Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Reduce surface acidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodemetalizing catalyst and its prepn

InactiveCN101066530AHigh thermal and hydrothermal stabilityHigh carbon capacity and metal contentPhysical/chemical process catalystsPolymer scienceActive component

The present invention discloses one kind of hydrodemetalizing catalyst and its preparation process. The catalyst has alumina containing P, Mg and K as carrier, VIII and VIB metal element as the active component and optional auxiliary components. It is prepared through a simple preparation process. The catalyst is especially suitable for the hydrodemetalizing process of hydrocarbon with high oxygen content, high metal content and high easy-to-coke component content, such as light coal tar oil fraction, and has the features of high hydrodemetalizing activity, high stability and long service life.

Owner:林方 +4

Process for preparing demetalizing and desulfurizing catalyst of heavy oil hydrogenation

InactiveCN1458236AReduce acidityImprove activity stabilityRefining to eliminate hetero atomsChemistryFuel oil

The present invention discloses a preparation process of heavy oil hydrogenating, demetallizing and desulfruizing catalyst. Aluminum containing material in two different forms, including roasted alumina and dry aluminum hydroxide glue powder, is used. Of the assistant alkali metal element and / or alkali earth metal element, part is mixed with dry aluminum hydroxide glue powder and part is loaded onto the carrier via soaking process, so as to result in the inhomogeneous distribution of the assistant on the carrier. The catalyst has high demetalizing activity and desulfurizing activity, and highactivity stability, especially high desulfurizing activity stability. The catalyst may be used in the hydrodemetalizing and hydrodesulfurizing treatment of heavy oil and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing demetalizing and desulfurizing catalyst of heavy oil hydrogenation

InactiveCN1205314CAdjust the pore size distributionImprove activity stabilityRefining to eliminate hetero atomsAlkaline earth metalHydrodesulfurization

The invention discloses a preparation method of heavy oil hydrogenation demetallization and desulfurization catalyst, which uses two kinds of aluminum-containing materials in different forms, one is calcined alumina, the other is aluminum hydroxide dry rubber powder, and the alkali metal And / or alkaline earth metal elements are additives, the additives are pre-mixed with aluminum hydroxide dry rubber powder, and part is loaded on the catalyst by impregnation method, so that the additives are unevenly distributed on the catalyst. The catalyst prepared by the method of the invention has high demetallization activity and desulfurization activity at the same time, and the stability of activity, especially the stability of desulfurization activity is good. It can be used in hydrodemetallization and hydrodesulfurization of heavy and residual oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation catalyst for producing biodiesel and preparation method and application of selective hydrogenation catalyst

InactiveCN105903488AImprove thermal conductivityUniform temperature distributionMolecular sieve catalystsHydrocarbon oils refiningBiodieselFreeze-drying

The invention discloses a selective hydrogenation catalyst for producing biodiesel and a preparation method and application of the selective hydrogenation catalyst. The selective hydrogenation catalyst comprises a carrier and a main metal active ingredient loaded on the carrier, the main metal active ingredient accounts for 5-30% of the catalyst in weight and is one of or a combination of oxides containing Co, Mo, Ni and W, and the carrier is composed of, by weight, 1-8% of a molecular sieved, 25-65% of amorphous sial, 30-65% of alumina and 2-10% of a graphene auxiliary. The preparation method includes: disposing the carrier in a metal salt solution containing Co, Mo, Ni or / and W for soaking for 4-20 h to obtain a soaked carrier; freeze-drying and then calcining the soaked carrier to obtain the selective hydrogenation catalyst. With same carrying capacity of the carrier, active surface area represented by the carrier is large, the selective hydrogenation catalyst has more active sites, reaction temperature is lowered, and hydrogenation performance is improved.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Alkane dehydrogenation catalyst and preparation method thereof

ActiveCN104588011AImprove activity stabilityImprove surface propertiesHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneAlcohol

The invention discloses a preparation method of a dehydrogenation catalyst. The method comprises the following steps: loading Sn by adopting an immersion process with alumina as a carrier; drying, roasting, and carrying out surface modification on the Sn supported alumina carrier by using an alcohol solvent; drying the modified Sn-containing alumina carrier, and loading an active component Pt by adopting the immersion process; and loading alkali metal Na. The catalyst prepared through the method can promote Pt-Sn interaction, so the selectivity of a target product propylene is improved, and the active stability of the catalyst is also improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Titanium oxide - aluminum oxide composite carrier, preparation method and application thereof

ActiveCN1689702AEasy to prepareThe reaction temperature is easy to controlCatalyst carriersCatalyst activation/preparationAluminateTitanium oxide

The present invention discloses one kind of composite titania-alumina carrier and its preparation process and application. The composite carrier contains titania in 10-50 wt% and in anatase and / or rutile form and contains alumina in alpha-Al2O3 form. The composite carrier has acid surface and total acid amount of 0.6-8 A / g / sq cm. The preparation process includes the following steps: mixing titanium tetrachloride solution and AlCl3.6H2O crystal through stirring and diluting, mixing with sodium meta-aluminate solution to obtain aluminum titanium hydroxide precipitate, ageing, filtering, washing, drying, crushing, kneading, and roasting at 800-1200 deg.c to obtain the carrier. The composite carrier is used in selective hydrogenation and is favorable to reducing side product 'green oil' and prolonging the life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

