Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

216 results about "Carbon dioxide reforming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide reformation (also known as dry reformation) is a method of producing synthesis gas (mixtures of hydrogen and carbon monoxide) from the reaction of carbon dioxide with hydrocarbons such as methane. Synthesis gas is conventionally produced via the steam reforming reaction. In recent years, increased concerns on the contribution of greenhouse gases to global warming have increased interest in the replacement of steam as reactant with carbon dioxide.

Catalyst for production of synthesis gas

ActiveUS20090314993A1Hydrogen/synthetic gas productionAlkaline-earth metal aluminates/aluminium-oxide/aluminium-hydroxide preparationPtru catalystPhysical chemistry

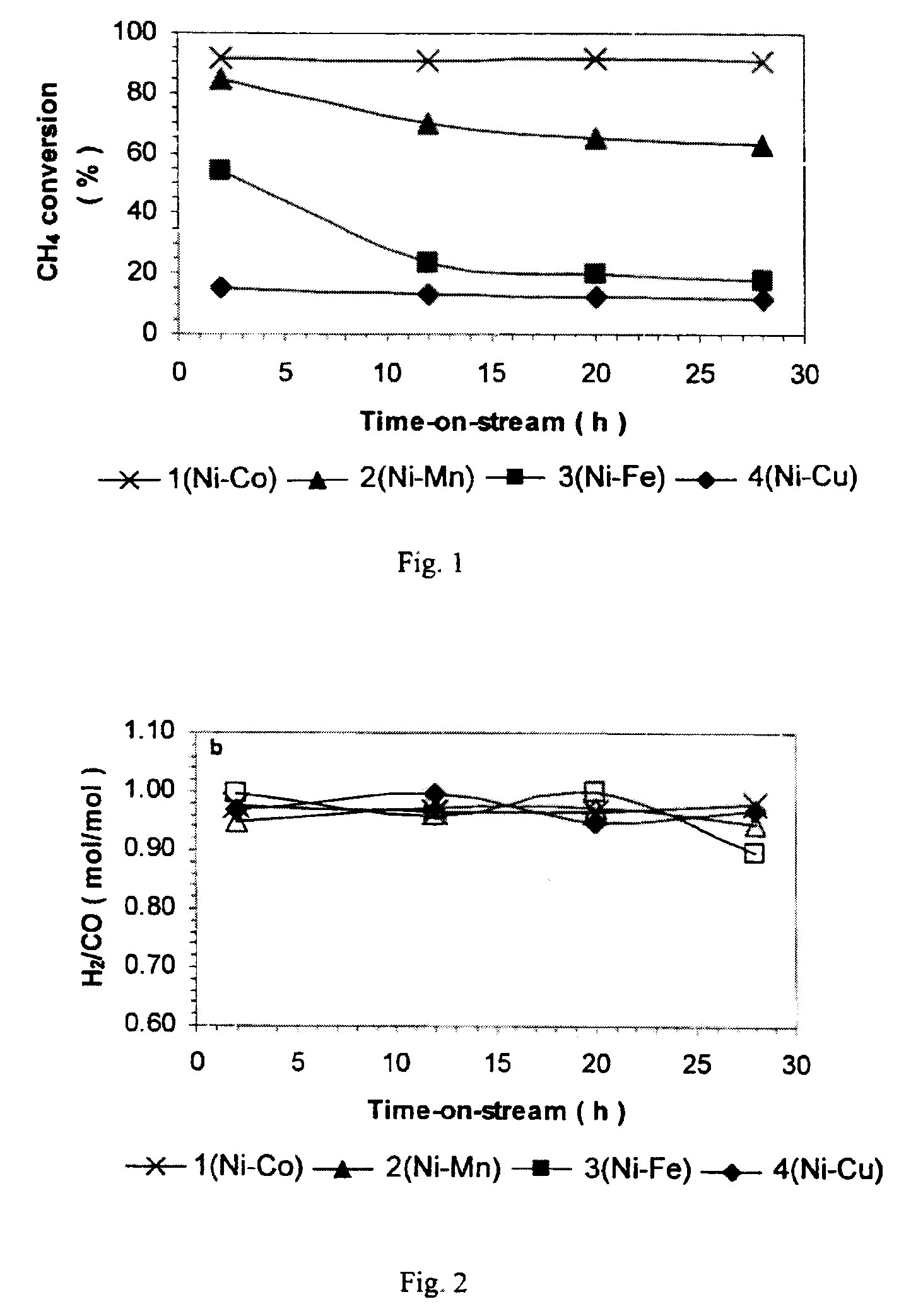

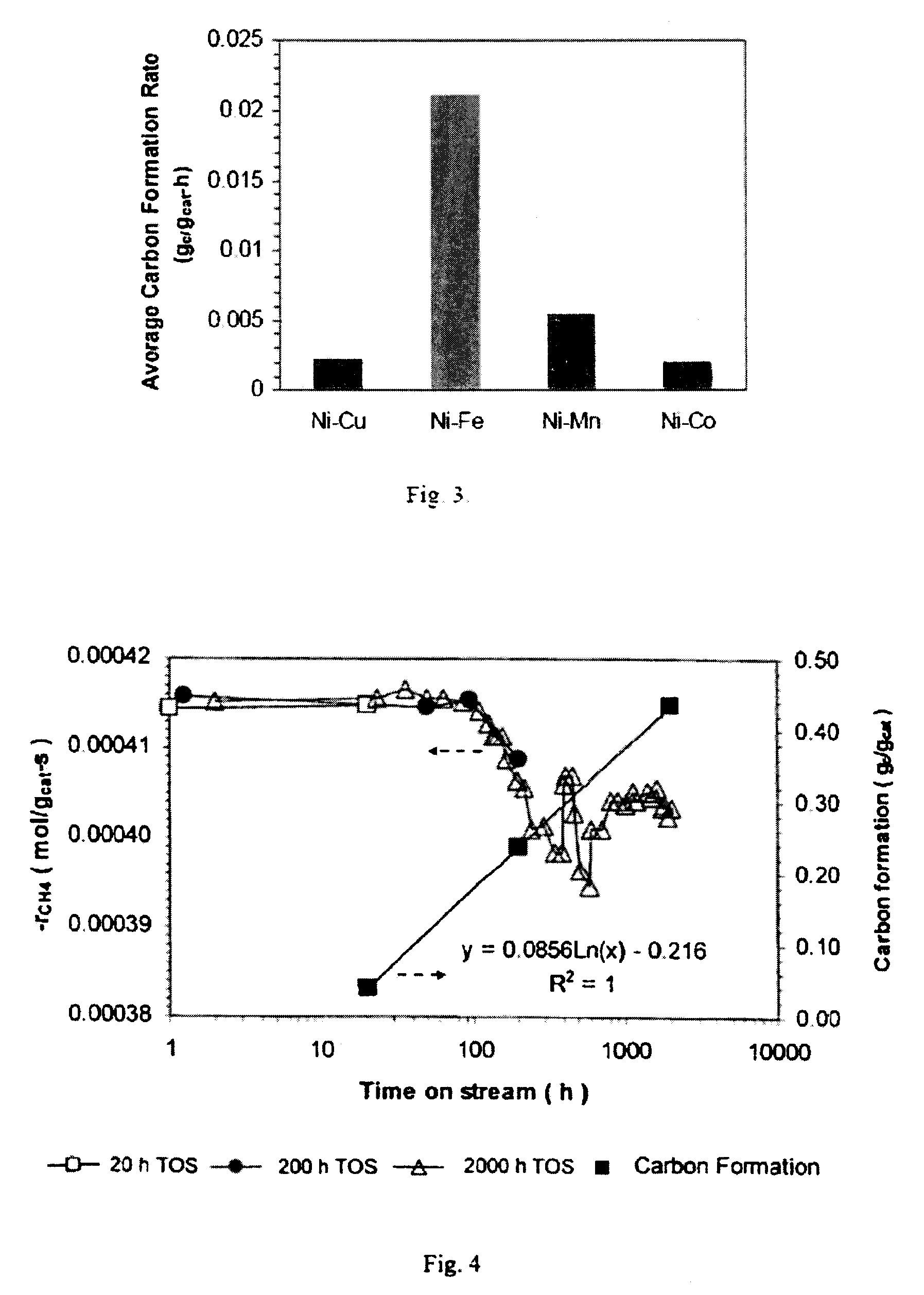

The present invention relates to a novel composite metal oxide catalyst, a method of making the catalyst, and a process for producing synthesis gas using the catalyst. The catalyst may be a nickel and cobalt based dual-active component composite metal oxide catalyst. The catalyst may be used to produce synthesis gas by the carbon dioxide reforming reaction of methane. The catalyst on an anhydrous basis after calcinations has the empirical formula:Mam+Nbn+Alc3+Mgd2+O(am2+bn2+32c+d)Mm+ and Nn+ are two transition metals serving as dual-active components and selected from the group consisting of Ni, Co, Fe, Mn, Mo, Cu, Zn or mixtures thereof, a+b+c+d=1, and 0.001≦a≦0.8, 0.001≦b≦0.8, 0.1≦c≦0.99, 0.01≦d≦0.99.

Owner:UNIVERSITY OF SASKATCHEWAN

Method for preparing catalyst for preparing synthesis gas by reforming methane and carbon dioxide

InactiveCN101637726ALow costHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel saltCerium

The invention relates to a method for preparing a catalyst for preparing synthesis gas by reforming methane and carbon dioxide, which comprises the following steps: soaking a carrier into a mixed solution of cerium(III) nitrate and lanthanum nitrate, and drying and roasting the soaked carrier for 2 to 10 hours to obtain a modified carrier (A); soaking the (A) into a soluble nickel salt solution orsoaking the (A) into a chloroplatinic acid solution, and drying and roasting the soaked carrier to obtain (B) or (C); soaking the (B) into the chloroplatinic acid solution or soaking the (C) into thesoluble nickel salt solution, and drying and roasting the soaked carrier to obtain a catalyst precursor, or soaking the modified carrier into a mixed solution of the soluble nickel salt solution andthe chloroplatinic acid, and drying and roasting the soaked carrier to obtain a catalyst precursor; and reducing the precursor in hydrogen and nitrogen mixed gas to obtain the catalyst. The catalyst has the advantages of low cost, good catalytic activity under the reaction condition of large space velocity, high selectivity for H2 and CO, and good sintering resistance and carbon deposition resistance.

Owner:PETROCHINA CO LTD

Catalysts for hydrogen production

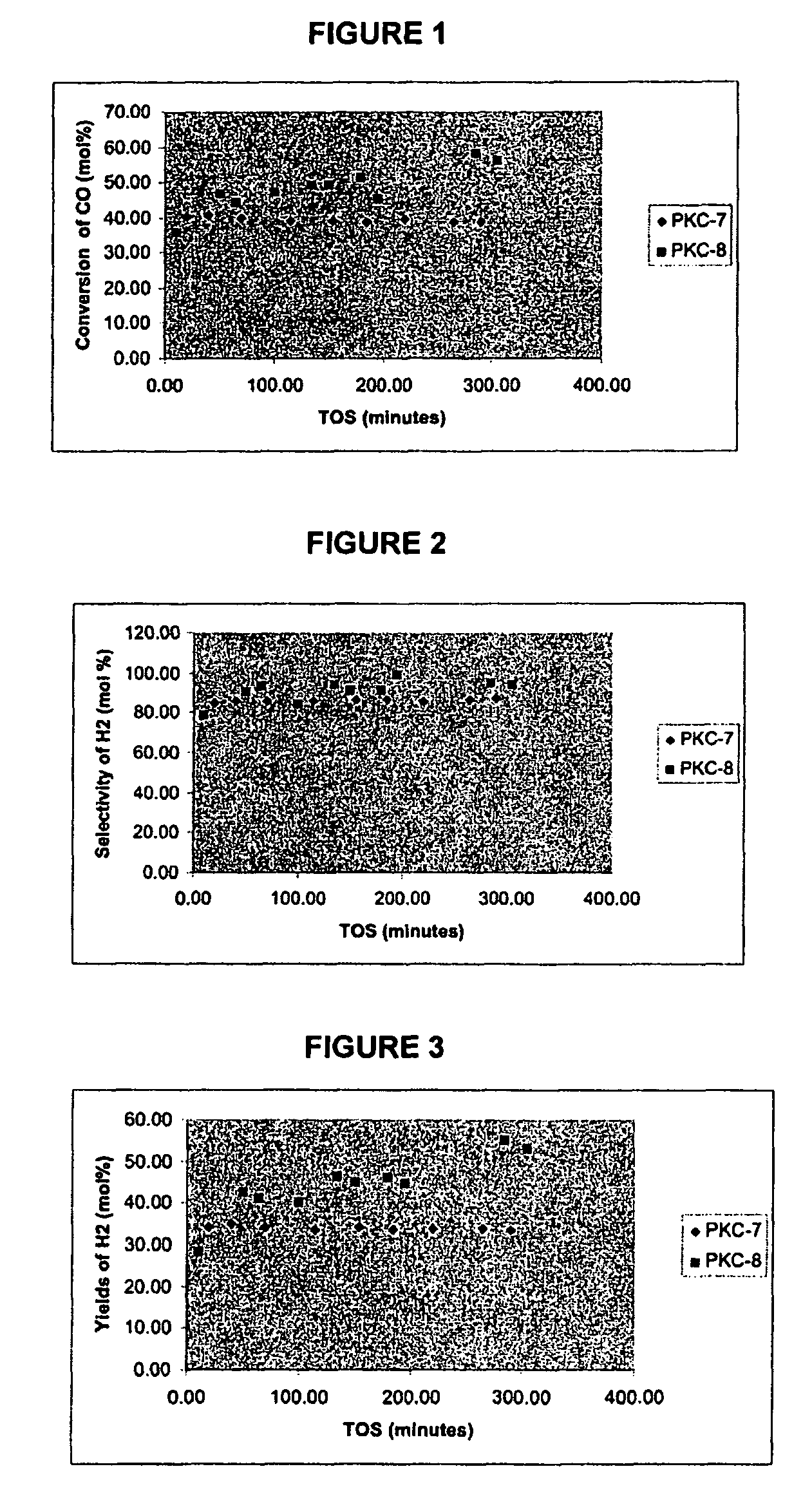

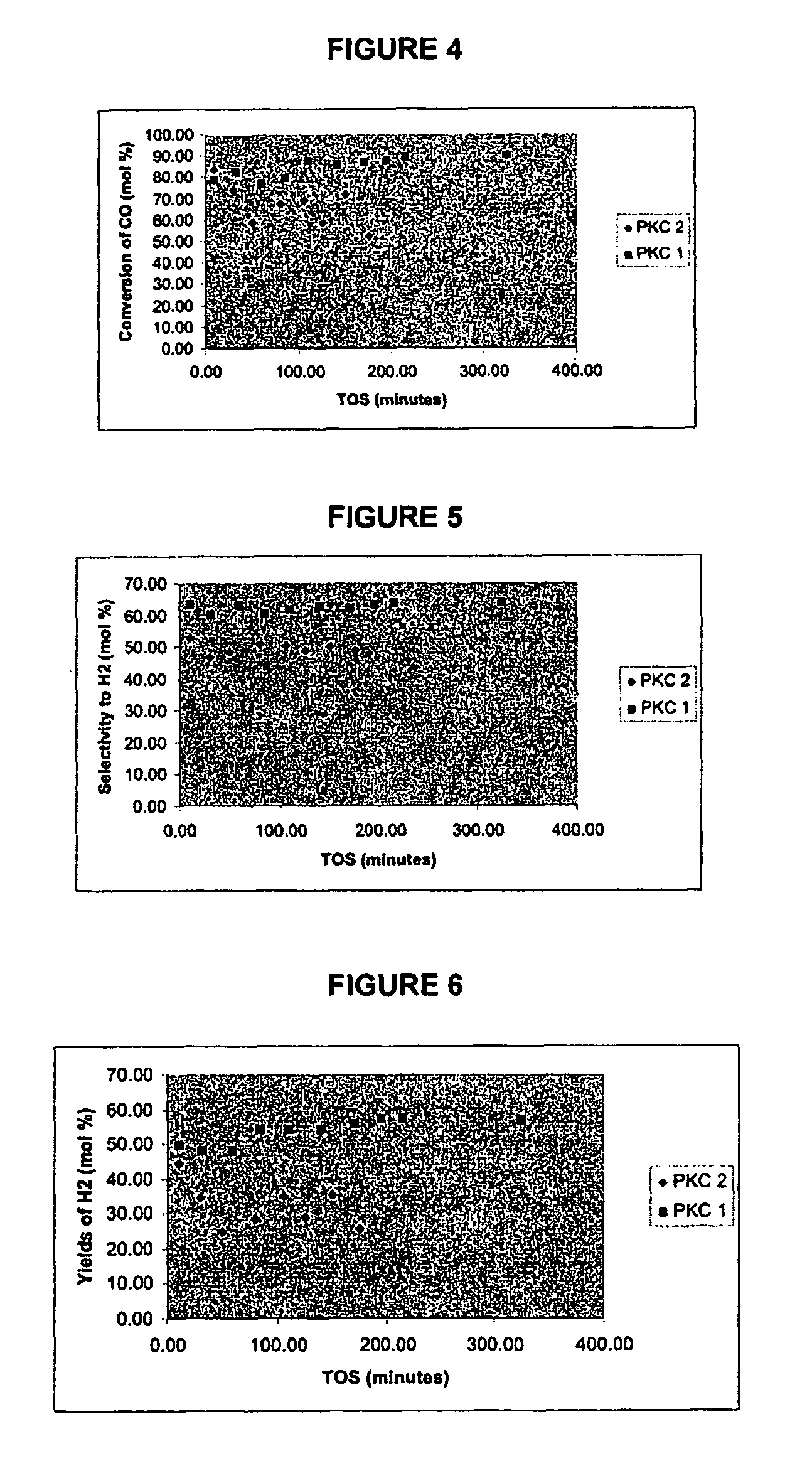

ActiveUS7824656B2Improve thermal stabilityIncrease temperatureHydrogenMolecular sieve catalystsPtru catalystWater-gas shift reaction

