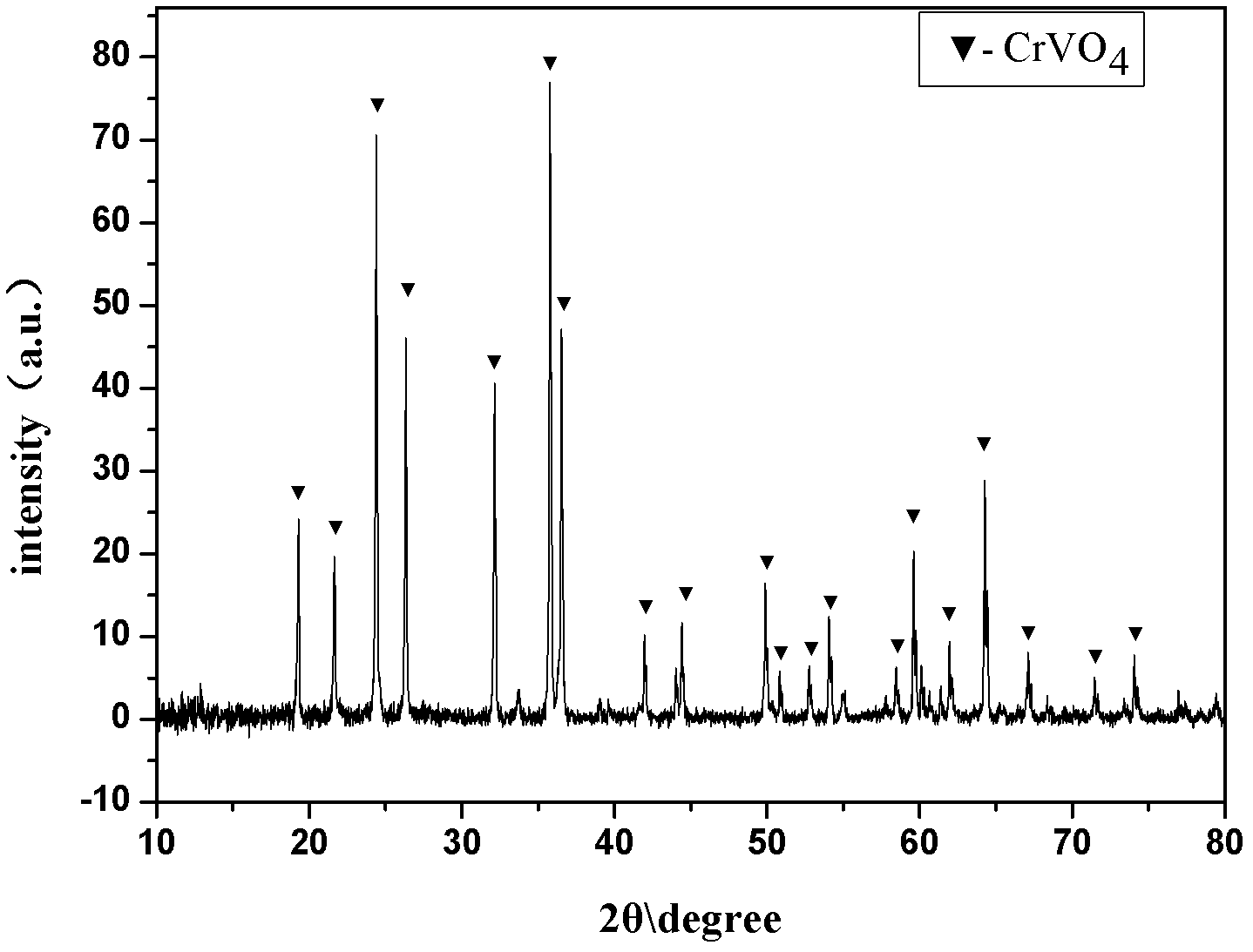

Nanometer chromium vanadate as well as preparation method and application thereof

InactiveCN102557135ASmall sizeUniform particle size distributionPreparation by hydrocarbon ammoxidationChromium compoundsReaction temperatureSolvent