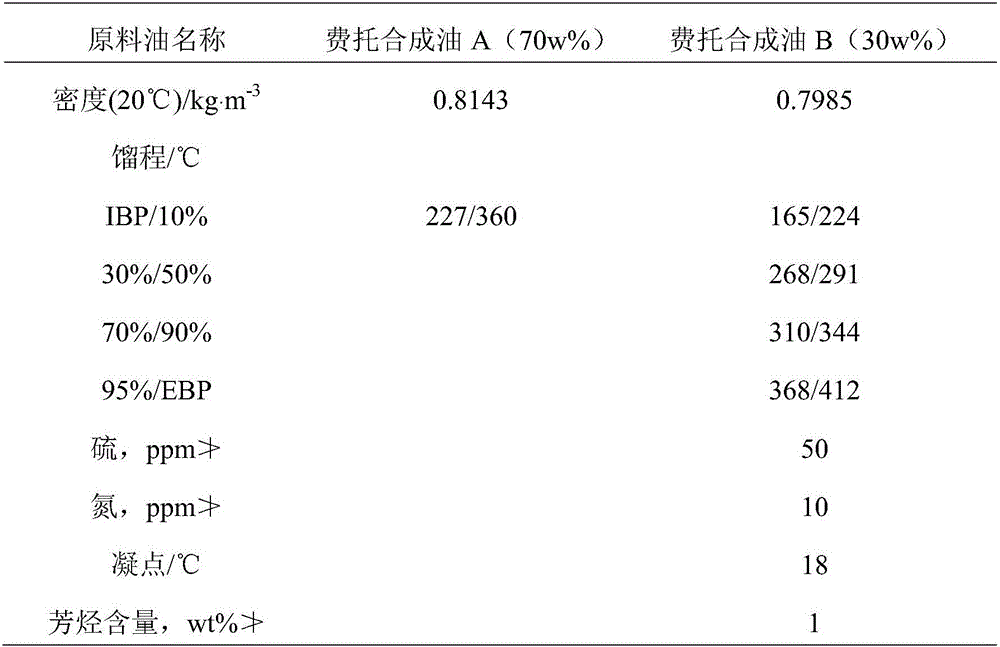

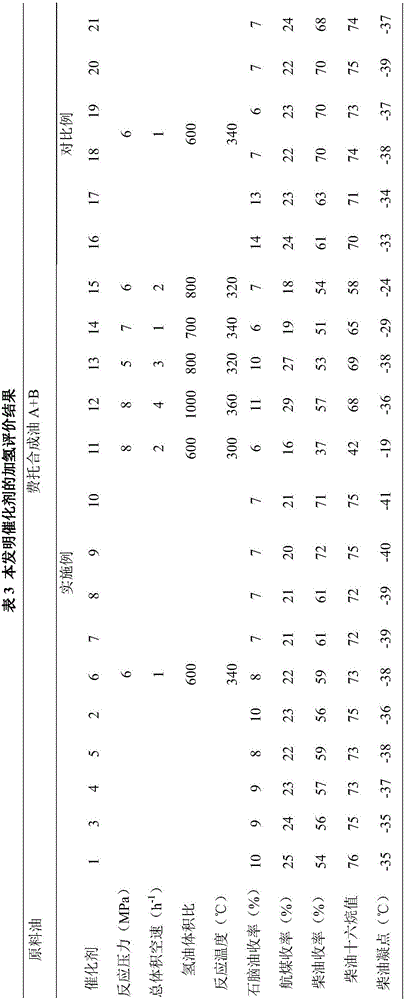

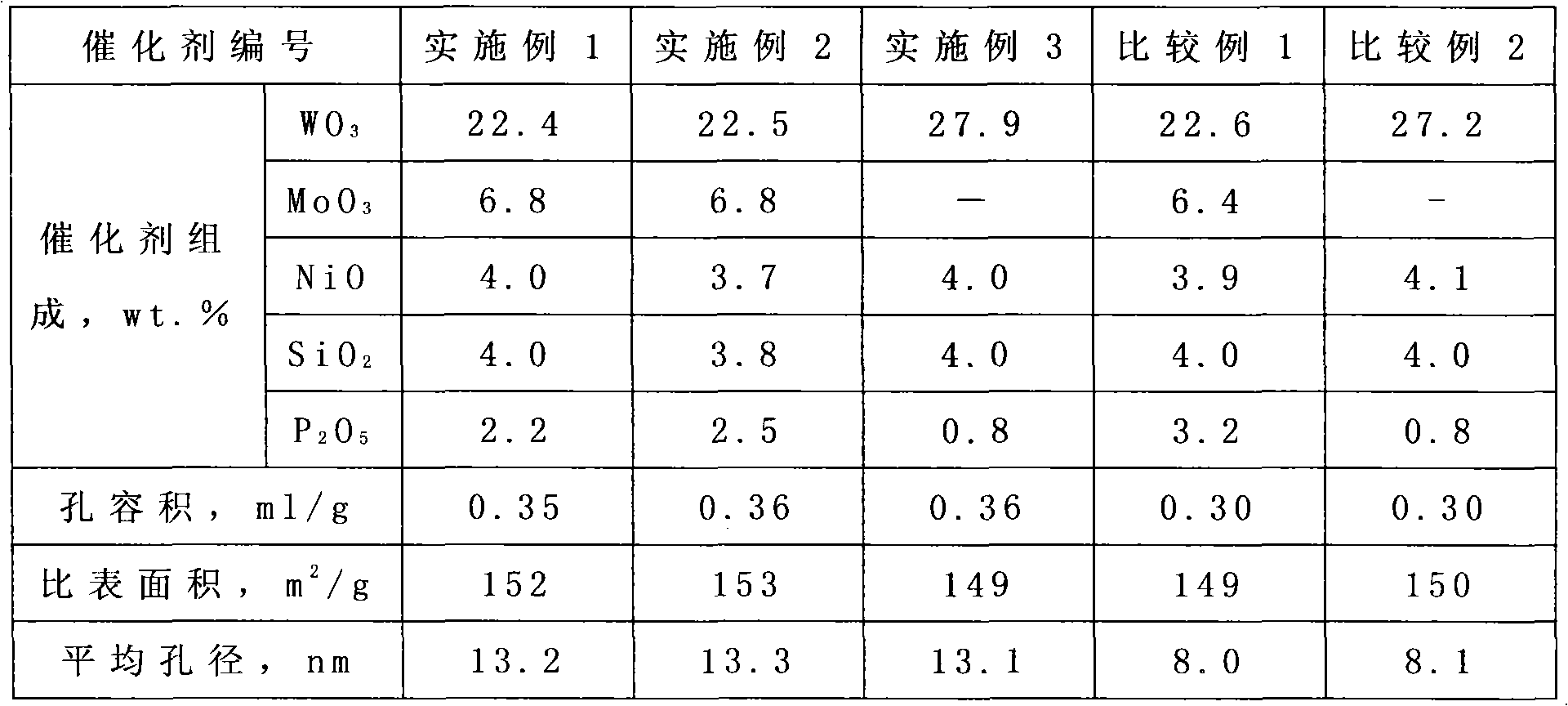

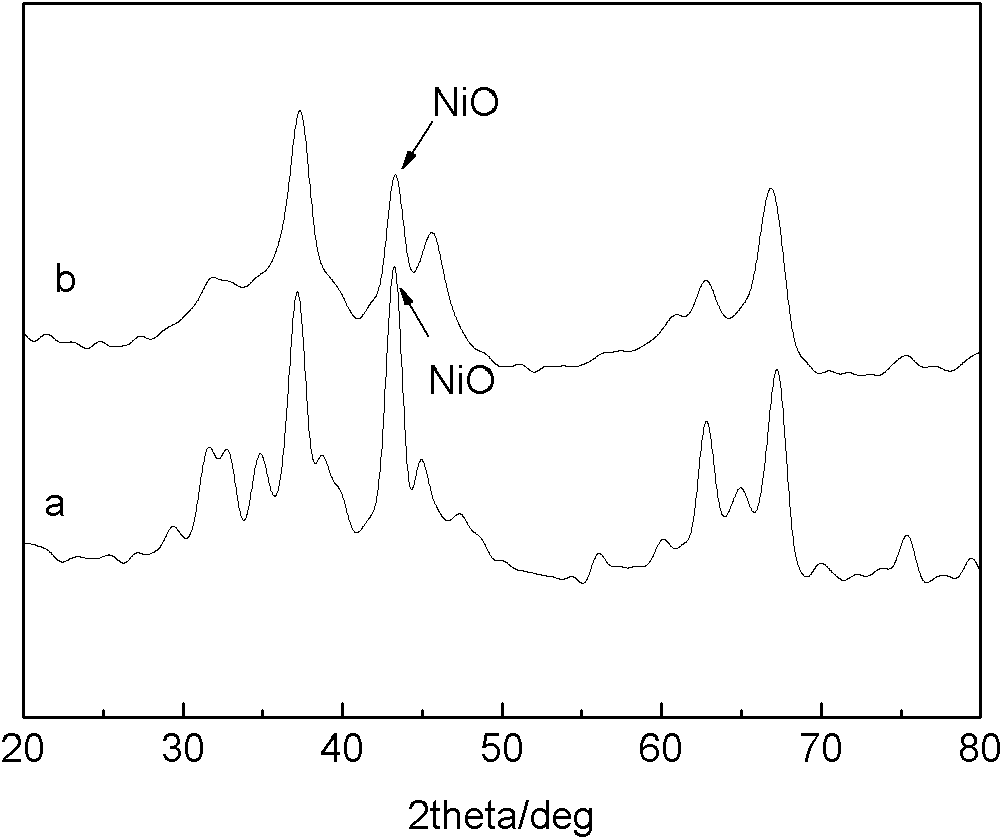

Method for hydrorefining petroleum wax

The invention relates to a method for hydrorefining petroleum wax. According to the invention, alumina is used as a carrier of a hydrorefining catalyst, and an active component in the catalyst is one or two selected from the group consisting of NiO, MoO3 and WO3, wherein, the content of NiO accounts for 2 to 7% of the total weight of the catalyst, and the content of MoO3 and / or WO3 accounts for 20 to 32% of the total weight of the catalyst; the content of SiO2 accounts for 1 to 9% of the total weight of the catalyst, and the content of P2O5 accounts for 1 to 7% of the total weight of the catalyst; the catalyst has a specific surface area of 120 m<2> / g to 190 m<2> / g, a pore volume of 0.30 ml / g to 0.55 ml / g, pores with a pore diameter of 5 nm to 14 nm account for 40 to 70% of the whole pore volume, and pores with a pore diameter of 20 nm to 40 nm account for 20 to 40% of the whole pore volume; the alumina carrier has a double-peak pore structure, the pore wall of a macroporous tunnel has weak surface acidity, and pore wall of a microporous tunnel has strong surface acidity.