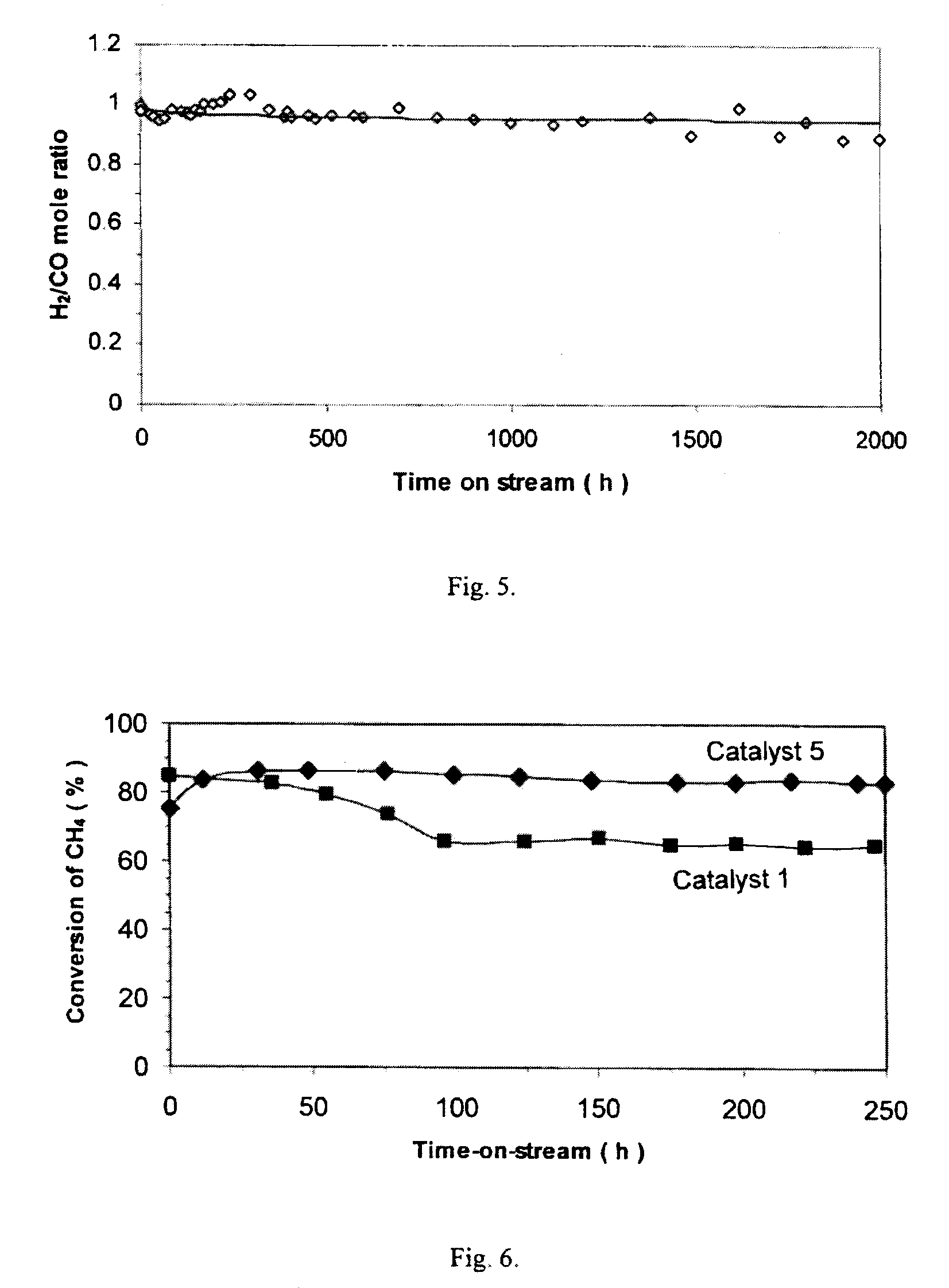

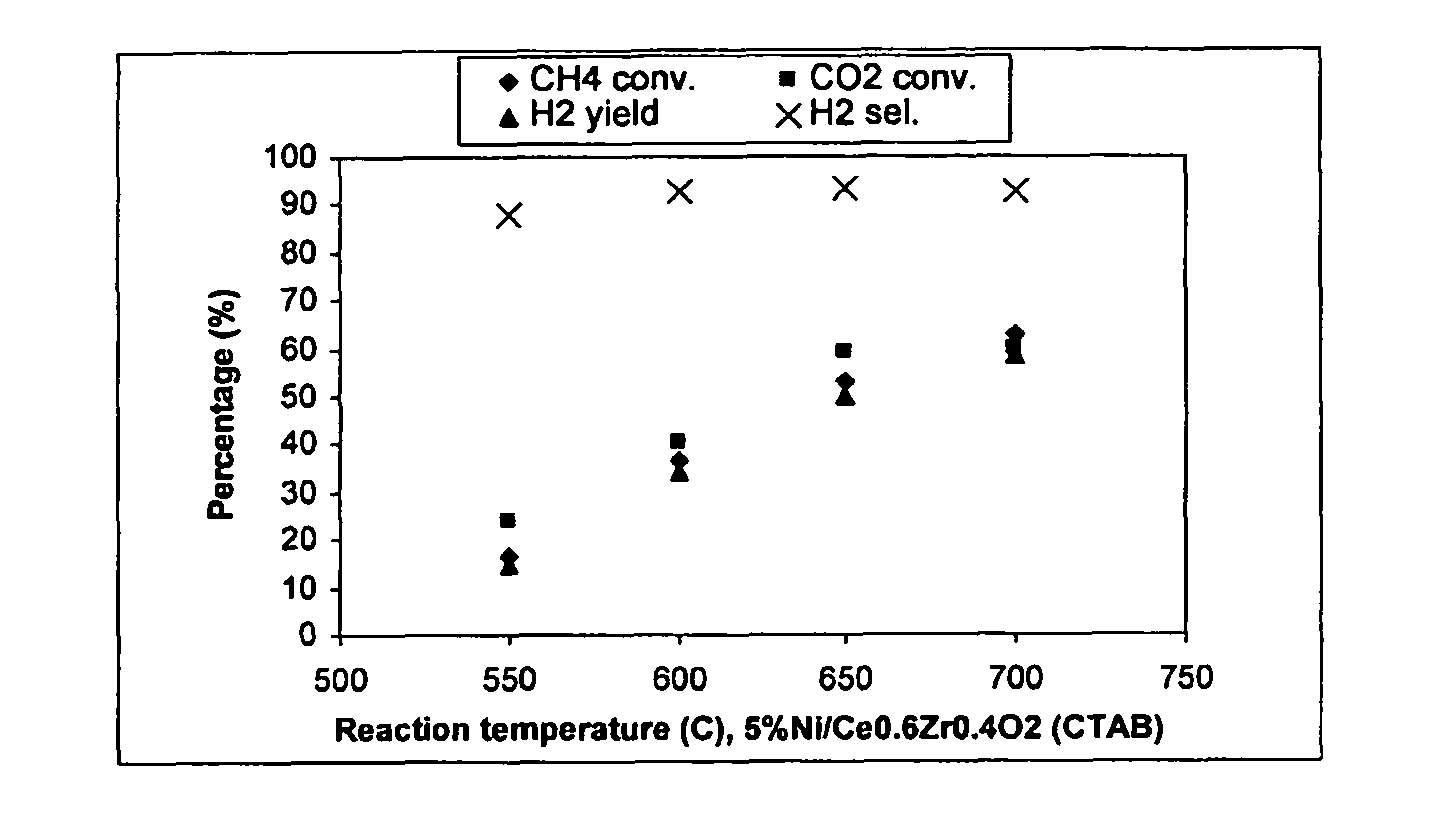

The present invention relates to catalysts for the production of hydrogen using the water gas shift reaction and the carbon dioxide reforming of hydrocarbon-containing fuels. The catalysts nickel and / or copper on a ceria / zirconia support, where the support is prepared using a surfactant templating method. The invention also includes processes for producing hydrogen, reactors and hydrogen production systems utilizing these catalysts.

Owner:UNIVERSITY OF REGINA

Catalyst for hydrocarbon reforming and method of reforming hydrocarbon with the same

The present invention provides a catalyst suitably employed in a variety of hydrocarbon reforming processes and a hydrocarbon reforming process including employing the catalyst in production of hydrogen or synthesis gas. The hydrocarbon reforming catalyst of the present invention contains an alumina carrier containing cerium oxide and, carried on the carrier, component (a), component (b), and optional component (c), the component (a) being at least one platinum group element selected from among ruthenium, platinum, rhodium, palladium, and iridium; the component (b) being cobalt and / or nickel, the component (c) being an alkaline earth metal. When steam reforming, autothermal reforming, partial-oxidation reforming, or carbon dioxide reforming of hydrocarbons is performed through employment of the catalyst, hydrogen or synthesis gas can be produced.

Owner:IDEMITSU KOSAN CO LTD

Methane-carbon dioxide reforming reactive catalyst and preparation method thereof

InactiveCN102151570AImprove thermal stabilityHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

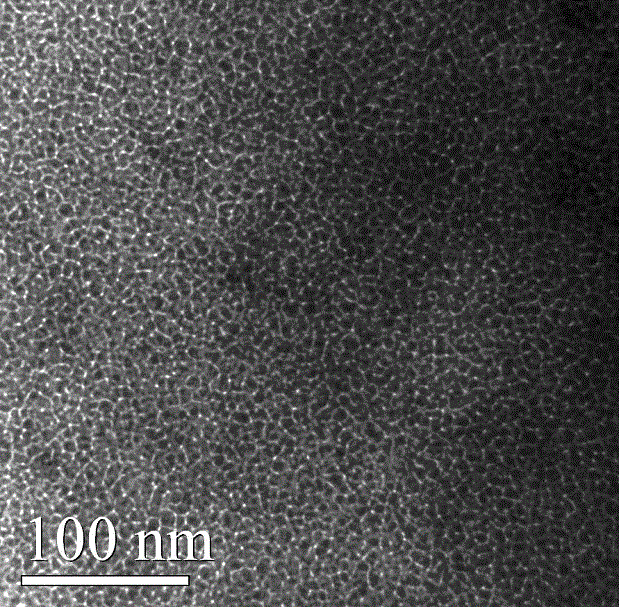

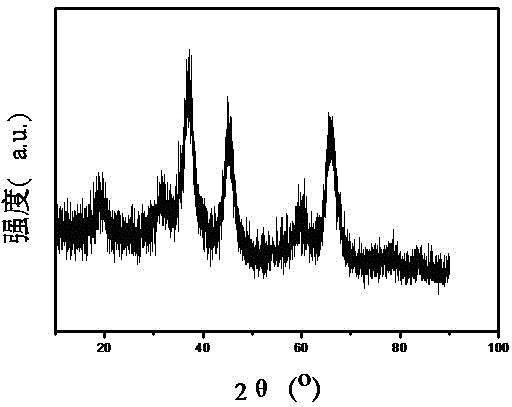

The invention discloses a methane-carbon dioxide reforming reactive catalyst and a preparation method thereof. The methane-carbon dioxide reforming reactive catalyst is a nanometer composite oxide with a mesoporous structure, formed by taking a carrier metal oxide as a substrate and taking another auxiliary metal oxide and an active metal oxide as disperse phases. The catalyst has the advantages of strong catalytic activity, high stability and good anti-carbon performance.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI +1

Carbon dioxide reforming process

ActiveUS20110089378A1Efficient executionCarbon depositionHydrogenHydrocarbon from carbon oxidesHydrogenAlkaline earth metal

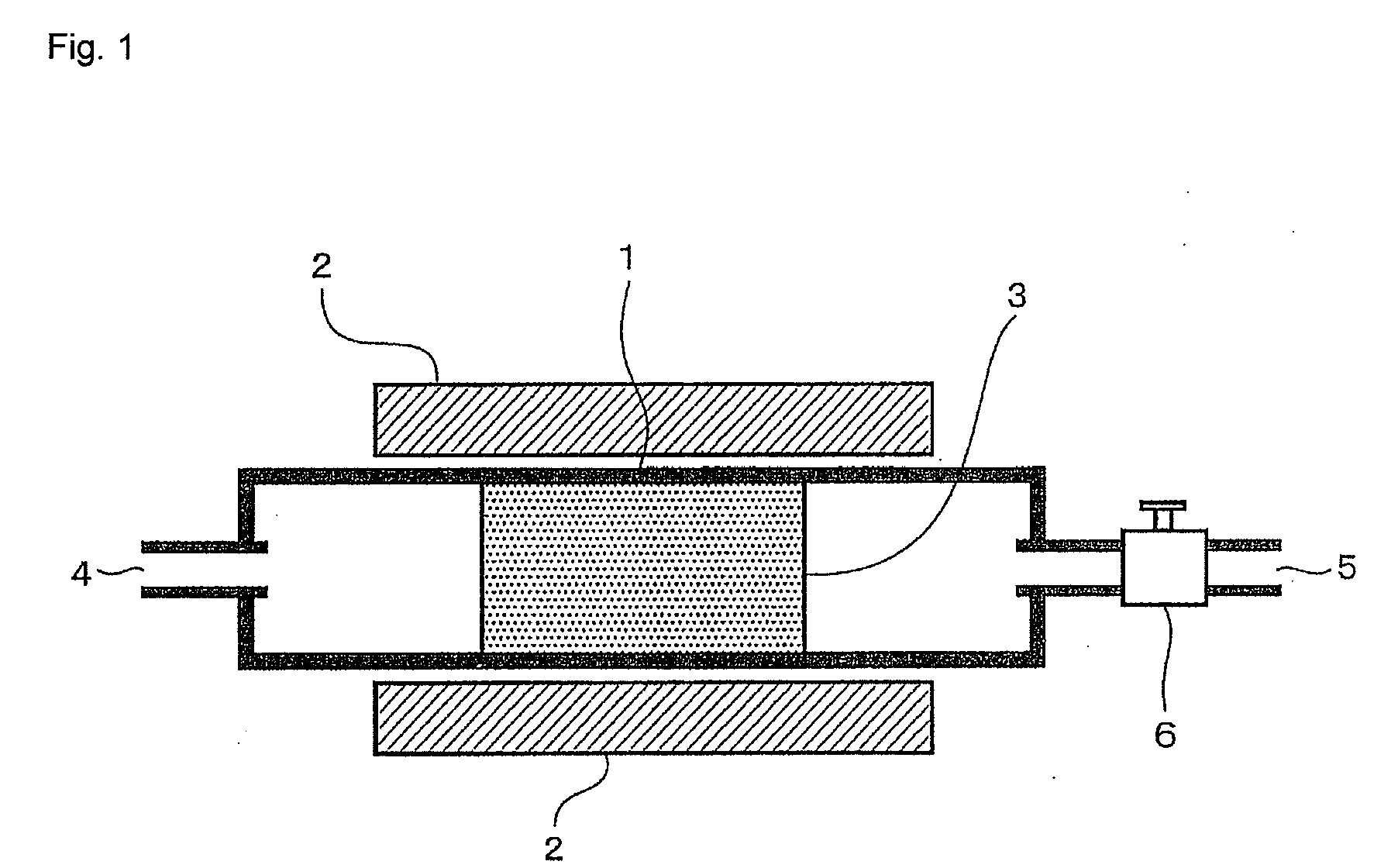

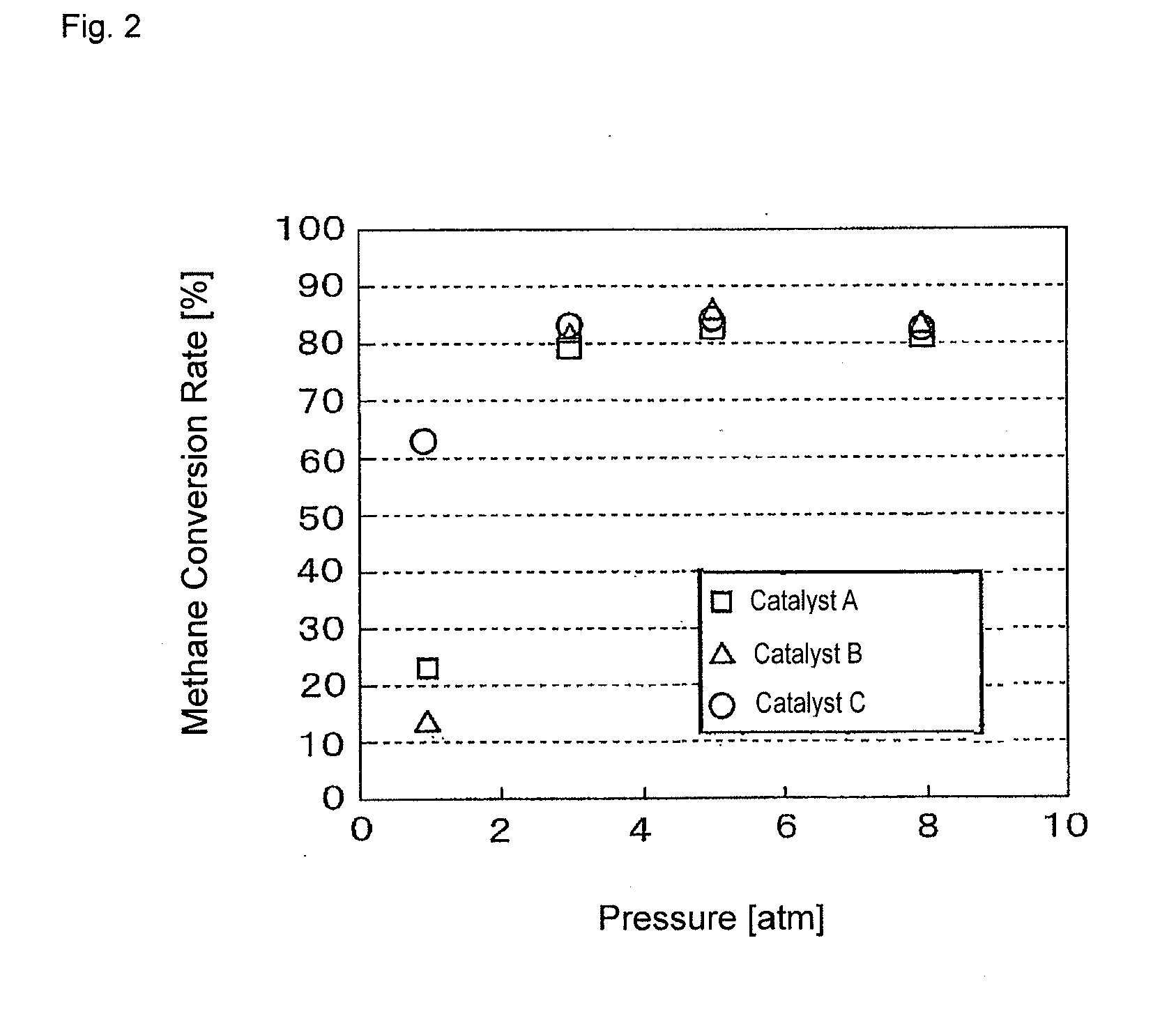

A synthetic gas containing hydrogen and carbon monoxide is efficiently obtained by reacting a hydrocarbon feedstock gas with carbon dioxide under pressure, while suppressing carbon deposition. The pressure is preferably 3 atmospheres (0.304 MPa), and used is a carbon dioxide reforming catalyst that contains at least one alkaline earth metal carbonate a catalytic metal promoting the decomposition reaction of a hydrocarbon feedstock gas, at least one alkaline earth metal selected from the group consisting of Ca, Sr, and Ba, and a complex oxide containing at least one component selected from the group consisting of Ti, Al, Zr, Fe, W, and Mo, such as ATiO3, AAl2O4, AZrO3, AFe2O4, A3W2O9, A2WO5, or AMoO4, where A is at least one of Ca, Sr, and Ba.