The invention discloses nanometer chromium vanadate as well as a preparation method and an application of the nanometer chromium vanadate. The nanometer chromium vanadate is in a particular or sticky structure, the particle size of the particular structure is 30 to 200n, the diameter of the sticky structure is 20 to 100nm, and the length of the sticky structure is 100 to 500nm. Vanadium sources and chromium sources are placed into a pressure container according to a metal atom mol ratio being 1:1, solvents are added, the materials are uniformly mixed, the temperature is raised to 120 to 300 DEG C after the sealing, the solvents take heat reaction for 2 to 200 hours, products are subjected to cooling, filtering, washing and vacuum drying, and precursors are obtained; and the precursors arecalcined for 0.1 to 10 hours at the temperature being 300 to 800 DEG C and are cooled to the room temperature, and the nanometer chromium vanadate is obtained. The prepared nanometer chromium vanadate has small dimension and uniform particle size distribution, the method is simple, raw materials are easy to obtain, and the cost is low. During the aromatic nitriles preparation through methyl aromatics ammoxidation reaction, the ammoxidation reaction temperature is 300 to 380 DEG C. Compared with the conventional chromium vanadate, the nanometer chromium vanadate has the advantages that the reaction temperature is obviously lowered, the selectivity is good, and in addition, the reaction activity is improved by 10 to 40 percent.

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

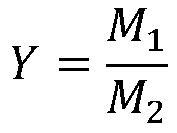

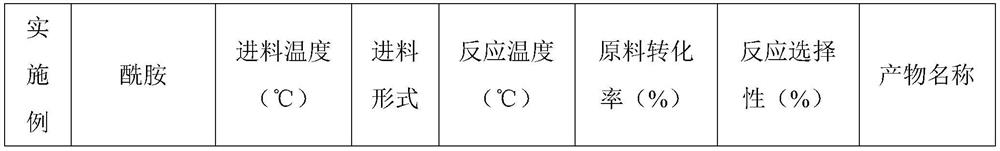

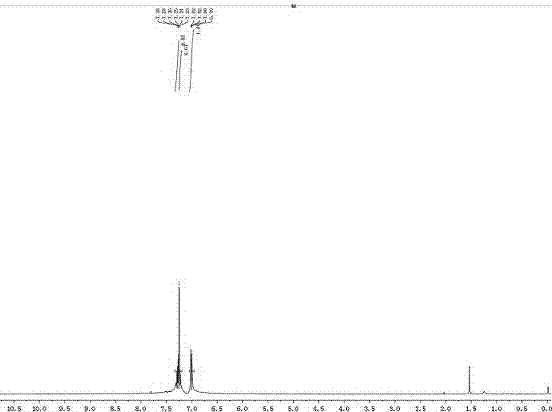

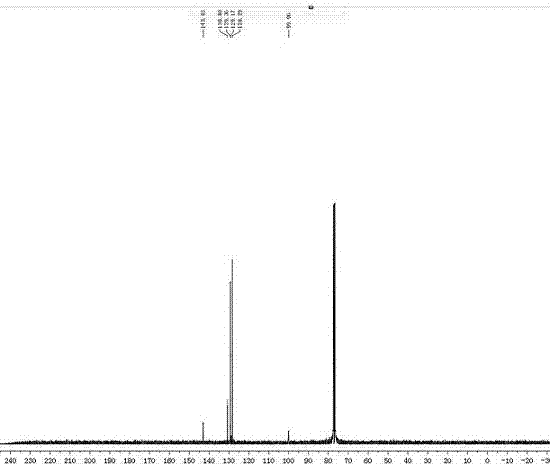

Method for continuously preparing nitrile from amide

ActiveCN112028726AReduce the discharge of three wastesSimple post-processingMolecular sieve catalystsThiol preparationMolecular sievePtru catalyst

The invention discloses a method for continuously preparing nitrile from amide, which comprises the following steps: preparing a molecular sieve-loaded lead catalyst from a lead salt and a molecular sieve by an impregnation method, and filling a fixed bed reactor with the molecular sieve-loaded lead catalyst; feeding an amide or an amide solution into the fixed bed reactor from the top of the fixed bed for catalytic dehydration, and leading out an obtained reaction product from the bottom of the fixed bed; and separating the reaction product to obtain a crude nitrile product corresponding to amide. A fixed bed continuous production process is adopted, the reaction process is simple, the production efficiency is high, product aftertreatment is simple, and industrial production is easy to achieve.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