Owner:PETROCHINA CO LTD

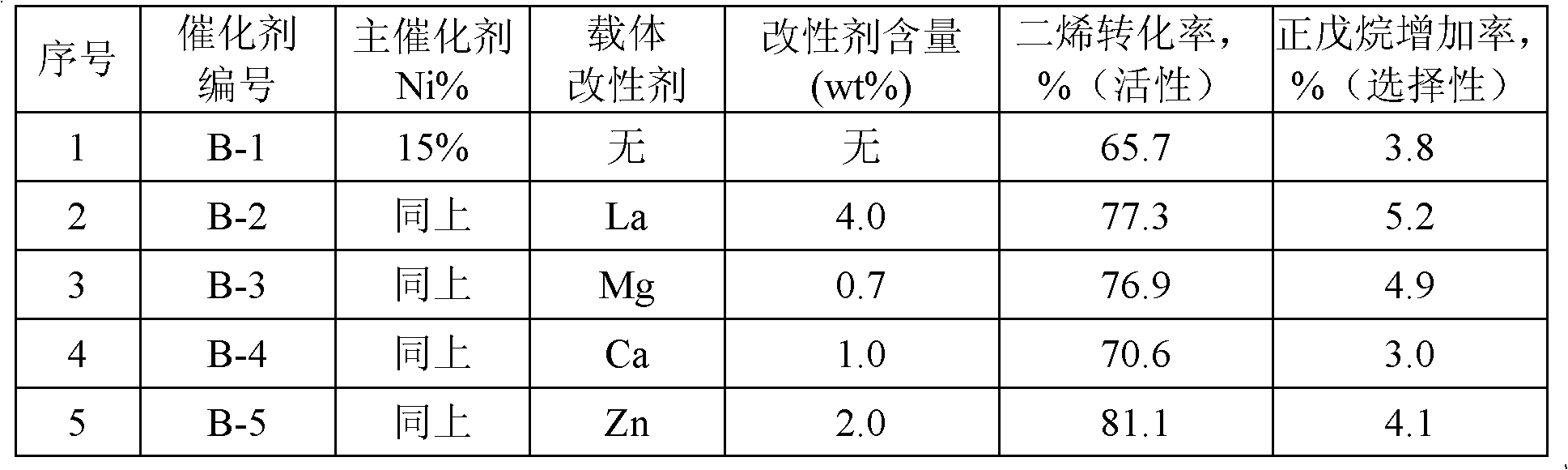

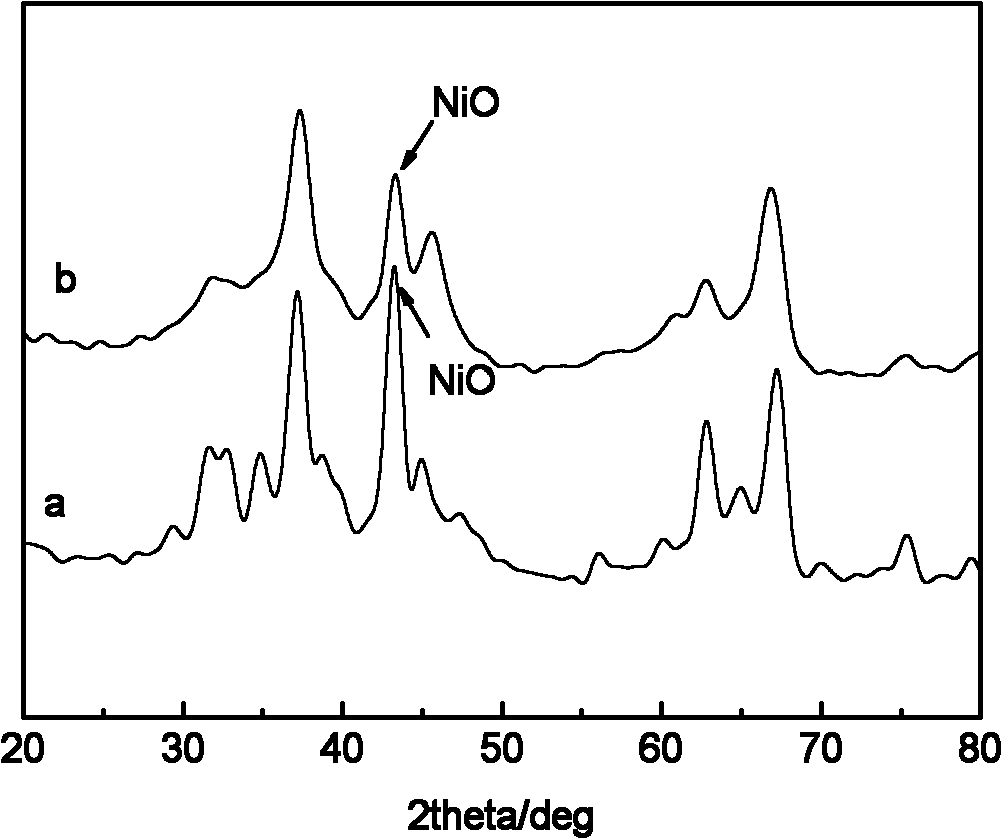

Modified Al2O3 carrier and preparation method thereof

InactiveCN102125878AInhibitory responseHigh activityCatalyst carriersCatalyst activation/preparationPtru catalystPhysical chemistry

The invention relates to a modified Al2O3 carrier and a preparation method thereof. The invention first provides the modified Al2O3 carrier, Al2O3 is used as a matrix in the carrier, and the surface of the carrier is provided with a layer of spinel compound formed by modifying the Al2O3 with a modifying element M, wherein the modifying element M is one of La, Ce, Pr, Mg, Ca, Sr, Ba and Zn. The invention also provides the preparation method for the modified Al2O3 carrier. By selecting the proper modifying element for modifying the surface of the Al2O3 matrix, the modifying element and the Al2O3 form the spinel compound on the surface of the matrix, so the acidity of the carrier surface can be greatly reduced, the reaction between the active metal on the surface of the catalyst and the carrier is inhibited, the surface structure of the carrier is improved, and a catalyst obtained by using the surface modified carrier as a carrier can keep high activity and stability in long-time operation.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of alkene epoxidation catalyst as well as catalyst prepared thereby

ActiveCN107930610AHigh reactivityReduce surface acidityOrganic chemistryMolecular sieve catalystsComposite oxideKinetic diameter

The invention relates to a preparation method of an alkene epoxidation catalyst. The preparation method of the alkene epoxidation catalyst comprises the following steps: (1) preparing titanium silicongel; (2) performing pore-enlarging treatment on the titanium silicon gel by using organic amine or liquid ammonia, drying and roasting to obtain titanium silicon composite oxide; (3) optionally performing alcohol solution treatment on organic alkali metal salt; and (4) optionally performing gas phase silanization treatment. The pore diameter of the catalyst prepared by the method is adjustable, so that the catalyst has higher activity on epoxidation reaction of olefin molecules with different kinetic diameter; and the catalyst is subjected to two-step modification, the surface acidity of thecatalyst is effectively reduced and the catalyst has higher epoxidation product selectivity.

Owner:WANHUA CHEM GRP

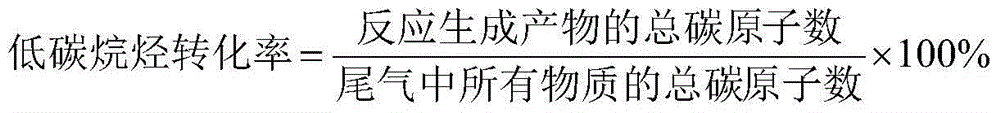

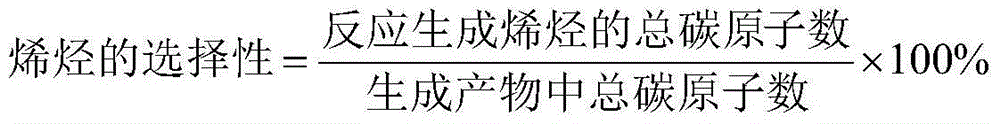

Catalyst used for producing olefin through low-carbon alkane dehydrogenation, and preparation method thereof

ActiveCN105582919AImprove anti-sintering performanceGood performance and stableHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsLow activityAlkane

The invention relates to a catalyst used for producing olefin through low-carbon alkane dehydrogenation, and a preparation method thereof. The invention mainly aims at solving the problems of low activity and poor stability of dehydrogenation catalysts prepared with prior arts. The low-carbon alkane dehydrogenation catalyst provided by the invention is prepared through an impregnation precipitation method, and comprises the following components, by weight: (a) 0.1-5 parts of Pt or oxide thereof, (b) 0.1-5 parts of Sn or oxide thereof, (c) 0.1-5 parts of alkali metal or oxide thereof, (d) 0.1-5 parts of Fe, Co, Ni, Cu, Zn or oxide thereof, (e) 0.1-10 parts of a Ce-La-O solid solution, and (f) 80-99 parts of a carrier Al2O3. With the above technical scheme, the problems are well solved. The catalyst can be applied in industrial productions for producing low-carbon olefin through low-carbon alkane dehydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of catalyst for selective hydrogenation of alkyne and alkadiene

InactiveCN103372432AGenerate good effectReduce churnHydrocarbon purification/separationHydrocarbonsAlkaline earth metalCerium

The invention relates to a preparation method of a catalyst for the selective hydrogenation of alkyne and alkadiene. A carrier of the catalyst is a compound of 30-99% of aluminum oxide, 1-50% of titanium oxide, 1-30% of magnetism oxide and 1-40% of zinc oxide based on the weight of the carrier of the catalyst as 100%; meanwhile, an alcohol reagent and an alkali metal or an alkaline-earth metal are used as modifying reagents; the preparation method is an acidity sol mixed kneading molding method; the active components of the catalyst comprise three or more of palladium, gold, silver, bismuth, cerium, lanthanum, tin and antimony, and a loaded solution of the active components is subjected to polymerization; the carrier of the catalyst prepared by the method has relatively low acid content; and the prepared catalyst shows up relatively appropriate reaction activity in the selective hydrogenation reaction of the alkyne and the alkadiene and has relatively good hydrogenation selectivity, relatively strong green oil generation resistance and relatively low palladium wastage rate.

Owner:PETROCHINA CO LTD

Iso-butane dehydrogenation catalyst and preparation method thereof

InactiveCN102614864AReduce surface carbon phenomenonSlow down inactivationHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementChemical reaction

An iso-butane dehydrogenation catalyst and a preparation method thereof relate to catalytic agents and preparation methods of the catalytic agents in chemical reactions. The catalyst comprises, by weight, 1-30% of vanadic oxide, 0.2-5% of alkali metal oxide, 0.1-10% of Ce containing rare earth elements or La oxide and 55-98.7% of nanometer Al2O3. The preparation method is first preparing an Al2O3 carrier, then mixing the carrier with vandic salt solution, alkali metal solution, the Ce containing the rare earth elements or La salt solution, and then stewing and filtering to obtain a catalyst sample, roasting the catalyst sample for a certain time at certain temperature, and finally preparing the iso-butane dehydrogenation catalyst. The prepared iso-butane dehydrogenation catalyst improves conversion rate of iso-butane and achieves high olefin selectivity on the bases of the vanadic system catalyst at present.