Owner:MURATA MFG CO LTD

Preparation method of catalyst for producing synthetic gas by methane and carbon dioxide reformation

InactiveCN102745648AHigh activityImprove stabilityProductsHydrogenBULK ACTIVE INGREDIENTActive ingredient

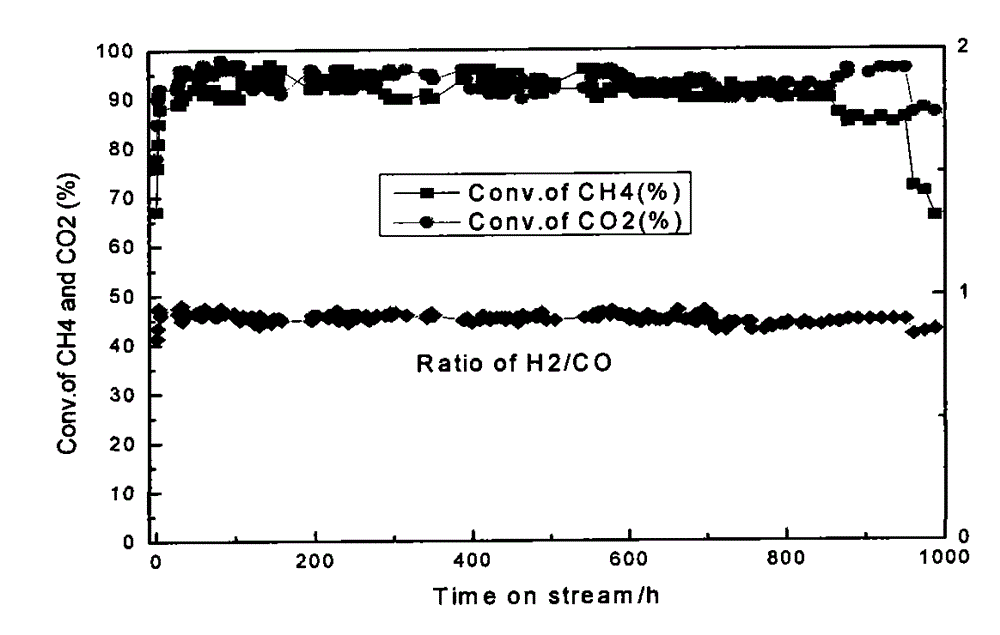

A preparation method of a catalyst for producing synthetic gas by methane and carbon dioxide reformation belongs to the fields of organic chemical industry and catalyst preparation. The preparation method is characterized in that each active ingredient of the catalyst and auxiliary agents are loaded on carries through a one-step or multi-step immersion method, and that catalytical reforming of methane with carbon dioxide is carried at normal pressure to produce synthetic gas. Predecessors after one or multiple immersions are subjected to standing, drying, roasting and reducing, and can be directly used for producing the synthesis gas by reforming of the methane with the carbon dioxide in a fixed bed. With the catalyst prepared by the method in the conditions of 1 atm, 800 DEG C and GHSV=1.2*10<4>h-1, the conversion rate of the methane is maintained at or over 90% when the reforming is carried out for 860h, and the conversion rate of the carbon dioxide is maintained at or over 90% when the reforming is carried out 960h. When the reaction lasts for 1000h, the conversion rate of the methane by using the catalyst is 70%, and the conversion rate of the carbon dioxide by using the catalyst is 86%.

Owner:TAIYUAN UNIV OF TECH

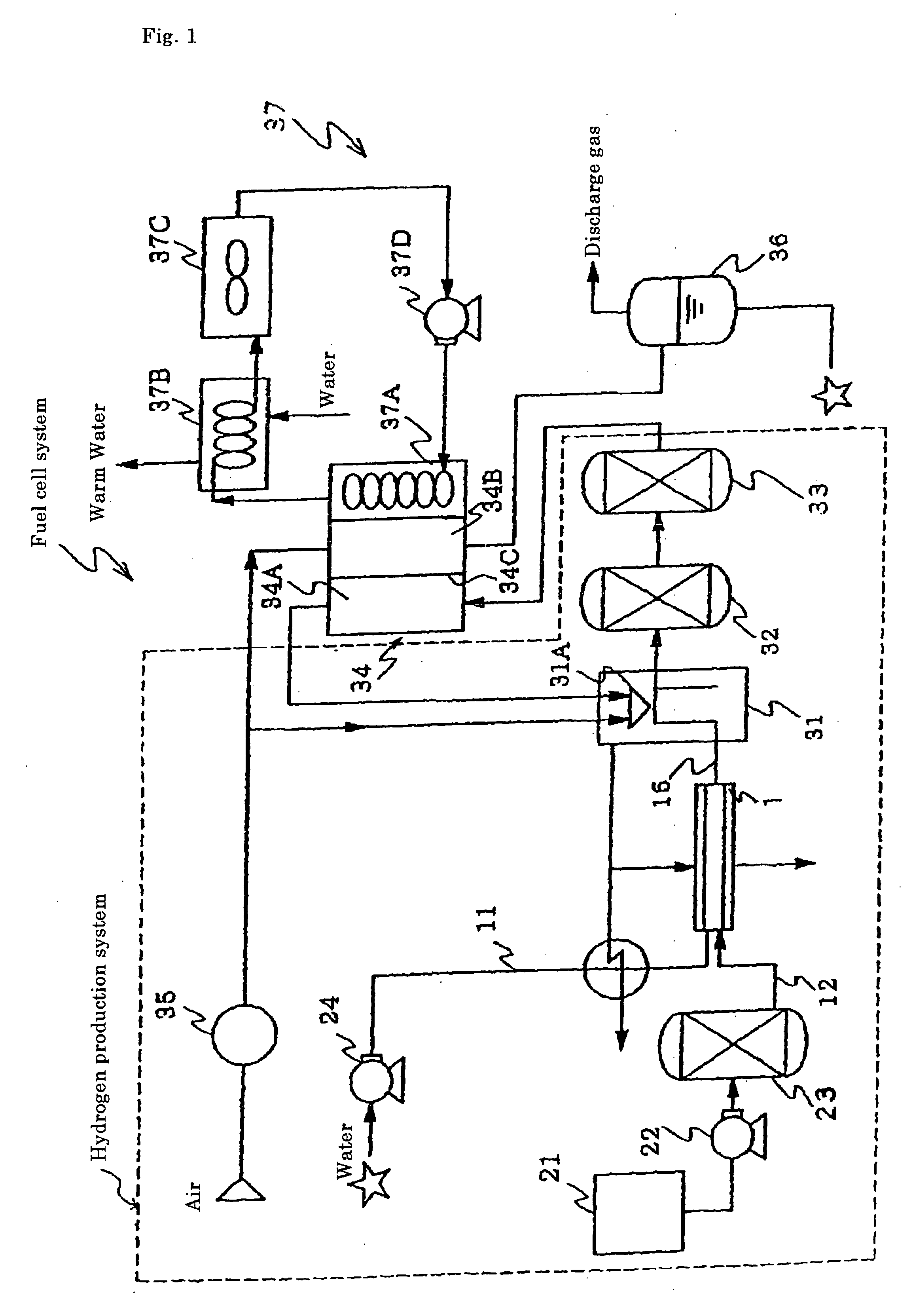

Reforming catalyst for hydrocarbon, method for producing hydrogen using such reforming catalyst, and fuel cell system

InactiveUS20070172416A1High catalytic activityImprove heat resistanceCatalyst activation/preparationHydrogen productionSteam reformingIridium

A hydrocarbon reforming catalyst which maintains carrier strength even after a long-term thermal history and which exhibits high catalytic activity is prepared by causing at least one noble metal component selected from among a ruthenium component, a platinum component, a rhodium component, a palladium component, and an iridium component to be supported on a carrier containing manganese oxide, alumina, and at least one compound selected from among lanthanum oxide, cerium oxide, and zirconium oxide, or a carrier containing silicon oxide, manganese oxide, and alumina. By use of the reforming catalyst, hydrogen is produced through steam reforming (1), autothermal reforming (2), partial-oxidation reforming (3), or carbon dioxide reforming (4). A fuel cell system is constituted from a reformer employing the reforming catalyst, and a fuel cell employing, as a fuel, hydrogen produced by the reformer.

Owner:IDEMITSU KOSAN CO LTD

High-dispersion high-load high-activity nickel-based catalyst for low-temperature methane reforming and application of high-dispersion high-load high-activity nickel-based catalyst for low-temperature methane reforming

ActiveCN105688916AReduce operating costsHigh reforming catalytic activityHydrogenHydrogen/synthetic gas productionSteam reformingChemical industry

The invention belongs to the field of chemical industry, and relates to a high-dispersion, high-load, high-activity low-temperature methane reforming nickel-based catalyst and its application. The invention provides a high-dispersion, high-load, high-activity low-temperature methane reforming nickel-based catalyst, which comprises the following components in terms of mass percentage: active component 20-25%; synergistic component 1-30%; carrier 45-79% . The present invention further provides a preparation method of a high-dispersion, high-load and high-activity low-temperature methane reforming nickel-based catalyst and its use in low-temperature methane reforming reactions. The invention provides a high-dispersion, high-load, high-activity low-temperature methane reforming nickel-based catalyst and its application, which is suitable for high-pressure and low-temperature methane-carbon dioxide reforming reaction at a reaction temperature of 400-800°C, high-pressure and low-temperature methane-steam reforming, high-pressure and low-temperature reforming Methane reforming processes such as methane-carbon dioxide-steam mixed reforming have high catalytic activity and stability.

Owner:高潞空气化工产品(上海)能源科技有限公司

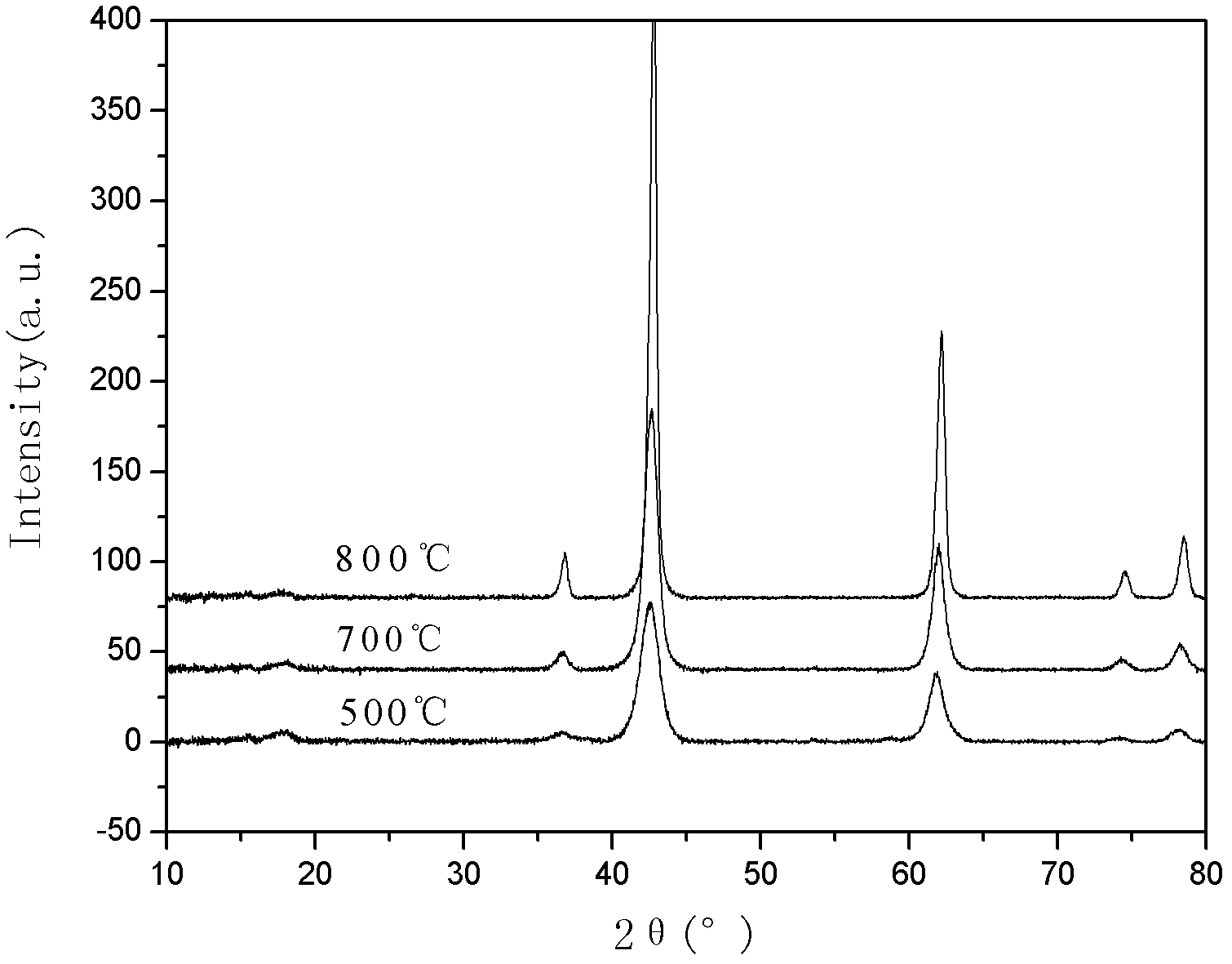

Preparation method and application of MgO (111) load nickel-base catalyst

InactiveCN102658145AImprove adsorption capacityHigh activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsWater methanolAnisyl alcohol

