Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "High conversion rate of methane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process and catalyst for methane conversion to aromatics

ActiveUS9950971B2High Aromatics YieldHigh methane incorporationMolecular sieve catalystsMolecular sieve catalystAromatizationCompound (substance)

A process and catalyst for use therein for the production of aromatics via the oxidative coupling of methane and methane co-aromatization with higher hydrocarbons in a single reaction stage. First, methane is partially converted to ethane and ethylene on an OCM catalyst component, and the OCM intermediate mixture containing methane, ethane and ethylene is subsequently converted into aromatics on an aromatization catalyst component. The reaction may be conducted at 550-850° C. and at about 50 psig. The claimed process and catalyst used therein achieves high methane conversion at lower temperatures (less than 800° C.), higher methane conversion into the aromatic products and significant reductions in production cost when compared to the traditional two (or more) step processes.

Owner:EXXONMOBIL CHEM PAT INC

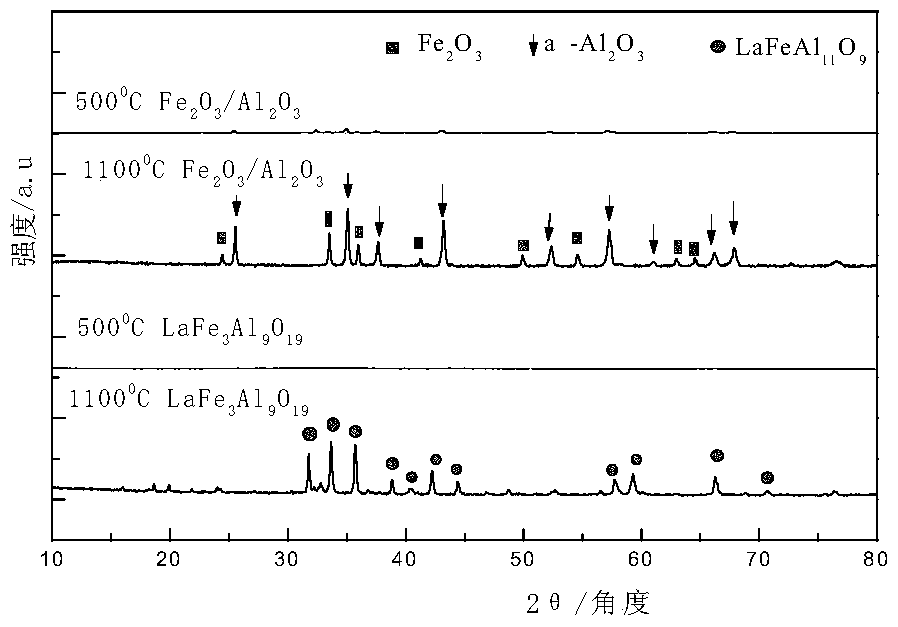

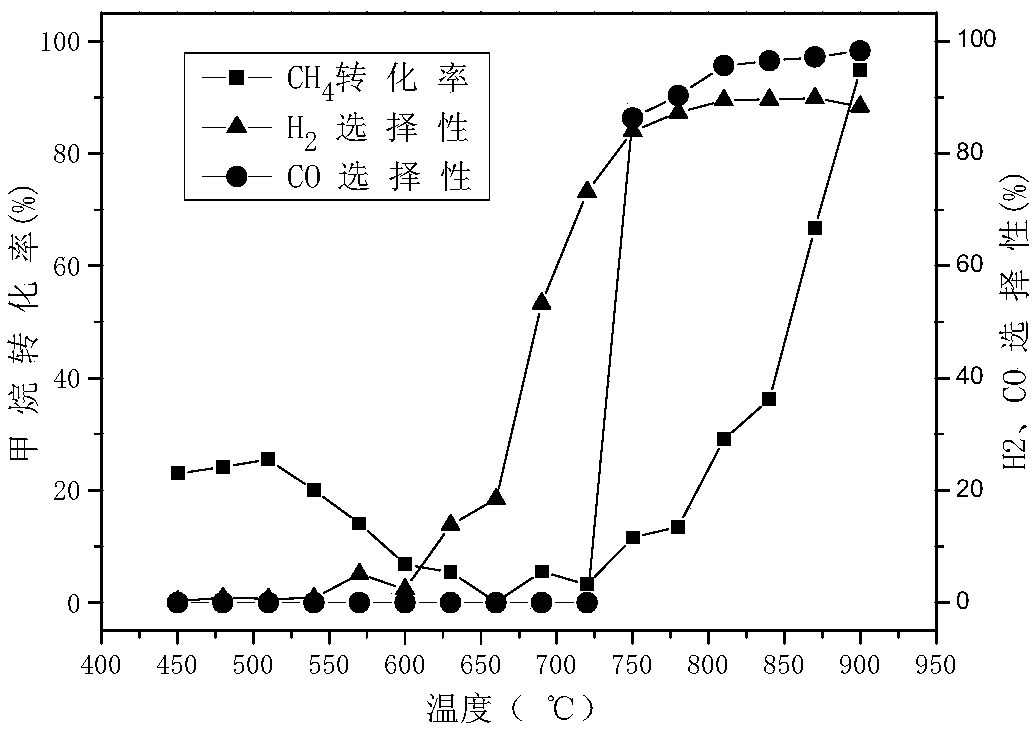

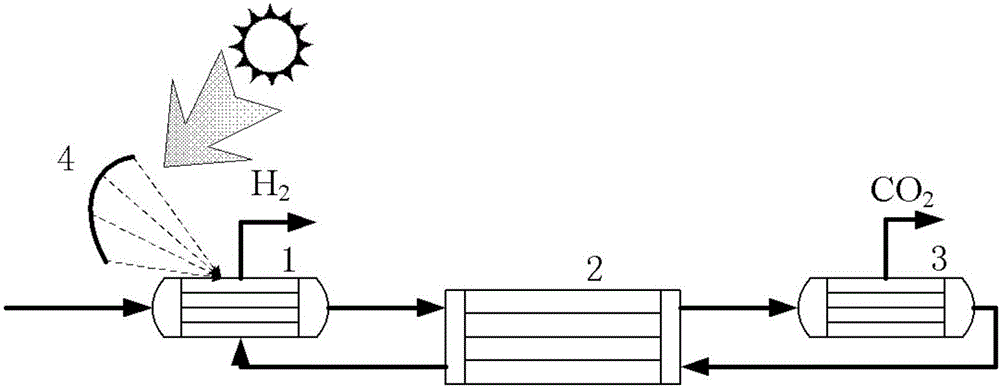

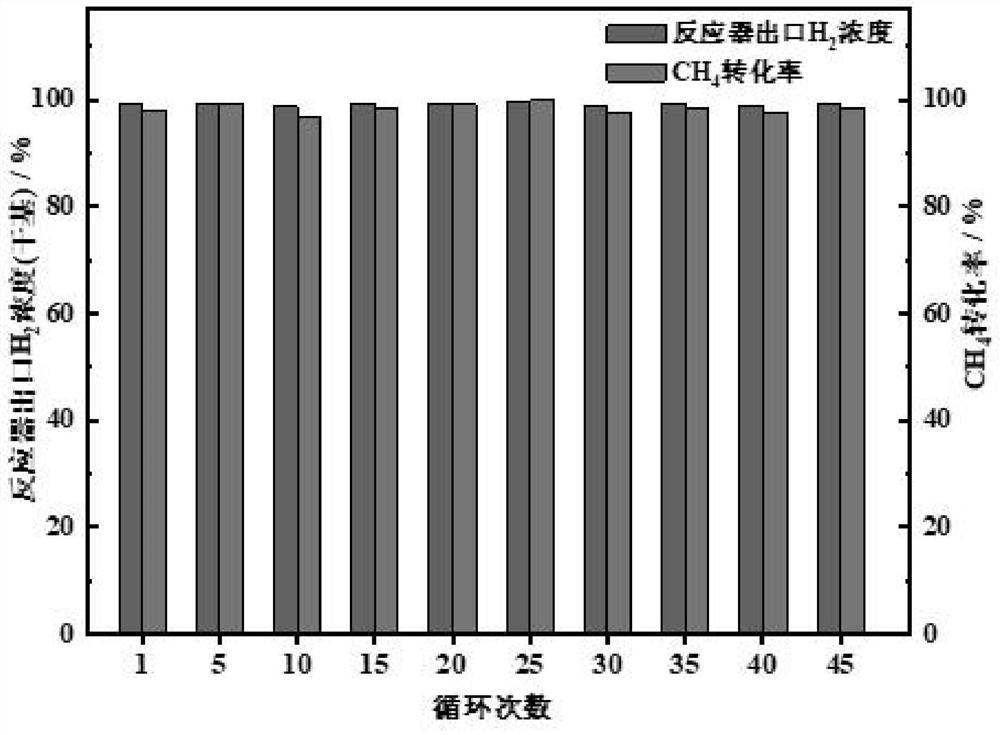

Oxygen carrier for chemical cycle dry gas reforming, and preparation method and application of oxygen carrier

ActiveCN105056955AEasy to prepareEase of industrial productionHydrogenMetal/metal-oxides/metal-hydroxide catalystsFiltrationRare earth

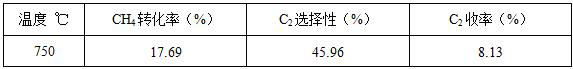

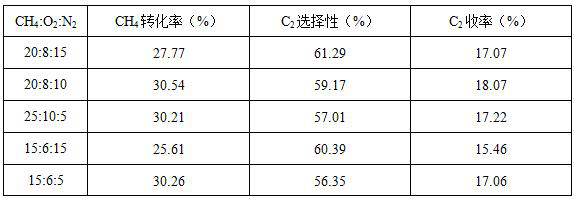

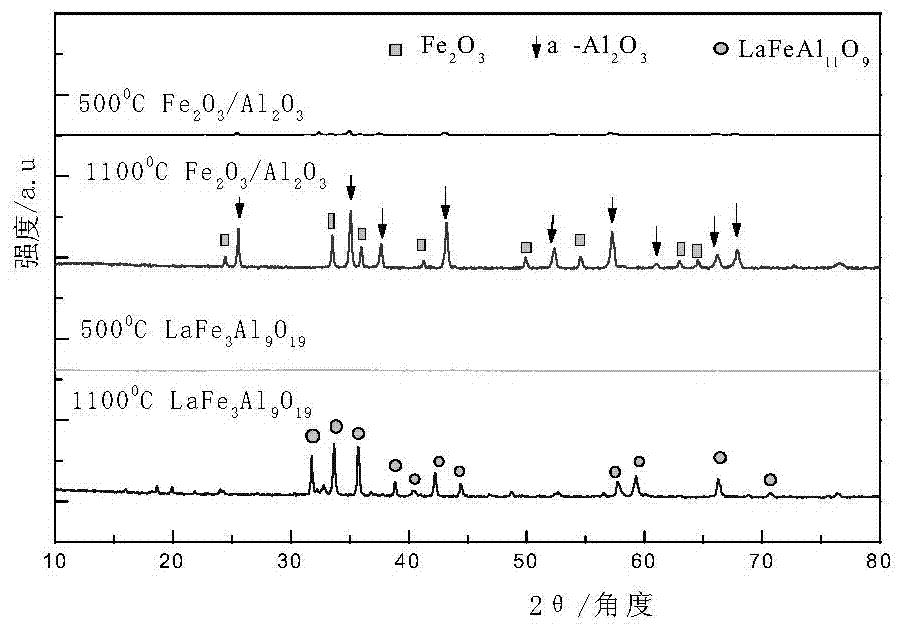

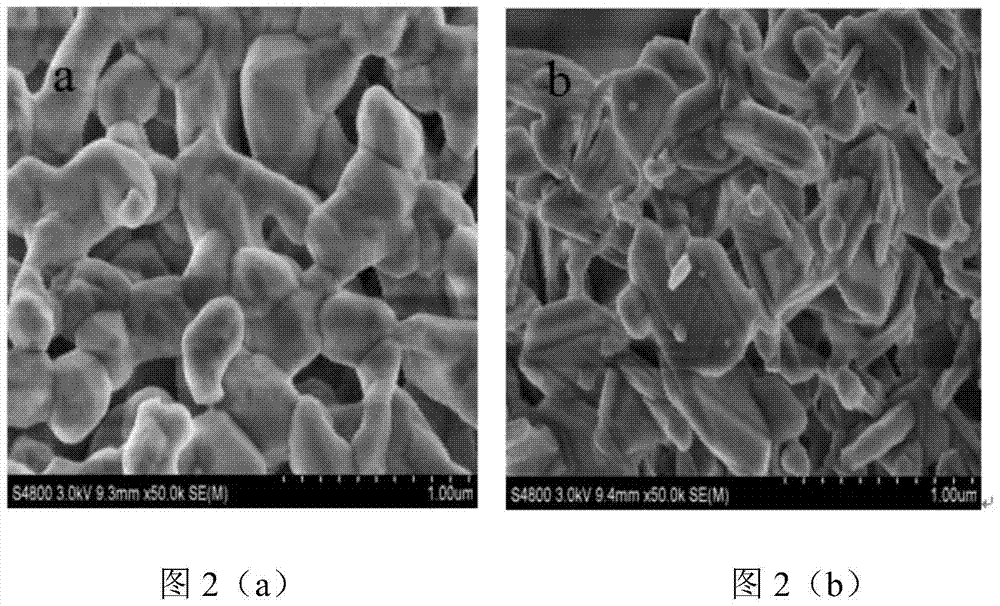

The invention provides an oxygen carrier for chemical looping dry gas reforming, and a preparation method and application of the oxygen carrier. The oxygen carrier is a composite metal oxide adopting a hexaaluminate structure, and has the general formula of AMxAl(12-x)O19, wherein A is rare earth metal lanthanum and / or barium, M is transition metal Fe, and x is greater than 0 or smaller than 5. The temperature of the oxygen carrier in a fuel reactor is 750-1000 DEG C, and the temperature of the oxygen carrier in an oxidation reactor is 750-1000 DEG C, and both of the reaction pressures are normal pressure. The preparation method comprises the following steps: using iron nitrate, aluminum nitrate, lanthanum nitrate and / or barium nitrate as a precursor to prepare a nitrate solution; adding ammonium carbonate as a precipitant for coprecipitation; performing suction filtration, washing, drying and roasting to obtain the oxygen carrier. The oxygen carrier has the advantages of being larger in oxygen-carrying rate, higher in reactivity, excellent in shock-resistant mechanical property and high temperature stability, environmental-friendly, low in cost and easy to prepare.