Owner:HENAN UNIV OF SCI & TECH

Metal compound-type arsenic removal agent, preparation method and application thereof

InactiveCN103877931ASimple production processLarge specific surface areaOther chemical processesRefining with metal oxidesSyngasCopper

The invention discloses a metal compound-type arsenic removal agent, a preparation method and an application thereof, the metal compound-type arsenic removal agent is composed of a carrier and a metal active ingredient loaded on the carrier; the carrier is active carbon, and the metal active ingredient is more than one selected from copper, iron, nickel or silver. The arsenic removal agent has the advantages of simple production technology, large specific surface area, and good active metal dispersibility, deep arsenic removal of the oil product can be realized, surface acidity is low, the colloid generation is reduced, so that the arsenic removal agent is benefit for prolonging the regeneration period of a catalyst, the arsenic removal agent has the advantages of high arsenic removal rate and low energy consumption, and is suitable for large-scale industrial production, and can be used for removing arsenic from the light dydrocarbon materials such as propylene, ethene and deeply purifying arsenic in synthetic gas prepared by taking coal, coke, heavy oil, oil residue or natural gas as raw materials.

Owner:SHANGHAI UNIV OF ENG SCI

Selective hydrogenation catalyst for producing aviation kerosene and preparation method and application thereof

InactiveCN105944752AReduce reunionAchieve high efficiencyMolecular sieve catalystsHydrocarbon oils refiningReaction temperatureCoal

The invention discloses a selective hydrogenation catalyst for producing biological aviation kerosene and a preparation method and an application thereof. The catalyst comprises a carrier and a main metal active component; the main metal active component is loaded on the carrier; the main active metal component accounts for 0.05-1.15 wt% of the catalyst finished product and is Pt or / and Pd; the carrier comprises the raw materials by the weight percentage: 2-10% of molecular sieve, 25-65% of amorphous silicon aluminum, 30-65% of alumina and 2-10% of a graphene auxiliary agent. The method comprises the steps: placing the carrier in a solution containing Pt and / or Pd metal salts, and immersing for 4-20 h, to obtain a carrier after impregnation; and drying the carrier obtained after impregnation, and then treating the dried carrier in a reducing atmosphere, to obtain the selective hydrogenation catalyst. Under the same loading capacity, the selective hydrogenation catalyst has larger representative active surface area and more active sites, reduces the reaction temperature, and improves the hydrogenation performance.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

Process for preparing octaene by butene oligomerization

ActiveCN1704388AReduce surface acidityImprove conversion rateHydrocarbons from unsaturated hydrocarbon additionButeneReaction temperature

The invention relates to a process for preparing octaene by butene oligomerizatio through using butene as raw material, using M-ZSM-5 molecular sieve as the catalyst for the reactive main body, and employing a reaction temperature of 250-350 deg. C, reaction pressure 4.0-5.0 MPa, liquid phase volume hourly space velocity of 0.5-3h-1, the prepared octaene can be used in the industrial production of octaene through butylenes oligomerization reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