Owner:SOUTH CENTRAL UNIVERSITY FOR NATIONALITIES

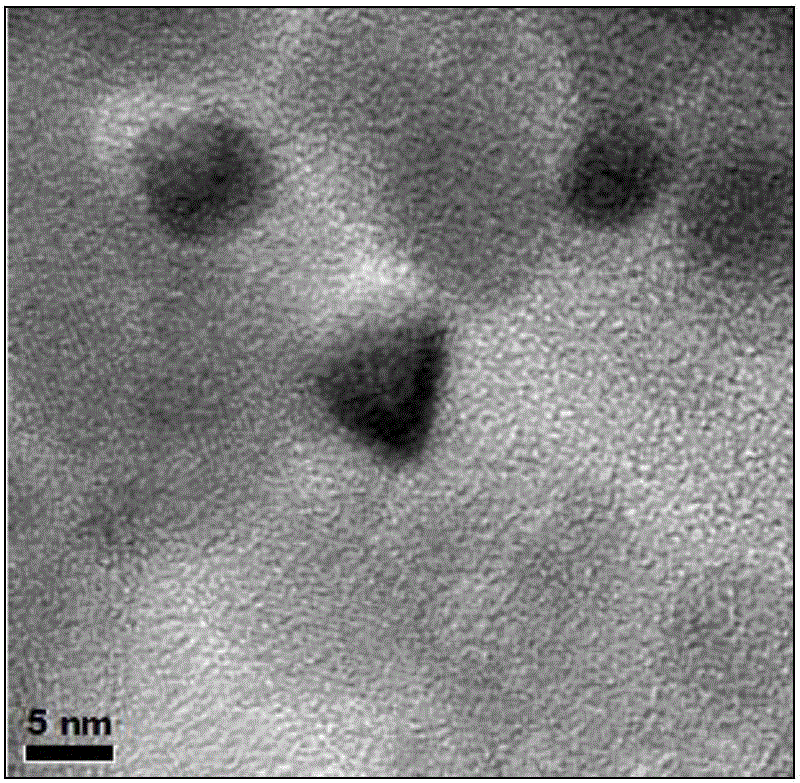

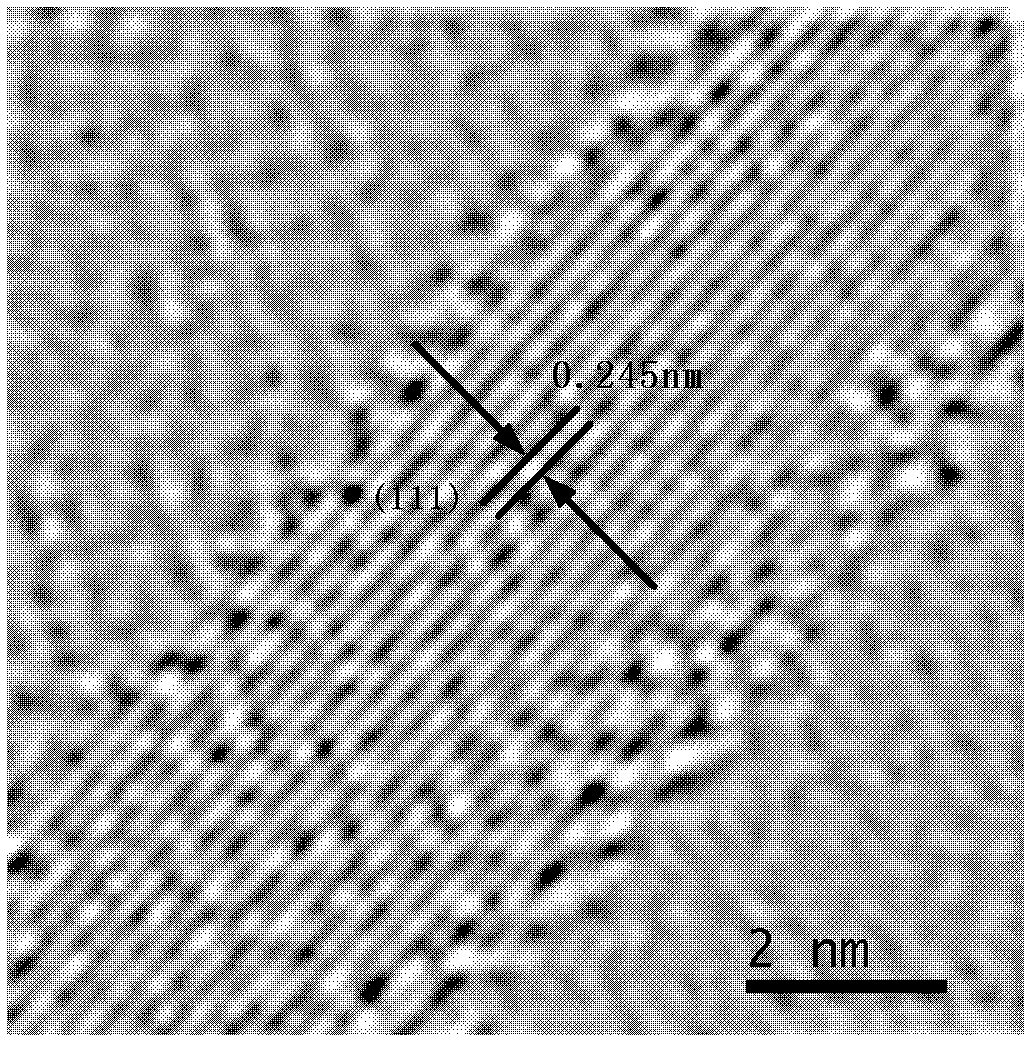

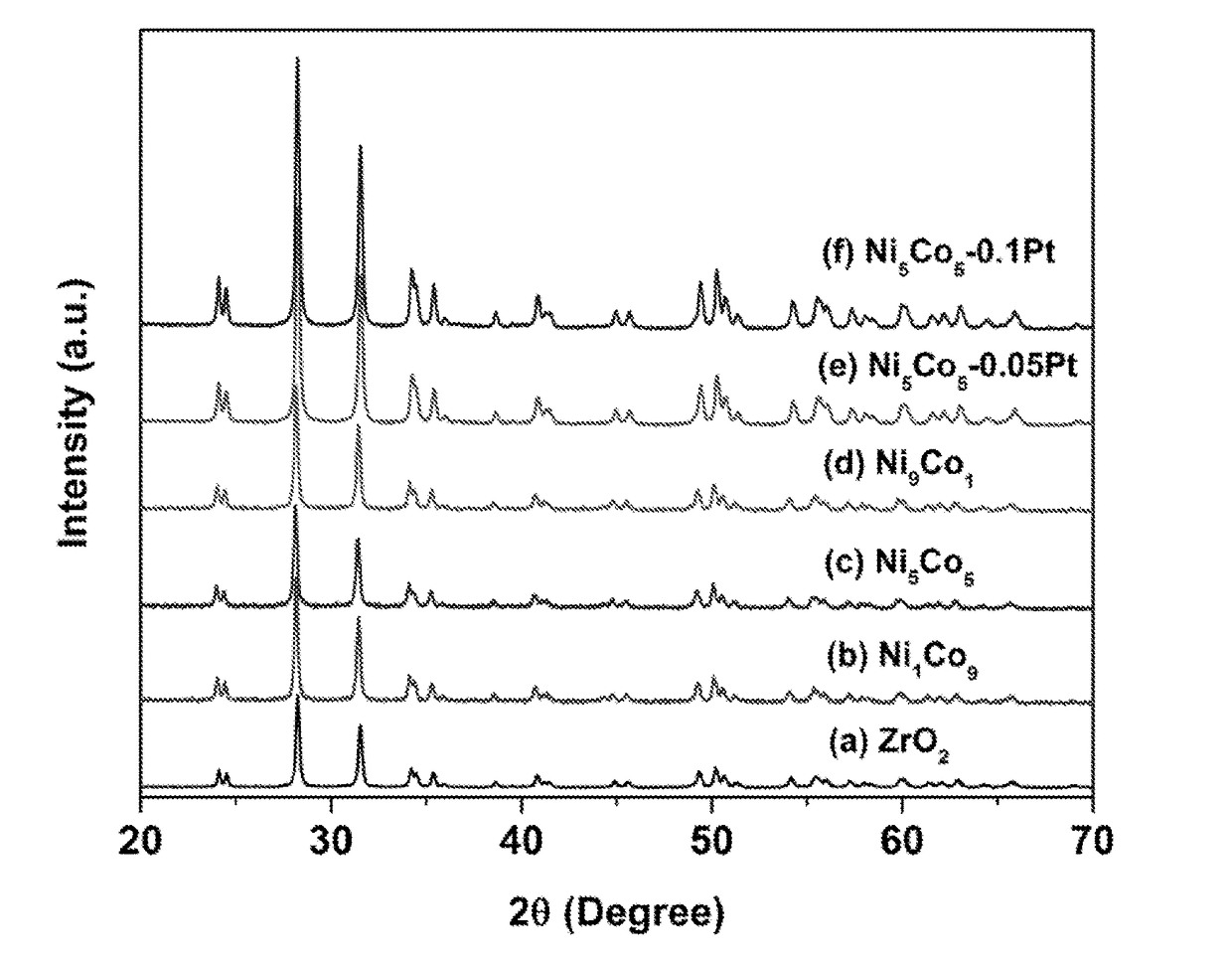

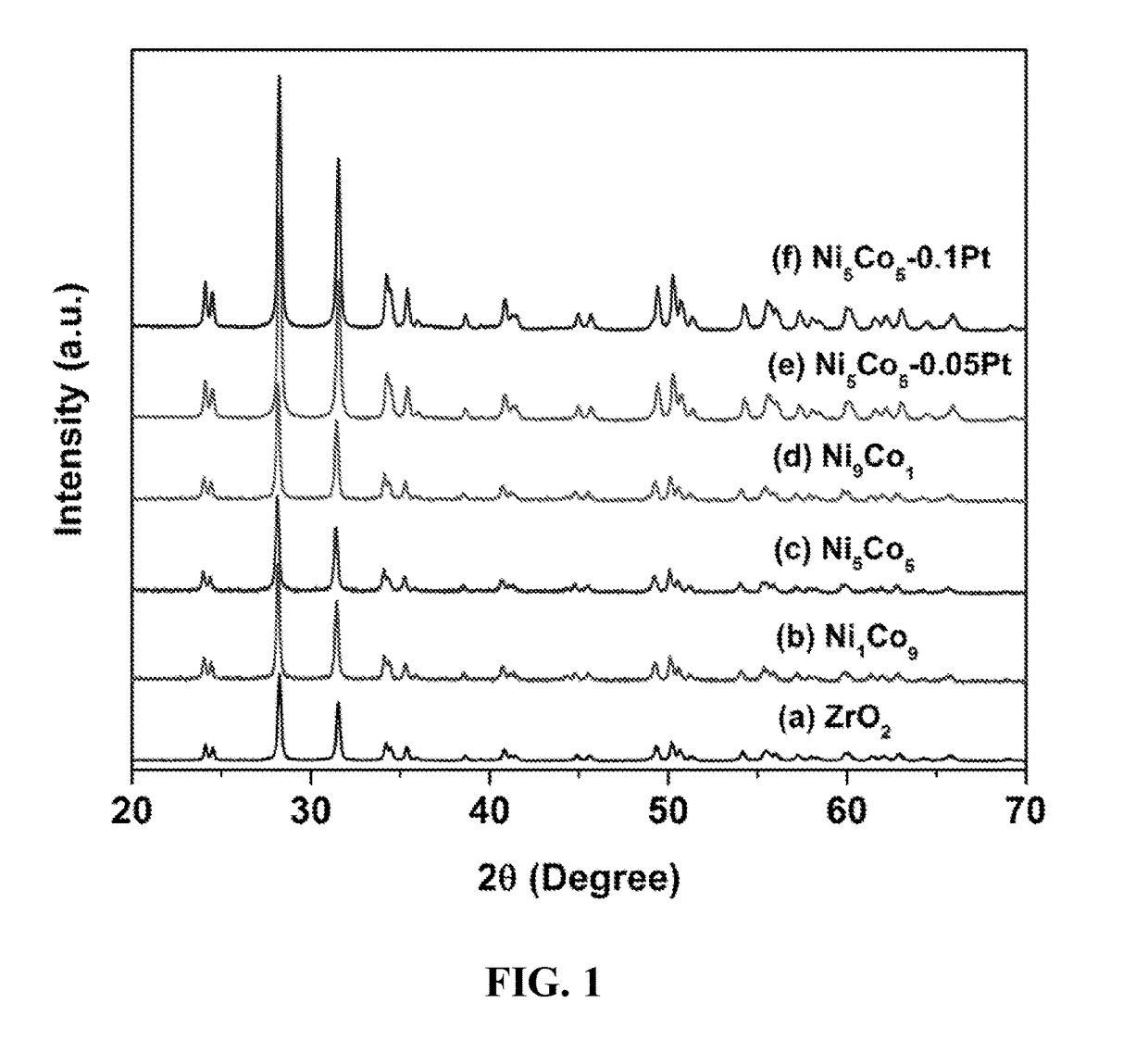

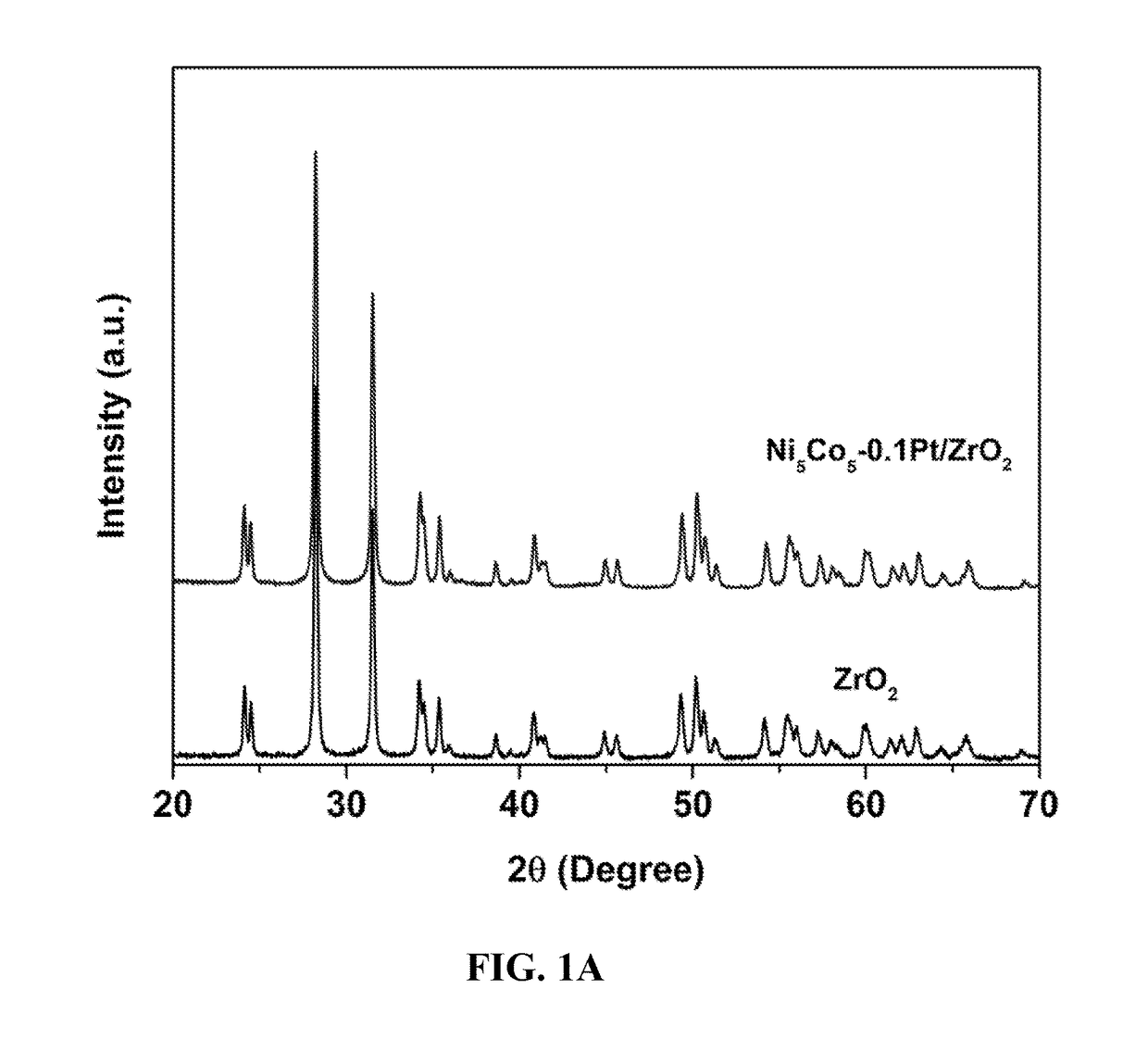

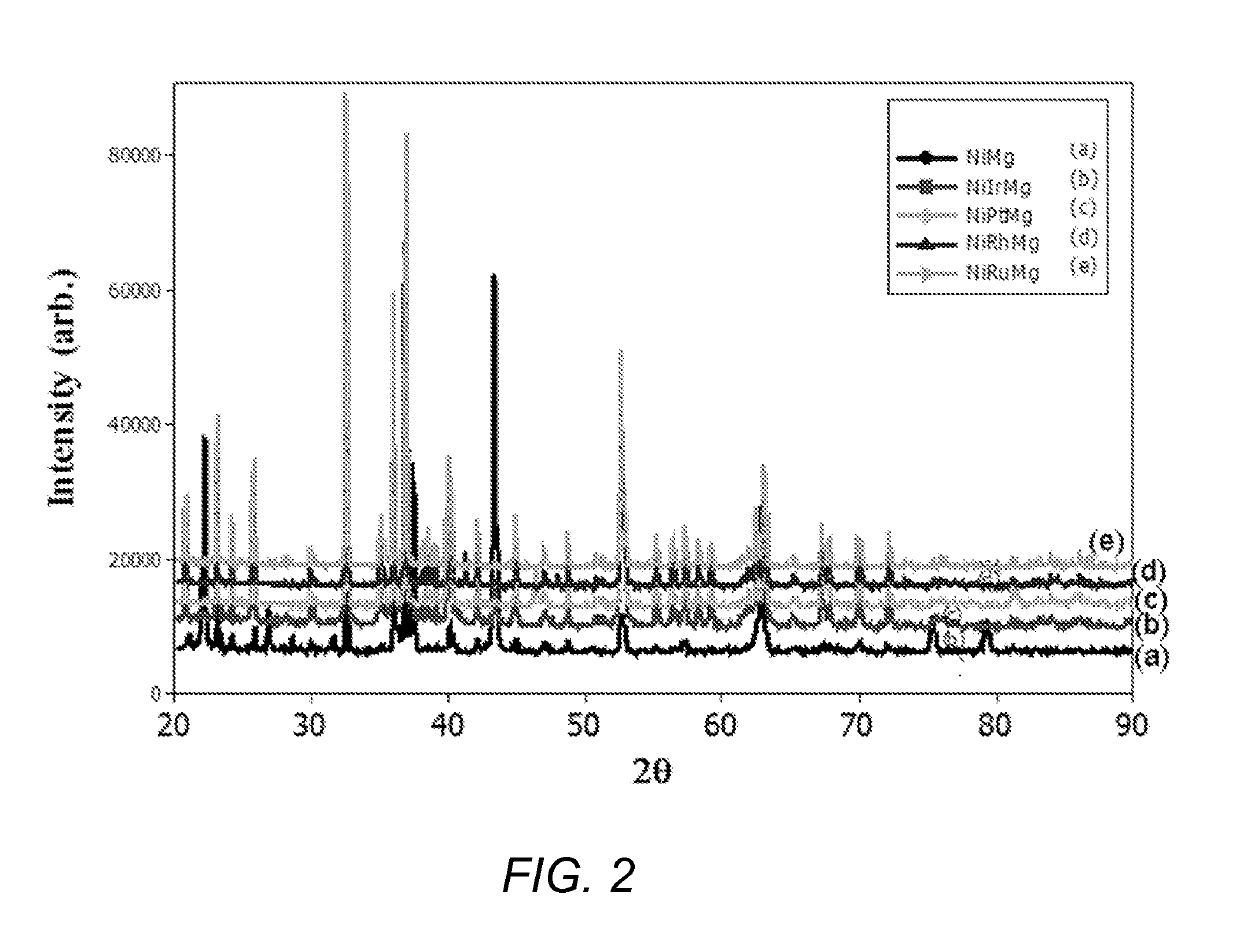

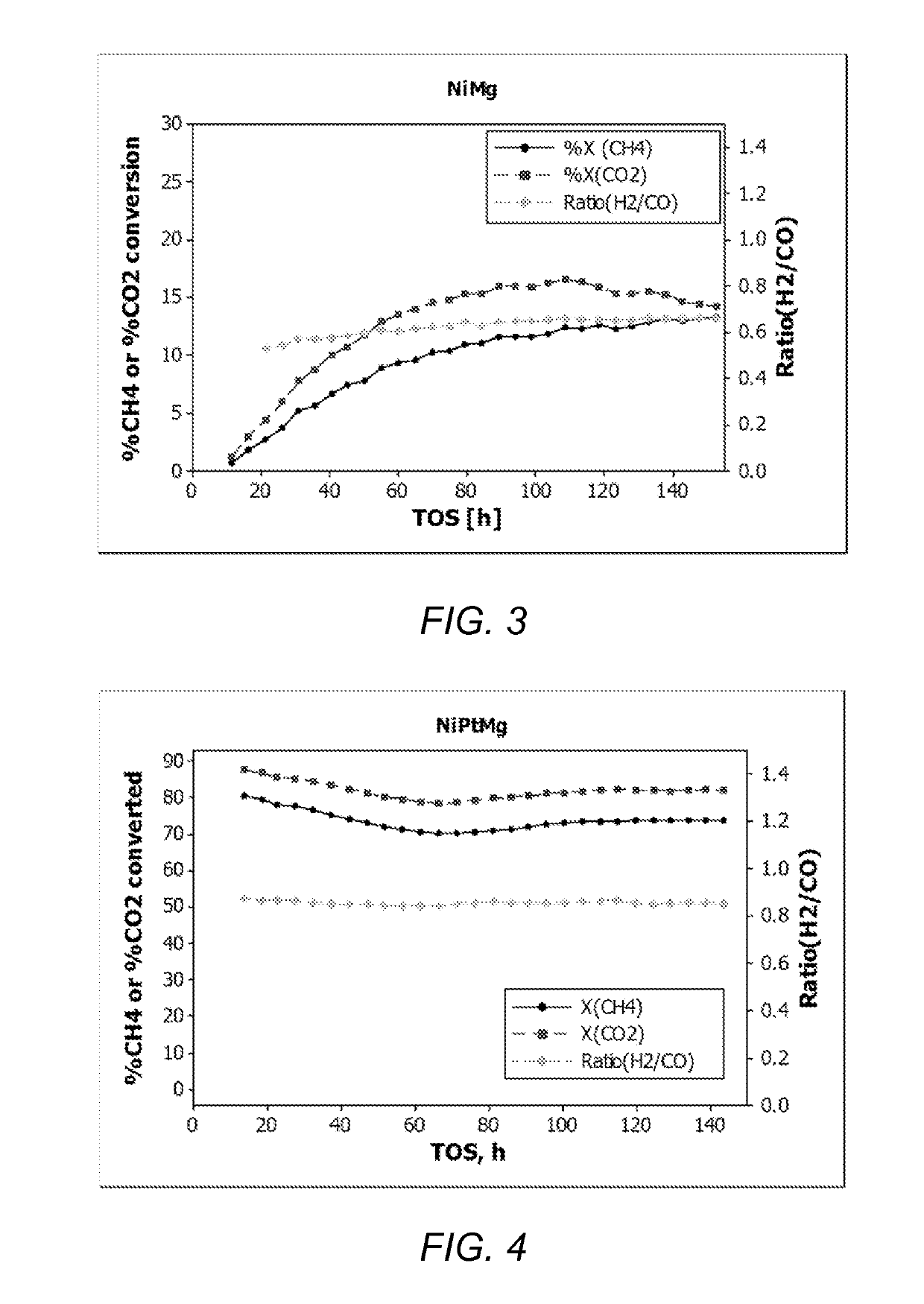

Synthesis of trimetallic nanoparticles by homogeneous deposition precipitation, and application of the supported catalyst for carbon dioxide reforming of methane