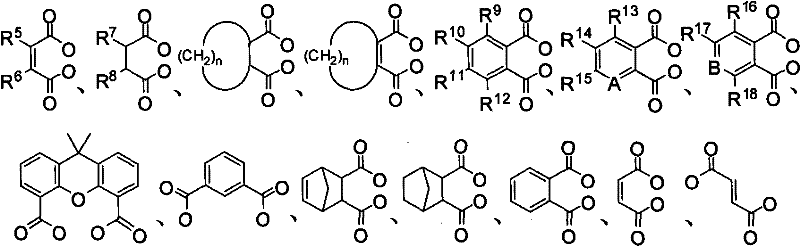

Synthesis method of functionally-substituted dicyanoethylene compounds

ActiveCN106966922AEasy to operateUniversalCarboxylic acid nitrile preparationOrganic compound preparationAlkaneTriethylphosphite

The invention discloses a synthesis method of functionally-substituted dicyanoethylene compounds. The synthesis method includes: using 2, 5-dinitrothiophene and triphenylphosphine / triethyl phosphate as raw materials; heating for reaction in an organic solvent, wherein reaction temperature is 90-180 DEG C, a reaction formula is shown as follows, and R refers to aromatic-ring substituent group or alkane substituent group. The synthesis method has the advantages that the synthesis method is simple to operate, wide in substrate application range and environment-friendly; the synthesis method has universality in synthesizing aromatic ring substituted dicyanoethylene compounds and alkyl substituted dicyanoethylene compounds.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Mixed metal oxide catalysts for the ammoxidation of propane and isobutane

Owner:INEOS USA LLC

Process for the ammoxidation of propane and isobutane

InactiveUS20080200715A1Organic compound preparationHeterogenous catalyst chemical elementsGas phaseCerium

A process for the ammoxidation of a saturated or unsaturated or mixture of saturated and unsaturated hydrocarbon to produce an unsaturated nitrile, said process comprising contacting the saturated or unsaturated or mixture of saturated and unsaturated hydrocarbon with ammonia and an oxygen-containing gas in the presence of a catalyst composition comprising molybdenum, vanadium, antimony, niobium, tellurium, optionally at least one element select from the group consisting of titanium, tin, germanium, zirconium, hafnium, and optionally at least one lanthanide selected from the group consisting of lanthanum, cerium, praseodymium, neodymium, samarium, europium, gadolinium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium. Such catalyst compositions are effective for the gas-phase conversion of propane to acrylonitrile and isobutane to methacrylonitrile (via ammoxidation).

Owner:INEOS USA LLC

Preparation methods of nitrile and corresponding amine

ActiveCN105016943AReduce dosageIncrease profitOrganic compound preparationPreparation by carboxylic acid amide dehydrationState of artAmmonia

The invention relates to a preparation method of nitrile. Compared with the prior art, the preparation method has the characteristics of obvious reduction of the usage amount of ammonia sources, low environmental pressure, low energy consumption, low production cost, high purity and yields of nitrile products, and the like, and can be used for obtaining nitrile with a more complex structure. The invention also relates to a method for preparing corresponding amine with nitrile.

Owner:SINOPEC YANGZI PETROCHEM +1

Preparation method of nitrile compound

ActiveCN102964196AEasy to getEasy to operatePreparation by hydrocarbon ammoxidationCyano group formation/introductionAlcoholHigh pressure

The invention discloses a method for effectively synthesizing a nitrile compound by reacting a copper salt, a ligand and a co-catalyst, a final oxidant such as with ammonia water under the mild condition in an alcohol and synthesizing multiple heterocyclic compounds with a one-pot method. In the method, the substrate adaptability is wide, the reaction time is short, the yield is high and the atom economy is high. Use of severe conditions, such as high temperature and high pressure and toxic starting materials is avoided; and the preparation method is simple in operation steps and less in corrosion on instruments, generates less waste gas, waste water and industrial residue, and is beneficial to further popularization and application, and industrial production.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