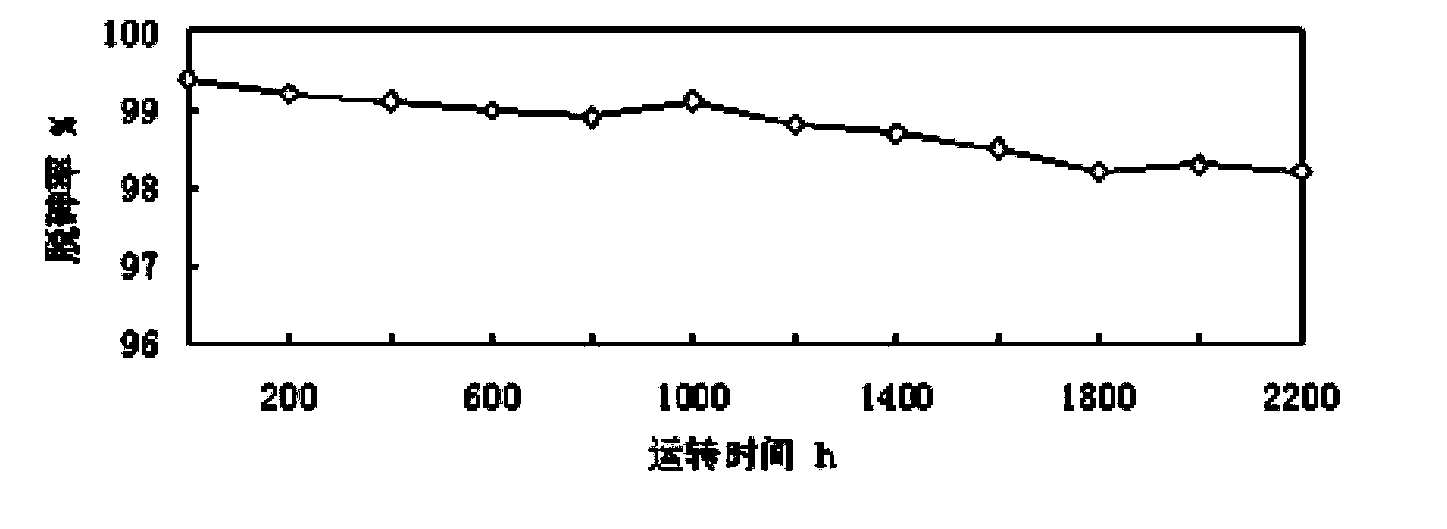

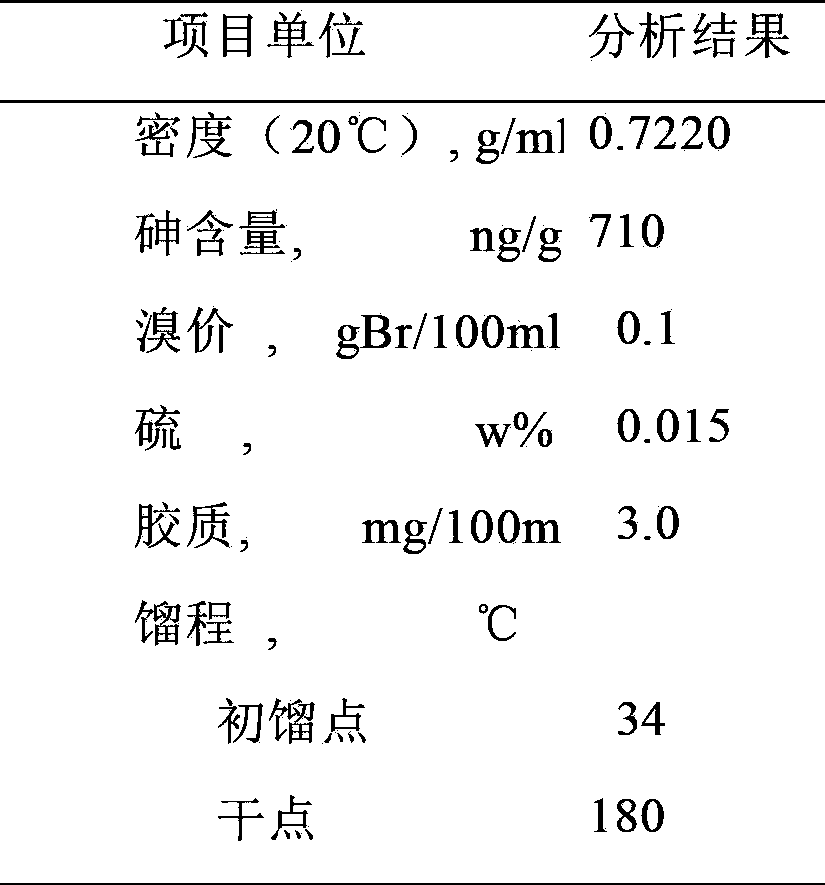

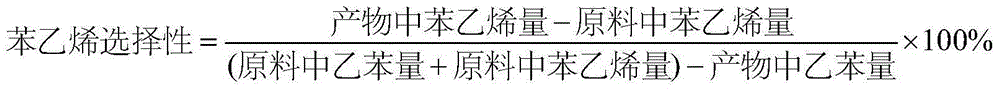

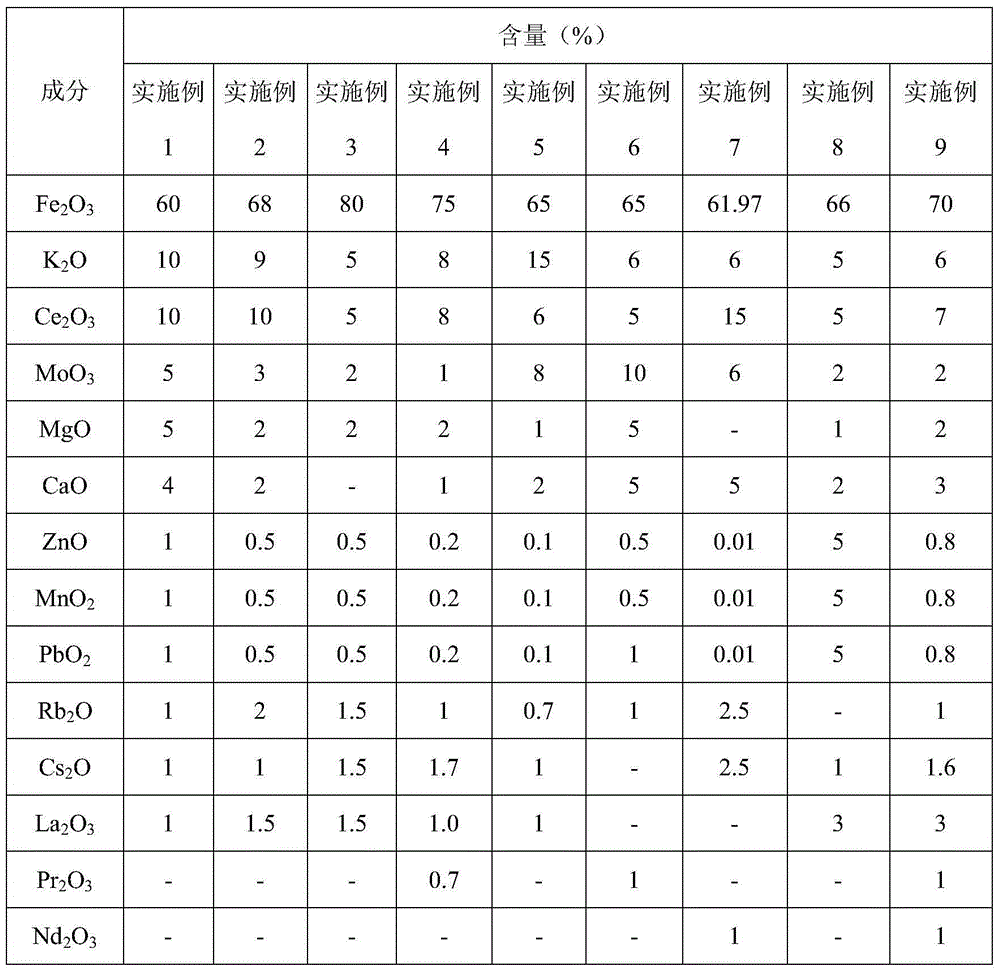

Catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene, and preparation method thereof

ActiveCN105749934AHigh activityImprove resistance to reductionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideDehydrogenation

The invention relates to a catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene. The catalyst comprises, by mass, 60-80 parts of iron oxide by Fe2O3, 5-15 parts of potassium oxide by K2O, 5-15 parts of cerium oxide by Ce2O3, 1-10 parts of molybdenum oxide by MoO3, 1-10 parts of magnesium or / and calcium oxide by MgO or / and CaO respectively, 1-5 parts of at least one of alkali metal oxides of Rb and Cs, respectively by Rb2O and Cs2O, wherein the alkali metal oxides are modified on the surface of the catalyst in a salt solution form; and light rare earth metal oxides of La, Pr and Nd without Ce, and oxides of Mn, Zn and Pb. The catalyst has a high activity and a good stability under a low steam-to-oil ratio.

Owner:PETROCHINA CO LTD

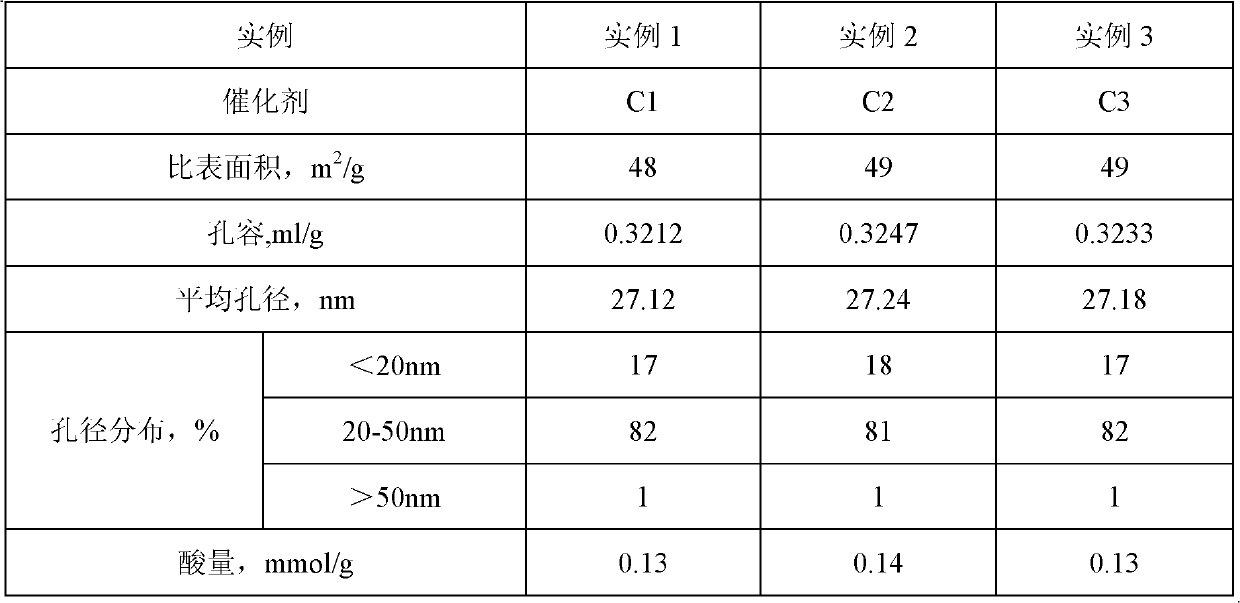

Mixed mesoporous carrier of light alkane dehydrogenation catalyst and preparation method thereof

ActiveCN107398296AHigh strengthHigh activityMolecular sieve catalystsHydrocarbonsAlkaneMolecular sieve

The invention relates to a catalyst carrier prepared from mixed aluminum oxide and mesoporous molecular sieve and a preparation method thereof. The mixed mesoporous carrier is prepared by the following steps of: adding the mesoporous molecular sieve and various auxiliary agent into a conventional aluminum oxide source; performing mixing and extrusion moulding; and then performing hydrothermal treatment, drying and roasting to finally obtain a finished product dehydrogenation catalyst carrier. The prepared light alkane dehydrogenation catalyst carrier has high mechanical strength, good thermal stability and enhanced catalysis activity.

