Preparation method of catalyst for carbon dioxide reforming of methane to produce synthesis gas

A reforming catalyst, carbon dioxide technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc., can solve the problems of cumbersome preparation process, unobtainable carrier, and high cost , to achieve the effect of cumbersome preparation process, conducive to industrialization and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

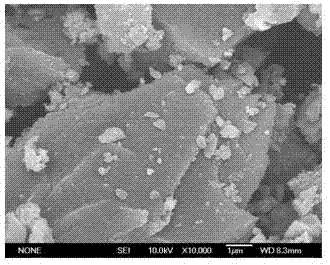

Image

Examples

Embodiment 1

[0030] Mix lignite activated carbon with a particle size of about 22 mesh and ammonia water with a mass concentration of 2% at a solid-to-liquid ratio of 1:2, and soak for 6 hours in an airtight manner, and then place it in a small airtight pressurized reactor for high temperature High-pressure hydrothermal reaction, the reaction conditions are: the reaction pressure is 2MPa, the reaction time is 6h, after the reaction is completed, it is naturally cooled, and dried at 110°C for 4h to obtain the modified lignite activated carbon.

[0031]The modified lignite activated carbon was mixed with a cobalt nitrate solution with a mass concentration of 20% at a solid-to-liquid ratio of 1:2, and was impregnated for 30 minutes under the conditions of ultrasonic frequency of 28MHz and 4MPa. Put it into a muffle furnace after drying, and roast in a nitrogen atmosphere for 5 hours at a roasting temperature of 500° C. to obtain the synthesis gas catalyst for carbon dioxide reforming of methan...

Embodiment 2

[0034] Mix lignite activated carbon with a particle size of 20-40 mesh and ammonia water with a mass concentration of 5% according to a solid-to-liquid ratio of 1:2, and airtightly soak for 6 hours, then place it in a small airtight pressurized reactor for High temperature and high pressure hydrothermal reaction, the reaction conditions are: the reaction pressure is 2MPa, the reaction time is 6h, after the reaction is completed, it is naturally cooled, and dried at 110°C for 4h to obtain the modified lignite activated carbon.

[0035] The modified lignite activated carbon was mixed with a 20% cobalt nitrate solution at a mass concentration of 1:2, and impregnated for 30 minutes at a frequency of 28 MHz ultrasonic and 4 MPa. Put it into a muffle furnace after drying, and roast in a nitrogen atmosphere for 5 hours at a roasting temperature of 500° C. to obtain the synthesis gas catalyst for methane carbon dioxide reforming of the present invention. The conversion rates of methan...

Embodiment 3

[0037] Mix lignite activated carbon with a particle size of 20-40 mesh and ammonia water with a mass concentration of 8% at a solid-to-liquid ratio of 1:2, and seal and soak for 6 hours, then place it in a closed small pressurized reactor for high temperature High-pressure hydrothermal reaction, the reaction conditions are: the reaction pressure is 2MPa, the reaction time is 6h, after the reaction is completed, it is cooled naturally, and dried at 110°C for 4h to obtain the modified lignite activated carbon.

[0038] The modified lignite activated carbon was mixed with a cobalt nitrate solution with a mass concentration of 20% at a solid-to-liquid ratio of 1:2, and impregnated for 30 minutes at a frequency of 28 MHz ultrasonic and 4 MPa. Put it into a muffle furnace after drying, and roast in a nitrogen atmosphere for 5 hours at a roasting temperature of 500° C. to obtain the synthesis gas catalyst for methane carbon dioxide reforming of the present invention. The conversion r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com