Owner:NORTHWEST UNIV(CN)

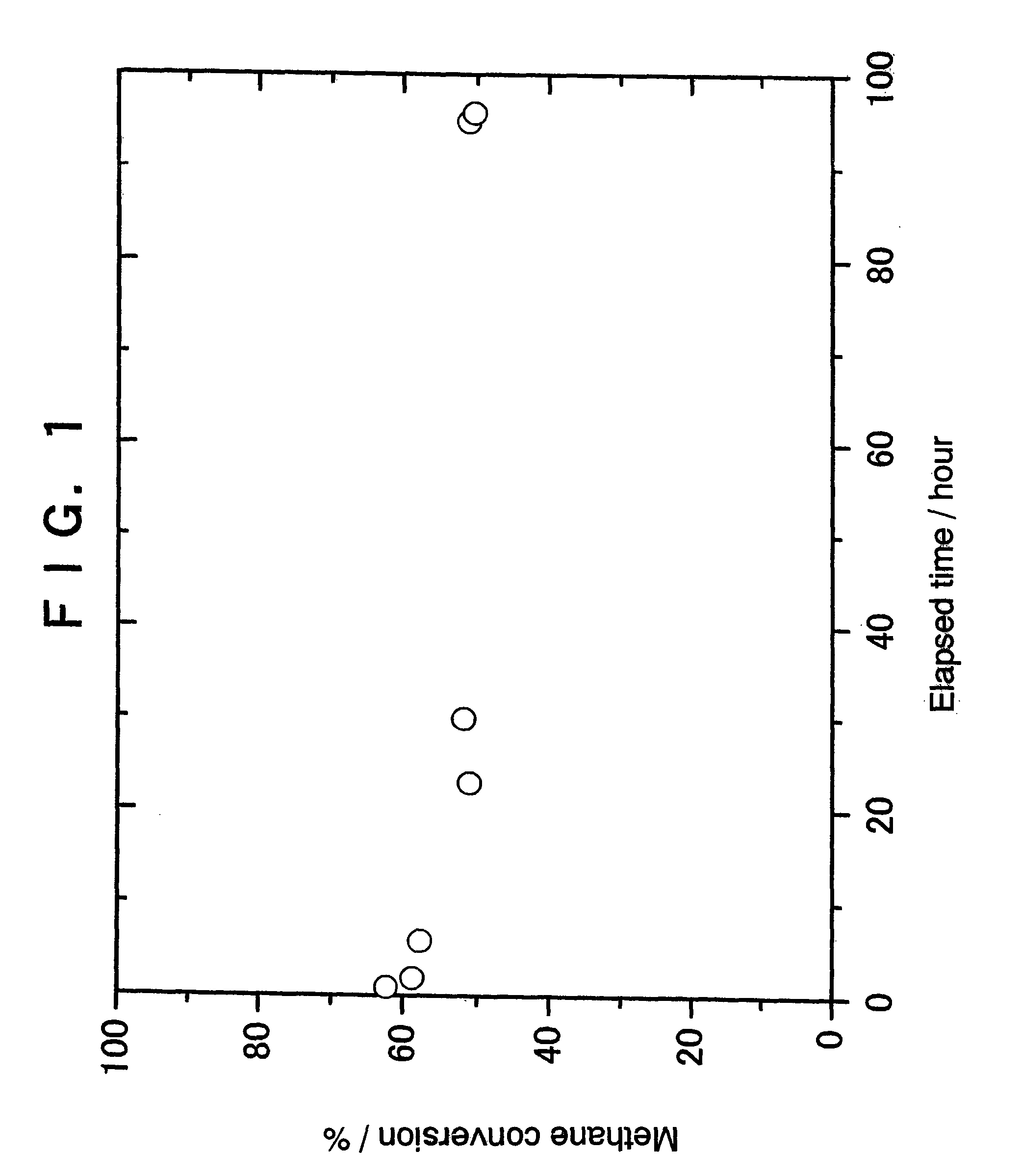

Nickel-based catalyst for obtaining synthetic gas through carbon dioxide reforming of methane and preparation method for nickel-based catalyst

ActiveCN102389801AHigh conversion rate of methaneExtend your lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to the technical field of catalysts for obtaining synthetic gas through carbon dioxide reforming of methane, and discloses a nickel-based catalyst for obtaining the synthetic gas through the carbon dioxide reforming of the methane and a preparation method for the nickel-based catalyst. The nickel-based catalyst for obtaining the synthetic gas through the carbon dioxide reforming of the methane consists of NiO, MgO and gamma-Al2O3. The preparation method comprises the following steps of: 1, preparing a mixed solution; and 2, preparing the nickel-based catalyst. Compared with the prior art, the method has the advantages that: the methane conversion rate of the nickel-based catalyst is greatly improved, the service life is also greatly prolonged, and the carbon deposition rate is greatly reduced; and the nickel-based catalyst is low in cost and has better economy.

Owner:XINJIANG UNIVERSITY

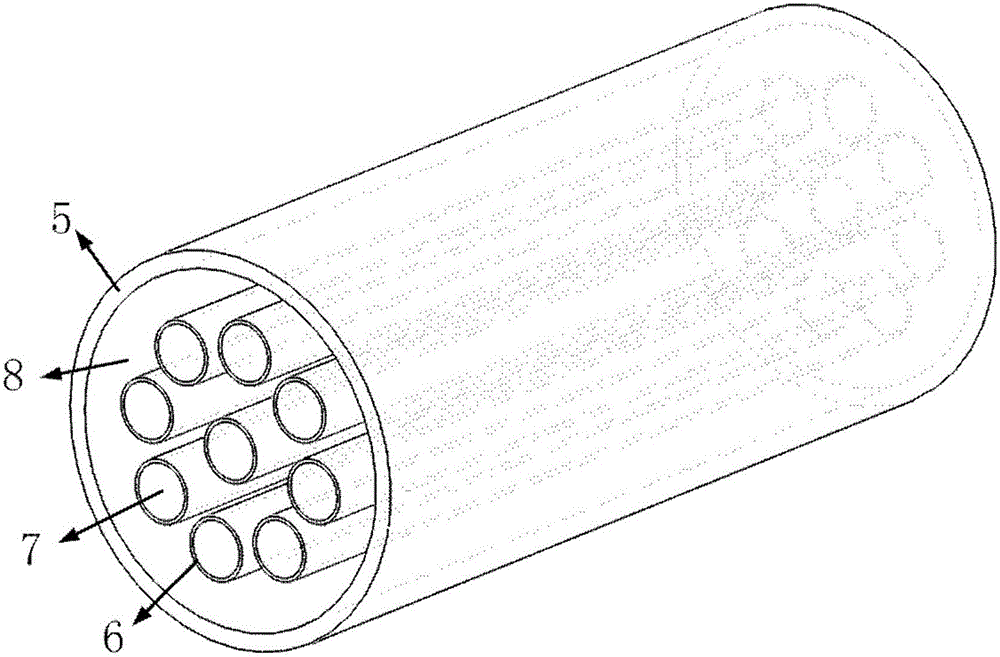

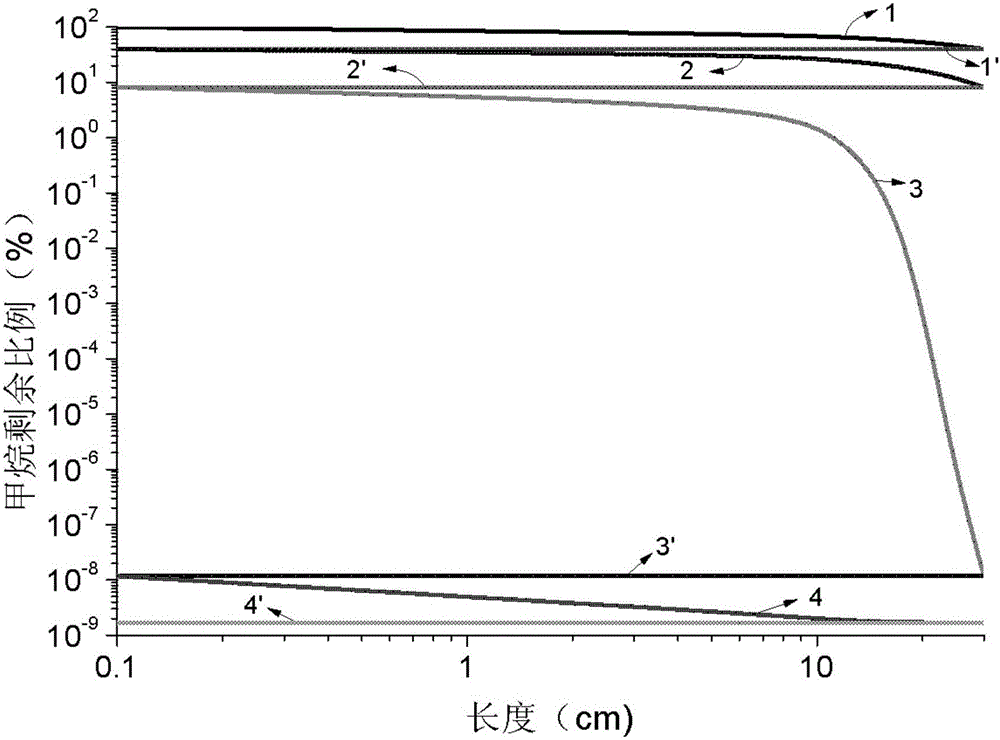

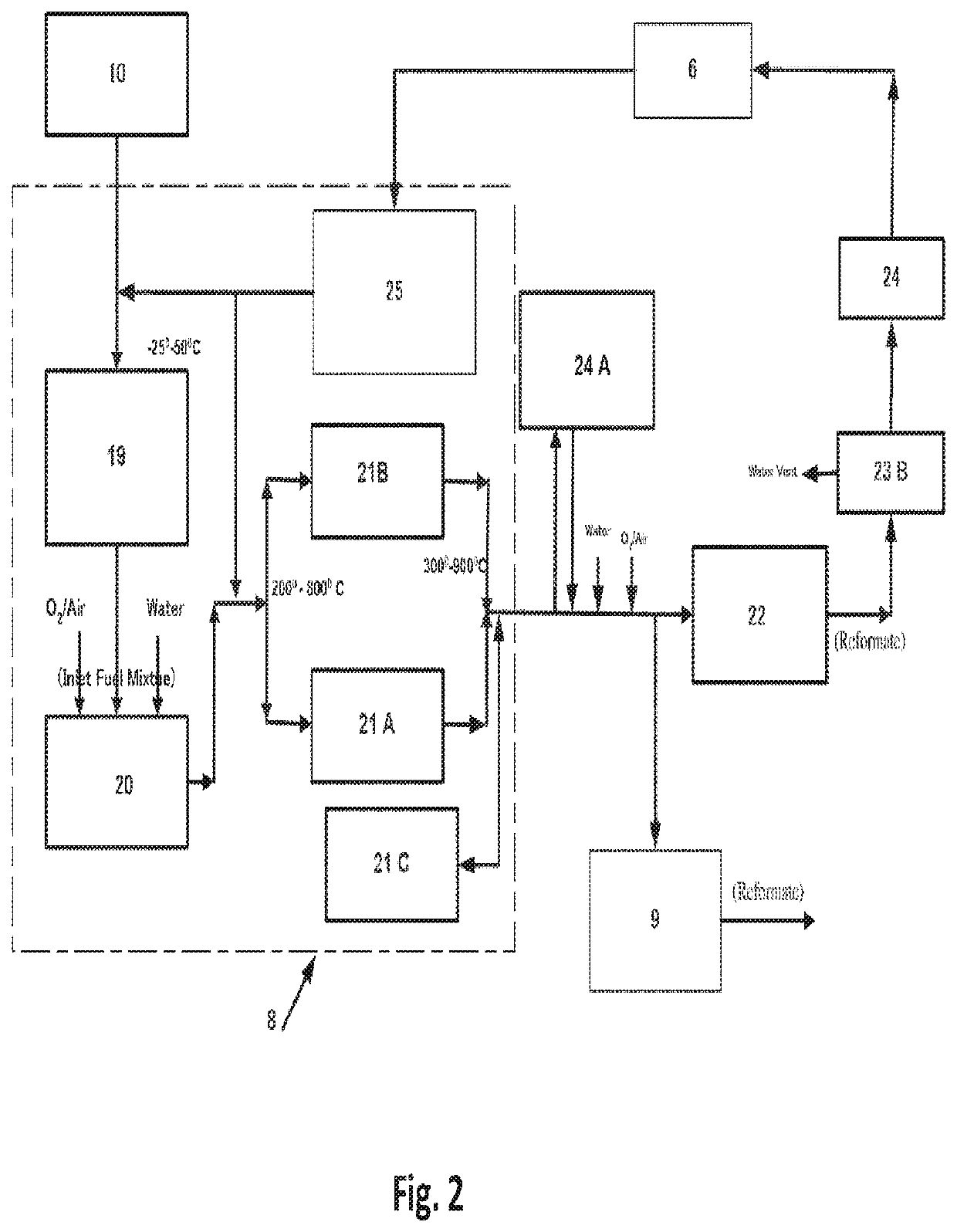

Methane reforming system

ActiveCN105776133AHigh conversion rate of methaneImprove energy utilizationHydrogenEnergy inputChemistryCarbon dioxide

The invention provides a methane reforming system.In the system, a methane and vapor pipeline passes through a hydrogen separation device and a carbon dioxide separation device in sequence in a circulating mode, hydrogen and carbon dioxide generated from wet reformation of methane are separated alternately to promote methane reformation reaction equilibrium to move to the forward direction, and then methane conversion rate is increased greatly compared with a one-time reaction conversion rate under the non-circulating condition.Besides, a heat exchanger is additionally arranged between the hydrogen separation device and the carbon dioxide device to recover lost heat generated by difference in operation temperatures of the hydrogen separation device and the carbon dioxide separation device, so that the energy utilization rate of the system is increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Catalyzer for preparing synthetic gas from natural gas partial oxidation and its preparation method