Owner:QINGDAO UNIV OF SCI & TECH

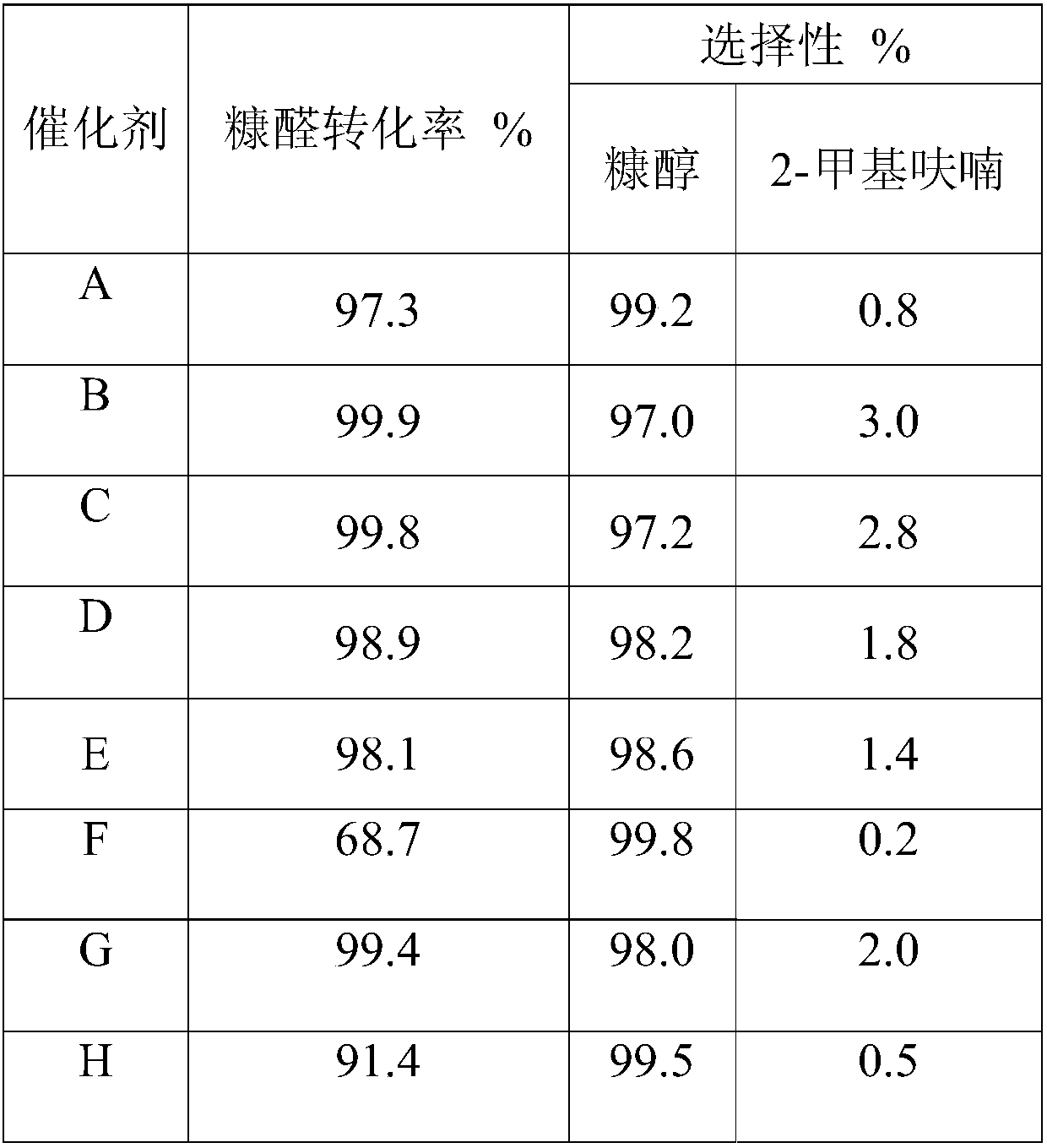

Catalyst for producing furfuryl alcohol, preparation method thereof, and furfuryl alcohol production method

ActiveCN109833897AIncrease lossDepletion accelerates catalyst deactivation at the same timeOrganic chemistryMolecular sieve catalystsAlkaline earth metalRare earth

The invention relates to a catalyst for producing furfuryl alcohol, a preparation method thereof, and a furfuryl alcohol production method. The catalyst comprises a main active component, an assistantand a passivated carrier, wherein the main active component is Cu, the assistant is one or more of an alkali metal, an alkali earth metal and a rare earth metal oxide, and the passivated carrier is asilicon oxide-containing inorganic carrier. The catalyst is characterized in that the passivation treatment of the carrier is one or more of heat treatment, silanization and etherification. The catalyst is prepared by an ammonia evaporation induced deposition precipitation process, so the preparation method has the advantages of simplicity, convenience, low requirements for devices needed by rawmaterial storage and catalyst preparation, and easiness in large-scale amplified amplification. The catalyst has the advantages of high single conversion of furfural, high furfuryl alcohol selectivity, long life and good industrial application prospect when applied to furfural hydrogenation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for gas phase hydrogenation of furfural to prepare furfuryl alcohol, preparation and application thereof

InactiveCN110152663ASimple compositionEasy to prepareOrganic chemistryMolecular sieve catalystsAlcoholGas phase

The invention provides a catalyst for gas phase hydrogenation of furfural to prepare furfuryl alcohol, preparation and application thereof. The catalyst is composed of a metal component and a siliconoxide carrier pretreated by alcohol amine. The preparation method of the catalyst includes the steps of: (a) adding a certain amount of alcohol amine liquid into a silicon oxide porous carrier; (b) conducting drying and roasting treatment successively on the mixture obtained in step (a) to obtain a pretreated carrier; (c) adding a certain amount of a copper precursor solution into the carrier obtained in step (b); and (d) conducting drying and roasting on the mixture obtained in step (c) in order to obtain the catalyst. The invention has the advantages that: the catalyst has simple composition, and does not contain toxic and carcinogenic Cr, the preparation method of the catalyst is simple and convenient, low in cost, and easy for large-scale application, and the catalyst has high furfuralhydrogenation low temperature activity and long catalyst lifetime.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for preparing hexanediol from dimethyl adipate and preparation method and application thereof

ActiveCN105727962AImprove heat stabilityImprove heat resistanceOrganic compound preparationHeterogenous catalyst chemical elementsHeat resistanceAdipate

The invention discloses a catalyst for preparing 1,6-hexanediol from dimethyl adipate.The catalyst is composed of a Cu-Zn-Al-Zr oxide, and comprises 25-60% of Cu, 25-50% of Zn, 10-30% of Al and 0.15-1.2% of Zr.The invention further discloses a preparation method of the catalyst.The catalyst is good in activity and heat resistance.Compared with the prior art, the reduction temperature of the catalyst is low and is 200-220 DEG C, the catalyst can be directly reduced in a reactor, and the cost is reduced; when the catalyst is in use, reaction pressure is reduced to 5-8 MPa, the air speed is decreased, and finally the production cost of hexanediol can be reduced; the preparation method is simple, no additional special equipment is needed, and the application prospect is good.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

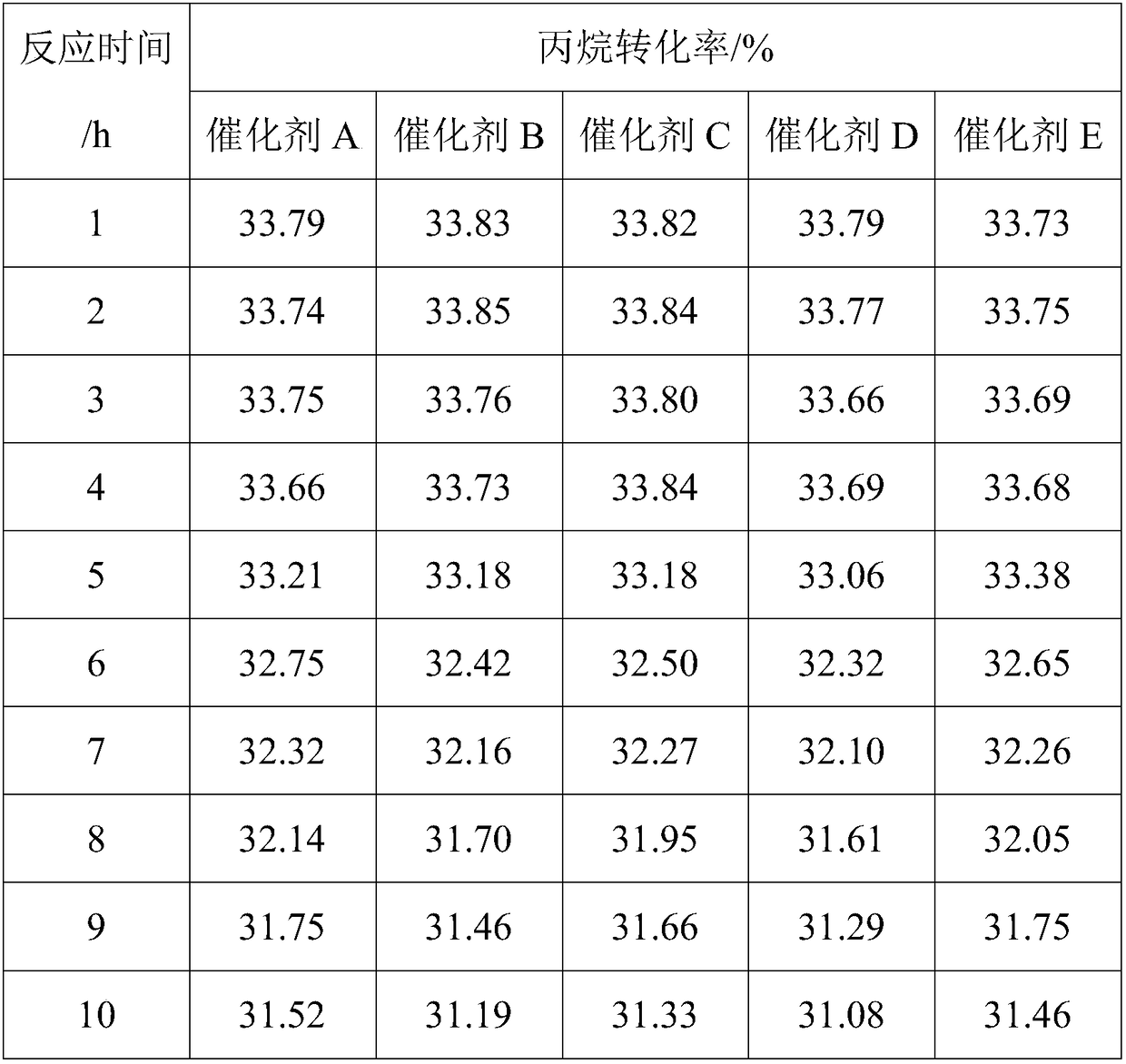

Platinum macroporous aluminum oxide catalyst for preparing propylene through propane dehydrogenation

ActiveCN106582630AFacilitated DiffusionImprove adsorption capacityCatalyst activation/preparationHydrocarbonsPlatinumActive component