InactiveUS20170354962A1Reduce controlImprove oxidation capacityMaterial nanotechnologyHydrogenManganeseCobalt

Disclosed is a supported nanoparticle catalyst, methods of making the supported nanoparticle 5 catalysts and uses thereof. The supported nanoparticle catalyst includes catalytic metals M1, M2, M3, and a support material. M1 and M2 are different and are each selected from nickel (Ni), cobalt (Co), manganese (Mn), iron (Fe), copper (Cu) or zinc (Zn), wherein M1 and M2 are dispersed in the support material. M3 is a noble metal deposited on the surface of the nanoparticle catalyst and / or dispersed in the support material. The nanoparticle catalyst is 10 capable of producing hydrogen (H2) and carbon monoxide (CO) from methane (CH4) and carbon dioxide (CO2).

Owner:SABIC GLOBAL TECH BV

Catalyst for producing synthesis gas by reforming natural gas and carbon dioxide and preparation method thereof

InactiveCN102380394AImprove stabilityExtend the life cycleHydrogenMetal/metal-oxides/metal-hydroxide catalystsRare earthPetrochemical

The invention relates to a catalyst for producing synthesis gas by reforming natural gas and carbon dioxide and a preparation method thereof, belonging to the fields of petrochemical engineering, natural gas chemical engineering and catalysts. The catalyst takes aluminum oxide as a carrier, takes nickel as an active ingredient and takes a rare earth metal oxide as an assistant, wherein the content by weight of an active ingredient, namely NiO is 4.0-12.0%, and the content by weight of an assistant, namely La2O3 is 0.5-6.0%. The preparation method comprises the following steps: firstly preparing the aluminum oxide carrier, and then loading the active ingredient and the assistant on the carrier, wherein the preparation of the aluminum oxide carrier is as follows: mixing an aluminum raw material, a binding agent and a pore-forming agent, forming, drying and then performing calcination, and the active ingredient and the assistant are loaded on the carrier in an impregnation way; and further drying and calcining to prepare the catalyst. As for the catalyst, the surface of the aluminum oxide carrier is modified by the rare earth metal oxide, thereby reducing the acidity of the surface of the carrier, reducing the carbon deposition trend of methane-carbon dioxide reaction, improving the anti-carbon deposition performance, improving the dispersivity of the active ingredient, reducing the generation of carbon, improving the stability of the catalyst, prolonging the life cycle of the catalyst and realizing the low cost.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method of catalyst for carbon dioxide reforming of methane to produce synthesis gas

InactiveCN103566936AFast preparationOvercoming inactivation problemsHydrogenCatalyst activation/preparationCooking & bakingCobalt

The invention discloses a preparation method of a catalyst for carbon dioxide reforming of methane to produce synthesis gas. The preparation method comprises the following steps: mixing lignite active carbon with ammonia water according to a proportion and performing closed immersion to obtain modified lignite active carbon; placing the modified lignite active carbon in a closed pressurized temperature control reaction kettle; performing hydrothermal reaction at certain temperature and under certain voltage; naturally cooling and drying to prepare ammonia water modified lignite active carbon; finally performing ultrasonic immersion treatment on the ammonia water modified lignite active carbon and cobalt nitrate solution under certain pressure and drying and baking to prepare the catalyst. The catalyst prepared by the method has the advantages of readily available raw materials, good catalytic activity, long life and easiness in industrial production.

Owner:SHANXI LUAN MINING GRP

Use of olivine catalysts for carbon dioxide reforming of methane

InactiveUS10357759B2Reducing or avoiding any significant coking and/or sinteringHigh activityHydrogenHeterogenous catalyst chemical elementsHydrogenOlivine

Disclosed are metal oxide catalysts, and methods for their use, that includes a bulk metal oxide catalyst composed of at least two metals and nesosilicate. The catalyst is capable of catalyzing the carbon dioxide reforming of methane to produce hydrogen and carbon monoxide.

Owner:SABIC GLOBAL TECH BV

Catalyst for preparing synthesis gas from natural gas and carbon dioxide, and preparation method thereof

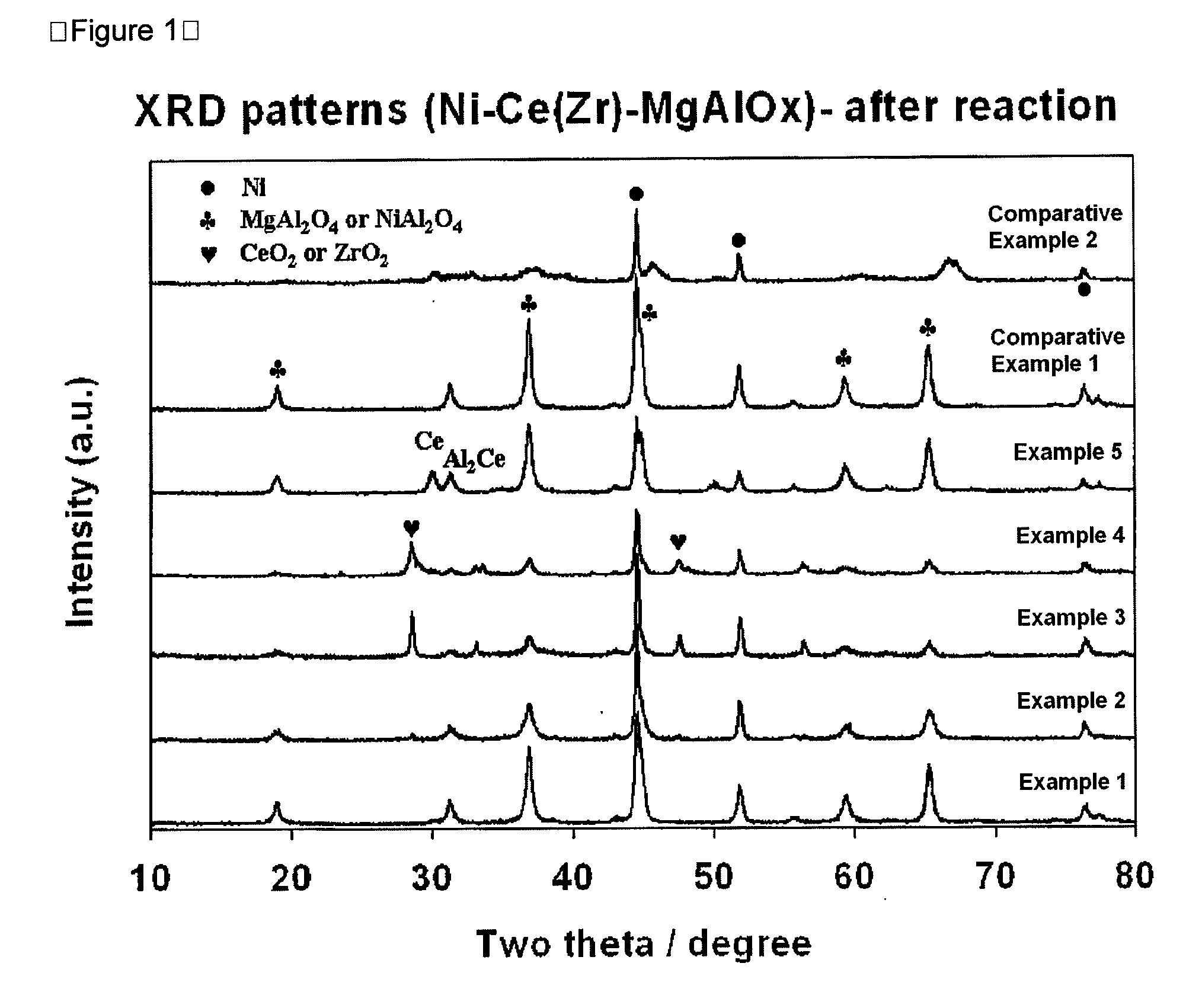

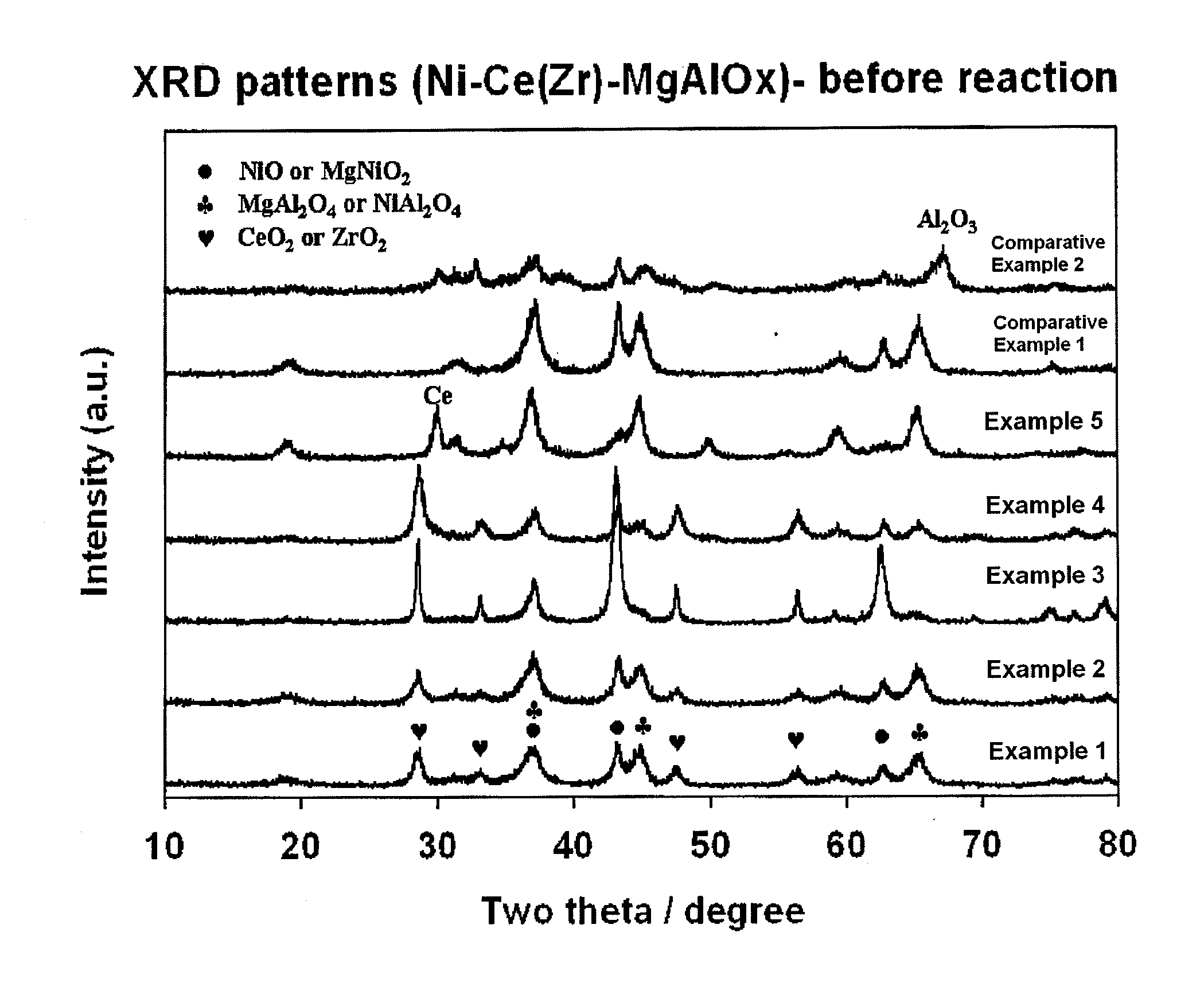

ActiveUS20110114892A1High activityAvoid deactivationHydrogenHydrocarbon from carbon oxidesSteam reformingNickel

