Method for preparing nano-tungsten powder from calcium tungstate

A technology of nano-tungsten powder and calcium tungstate, applied in the field of powder metallurgy, can solve the problems of high contact resistance of nano-powder particles, slow solid-state reduction process, low product purity, etc., to alleviate resource crisis, uniform size and high purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 2g of calcium tungstate powder, press it into a thin slice with a diameter of 15mm under 6MPa, place the thin slice in an electric furnace for sintering, the heating program is 4K / min to 750°C, and then keep it warm for 2 hours. After natural cooling, take out the thin slice and wrap it with a tungsten wire. It is connected with a metal wire to make a cathode for electrolysis. Weigh 300g of calcium chloride and 150g of sodium chloride respectively into an alumina crucible, and place it in a closed reactor. The electric furnace is raised to 250°C at 4K / min, and after 48 hours of heat preservation, it is raised to 850°C at 4K / min under the protection of argon, kept at 20 minutes, and cooled to 750°C after the mixed salt is completely melted. Insert the graphite anode and the nickel sheet cathode into the molten salt and apply a voltage of 2.7-2.8V for pre-electrolysis for 4-8 hours to remove residual moisture and impurities in the molten salt. Then take out the nic...

Embodiment 2

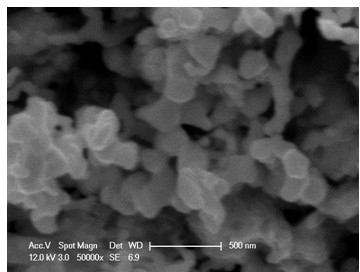

[0029] Weigh 2g of dried calcium tungstate powder, wrap it with foamed nickel and connect it with a metal wire to make a cathode for electrolysis. 2 - After 12 hours of electrolysis at a constant voltage of 3.0-3.6V in NaCl mixed salt. Reduce the cell voltage to 2.5V, raise the temperature of the electric furnace to 900°C, and slowly take out the reaction electrode after holding for 10 minutes. After being completely cooled, put it into a 50ml beaker filled with deionized water and soak for 1 hour. After removing the nickel foam shell, the product is cleaned with deionized water and centrifuged until the supernatant cannot detect chloride ions with silver nitrate, and then the product Put it into a vacuum drying oven at 80°C for 2 hours to obtain nano-tungsten powder.

[0030]

Embodiment 3

[0032] Weigh 2g of calcium tungstate powder, press it into a sheet with a diameter of 15mm under 6MPa, wrap it with tungsten wire and connect it with the tungsten wire to make a cathode for electrolysis; use metal calcium or calcium alloy as the anode, CaCl 2 -NaCl mixed salt is used as the electrolyte, the temperature is controlled at 600-700°C, the two electrodes are first short-circuited for 1 hour, and then a voltage of 0.1-0.5V is applied between the two electrodes for 8 hours of constant voltage electrolysis. Afterwards, take out the anode and place it in a low-temperature zone, raise the temperature of the molten salt to 850°C, and slowly take out the reaction electrode after keeping the temperature for 20 minutes. Wash the product after it is completely cooled, and dry it in vacuum to obtain nano-tungsten powder with a carbon content of less than 0.005%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com