InactiveCN1544311AHigh conversion rate of methaneHigh selectivityHydrogenCatalyst activation/preparationPartial oxidationRare earth

A catalyst for synthetic gas preparation through partial natural gas oxidation, whose percentage by weight is nickel oxide 6-25%, rare-earth oxide 0-6%, silicon carbide 69-94%, they catalyst is prepared through the steps of, dissolving soluble metallic nickel salt or the mixture of metallic nickel salt and rare-earth metal salt into distilled water or ethanol solvent, immersing the silicon carbide with high specific surface area into the solution, wherein metal salt is deposited on the carbonization silicon face, and catalyst is obtained through roasting.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

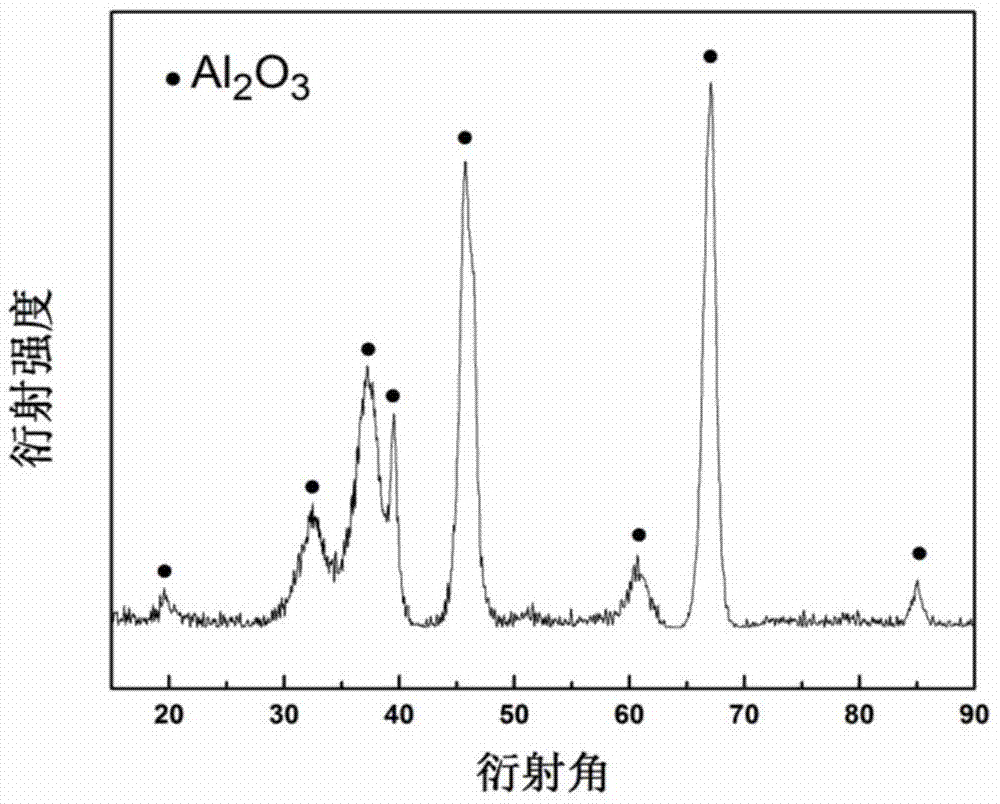

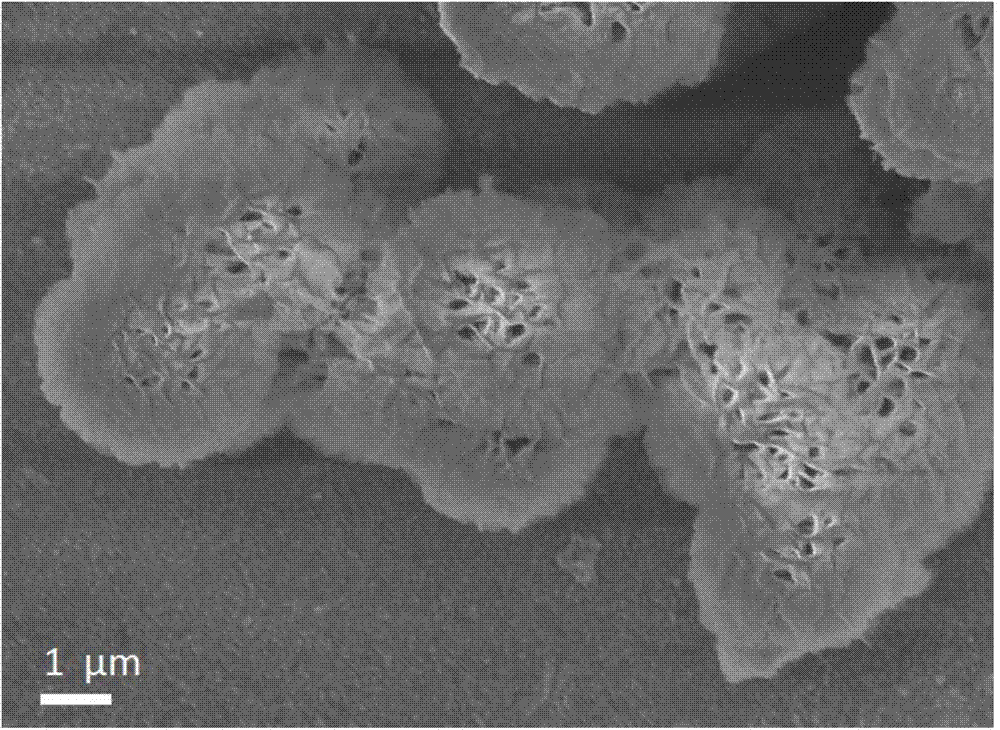

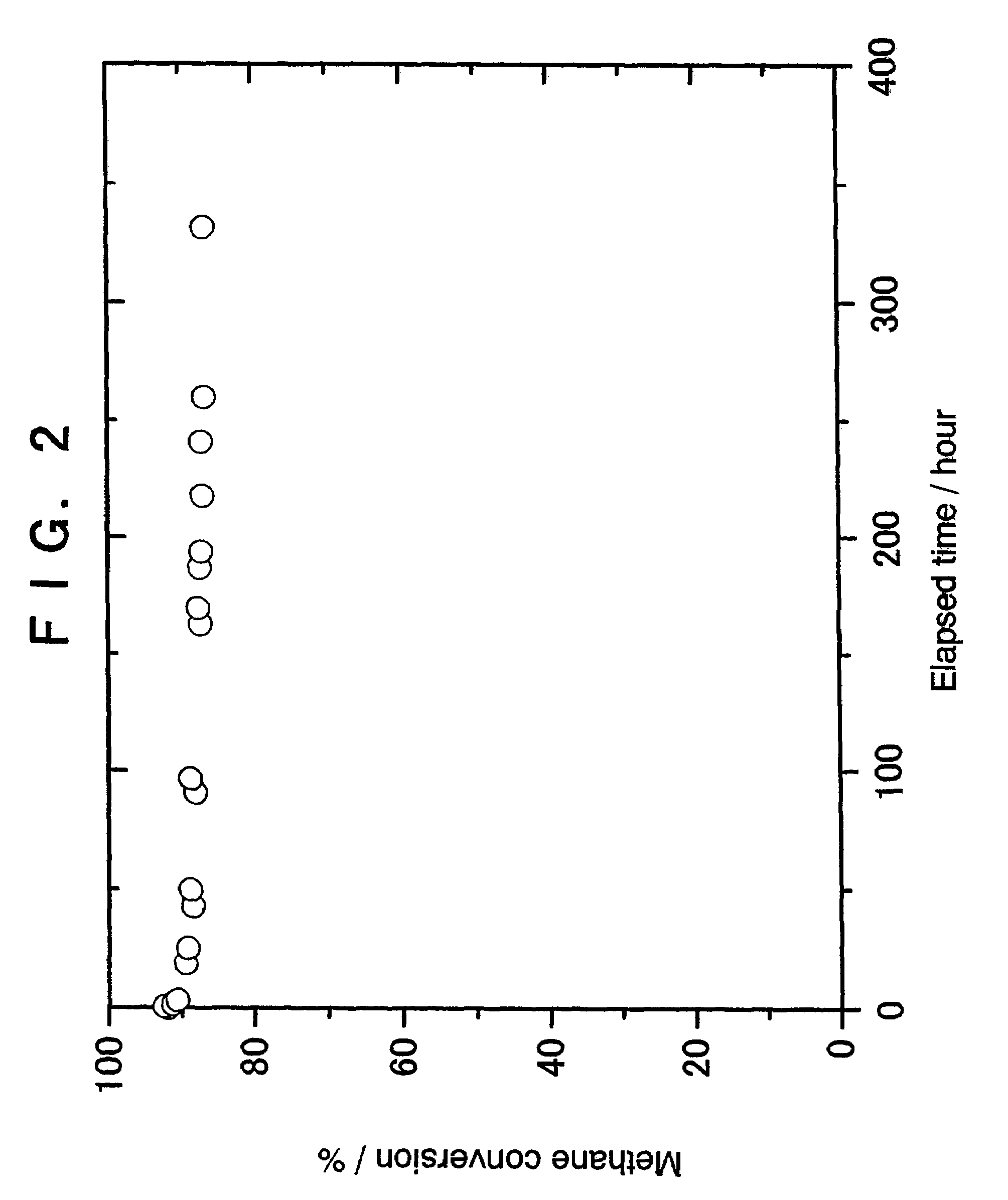

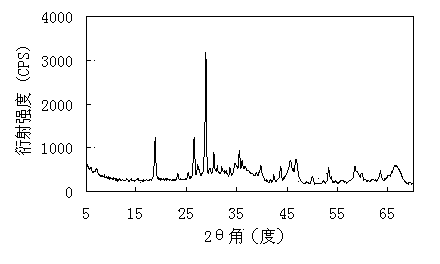

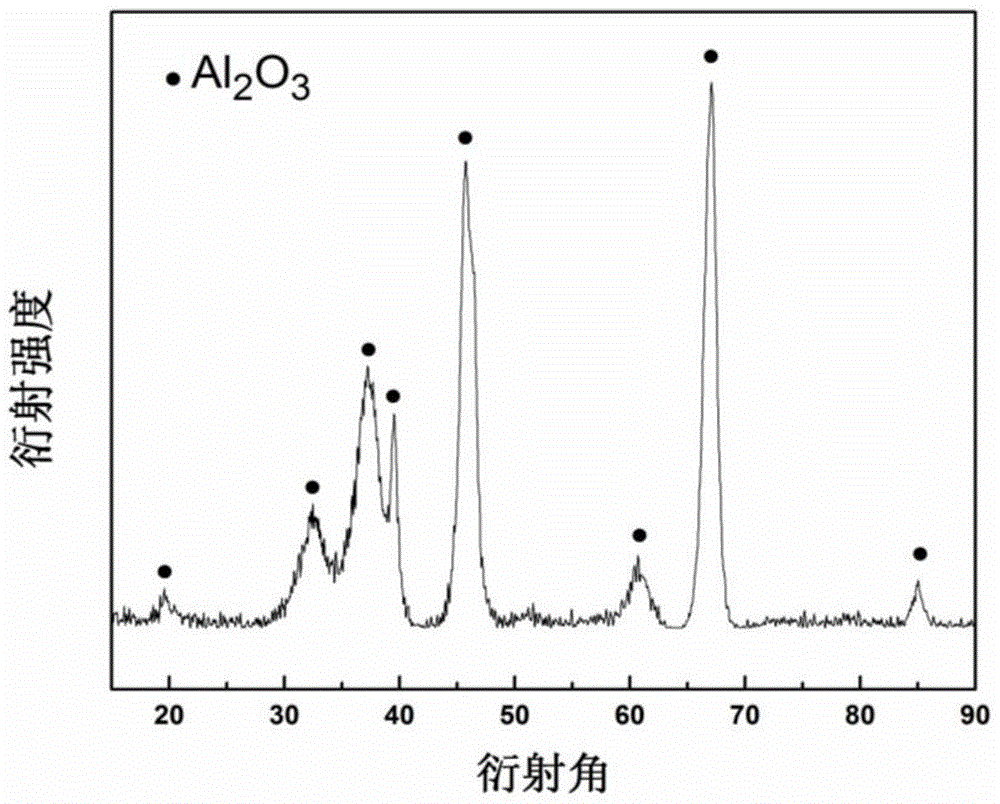

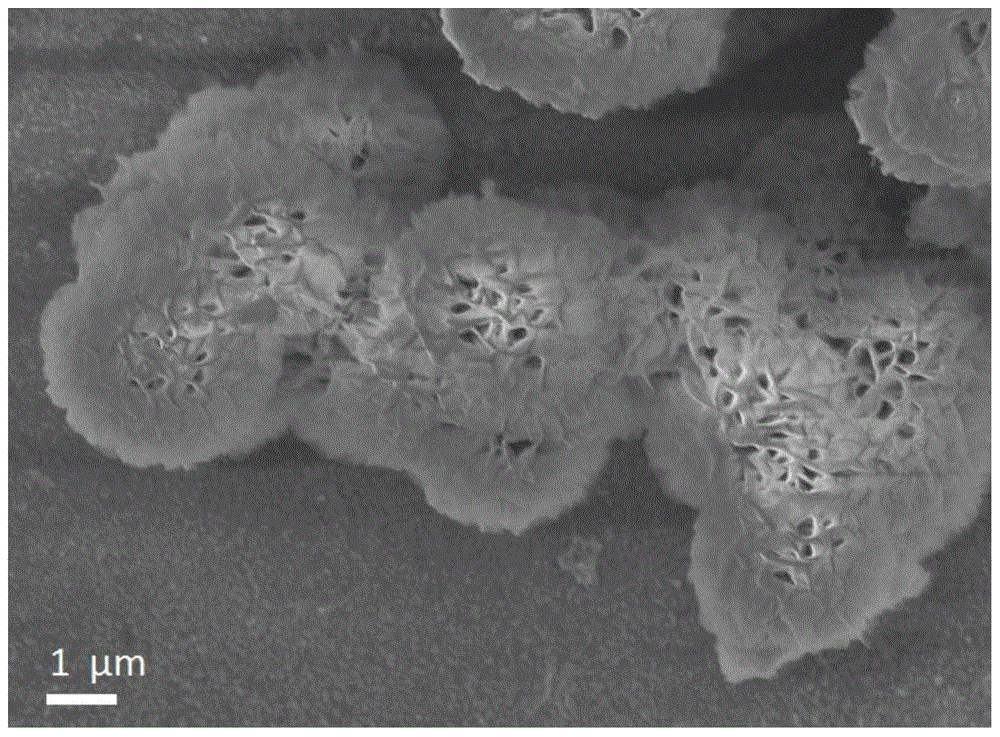

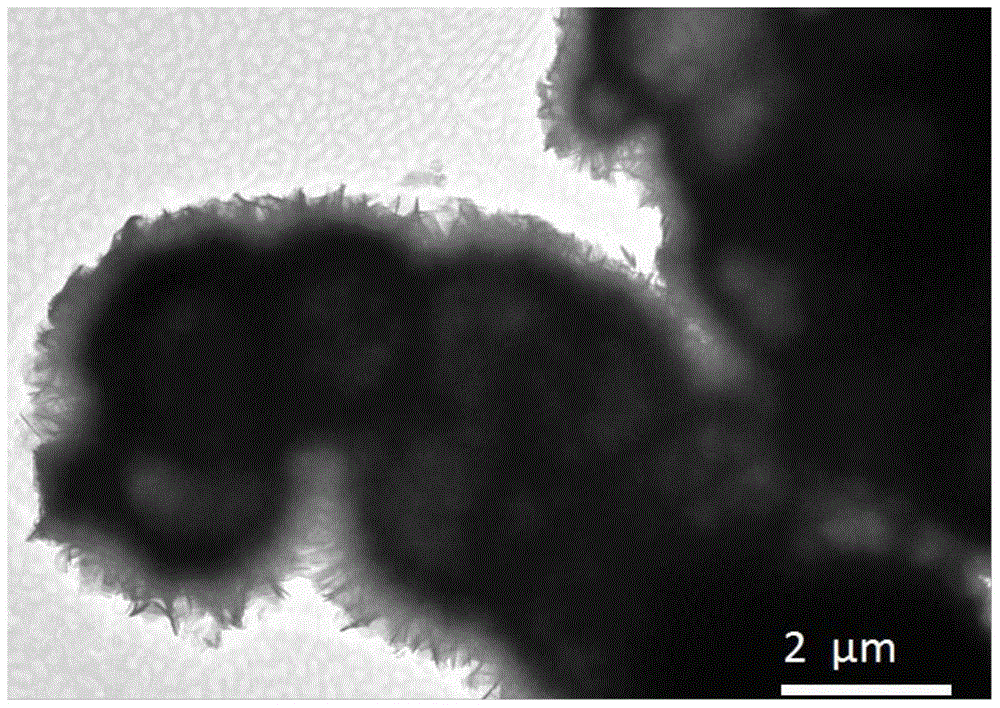

Gamma-aluminium oxide nanometer material and preparation method of nickel/gamma-aluminium oxide catalyst

ActiveCN104709932ALow equipment requirementsCheap and easy to getMetal/metal-oxides/metal-hydroxide catalystsAluminium oxides/hydroxidesNickel saltSynthesis methods

The invention discloses a synthesis method for a gamma-aluminium oxide nanometer material. The synthesis method comprises the following steps: at room temperature, adding alum and carbamide into deionized water, cooling, centrifugating and washing the sediment after the hydrothermal reaction; calcining the dried hydrothermal products to obtain the gamma-aluminium oxide nanometer material. The gamma-aluminium oxide nanometer material prepared by adopting the synthesis method has a relatively high specific surface area and a certain pore structure. The invention further provides a method for prepare a nickel / gamma-aluminium oxide catalyst by adopting the gamma-aluminium oxide nanometer material obtained by adopting the synthesis method as the raw material. The method comprises the following steps: impregnating the gamma-aluminium oxide nanometer material into a nickel salt solution in the appropriate concentration, carrying out magnetic stirring till the solvent evaporates; collecting the dried impregnating products and grinding into powders, and carrying out heating reduction in the reducing atmosphere to obtain the nickel / gamma-aluminium oxide catalyst. The catalyst can be used for catalyzing the methane dry-process reforming reaction, has a relatively high methane conversion rate, and can still maintain excellent stability and carbon formation resistance in the long-term catalytic reaction under high temperature.