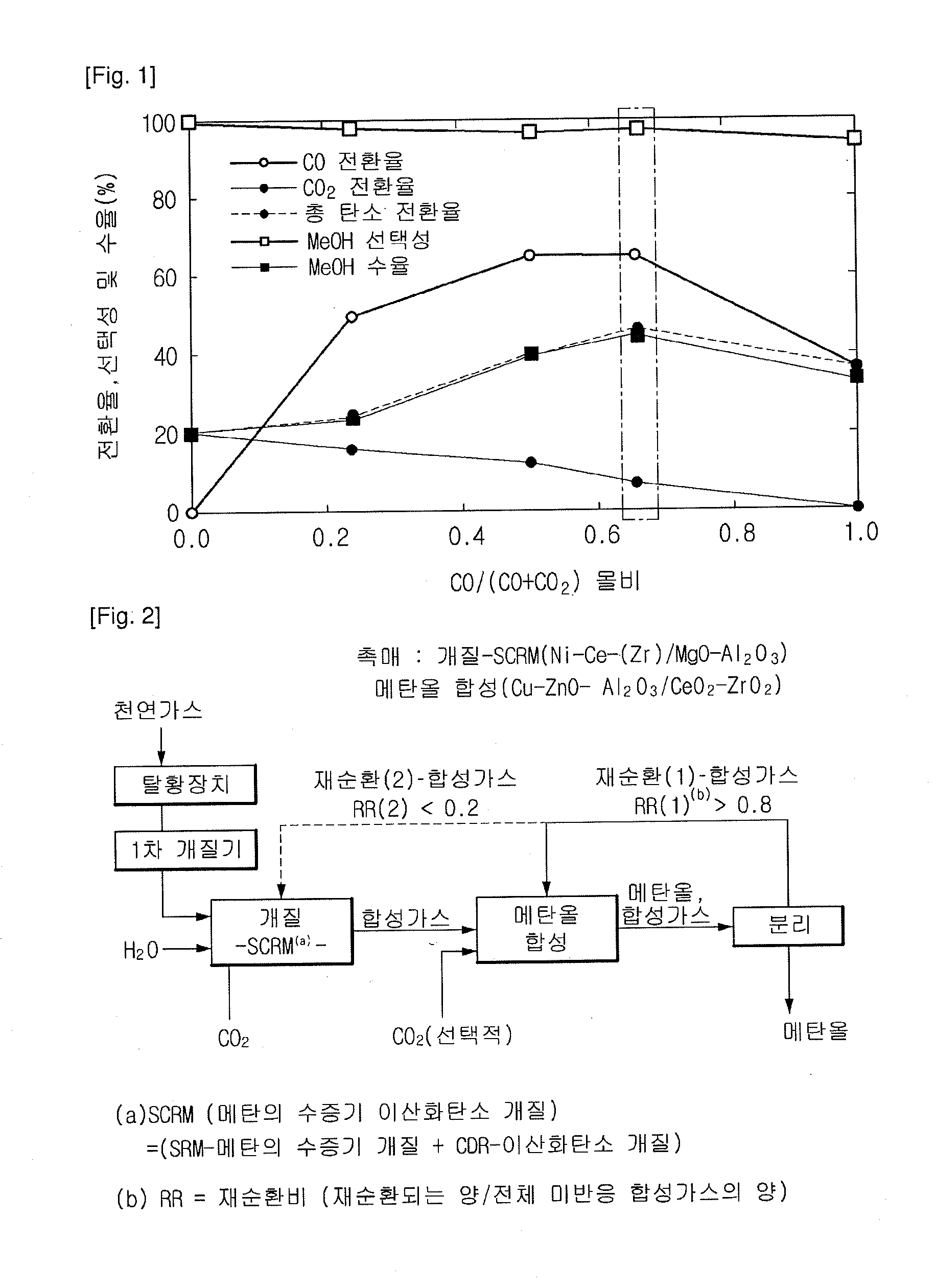

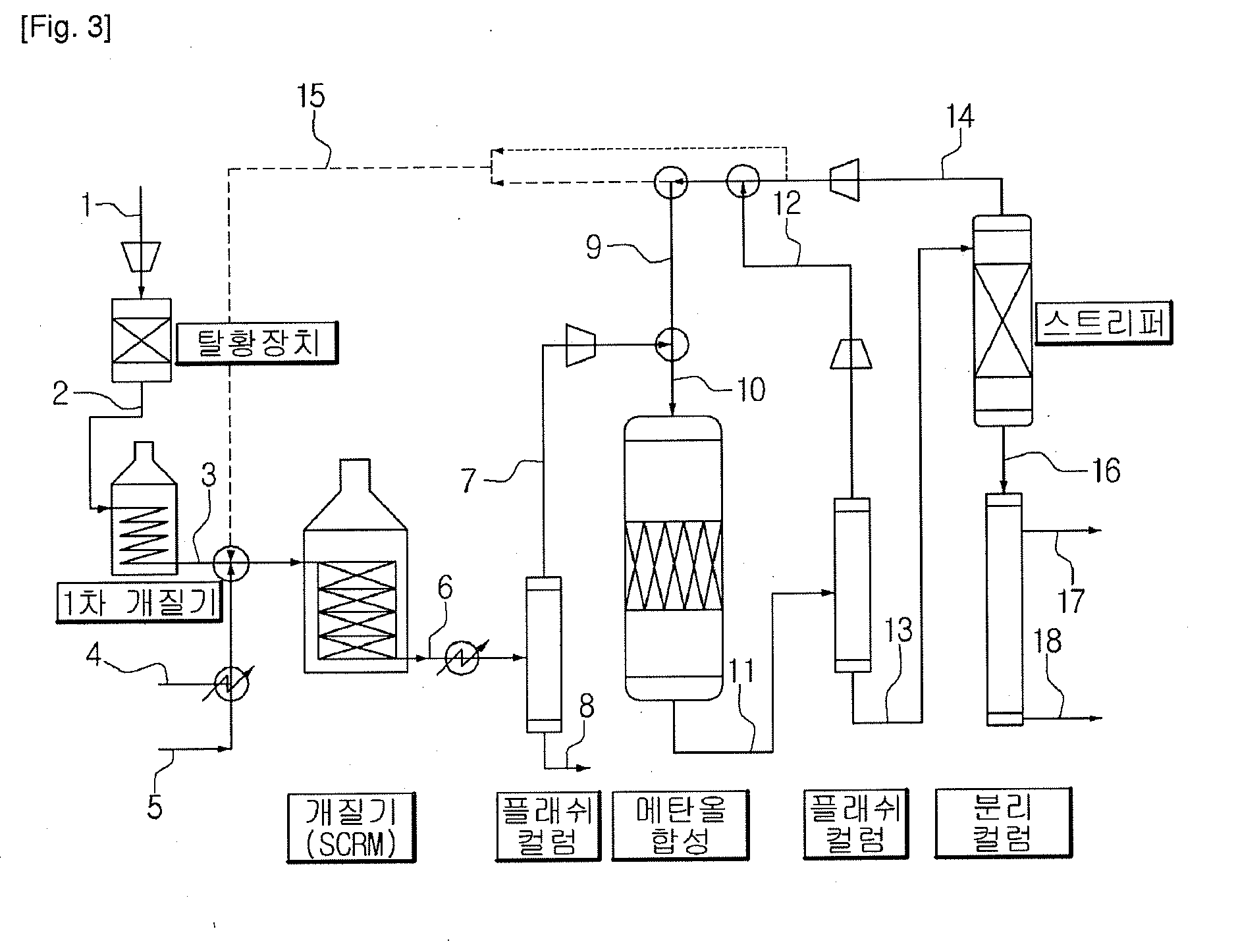

Disclosed are a catalyst for preparing synthesis gas from natural gas and carbon dioxide, and a method for preparing the same. More particularly, a combined reforming process is performed as an economical way of using carbon dioxide, wherein steam reforming of natural gas is carried out simultaneously with carbon dioxide reforming of methane in such a manner that a predetermined ratio of carbon monoxide / carbon dioxide / hydrogen (H2 / (2CO+3CO2)=0.85-1.15) is maintained. In this manner, the catalyst is used to prepare synthesis gas suitable for methanol synthesis and Fischer-Tropsch synthesis. Disclosed also is a method for preparing synthesis gas on a specific catalyst consisting of Ni / Ce / MgAlOx or Ni / Ce—Zr / MgAlOx. The catalyst is inhibited from deactivation caused by generation of cokes during the reaction as well as deactivation caused by reoxidation of nickel with water added during the reaction. Therefore, the catalyst shows excellent activity as compared to other catalysts for use in combined reforming.

Owner:KOREA RES INST OF CHEM TECH +1

Catalyst for preparing synthetic gas by reforming of methane and carbon dioxide as well as preparation method and application of catalyst

ActiveCN103816913AWell-developed poresLarge specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsActivated carbonPtru catalyst

The invention discloses a catalyst for preparing synthetic gas by reforming of methane and carbon dioxide as well as a preparation method and application of the catalyst, and belongs to the technical field of preparing catalysts. The catalyst is characterized in that activated charcoal is adopted as a carrier, multi-metal matters of cobalt, zirconium and molybdenum are adopted as active matters, wherein the content of the activated charcoal is 80-89%; the content of the multi-metal matters of cobalt, zirconium and molybdenum is 11-20%. Raw materials preparing the activated charcoal are broad in source, low in price and easy to obtain; the prepared activated charcoal has good pore structures and large specific surface area and strong sticking function to active matters; the prepared multi-metal catalyst of cobalt, zirconium and molybdenum is favorable in catalytic performance; under normal pressure and at a temperature of 750 DEG C, conversion rate of methane reaches to above 90%; conversion rate of carbon dioxide reaches to above 87%; after a service life test of 300 hours, the catalyst performs excellent catalytic activity and stability.

Owner:岳阳振兴中顺新材料科技股份有限公司

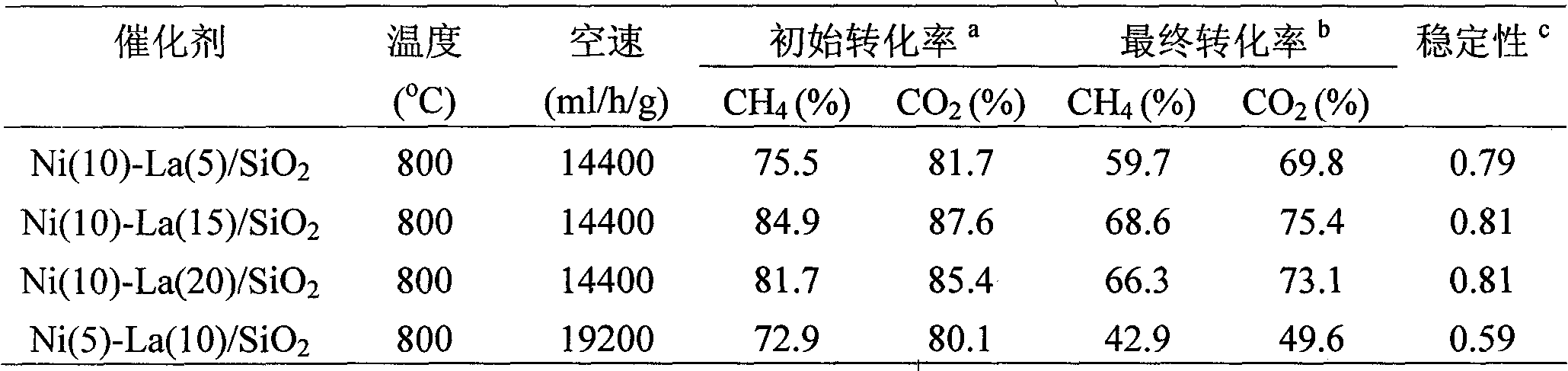

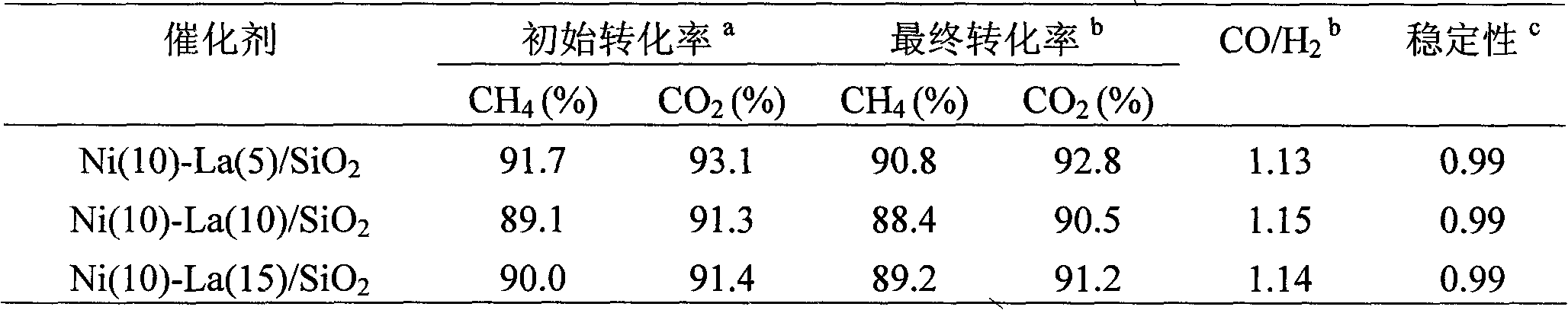

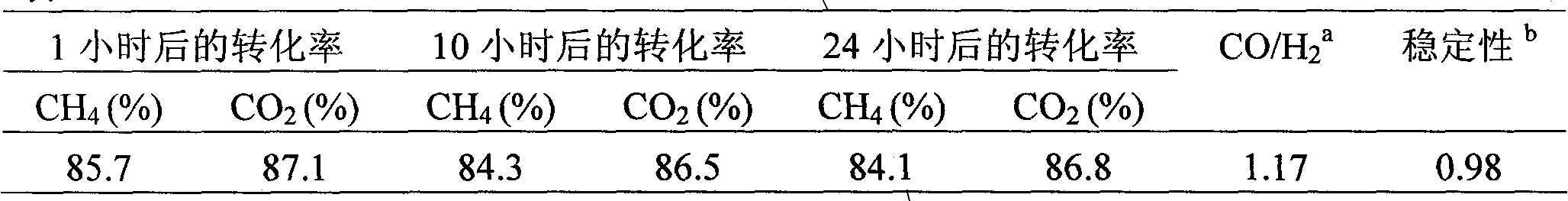

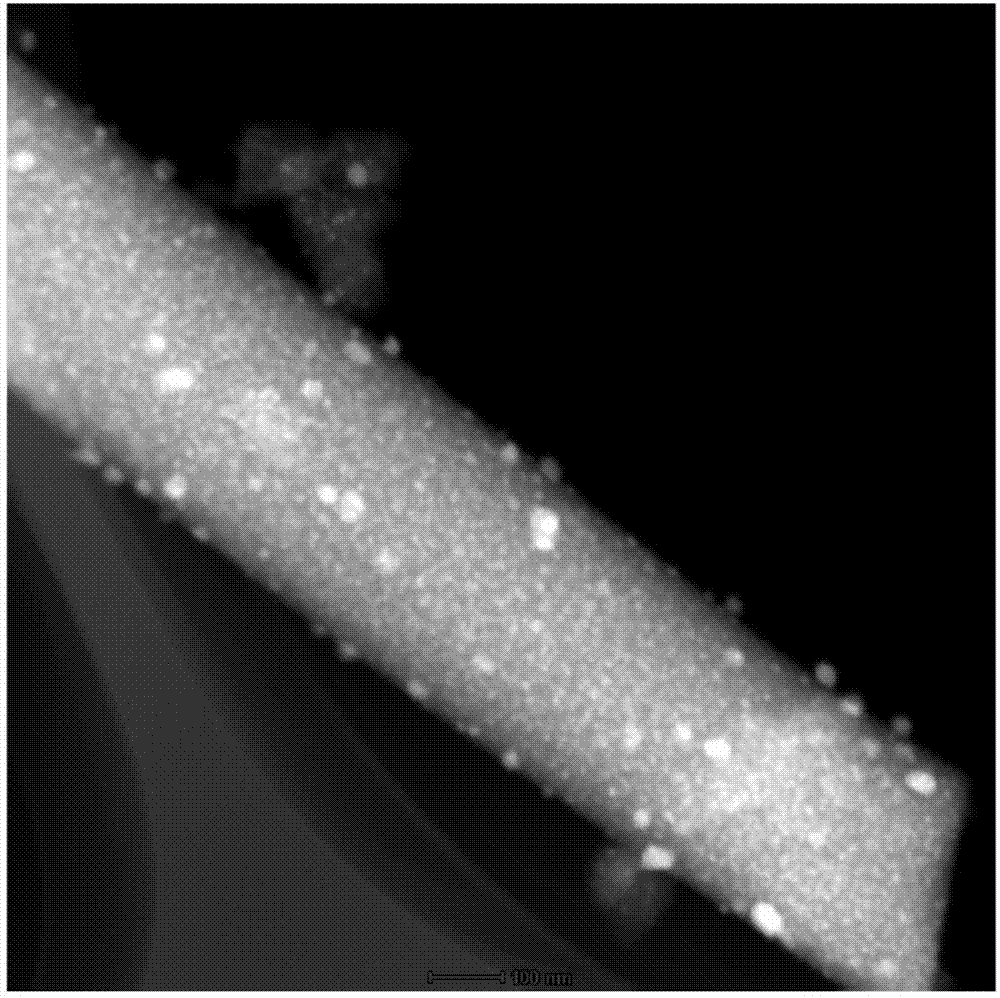

Catalyst for reforming methane with carbon dioxide for preparing synthetic gas and preparation method thereof

InactiveCN101773835AImprove mechanical propertiesImprove thermal stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsActive componentThermal stability

The invention relates to a catalyst for reforming methane with carbon dioxide for preparing synthetic gas, which is a bead catalyst prepared by taking SiO2 as a vector and Ni and La as active components by a co-impregnation method. The catalyst provided by the invention has good mechanical properties and thermal stability, long service life, simple preparation method, low cost and easy acquisition of raw materials, relatively mild reaction conditions and no need of any diluent gas; the catalyst has good catalytic property for reforming the methane with the carbon dioxide for preparing the synthetic gas; the conversion rates of the methane and the carbon dioxide can respectively reach 79.4-90.8% and 86.1%-92.8% under ordinary pressure; and the volume ratio CO to H2 in the prepared synthetic gas is 1.13-1.18.

Owner:SICHUAN UNIV

Method for preparing synthesis gas through catalytic reforming of methane and carbon dioxide

ActiveCN106281464AImprove conversion rateGuaranteed uptimeHydrogenCarburetting gasesCatalytic reformingIridium

The invention discloses a method for preparing synthesis gas through catalytic reforming of methane and carbon dioxide and belongs to the technical field of catalytic reactions. According to the method, a supported uranium-based multi-metal catalyst is taken as a catalyst for a reforming reaction of methane and carbon dioxide. The catalyst is prepared from a primary reactive metal component, namely, uranium, secondary reactive metal components and a carrier, wherein the content of uranium in the catalyst is 0.05%-30% by mass, the secondary reactive metal components comprise one or more of thorium, nickel, cobalt, molybdenum, palladium, platinum, ruthenium, rhodium and iridium, and the content of the secondary reactive metal components in the catalyst is 0.01%-20% by mass; the carrier is one of a carbon carrier, inorganic oxide and molecular sieves or a mixed carrier of more of the carbon carrier, inorganic oxide and the molecular sieves. The pressure for the reforming reaction of methane and carbon dioxide is 50 atm lower than the normal pressure, and the reaction temperature is 450-950 DEG C. The method for preparing the synthesis gas through catalytic reforming of methane and carbon dioxide has the advantages of wide reaction temperature range, high catalyst activity, good stability, carbon deposition resistance and the like.

Owner:TSINGHUA UNIV

Efficient methane and carbon dioxide reforming Ni/SiO2 catalyst and electrostatic spinning preparation method

ActiveCN104511279AHigh catalytic activityRaw materials are easy to getHydrogenMetal/metal-oxides/metal-hydroxide catalystsCatalytic reformingSilicon dioxide

Owner:BEIJING UNIV OF CHEM TECH

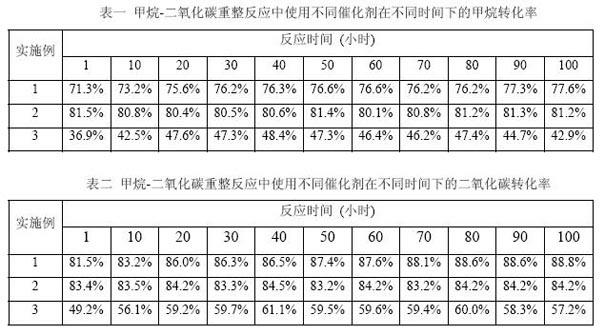

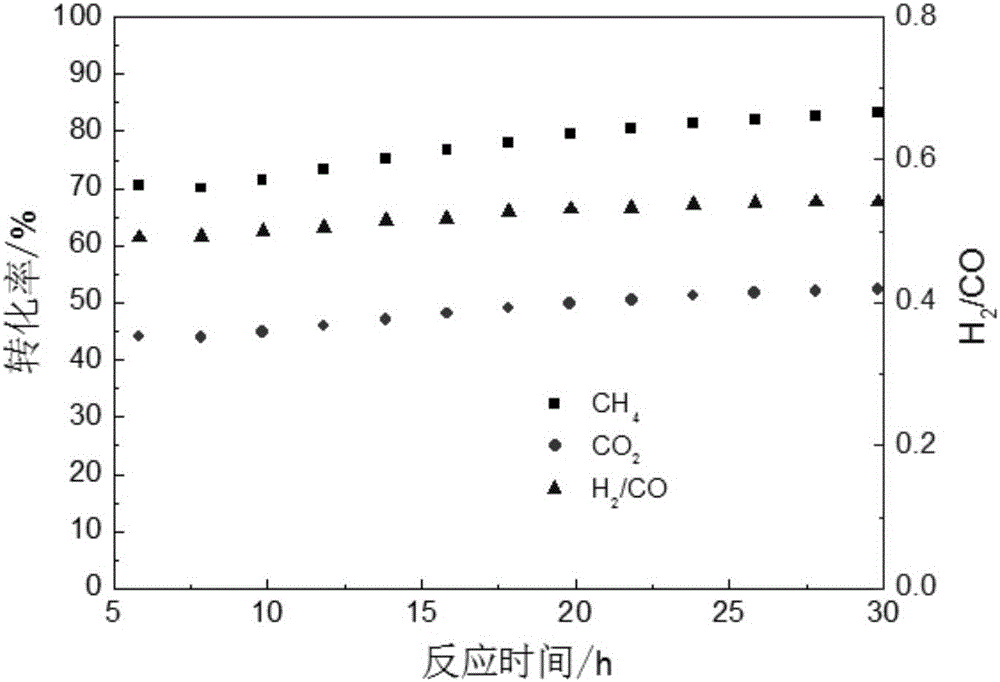

Process for producing synthetic gas by methane and CO2 reformation

InactiveCN101456536AImprove catalytic stabilityNo apparent inactivationHydrogenBulk chemical productionActive componentReaction temperature

The invention discloses a method for preparing synthesis gas by reforming methane and carbon dioxide. An active component of a catalyst adopted by the method is NiO, a carrier consists of TiO2 and SiO2, the reaction temperature is between 700 and 850 DEG C under normal pressure, and the components are subjected to reforming reaction in a fixed bed reactor under the operation condition that the air speed is 18,000 to 72,000mlh<-1>g<-1>. The highest conversion rates of the methane and the carbon dioxide reach more than 88 percent and 97 percent respectively, the highest yields of H2 and CO reach more than 85 percent and 93 percent respectively, and the catalyst after being stabilized for 30 hours does not lose activity remarkably.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Catalyst for reforming hydrocarbon and method for preparation thereof, and process for reforming hydrocarbon using said catalyst

InactiveUS20050221977A1Efficient implementationPresent inventionHydrogenOther chemical processesSteam reformingIridium

The present invention relates to a catalyst for reforming a hydrocarbon comprising a carrier containing manganese oxide and carried thereon (a) at least one component selected from a ruthenium component, a platinum component, a rhodium component, a palladium component, an iridium component and a nickel component and a process for producing the same and to a process for reforming a hydrocarbon (steam reforming, self thermal reforming, partial oxidation reforming and carbon dioxide reforming) using the above catalyst. Provided are a catalyst for reforming a hydrocarbon which comprises ruthenium, platinum, rhodium, palladium, iridium or nickel as an active component and in which a reforming activity is elevated, a process for producing the same, and a steam reforming process, a self thermal reforming process, a partial oxidation reforming process and a carbon dioxide reforming process for a hydrocarbon using the above catalyst.