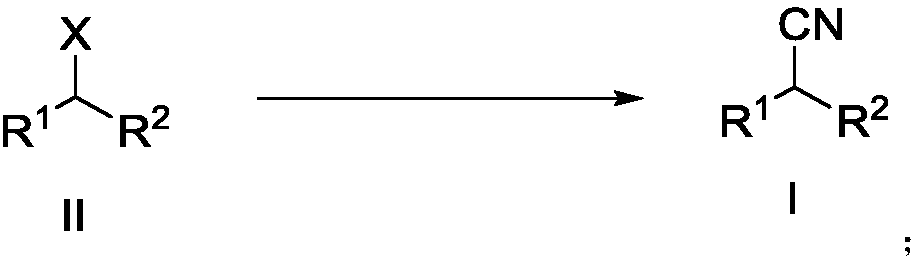

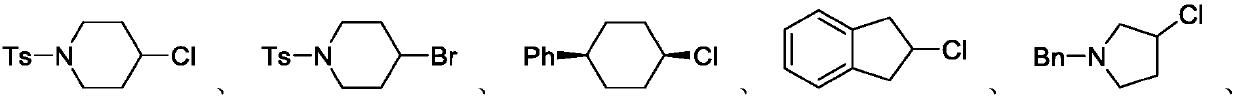

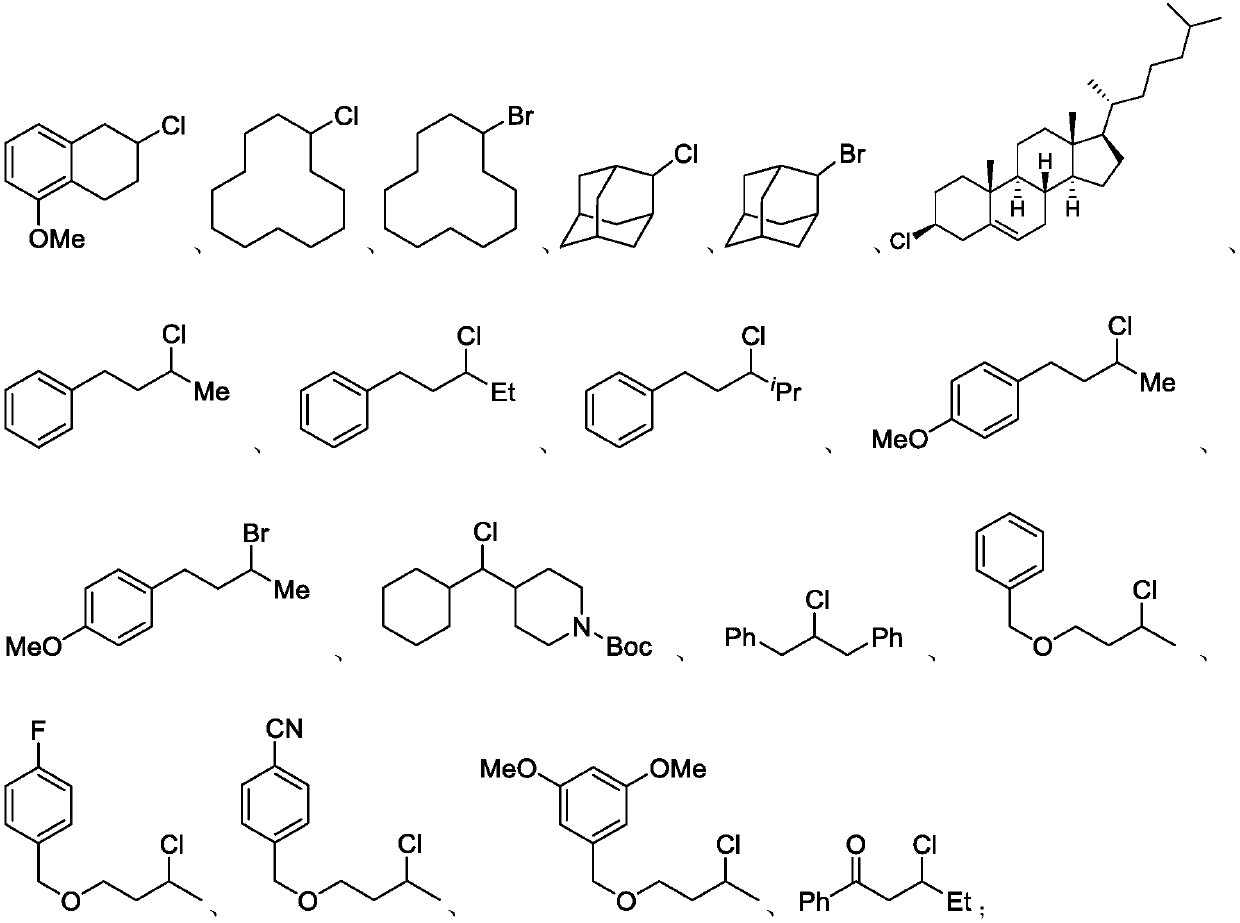

Preparation method of alkyl nitrile compound

ActiveCN111099941AAchieve cyanationImprove compatibilityPreparation by cyanide reactionSteroidsNickel saltPtru catalyst

The invention discloses a preparation method of an alkyl nitrile compound shown as formula I. The preparation method comprises the following step: in a solvent, in the presence of an additive and a catalyst, Zn (CN) 2 and an alkyl halide shown as formula II are subjected to a coupling reaction as shown in the specification to obtain the alkyl nitrile compound as shown in the formula I, wherein theadditive comprises an alkali, the catalyst comprises a nickel compound and a phosphine ligand; the nickel compound is one or more of zero-valent nickel, monovalent nickel salt and divalent nickel salt; when the nickel compound contains zero-valent nickel or divalent nickel salt, the catalyst further comprises a reducing agent. According to the preparation method disclosed by the invention, cyanation of an alkyl halide can be simply, conveniently and efficiently realized by using a cheap catalytic system, and the preparation method also has good functional group compatibility and substrate universality.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

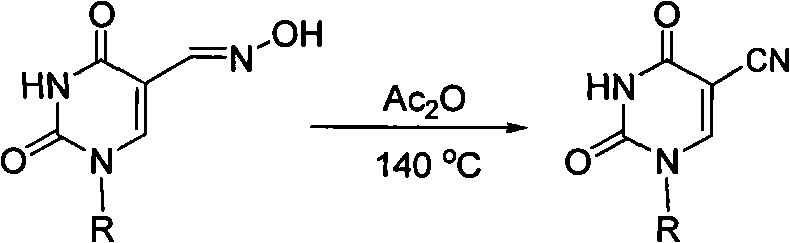