The invention provides a platinum macroporous aluminum oxide catalyst for preparing propylene through propane dehydrogenation. According to the catalyst, macroporous aluminum oxide with the diameter being 1.3-1.4 mm and the pore diameter being 15-41 nm serves as a carrier, Pt serves as an active component, Na serves as a first aid, and K, Sn and Ca serve as a second aid. The catalyst has the advantages of being long in service life, good in usability and easy to prepare, the single service life is larger than or equal to 400 hours under the conditions of 80-680 DEG C and pressure being 0-3 kg, the average conversion rate of propane is larger than or equal to 20%, the average selectivity of the propylene is larger than or equal to 94%, and the catalyst after regeneration is carried out five times is stable in structure and still has a good catalysis effect.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

Propane dehydrogenation catalyst and preparation method thereof

ActiveCN108067228AGuaranteed thermal stabilityGood dispersionCatalyst activation/preparationCatalytic reactionsActive componentDehydrogenation

The invention discloses a propane dehydrogenation catalyst and a preparation method thereof. The propane dehydrogenation catalyst adopts CaO-Al2O3 composite oxide balls as a carrier, adopts metal Pt as an active component, and adopts Sn and Bi as additives; by adoption of the mass of the catalyst as a reference, the content of the metal Pt is 0.1-1.0wt%, the content of the Sn is 0.1-2.0wt%, the content of the Bi is 0.1-1.0wt%, the content of CaO is 1.0-5.0wt% and the rest is Al2O3. The propane dehydrogenation catalyst and the preparation method disclosed by the invention have the beneficial effects that the catalyst is prepared by adopting a coprecipitation process and can ensure heat stability and enough specific surface area and pore volume of catalyst carriers; the reaction property andanti-carbon-deposition capability of the catalyst are excellent; the dehydrogenation activity of the catalyst is very high under a high-temperature condition, the propylene selectivity can reach 90%or more, and the stability is good.

Owner:WANHUA CHEM GRP CO LTD

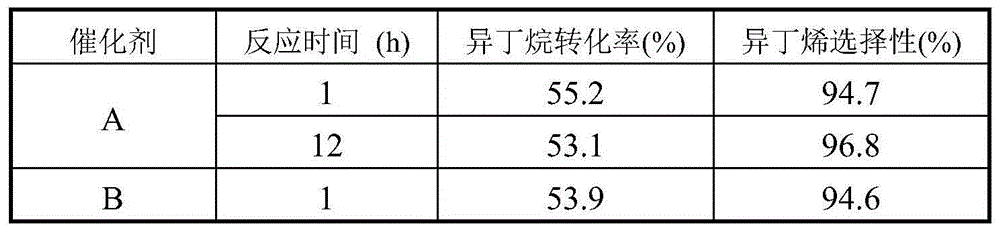

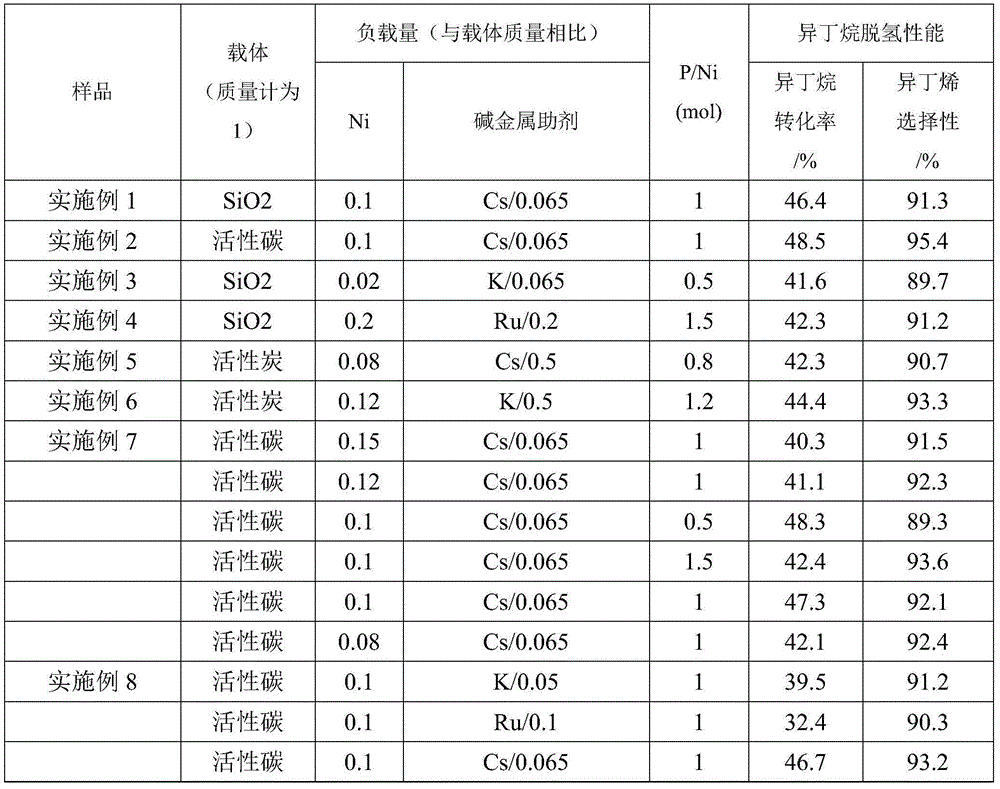

Low alkane-to-olefin catalyst by dehydrogenation and preparation method

InactiveCN105214697AGood dispersionReduce surface acidityPhysical/chemical process catalystsHydrocarbonsAlkaneDehydrogenation

The invention discloses a low alkane-to-olefin catalyst by dehydrogenation and a preparation method. The catalyst is loaded with nickel phosphide and alkaline metals by taking SiO2 spheres or active carbon spheres as a carrier, wherein the mass ratio of the carrier to Ni to the alkaline metals is 1: (0.02-0.2): (0.01-0.2) and the P / Ni molar ratio is 0.5-1.5. In the aspect of dehydrogenation performance of the low-carbon alkane of the catalyst, compared with commercially available d Pt-serial catalysts, the iso-butane conversion ratio is slightly high, and the iso-butane selectivity is equivalent. However, compared with the existing industrially applied PT-serial catalyst preparation process, the preparation cost is low. Compared with Cr-serial catalysts, the catalyst further has a good environmental-friendly advantage.

Owner:TIANJIN UNIV

Method for preparing nickel catalyst supported on SiO2 microspheres and application of nickel catalyst

ActiveCN107899581ALarge specific surface areaHigh activityOrganic compound preparationAmino compound preparationNickel saltFiltration

A method for preparing a nickel catalyst supported on SiO2 microspheres comprises the steps of preparing a water-soluble silicon source solution A; preparing an emulsifier B; preparing an aqueous solution C of a nickel salt and an optional additive metal salt; adding the emulsifier B to the solution A, and performing stirring, suction filtration, washing and drying, so as to obtain SiO2 microspheres; and performing post-treatment on the microspheres by using dilute ammonia water, adding the solution C, and performing impregnation, rotary evaporation, microwave drying, roasting and reduction toobtain the nickel catalyst supported on the SiO2 microspheres. When the nickel catalyst is applied to catalytic hydrogenation of dinitrotoluene DNT for preparing toluene diamine TDA, the conversion rate of DNT is 100% and the selectivity of TDA is 99.9%.

Owner:WANHUA CHEM GRP CO LTD

High-precision desulfurization and denitrification catalyst carrier and preparation method thereof

ActiveCN105498854AImprove desulfurization and denitrification efficiencyReduce surface acidityCatalyst carriersMolecular sieve catalystsMolecular sieveSilicon oxide

The invention provides a high-precision desulfurization and denitrification catalyst carrier which comprises the following components by weight part: 10-20 parts of magnesium oxide, 0.1-10 parts of zirconium oxide, 0.1-10 parts of MCM-22 molecular sieves and 70-90 parts of a mixture of silicon oxide and aluminum oxide. The desulfurization and denitrification efficiency of a catalyst prepared with the catalyst carrier can be obviously increased by taking silicon and aluminum as a carrier and adding magnesium oxide, zirconium oxide and MCM-22 molecular sieves into the carrier; the catalyst carrier has high mechanical strength and high compression-resisting abrasive resistance; the problem of low desulfurization and denitrification efficiency of a catalyst prepared with a catalyst carrier in the prior art is solved.

Owner:SHENYANG SANJUKAITE CATALYST

Hydrogen selective oxidation catalyst used in the propane dehydrogenation process and preparation method thereof

ActiveCN102218314AReduce surface acidityReduce deep oxidationHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsHydrogen oxidationOxide

The invention relates to a hydrogen selective oxidation catalyst used in the propane dehydrogenation process and a preparation method thereof, and mainly solves the problems of low oxygen conversion rate and high hydrocarbon loss of the hydrogen oxidation catalyst in the prior art. By adopting a technical scheme that the hydrogen selective oxidation catalyst comprises the following components in percentage by weight: 0.1 to 10 percent of Pt or oxide thereof, 0.25 to 10 percent of Sn or oxide thereof, 0.1 to 10 percent of Li or oxide thereof, and 80 to 99 percent of nano alumina, and a preparation method for the catalyst is provided, the problems are better solved; and the catalyst can be used for propane dehydrogenation-hydrogen selective oxidation industrial production.

