Catalyst for gas phase hydrogenation of furfural to prepare furfuryl alcohol, preparation and application thereof

A catalyst and a technology for preparing furfuryl alcohol, which are applied in catalyst activation/preparation, molecular sieve catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problems of complex catalyst composition, complex preparation procedure, cumbersome preparation process, etc. The effect of easy storage, low preparation cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Select silica pellets produced by Shandong Ocean Chemical Industry Co., Ltd. as the porous carrier, weigh 5g of the above-mentioned carrier and place it in a beaker, add 20g of ethanolamine, soak for 12h, and dry the mixture at 120°C for 48h in an air atmosphere. Lower roasting for 2 hours to obtain a pretreated carrier. 0.60g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 5ml of deionized water, 3g of silicon oxide obtained by the above-mentioned ethanolamine treatment was added to the solution, soaked at room temperature for 12 hours, dried at 120°C for 12 hours, and then roasted at 350°C for 4 hours to obtain a catalyst, which is designated as A, and the composition of catalyst A 5% Cu / SiO 2 .

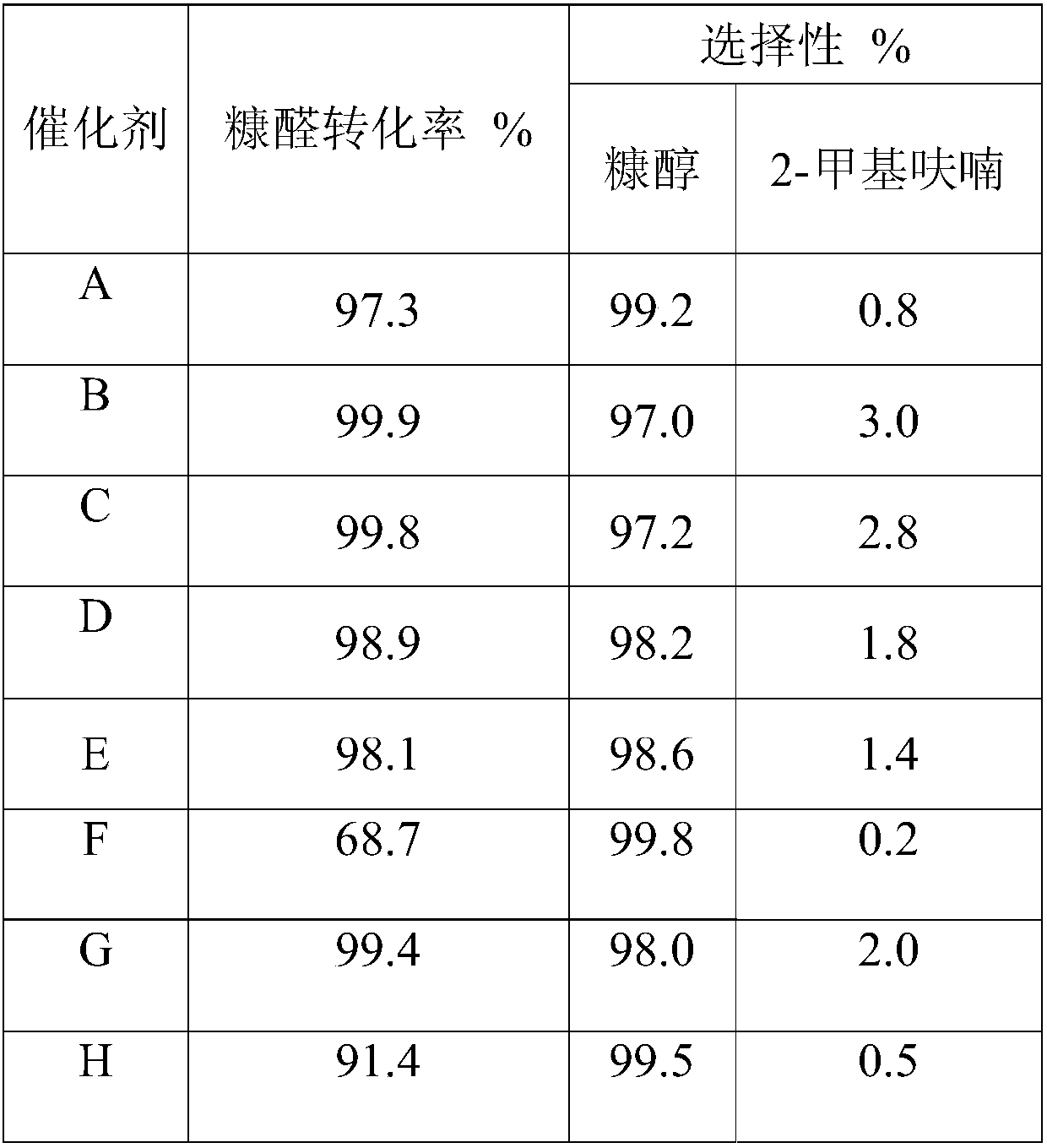

[0034] The loading amount of the catalyst was 1 g, and the catalyst was reduced in hydrogen at 300° C. for 5 hours before use. After the reactor bed temperature dropped to 130°C, furfural was injected into the reactor at a rate of 0.4g / h, and the H 2 / furfural molar ratio is 10, ...

Embodiment 2

[0036] Select silicon oxide powder produced by Shandong Ocean Chemical Industry Co., Ltd. as the porous carrier, weigh 5g of the above-mentioned carrier and place it in a beaker, add 15g of triethanolamine, soak for 6h, and dry the mixture at 100°C for 50h in an air atmosphere. Lower roasting for 3 hours to obtain a pretreated carrier. 7.60g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 5ml of deionized water, 3g of the carrier obtained by the above-mentioned triethanolamine treatment was added to the solution, soaked at room temperature for 12 hours, dried at 100°C for 12 hours, and then roasted at 350°C for 3 hours to obtain a catalyst, denoted as B, the catalyst B Composition is 40% Cu / SiO 2 .

[0037] See Example 1 for the catalyst evaluation protocol. The reaction results are listed in Table 1.

Embodiment 3

[0039] Select silicon oxide particles produced by Shandong Ocean Chemical as the porous carrier, weigh 5g of the above-mentioned carrier and place it in a beaker, add 20g of diethanolamine, soak for 6h, and dry the mixture at 90°C for 96h in an air atmosphere. Lower roasting for 3 hours to obtain a pretreated carrier. 2.01g Cu(NO 3 ) 2 ·3H 2 O was dissolved in 5ml of deionized water, 3g of the carrier obtained by the above-mentioned diethanolamine treatment was added to the solution, soaked at room temperature for 12h, dried at 105°C for 12h, and then calcined at 300°C for 3h to obtain a catalyst, denoted as C Catalyst C Composition 15%Cu / SiO 2 .

[0040] See Example 1 for the catalyst evaluation protocol. The results of the reaction are listed in Table 1 and figure 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com