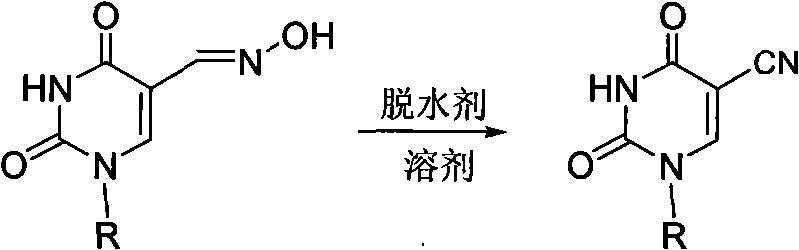

Method for synthesizing 5-cyano pyridine nucleoside derivatives

InactiveCN102515998AEasy to recycle and reuseEasy to operateSugar derivativesSugar derivatives preparationAcetic anhydrideSolvent

The invention discloses a method for synthesizing 5-cyano pyridine nucleoside derivatives. Pyridine nucleoside-5-formaldehyde oxime is added into acetic anhydride to be heated and dehydrated to efficiently generate 5-cyano pyridine nucleoside. The reaction process is simple; needed raw materials are easy to obtain; reagents are safe; and the acetic anhydride not only can be as a dehydrating agent but also can be used as a reaction solvent, is easy to recycle and can be repeatedly utilized. The method for synthesizing the 5-cyano pyridine nucleoside derivatives has the advantages of simple and feasible reaction process, cleanness and high efficiency, thereby being applicable to industrial production in a large scale.

Owner:HENAN NORMAL UNIV

Popular searches

Hydroxy compound preparation Amino group formation/introduction Ketenes preparation Oxygen compounds preparation by hydrocarbon oxidation Graphene Ether/acetal/ketal group formation/introduction Amino compound preparation Carboxylic preparation by oxidation Chemical/physical/physico-chemical microreactors Carbonyl compound preparation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com