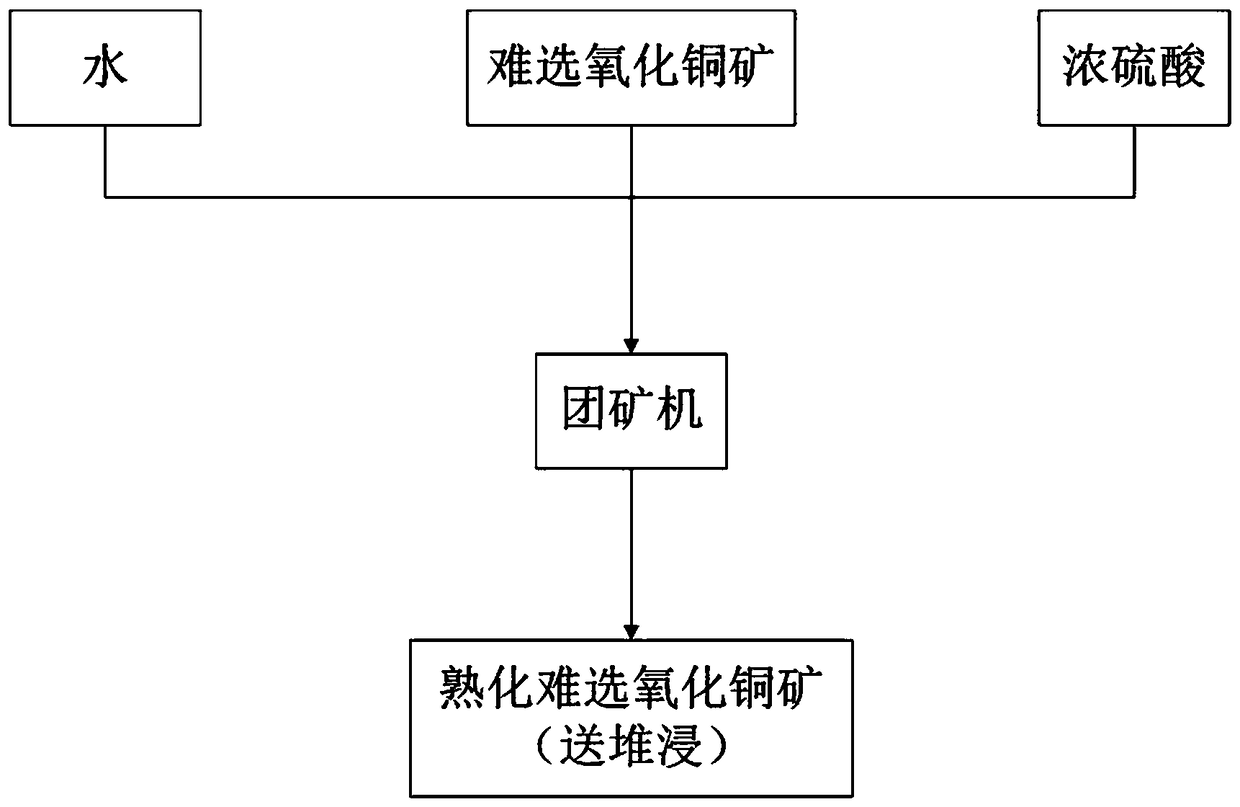

Difficult-to-separate copper oxide ore and sulfuric acid curing pretreatment method

A copper oxide ore and pretreatment technology, applied in the metallurgical field, can solve the problems of long aging time, high energy consumption and high grade, and achieve the effects of good economic benefit, high recovery rate and resource utilization rate, and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Add refractory copper oxide ore, water, ore concentrated sulfuric acid (containing 98.3% sulfuric acid) into the Ф2000×6000 pellet machine at a mass ratio of 100:5:10. The centerline of the pellet machine is at an angle of 10 degrees to the horizontal plane. The mining machine rotates, water, concentrated sulfuric acid and refractory copper oxide ore are evenly stirred, and the reaction occurs to dissociate copper from gangue or other minerals, and make the refractory copper oxide ore loose and increase the porosity. The mature refractory copper oxide ore is transported by its own weight from the rear end of the pellet machine through the discharge hopper to the truck transportation yard for heap leaching.

Embodiment 2

[0018] Add refractory copper oxide ore, water, ore concentrated sulfuric acid (containing 98.3% sulfuric acid) into the Ф2000×6000 lump mining machine according to the mass ratio of 100:10:5. The angle between the center line of the lump mining machine and the horizontal plane is 20 degrees. The mining machine rotates, water, concentrated sulfuric acid and refractory copper oxide ore are evenly stirred, and the reaction occurs to dissociate copper from gangue or other minerals, and make the refractory copper oxide ore loose and increase the porosity. The mature refractory copper oxide ore is transported by its own weight from the rear end of the pellet machine through the discharge hopper to the truck transportation yard for heap leaching.

Embodiment 3

[0020] Add refractory copper oxide ore, water, ore concentrated sulfuric acid (containing 98.3% sulfuric acid) into the Ф2000×6000 lump mining machine according to the mass ratio of 100:20:2. The angle between the center line of the lump mining machine and the horizontal plane is 30 degrees. The mining machine rotates, and the water, concentrated sulfuric acid and refractory copper oxide ore are evenly stirred, and a reaction occurs to dissociate copper from gangue or other minerals, and make the refractory copper oxide ore loose and increase the porosity. The mature refractory copper oxide ore is transported by its own weight from the rear end of the pellet machine through the discharge hopper to the truck transportation yard for heap leaching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com