Owner:CHINA PETROLEUM & CHEM CORP +1

HZSM-5/SAPO-5 core-shell molecular sieve as well as preparation method and application thereof

ActiveCN109174174AUneven coatingOptimize conversion rateMolecular sieve catalystsCatalyst activation/preparationMolecular sieveNanocrystal

The invention relates to an HZSM-5 / SAPO-5 core-shell molecular sieve as well as a preparation method and an application thereof, belongs to the field of core-shell molecular sieve catalysts and provides a preparation method of the uniformly-covered HZSM-5 / SAPO-5 core-shell molecular sieve. The preparation method comprises the steps of adhering a nano-SAPO-5 molecular sieve obtained through an ionothermal method to the surface of a cation-modified HZSM-5 surface through electrostatic adsorption, roasting HZSM-5 adhered with SAPO-5 nanocrystals, feeding roasted HZSM-5 into SAPO-5 hydrothermal sol in different solid-liquid ratios, carrying out ageing, low-temperature crystallization, shock cooling and stirring, and carrying out high-temperature crystallization, so as to obtain the HZSM-5 / SAPO-5 core-shell molecular sieve. An SAPO-5 shell layer on the surface of HZSM-5 is completely covered, is uniform and compact and is provided with accumulated mesopores, and the coverage degree of the shell layer is over 95 when the core-shell solid-liquid ratio is 4 / 20-5 / 20 g / ml.

Owner:TAIYUAN UNIV OF TECH

Catalyst for preparing low-carbon olefin through Fischer-Tropsch synthesis and preparation method of catalyst

ActiveCN103521239AImprove conversion rateEnhance the interaction strengthHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsComposite oxideOxide

The invention relates to a catalyst for preparing low-carbon olefin through Fischer-Tropsch synthesis and a preparation method of the catalyst, and mainly aims to solve the problems of low CO conversion rate and low-carbon olefin selectivity in reaction for preparing the low-carbon olefin through Fischer-Tropsch synthesis in the prior art. The invention adopts the following technical schemes: a composite oxide consisting of titanium oxide and alpha-aluminum oxide is adopted as a carrier, and an active component is loaded on the composite oxide carrier and contains a composition with the following chemical formula in an atomic ratio: Fe100AaBbCcOx, wherein A is selected from a transition metal of Mn, B is selected from at least one of alkali metals of Mg and Ca, and C is selected from at least one of K and Cs; the dosage of the composite oxide carrier is 20-80% of the weight of the catalyst; alpha-aluminum oxide contained in the composite oxide carrier accounts for 50-99% of the weight of the composite oxide carrier by weight. The catalyst disclosed by the invention well solves the problems, and can be applied to industrial production of low-carbon olefin prepared through Fischer-Tropsch synthesis.

Owner:CHINA PETROLEUM & CHEM CORP +1

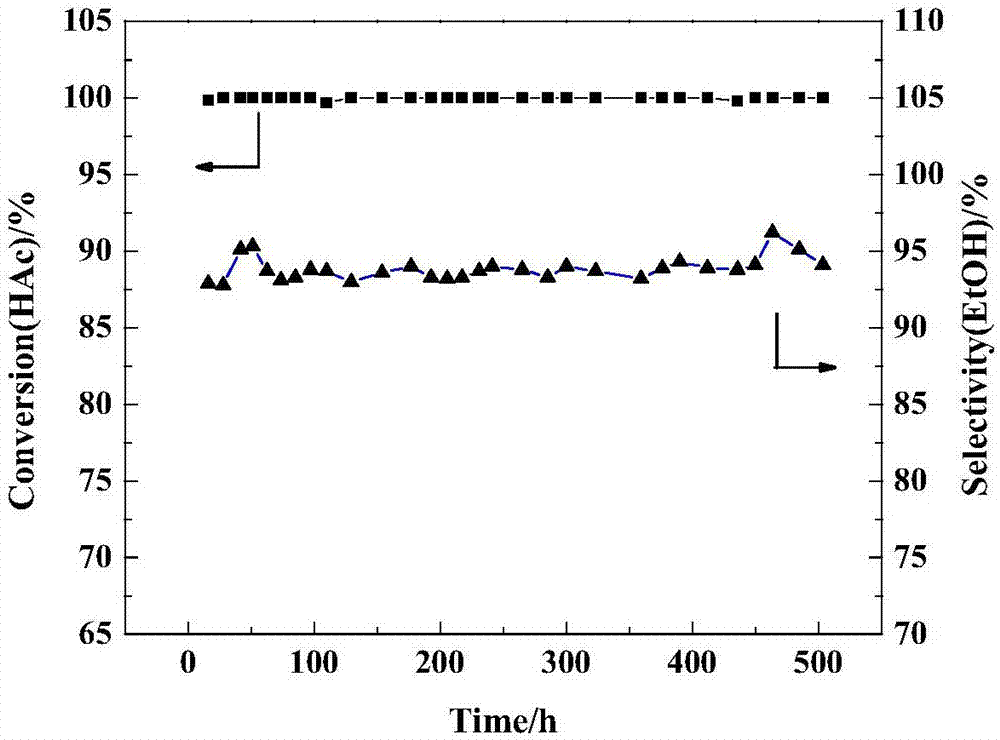

Preparation method of ethanol Pt-Sn/Li-Al-O catalyst through acetic acid hydrogenation

ActiveCN107115863AReduce surface acidityGood dispersionCatalyst carriersOrganic compound preparationActive componentLithium

The invention provides a preparation method of an ethanol Pt-Sn / Li-Al-O catalyst through acetic acid hydrogenation and belongs to the technical field of catalyst preparation. The method comprises the steps of (1) immersing Al2O3 into a soluble metal salt solution containing lithium, drying and roasting to obtain a Li-Al-O carrier; and (2) immersing the obtained Li-Al-O carrier into a soluble metal salt solution containing active components Sn and Pt and then drying and roasting to obtain a Pt-Sn / Li-AlO catalyst. The Li-Al-O of a lithium aluminum spinel structure is adopted as the carrier, the surface property of the carrier is stable and the dispersibility of the active components can be improved, thereby improving the activity and the stability of a finished product catalyst. The prepared catalyst has relatively low surface acid property and the selectivity of ethanol can be effectively improved. The method is applied to preparation of the ethanol through acetic acid hydrogenation, so that the acetic acid conversion rate can reach 100% and the ethanol selectivity can reach over 95%. The catalyst prepared through the preparation method has good stability, and the catalyst activity and the ethanol selectivity are basically kept invariable after reaction for 500h.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

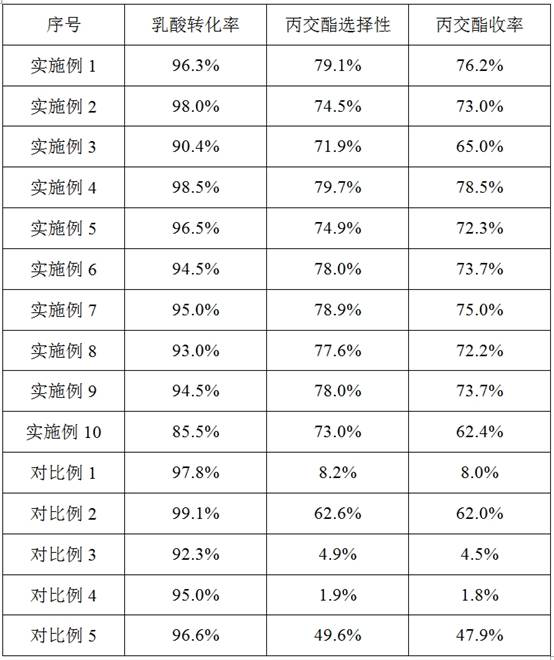

Method for preparing lactide from lactic acid

PendingCN114437017AHigh yieldHigh selectivityOrganic chemistryMolecular sieve catalystsMolecular sievePtru catalyst

The invention relates to a method for preparing lactide from lactic acid, which comprises the following steps: mixing a lactic acid solution with an organic solvent, adding a Si-Beta / H-Beta core-shell molecular sieve, carrying out a stirring reflux reaction at normal pressure and a certain temperature, adding water after the reaction is completed, carrying out liquid-liquid two-phase separation, and carrying out reduced pressure distillation on an organic phase to obtain a lactide product, the core shell of the Si-Beta / H-Beta core-shell molecular sieve is a catalyst which takes an H-Beta molecular sieve as a core and Si-Beta as a shell, and the catalyst comprises the following components in percentage by mass: 91.1%-96.5% of the H-Beta molecular sieve and 3.5%-8.9% of the Si-Beta molecular sieve. The catalyst adopted by the invention can complete the synthesis of lactide from lactic acid by a one-step method under normal pressure, and overcomes the defects of harsh reaction conditions, complex process flow and the like in the existing lactide preparation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com