Owner:IDEMITSU KOSAN CO LTD

Catalyst for producing synthesis gas by reforming natural gas-carbon dioxide for industry

ActiveCN101462058AImprove performanceHigh catalytic activityHydrogenMolecular sieve catalystsCoalChemistry

The invention provides an industrial catalyst for producing synthesis gas by natural gas-carbon dioxide reforming. The catalyst comprises the following components in percentage by weight: 5 to 19 percent of Ni, 20 to 70 percent of La, and 0 to 2 percent of precious metal; and the catalyst is prepared by powder molding or the impregnation of a carrier by an active constituent, and the carrier is amolecular sieve and a molding additive. The catalyst has high catalytic activity through a micro-reactor and pilot magnification activity evaluation; and compared with other catalysts, the catalyst has strong carbon deposition resistance and steady performance. The catalyst is suitable to produce the synthesis gas by reforming natural gas and carbon dioxide, and also is suitable to produce the synthesis gas by reforming combined raw materials such as flue gas, coke-oven gas and coal bed gas of fuel electric plants, dry gas of oil refineries and the like.

Owner:SHANGHAI HUAYI ENERGY CHEM +1

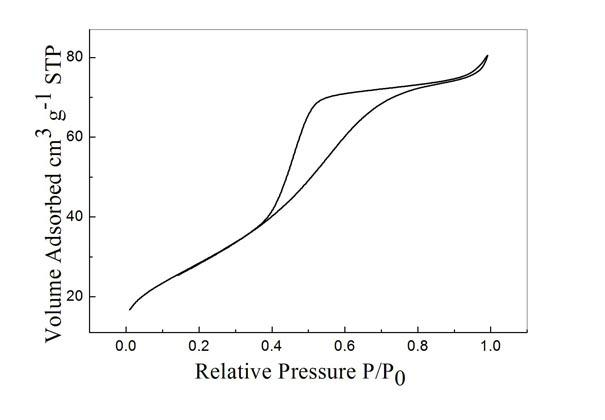

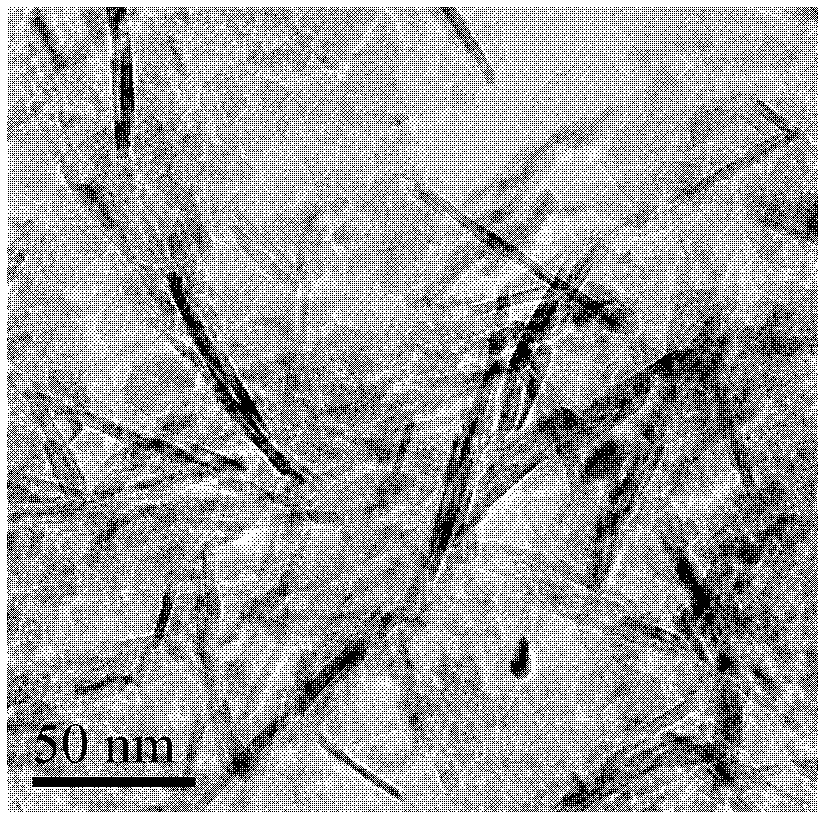

Preparation method of highly-dispersed Ni catalyst used for producing synthesis gas through carbon dioxide reforming of methane

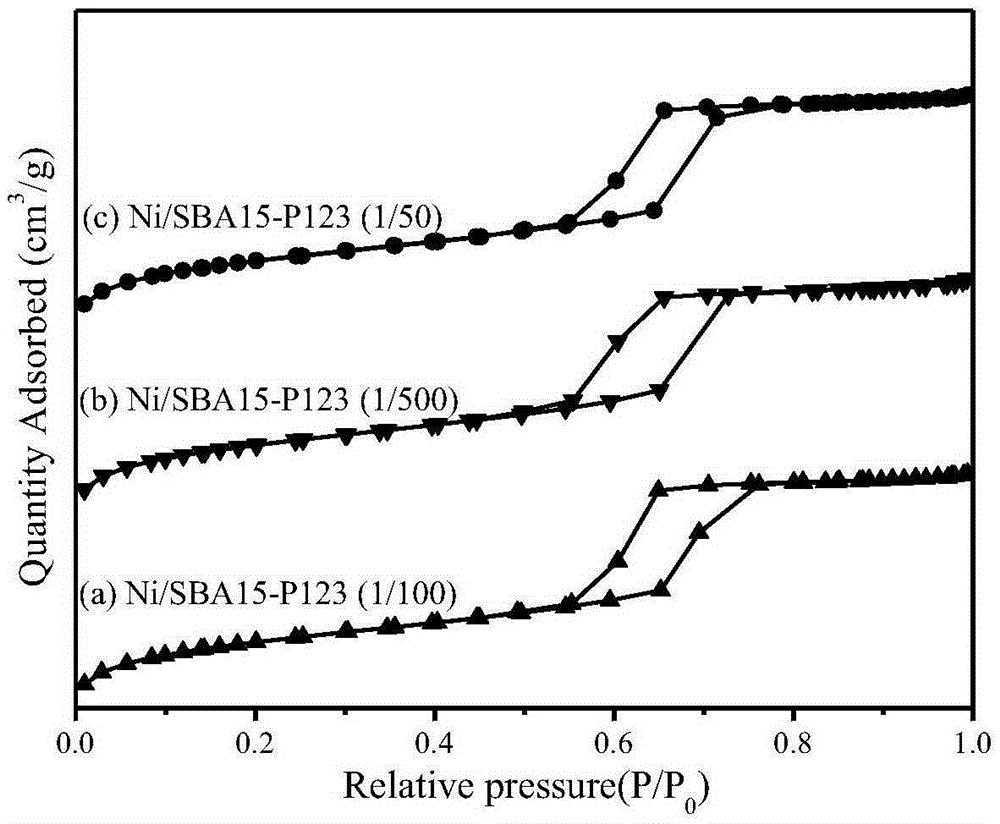

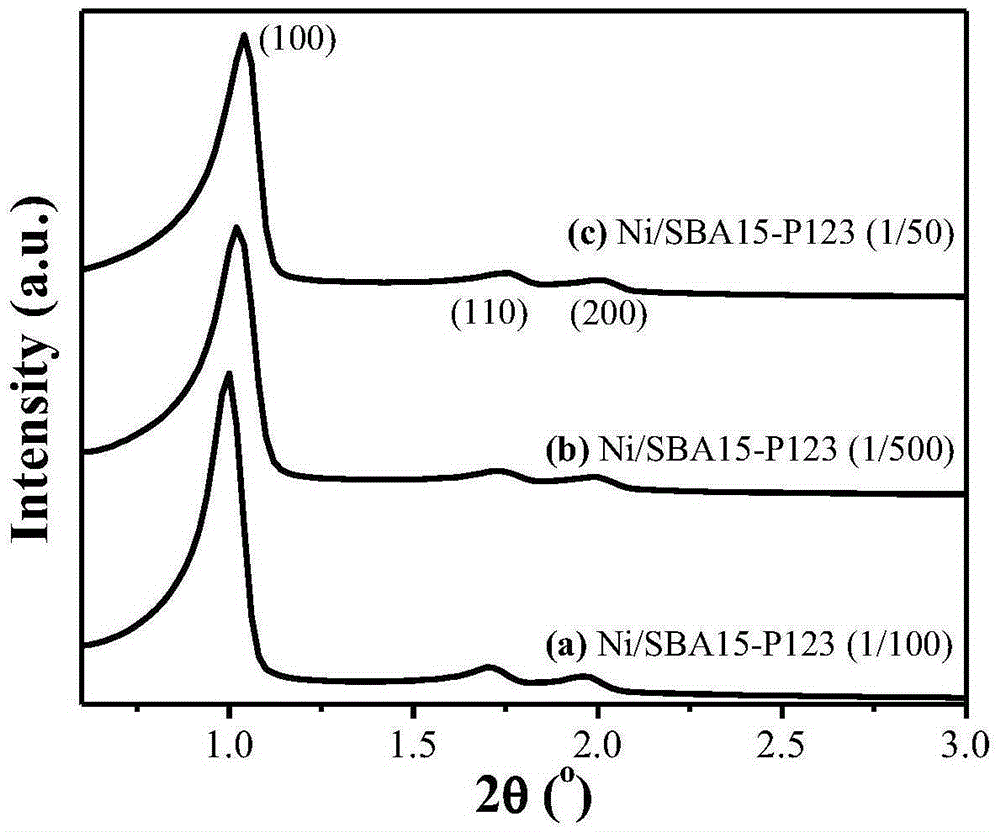

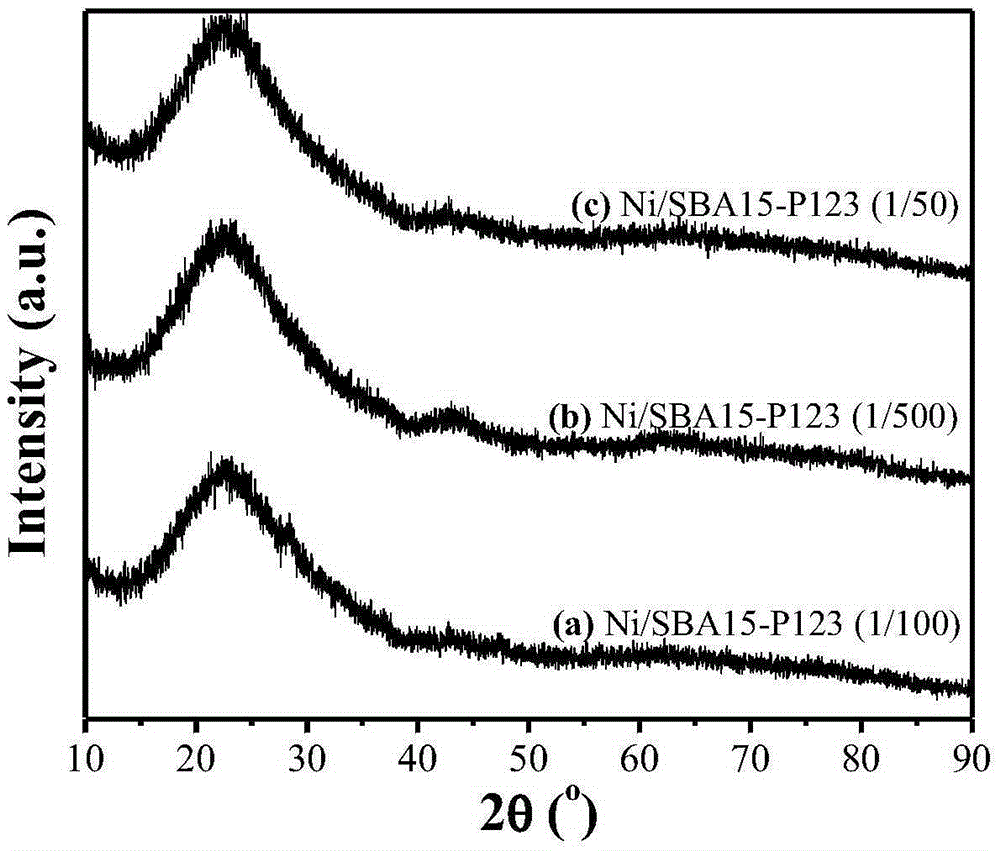

InactiveCN105381818AHigh activityImprove stabilityHydrogenOrganic-compounds/hydrides/coordination-complexes catalystsChemical industryMesoporous silica

The present invention relates to a preparation method of a highly-dispersed supported Ni catalyst used for producing synthesis gas through carbon dioxide reforming of methane, and belongs to the technical fields of nature gas chemical industry and catalyst manufacturing engineering. The preparation method is characterized by comprising the following steps: adopting a tri-block copolymer P123 (polyethylene glycol-polypropylene glycol-polyethylene glycol, PEG-PPG-PEG) as an auxiliary additive in a Ni catalyst preparation process; using an aqueous solution of Ni(NO3)2-6H2O and P123 as impregnation liquid; using mesoporous silica SBA-15 as a carrier; and carrying out the process of impregnation, drying and calcinations to prepare the supported Ni catalyst Ni / SBA15-P123(1 / X). The addition amount of P123 in the preparation process of the supported Ni catalyst is that the molar ratio 1 / X of P123 to Ni being 1 / 750-1 / 3, preferably 1 / 500-1 / 50. The synthesis gas is prepared after a reaction under a normal pressure by using the supported Ni / SBA15-P123 (1 / X) as a catalyst and using methane and carbon dioxide as raw material gas. The Ni / SBA15-P123 (1 / X) catalyst prepared by using the process method of the present invention has high activity and excellent stability in the reaction of reforming the methane with the carbon dioxide.

Owner:TSINGHUA UNIV

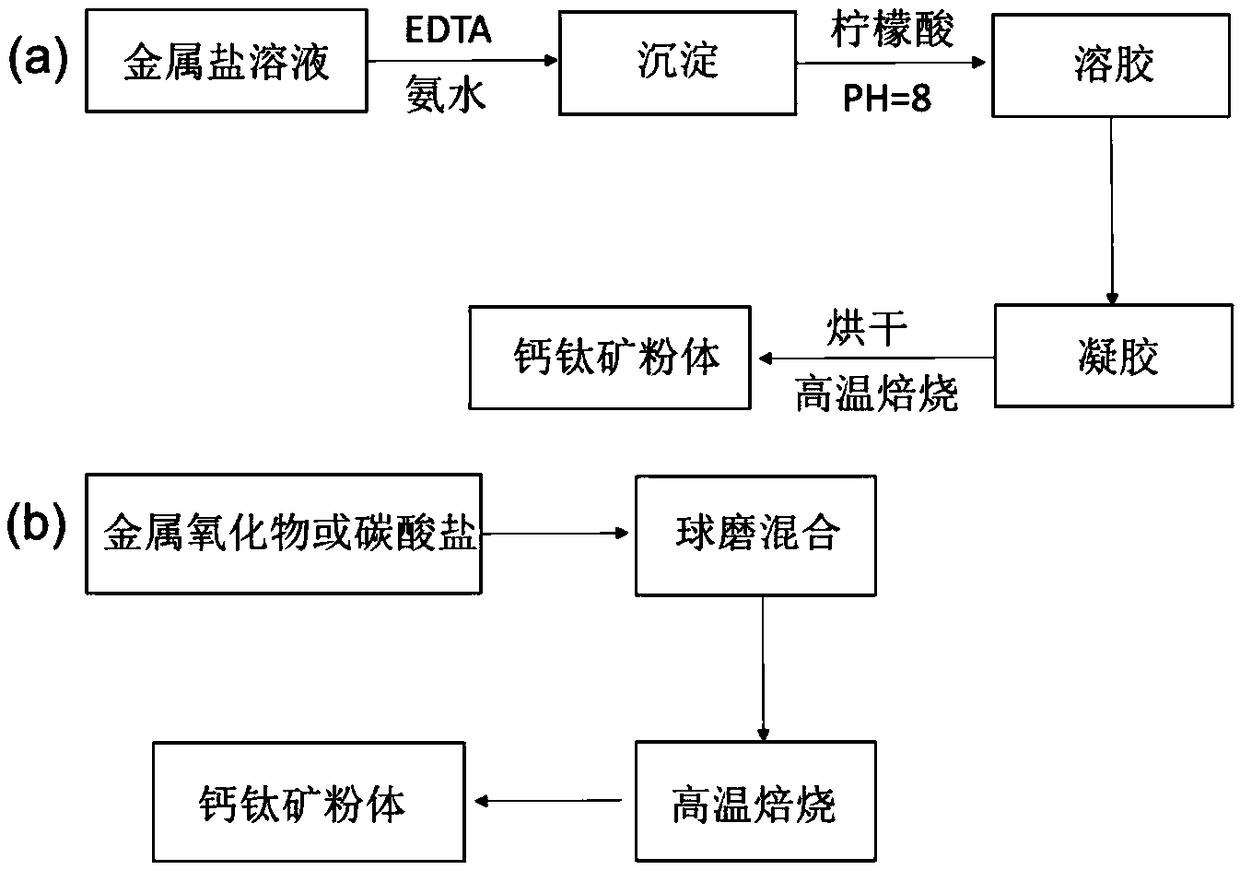

Perovskite catalyst, preparation method thereof and in-situ testing method of perovskite catalyst

InactiveCN108654592AHighly dispersed and stable dispersedImprove anti-coking performanceChemical analysis using catalysisHydrogenRare-earth elementAlkaline earth metal

The invention discloses a novel solid catalyst material for methane carbon dioxide reforming reaction, a corresponding widely-applicable preparation method and a simply and easily operated testing andreacting process. According to the perovskite catalyst, a substrate is a perovskite material which includes in-situ precipitated B-site doped metal nano-particles and an A site short of positive ions. The in-situ precipitated B-site high-activity metal nano-particles for catalyzing cover the surface of the substrate, the A site is any one of a rare earth element and an alkali-earth metal element,and a B-site substrate is doped transition metal with various valence states. The perovskite catalyst can provide good catalytic performances, and carbon deposit and catalyst deactivation caused by carbon deposit in reforming reaction are avoided. The in-situ precipitated-in-situ reaction preparation and testing method has the advantages of simplicity in operation, practicability, high efficiencyand novelty. The method has a good application prospect in a preparation and testing process of the catalyst.