Owner:SHANGHAI JIAO TONG UNIV

Process and Catalyst for Methane Conversion to Aromatics

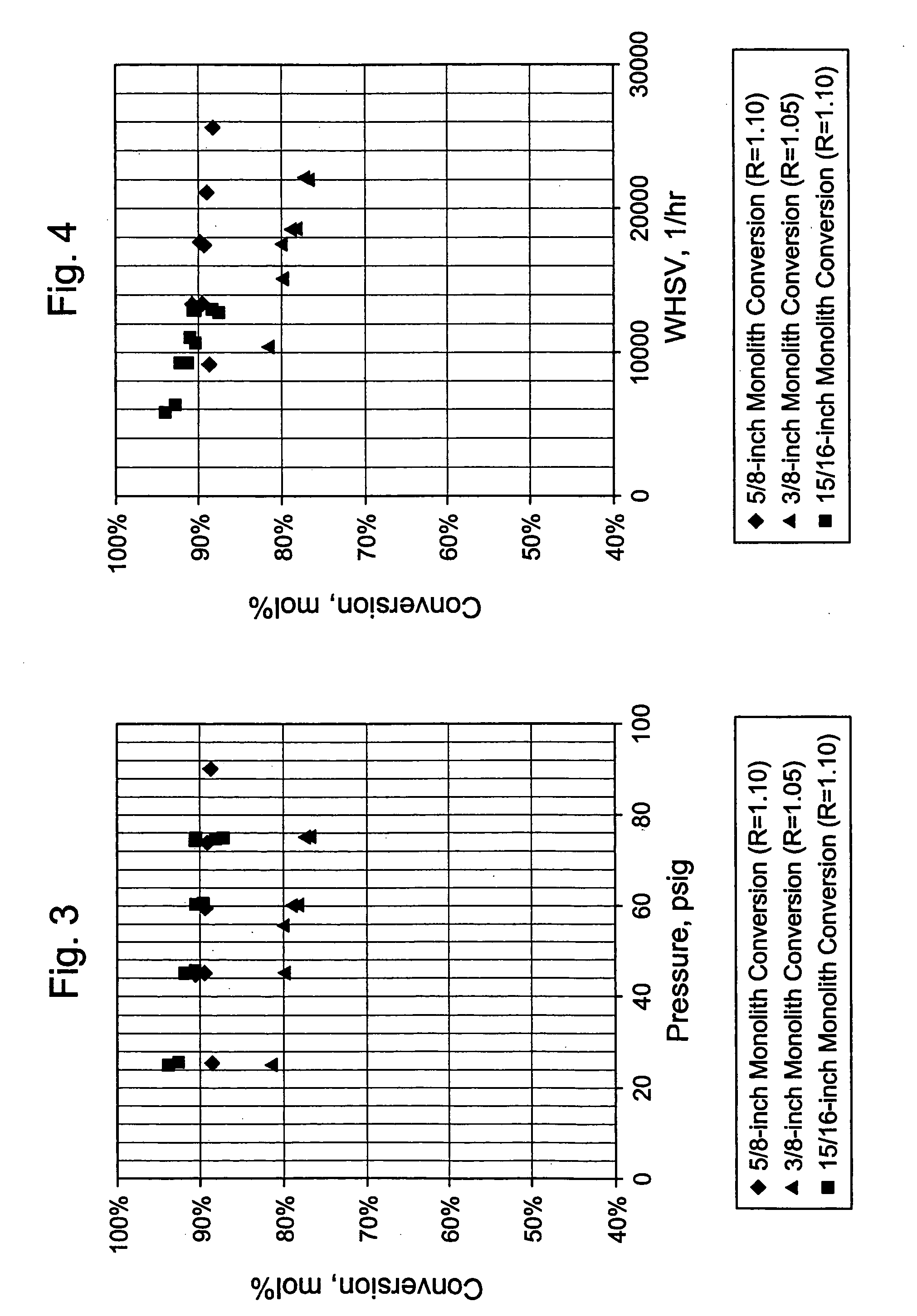

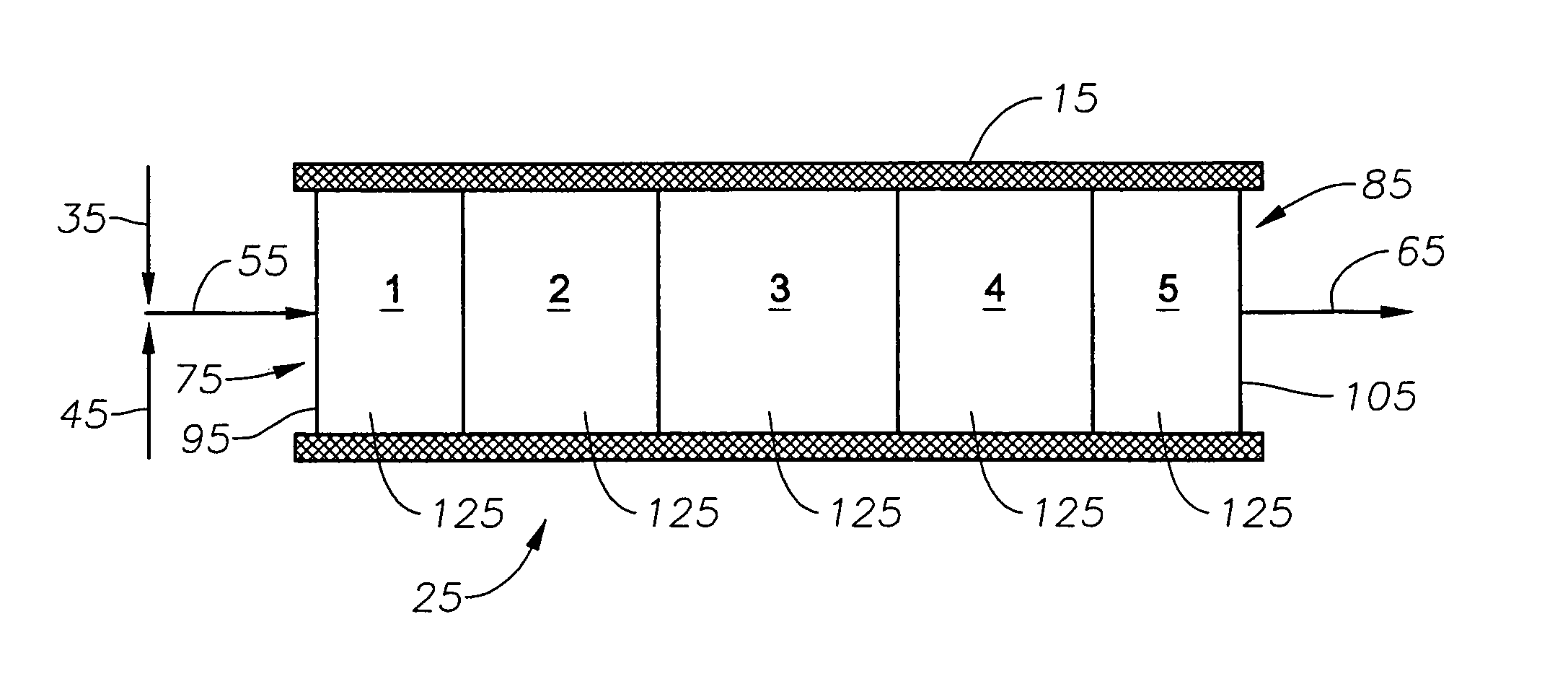

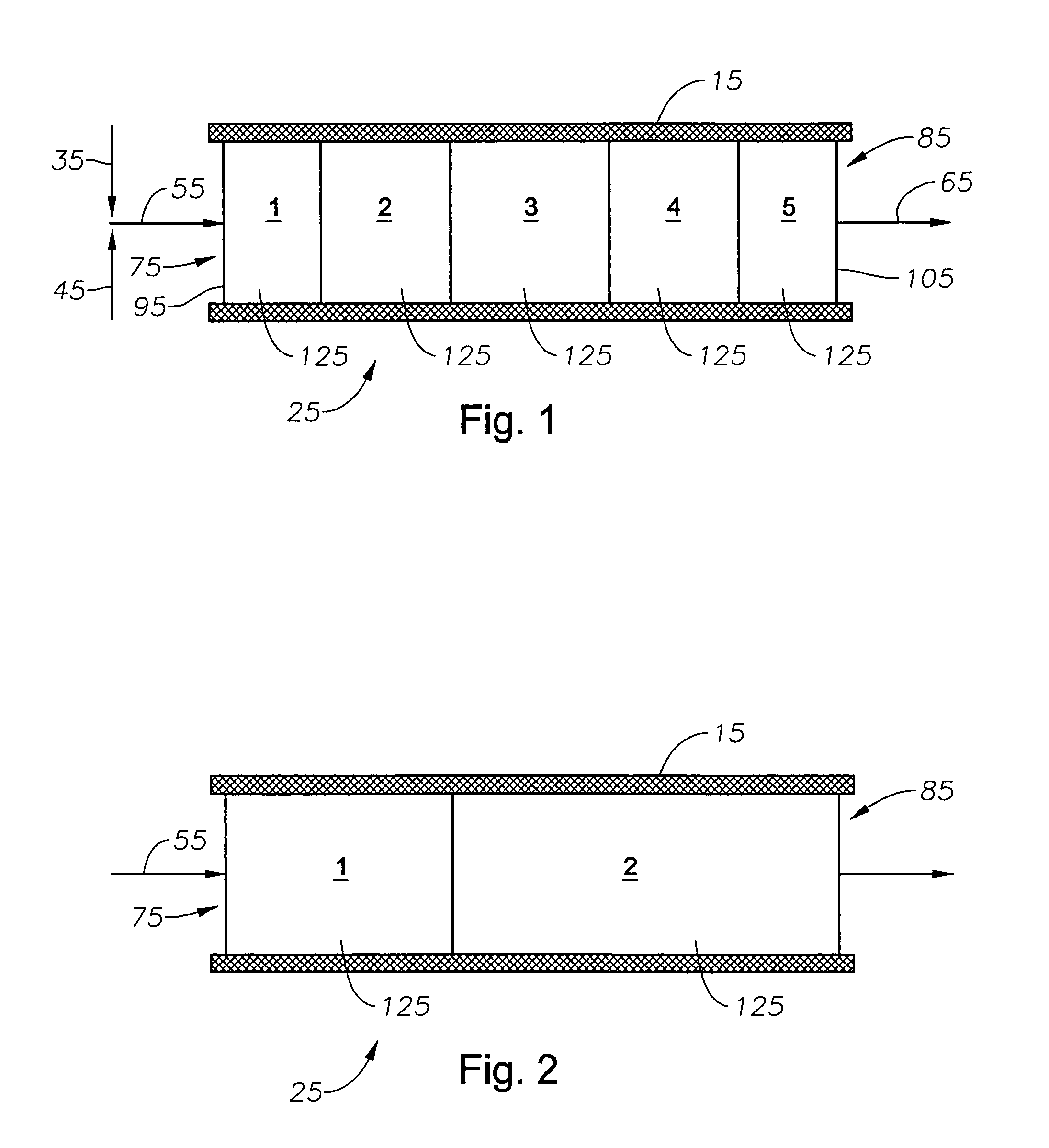

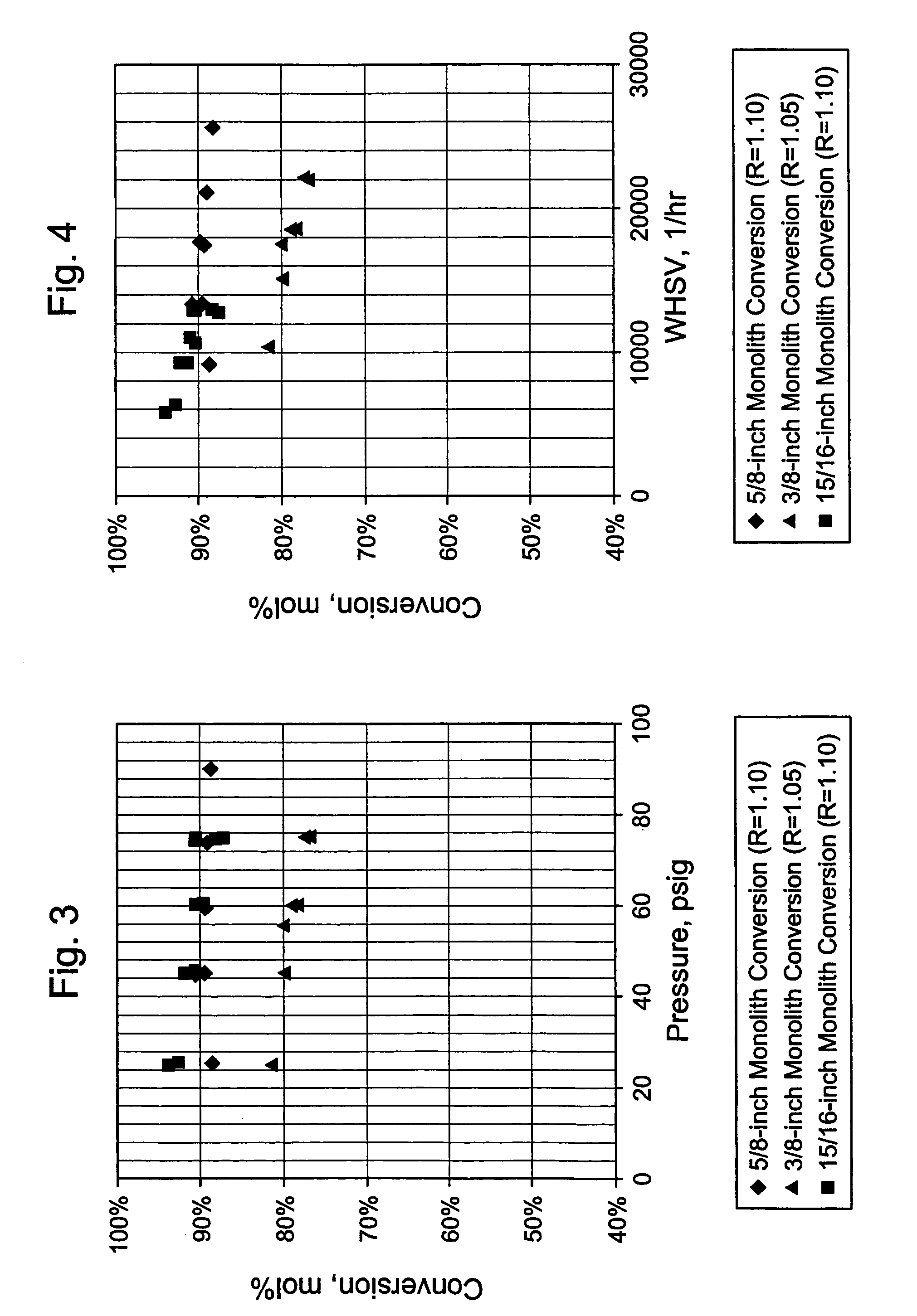

ActiveUS20160023962A1Reduce the amount of solutionHigh Aromatics YieldMolecular sieve catalystsMolecular sieve catalystAromatizationOxidative coupling of methane

A process and catalyst for use therein for the production of aromatics via the oxidative coupling of methane and methane co-aromatization with higher hydrocarbons in a single reaction stage. First, methane is partially converted to ethane and ethylene on an OCM catalyst component, and the OCM intermediate mixture containing methane, ethane and ethylene is subsequently converted into aromatics on an aromatization catalyst component. The reaction may be conducted at 550-850° C. and at about 50 psig. The claimed process and catalyst used therein achieves high methane conversion at lower temperatures (less than 800° C.), higher methane conversion into the aromatic products and significant reductions in production cost when compared to the traditional two (or more) step processes.

Owner:EXXONMOBIL CHEM PAT INC

Catalyst for purifying methane-containing waste gas and method of purifying methane-containing waste gas

This invention provides a catalyst for removing hydrocarbons from a combustion gas containing methane and containing an excess of oxygen, which comprises iridium supported on zirconium oxide; and a method of removing hydrocarbons from a combustion gas containing methane and containing an excess of oxygen, which comprises using this catalyst.

Owner:OSAKA GAS CO LTD

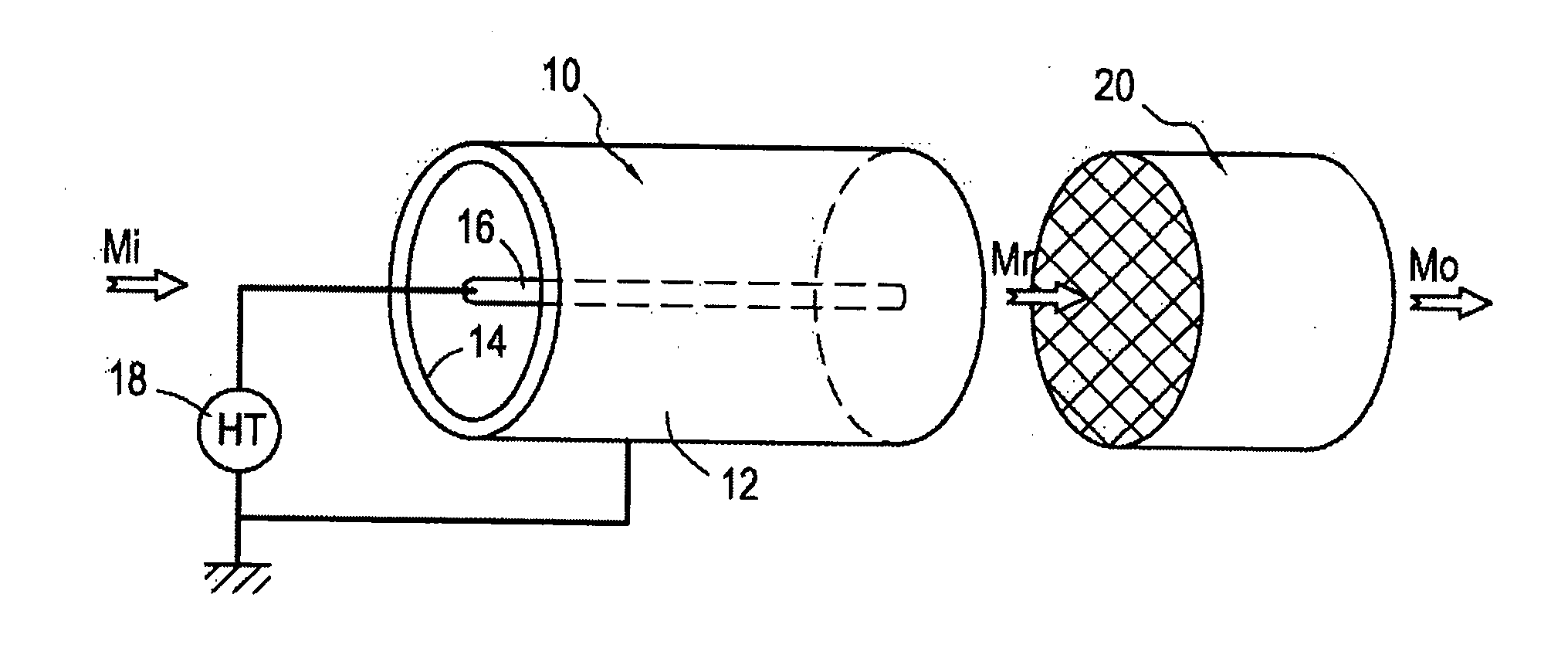

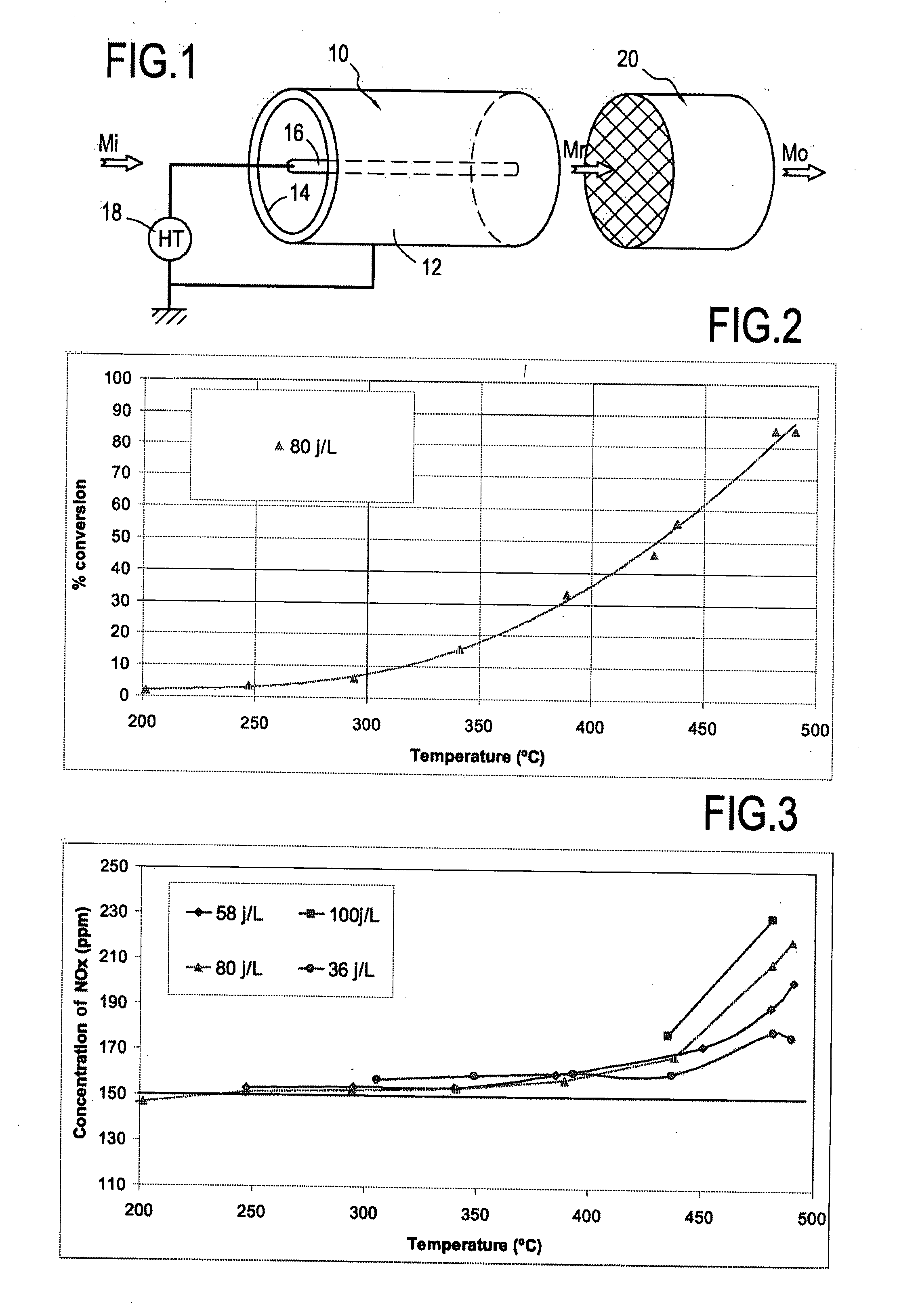

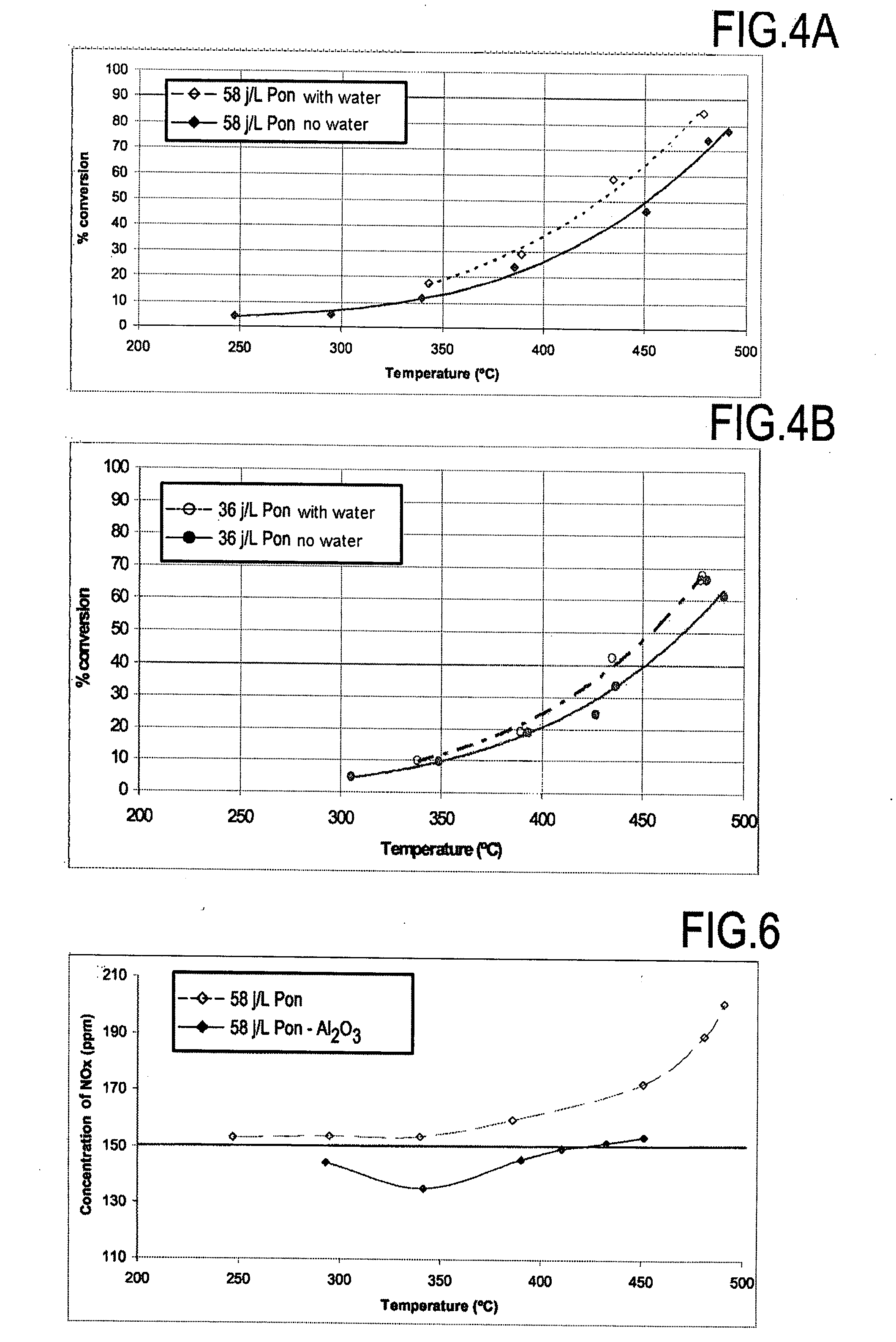

Method of treating unburnt methane by oxidation by plasma

InactiveUS20080173534A1Improve conversion rateHigh conversion rate of methaneGas treatmentDispersed particle separationVolumetric Mass DensityHigh pressure

A method of treating a methane residue in a gas mixture at a temperature lying in the range 200° C. to 500° C. and including at least methane at a concentration lying in the range 50 ppm to 2500 ppm and oxygen at a concentration lying in the range 0.5% to 12% by volume. According to the invention, the methane residue is treated by a plasma having energy density lying in the range 15 J / L to 100 J / L generated in a plasma reactor by applying a high voltage electrical signal between an internal electrode and an external electrode of the plasma reactor, the external electrode being cylindrical in shape and surrounding the internal electrode, and at least one of the electrodes being covered in a dielectric material to create a dielectric barrier discharge in the gas mixture and convert part of the methane residue into carbon monoxide.

Owner:GDF SUEZ SA +1

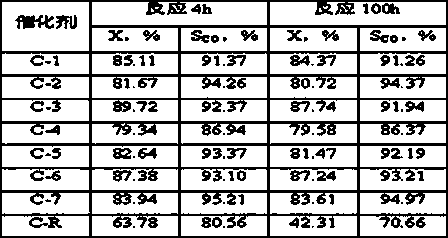

NiO/gamma-Al2O3 catalyst of methane and carbon dioxide reforming synthesis gas and method for preparing NiO/gamma-Al2O3 catalyst of methane and carbon dioxide reforming synthesis gas

ActiveCN102974353AHigh conversion rate of methaneHigh hydrogen selectivityHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystHydrogen selectivity

The invention relates to the technical field of catalysts of a synthesis gas which is obtained through reforming methane and carbon dioxide, and in particular relates to a NiO / gamma-Al2O3 catalyst of a methane and carbon dioxide reforming synthesis gas and a method for preparing the NiO / gamma-Al2O3 catalyst of the methane and carbon dioxide reforming synthesis gas. The NiO / gamma-Al2O3 catalyst of the methane and carbon dioxide reforming synthesis gas is prepared through the following step that: step 1, 8-9 parts of nickel nitrate hexahydrate and 10 parts of gamma-aluminium oxide are respectively weighed by weight. Compared with a conventional method for producing a NiO / gamma-Al2O3 catalyst, the method has a simple and convenient operating process, the NiO / gamma-Al2O3 catalyst which is produced through adopting the method has the characteristics of high methane conversion rate, high hydrogen selectivity and long service life of the catalyst; and moreover, the produced NiO / gamma-Al2O3 catalyst is low in use cost and has good economy.

Owner:XINJIANG UNIVERSITY

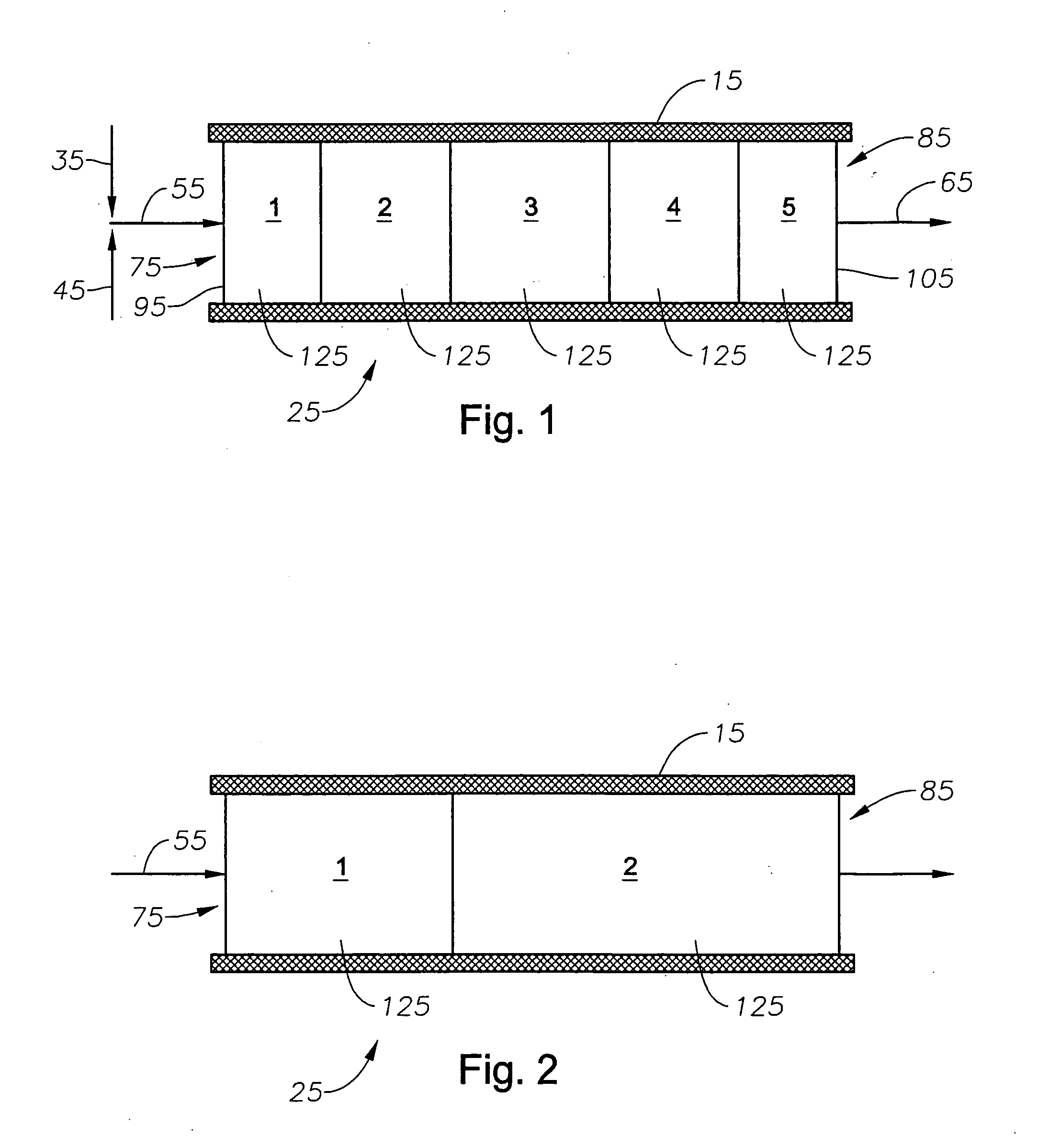

Catalyst system for enhanced flow syngas production

ActiveUS20050181939A1Increase conversionsHigh selectivityCatalytic gas-gas reactionHydrogenSyngasOxygen

Owner:PHILLIPS 66 CO

Catalyst system for enhanced flow syngas production

ActiveUS7922977B2Increase conversionsHigh selectivityCombination devicesExhaust apparatusSyngasProduct gas

A method and apparatus for converting a hydrocarbon and oxygen containing gas feed stream to a product stream, such as syngas, including catalytically partially oxidizing the hydrocarbon feed stream over a catalyst bed. The catalyst bed has a downstream zone which is less resistant to flow than the upstream zone.

Owner:PHILLIPS 66 CO

Method for preparing methyl alcohol, formaldehyde and CO used for methane direct selective oxidation