Owner:HUAZHONG UNIV OF SCI & TECH

Nickel-based catalyst for obtaining synthetic gas through carbon dioxide reforming of methane and preparation method for nickel-based catalyst

ActiveCN102389801AHigh conversion rate of methaneExtend your lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to the technical field of catalysts for obtaining synthetic gas through carbon dioxide reforming of methane, and discloses a nickel-based catalyst for obtaining the synthetic gas through the carbon dioxide reforming of the methane and a preparation method for the nickel-based catalyst. The nickel-based catalyst for obtaining the synthetic gas through the carbon dioxide reforming of the methane consists of NiO, MgO and gamma-Al2O3. The preparation method comprises the following steps of: 1, preparing a mixed solution; and 2, preparing the nickel-based catalyst. Compared with the prior art, the method has the advantages that: the methane conversion rate of the nickel-based catalyst is greatly improved, the service life is also greatly prolonged, and the carbon deposition rate is greatly reduced; and the nickel-based catalyst is low in cost and has better economy.

Owner:XINJIANG UNIVERSITY

Method for methanol synthesis using synthesis gas generated by combined reforming of natural gas with carbon dioxide

ActiveUS20110237689A1Maximize energy efficiencyReduce carbon dioxide emissionsOrganic compound preparationOxygen compounds preparation by reductionSteam reformingCerium

Disclosed is a method for methanol synthesis using synthesis gas obtained from reforming of natural gas with carbon dioxide. First, synthesis gas is obtained from steam carbon dioxide reforming of methane, in which steam reforming of natural gas is carried out simultaneously with carbon dioxide reforming of methane, by using a catalyst (Ni / Ce / MgAlOx, or Ni / Ce—Zr / MgAlOx) and processing condition capable of maintaining a predetermined ratio of carbon monoxide, carbon dioxide, and hydrogen [H2 / (2CO+3CO2)=0.85-1.15] Next, methanol synthesis is carried out by using the obtained synthesis as and a catalyst system suitable for methanol synthesis with minimum byproduct formation (a catalyst system including a Cu—Zn—Al oxide containing CuO, ZnO, and Al2O3 at a predetermined ratio in combination with a cerium-zirconium oxide obtained by a sol-gel process). In addition, unreacted synthesis gas remaining after the operation of methanol synthesis is recycled efficiently to improve the carbon availability (methane and CO2 availability) and energy efficiency in the overall process.

Owner:KOREA RES INST OF CHEM TECH +1

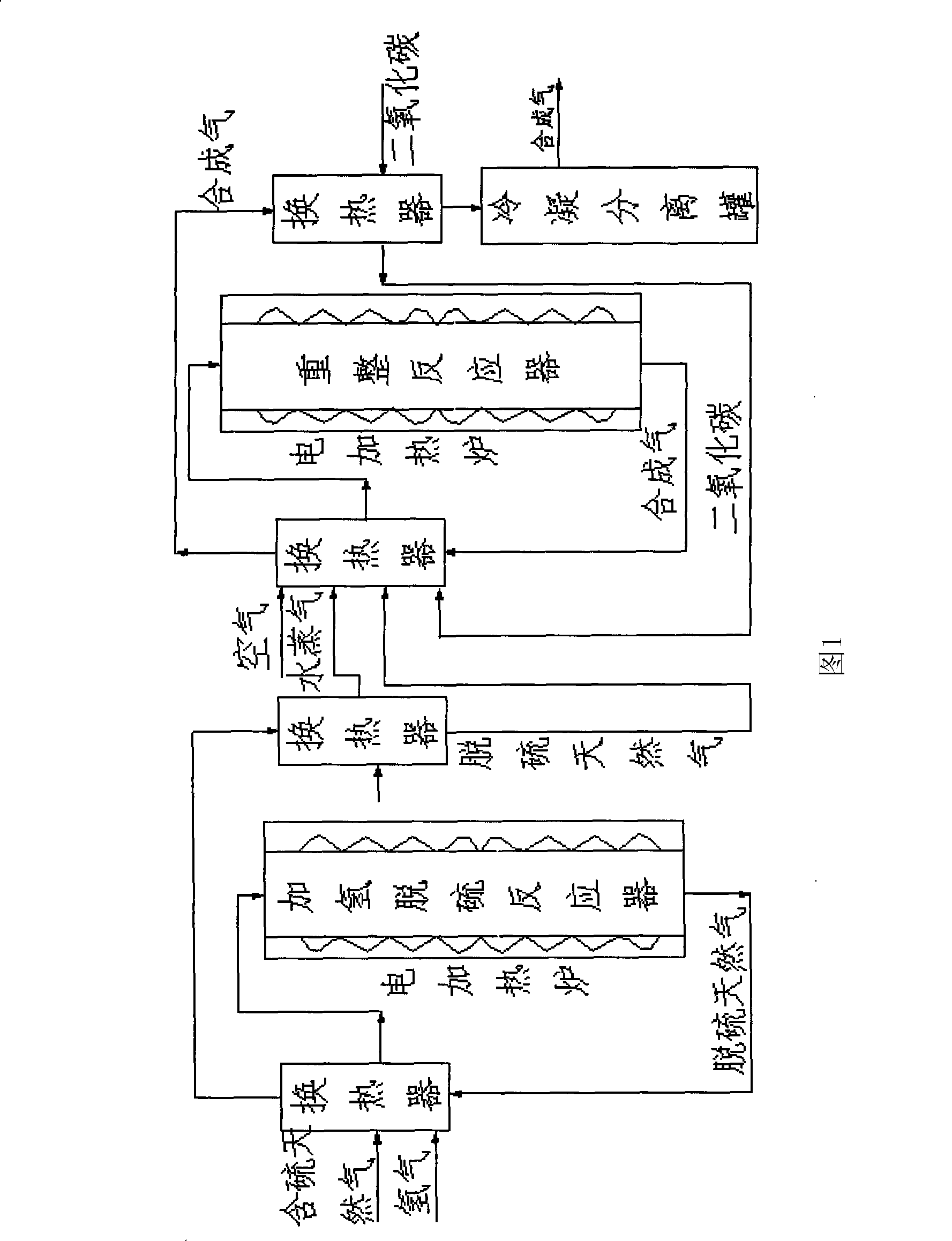

Method and apparatus for preparing synthesis gas by natural gas-carbon dioxide reforming

The invention provides a method and a device for preparing syngas by reforming natural gas and carbon dioxide. The method comprises the following steps: sulfur-containing natural gas with the concentration of at least 99.0 mol percent and hydrogen are premixed, preheated, and sent into a hydrodesulphurization reactor as a desulphurization unit; the sulfur content of the natural gas is lowered through the hydrogenation and adsorption of a catalyst; and the syngas is obtained in a reforming reactor provided with a reforming nickel catalyst after the natural gas and carbon dioxide are premixed and preheated. The method and the special device thereof are applicable to the comprehensive utilization of natural gas and carbon dioxide.

Owner:SHANGHAI HUAYI ENERGY CHEM

Preparation method for rapidly preparing highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide

InactiveCN106000444ASimple preparation processShorten evaporation timeHydrogenMolecular sieve catalystsNickel catalystHigh carbon

The invention discloses a preparation method for rapidly preparing a highly-dispersed nickel-based catalyst for methane reforming with carbon dioxide. A high-temperature-resistant mesoporous material with a large specific surface area and ordered mesoporous passages is adopted as a carrier of the catalyst, a nickel precursor salt and the mesoporous material are ground and stirred to uniformly disperse the nickel precursor salt on the surface of the mesoporous material carrier which is not de-molded by adopting a solid-state grinding method, and during drying, the nickel precursor salt enters the passages to obtain a nickel catalyst with highly-dispersed active ingredients and high carbon deposition resistance and sintering resistance by calcination and H2 reduction. The preparation method has the advantages of simple preparation process, high catalysis efficiency, energy saving (calcination is not required during preparation of the carrier), uniform distribution of the active ingredients and the like.

Owner:KUNMING UNIV OF SCI & TECH

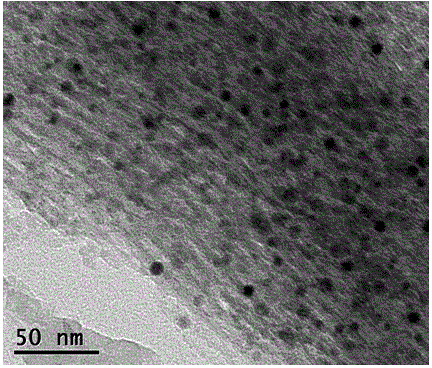

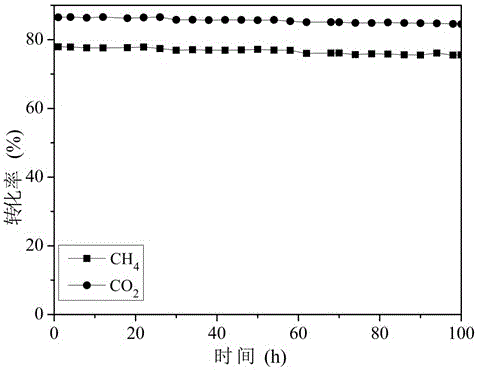

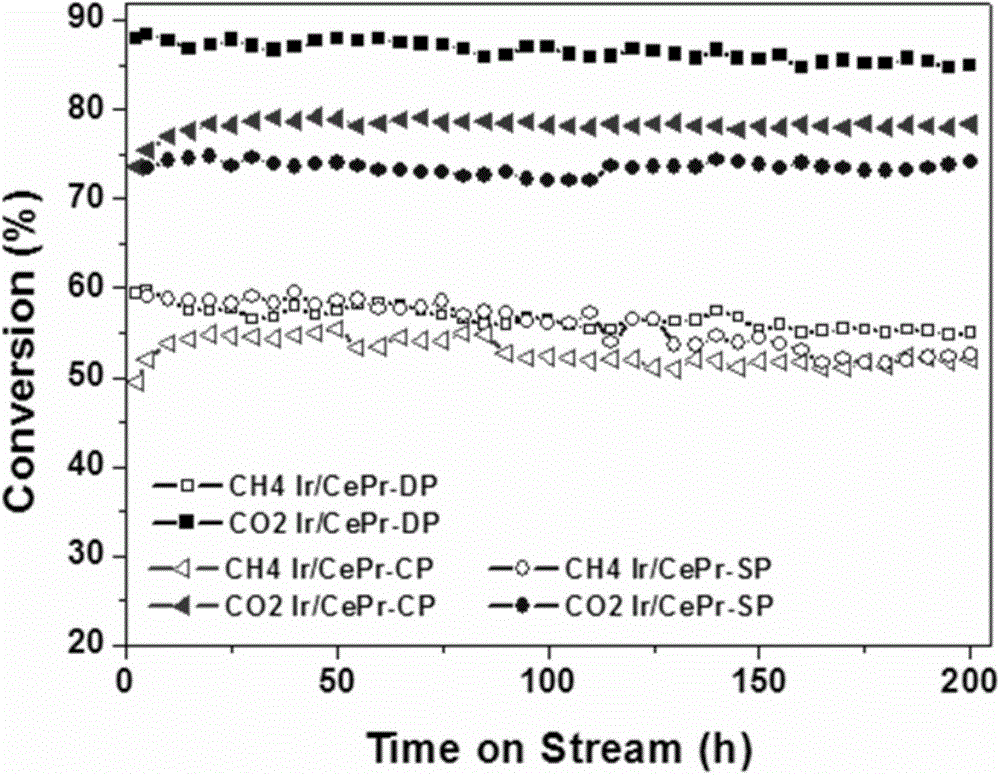

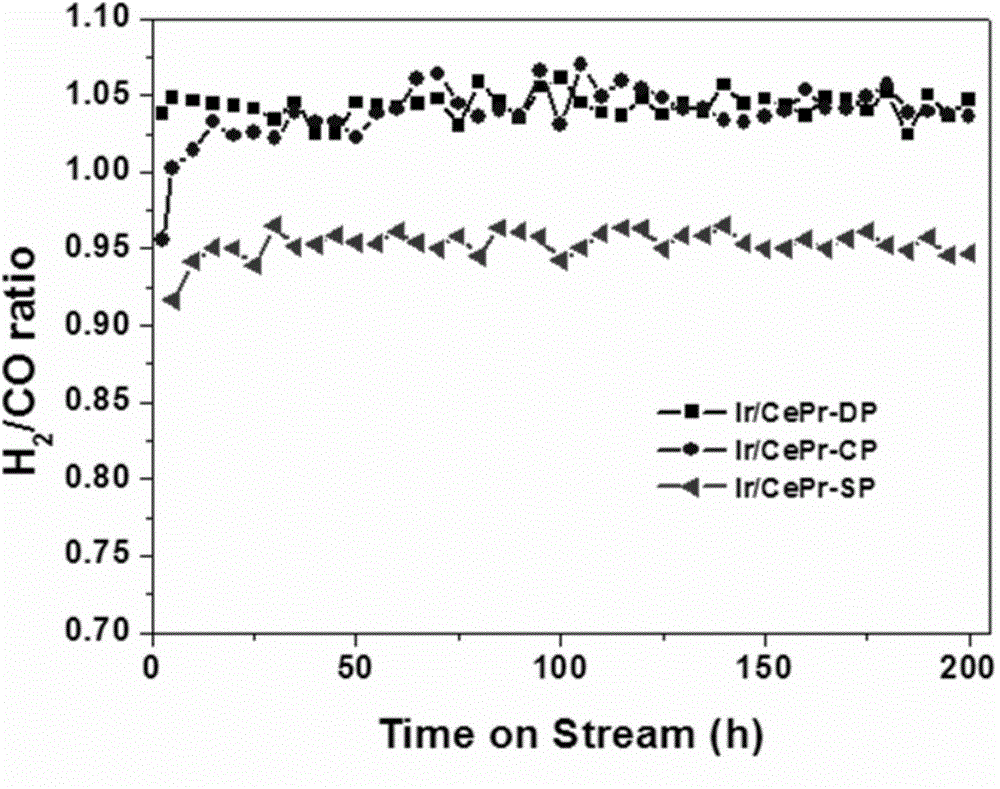

Catalyst for reforming methane and carbon dioxide to prepare synthesis gas, and preparation method for catalyst

The invention discloses a catalyst for reforming methane and carbon dioxide to prepare synthesis gas. The catalyst is prepared from the components in percentage by mass: 2-3% of metal iridium and 97-98% of a cerium oxide-based solid solution, wherein the cerium oxide-based solid solution is pure cerium oxide, a cerium oxide-lanthanum oxide solid solution, a cerium oxide-praseodymium oxide solid solution, a cerium oxide-zirconium oxide solid solution or a cerium oxide-titanium oxide solid solution. According to the invention, the catalyst for reforming methane and carbon dioxide to prepare synthesis gas is prepared through a simple deposition-precipitation, coprecipitation or sequential precipitation method, and the catalyst shows the characteristic of high catalytic efficiency in reforming reaction of dried methane gas at 750-800 DEG C, and has relatively good stability.

Owner:NAT UNIV OF SINGAPORE SUZHOU RES INST +1

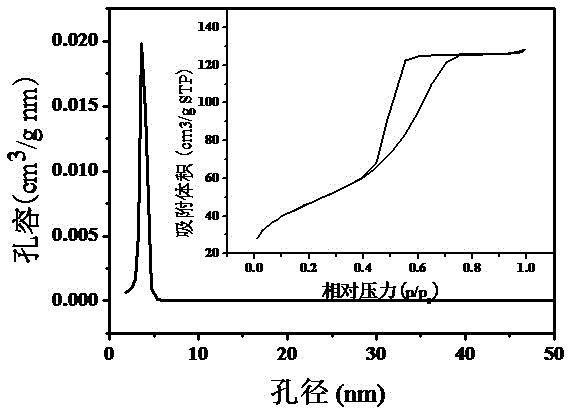

Mesoporous alumina nickel-based catalyst with high activity and high stability for CO2 reforming CH4 reaction and preparation method of mesoporous alumina nickel-based catalyst

InactiveCN104549289AHigh catalytic activityImprove catalytic stabilityHydrogenMetal/metal-oxides/metal-hydroxide catalystsInorganic saltsPtru catalyst

The invention mainly relates to a mesoporous alumina nickel-based catalyst for carbon dioxide reforming methane reaction and a preparation method of the mesoporous alumina nickel-based catalyst. The method comprises the following steps: forming sol-gel by controlling the titration rate of ammonium carbonate through partial hydrolysis methods of an inorganic salt and the ammonium carbonate; and then burning at 800 DEG C to prepare the nickel-based catalyst, wherein addition of a template agent and an organic salt is not required. The nickel-based catalyst prepared by the method has super-high activity and stability; and the activity and the stability of lanthanum added as an assistant are the best. The preparation method is simple in process and low in cost; the prepared nickel-based catalyst has the advantages of high specific surface area, narrow pore size distribution and relatively large pore volume; nickel oxides and assistants metal oxides are highly dispersed and have relatively high CO2 reforming CH4 catalytic activity and stability; the raw materials are cheap and easy to get; and the preparation process is easy to control and easy to industrialize.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com