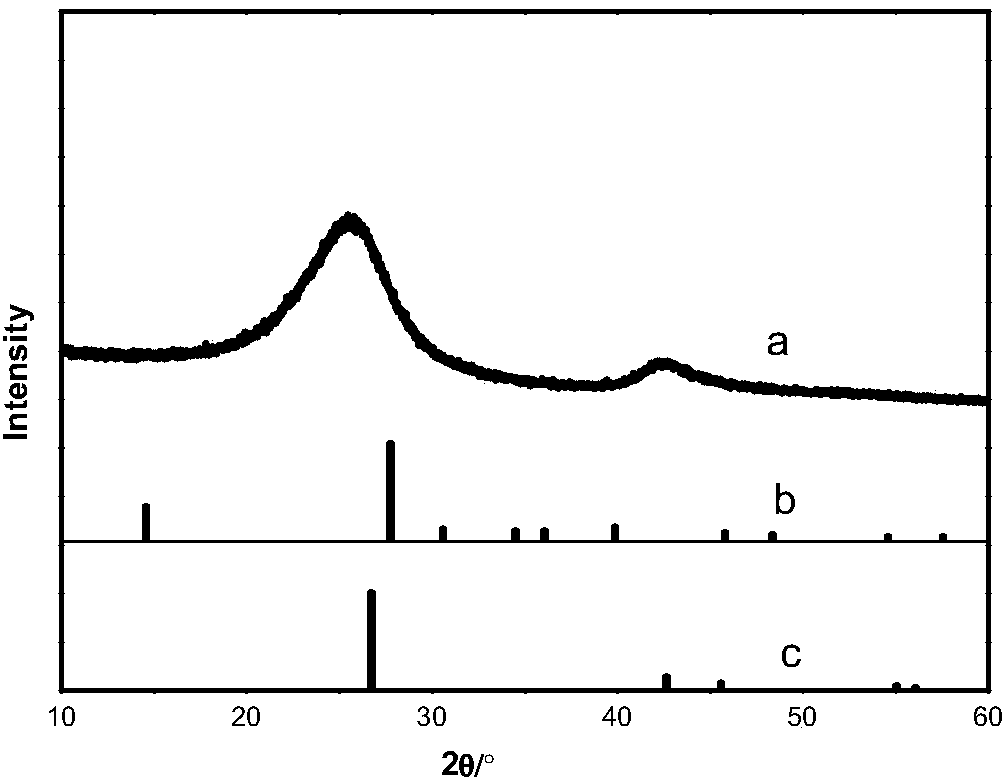

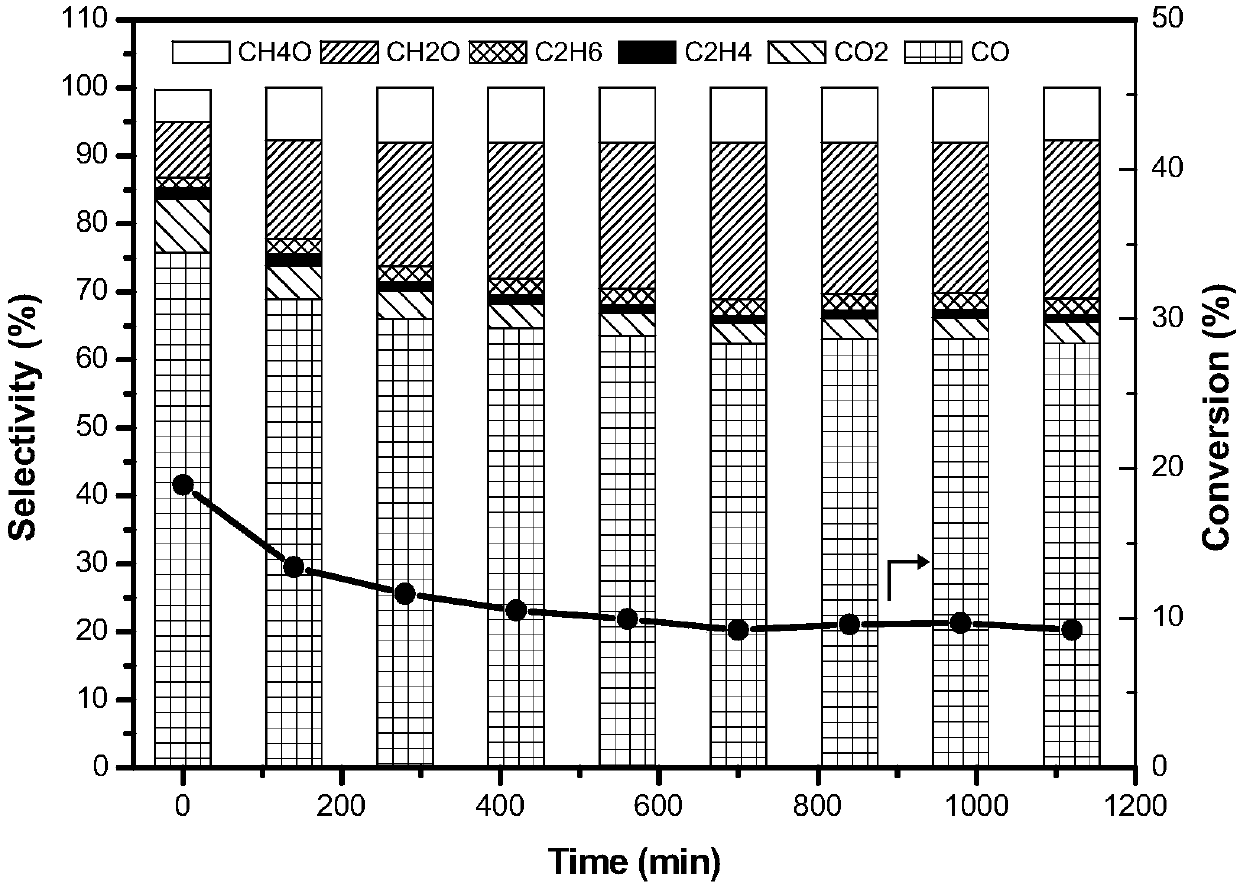

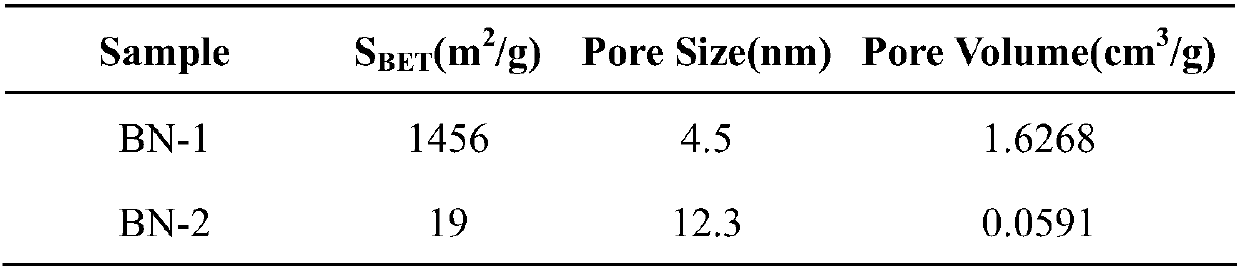

ActiveCN107739297ALow costImprove reaction stabilityPreparation by oxidation reactionsPhysical/chemical process catalystsReaction temperatureContinuous flow

The invention discloses a method for preparing methyl alcohol, formaldehyde and CO used for methane direct selective oxidation. The method comprises the following steps: preparing a BN powder materialcatalyst, after mixing boric acid with urea, dissolving and stirring with a water and methyl alcohol mixed solvent, carrying out thermostatic waterbath standing for crystallization, and roasting under an inert atmosphere to obtain a BN powder material; tabletting and forming a roasted sample, smashing and sieving to obtain a BN powder material catalyst; catalyst activation: introducing oxygen-containing gas into a continuous flow reactor filled with the BN powder material catalyst for heating, activating, introducing inert gas, adjusting to a reaction temperature, and switching into a reaction gas; and preparing methyl alcohol, formaldehyde and CO.

Owner:XIAMEN UNIV

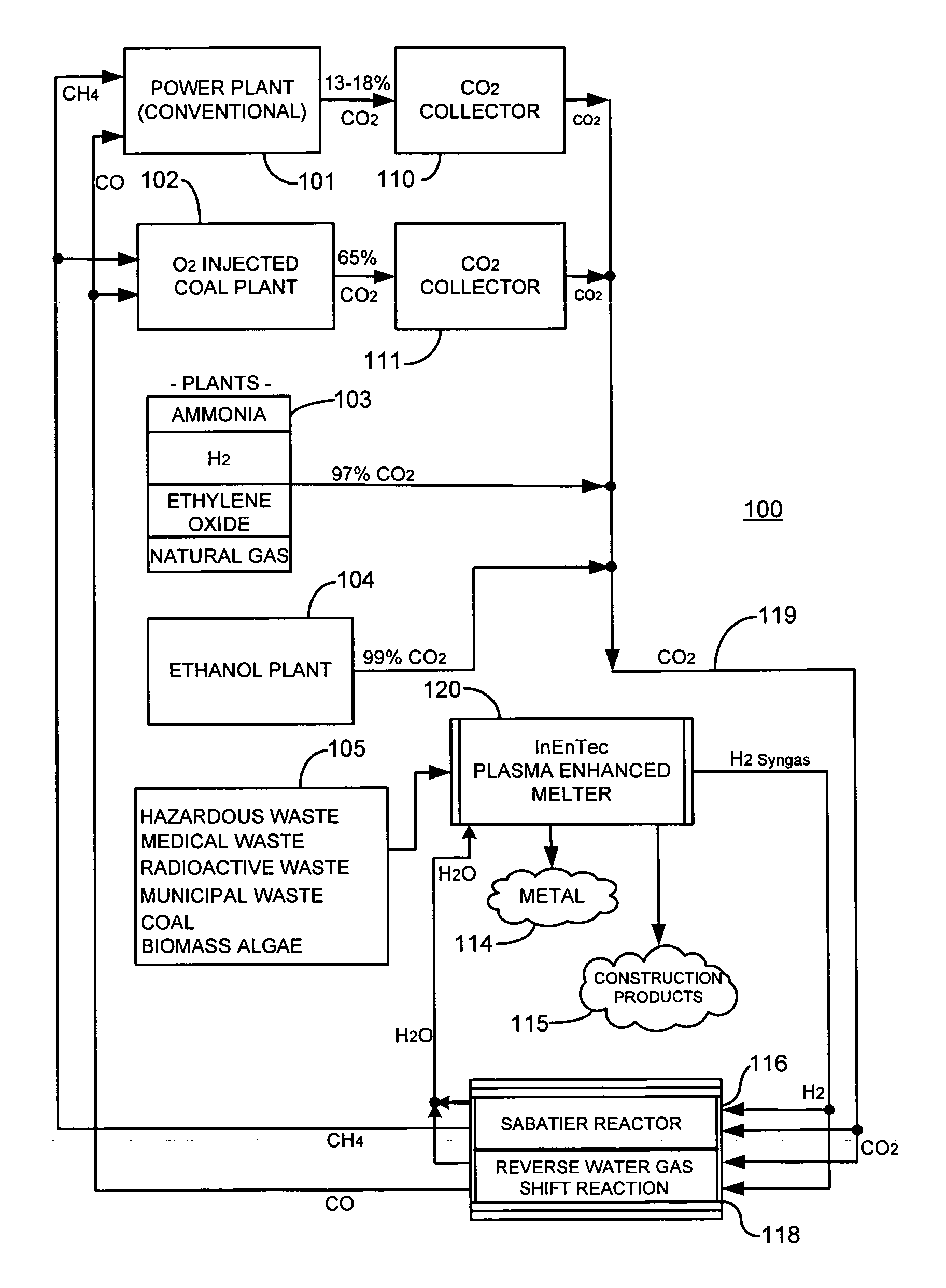

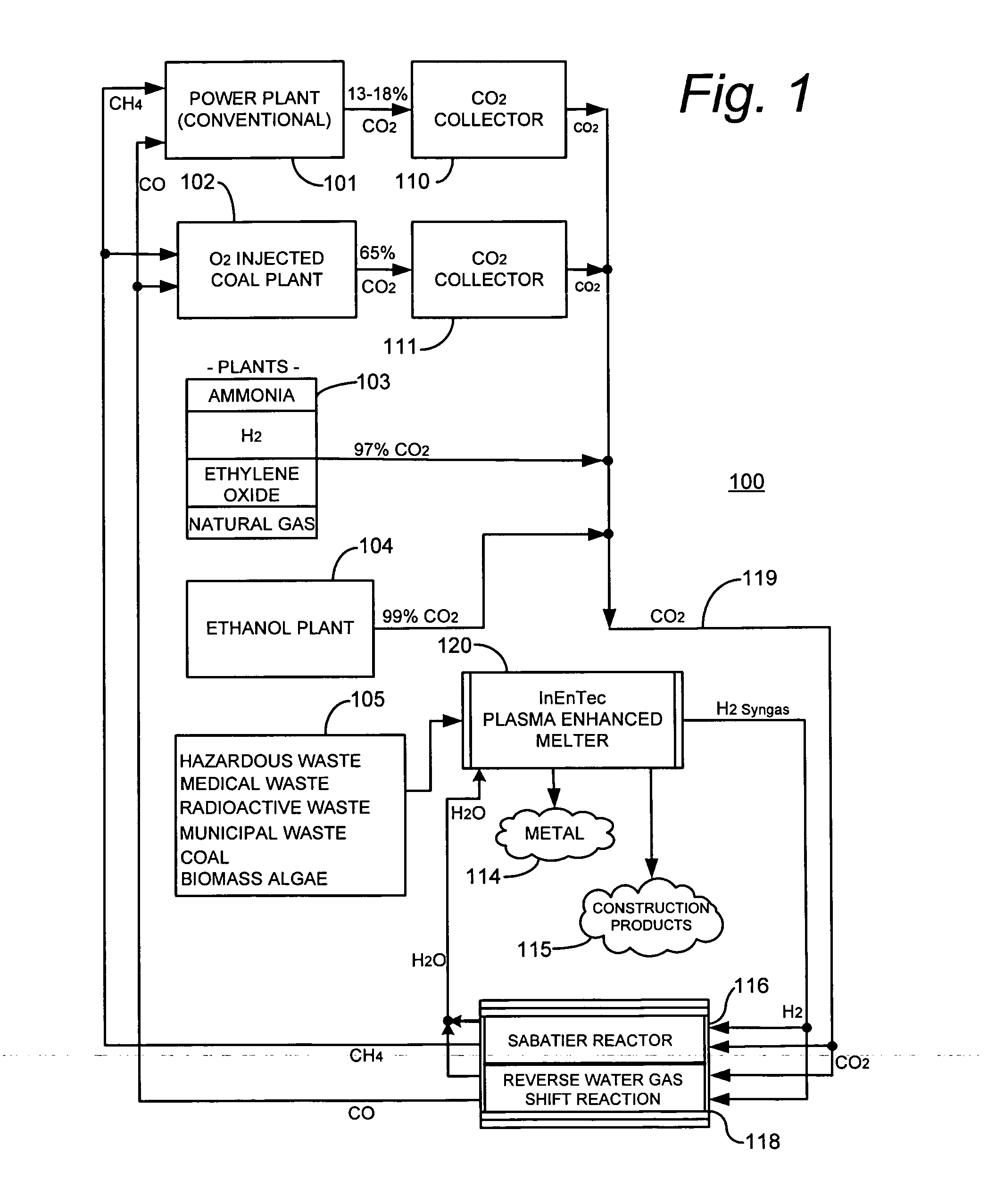

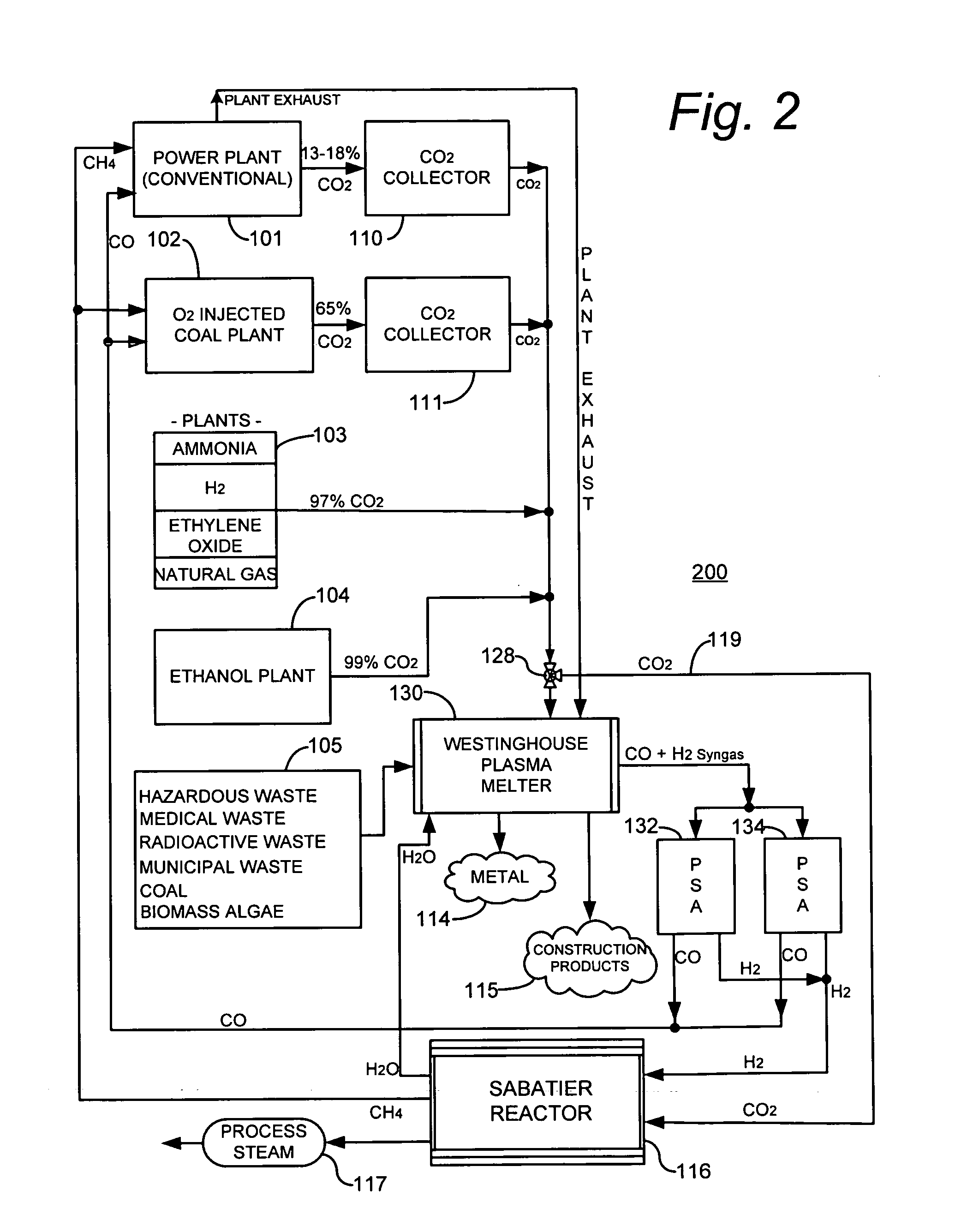

Recyling and reburning carbon dioxide in an energy efficient way

InactiveUS20110250100A1High conversion rate of methaneEasy to disassembleProductsReagentsSyngasCarbon footprint

A system for converting carbon dioxide into a fuel to be re-burned in an industrial process. The preferred feed stocks are taken from large volume carbon dioxide producers, and municipal waste. The reaction and processes reclaim lost energy in municipal waste, and industrial exhaust gas. The system is provided with a plasma melter having a feedstock input for receiving a feed fuel, and a syngas output for producing a syngas having an H2 component. Additionally, a Sabatier reactor is provided having a hydrogen input for receiving at least a portion of the H2 component produced by the plasma melter, and a methane output for producing CH4. The process has a large negative carbon footprint.

Owner:JURANITCH JAMES CHARLES

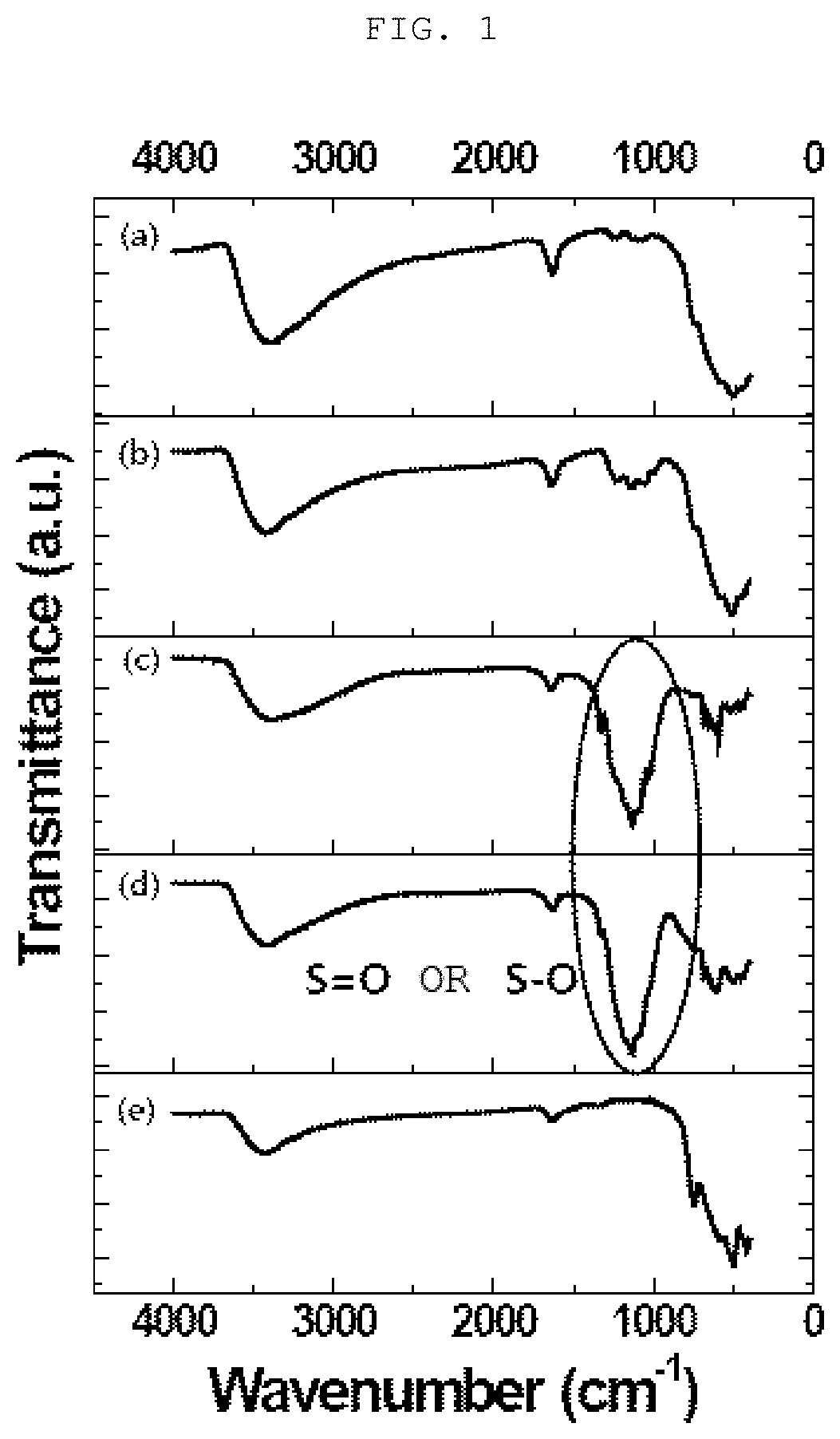

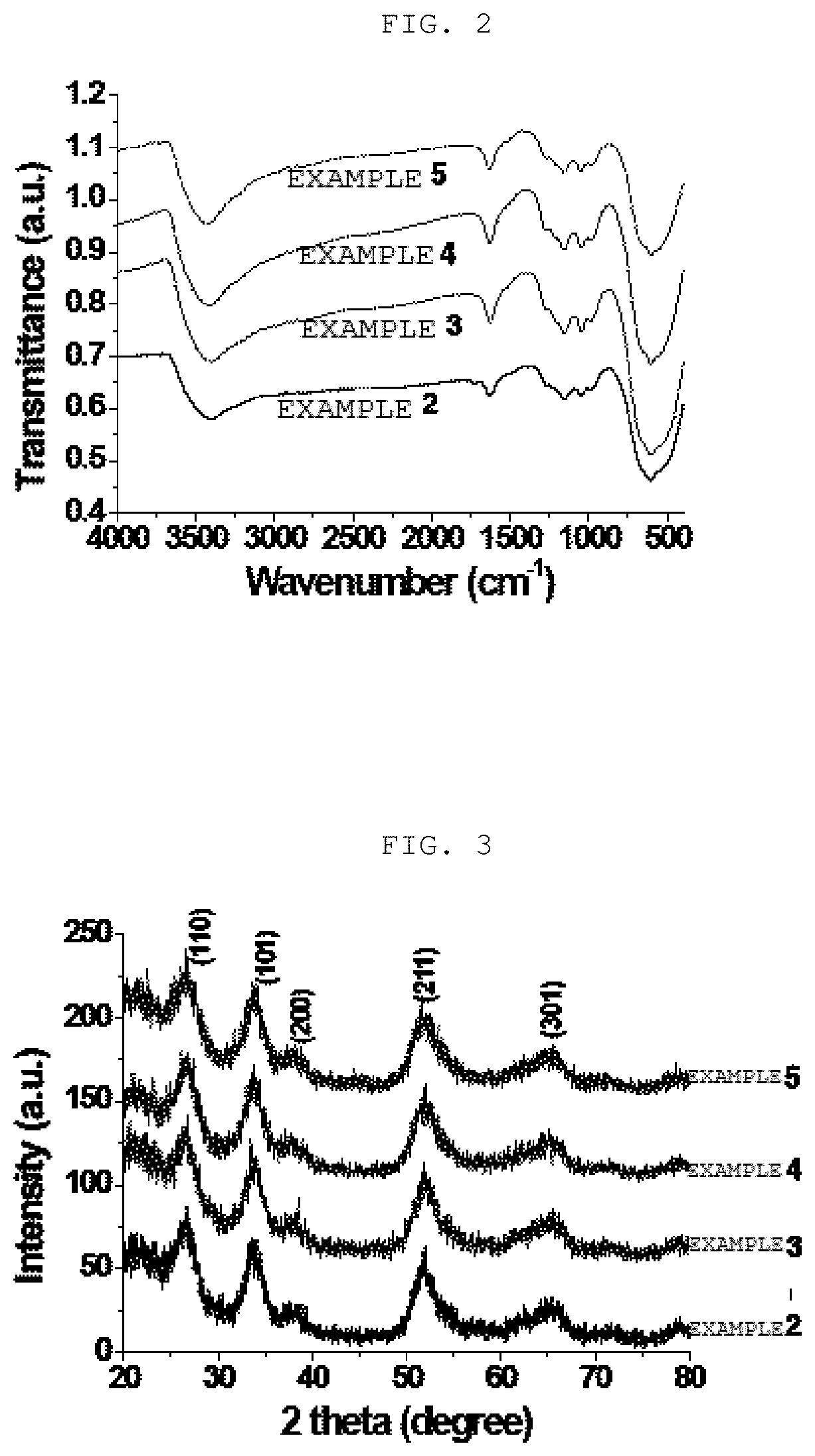

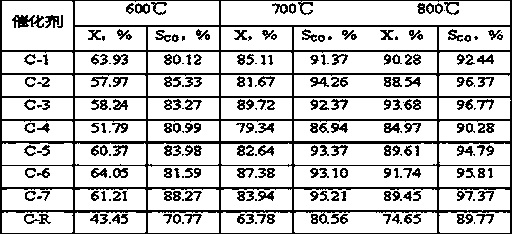

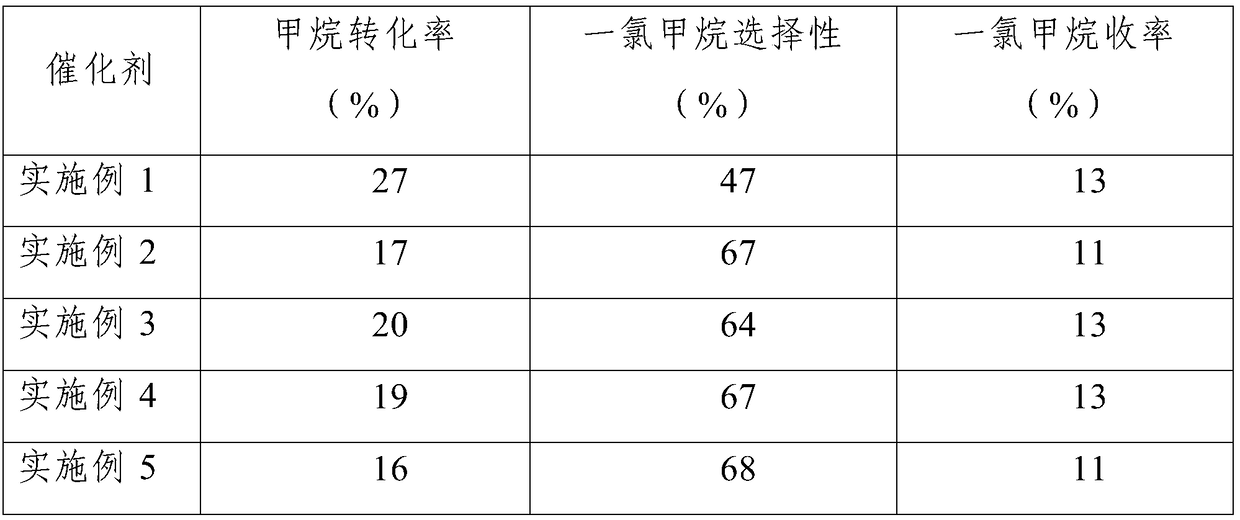

Method for preparing sulfated metal oxide catalyst for chlorination, and chlorination method using sulfated metal oxide catalyst

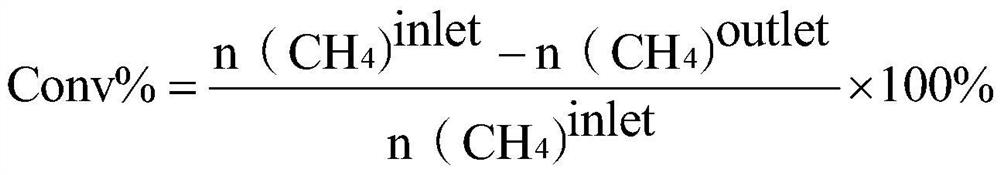

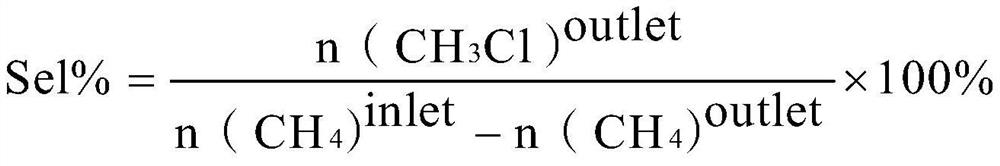

ActiveUS20210069689A1Increase methane conversionExcellent selectivityCatalystsHydrocarbon preparation catalystsEnvironmental chemistrySulfuric acid

The present invention relates to a method for preparing a sulfated metal oxide catalyst for chlorination, and a method for producing a reaction product containing methyl chloride (CH3Cl) by using the sulfated metal oxide catalyst. A sulfated zirconia catalyst and a sulfated tin oxide catalyst are disclosed as the sulfated metal oxide catalyst for chlorination.

Owner:KOREA RES INST OF CHEM TECH

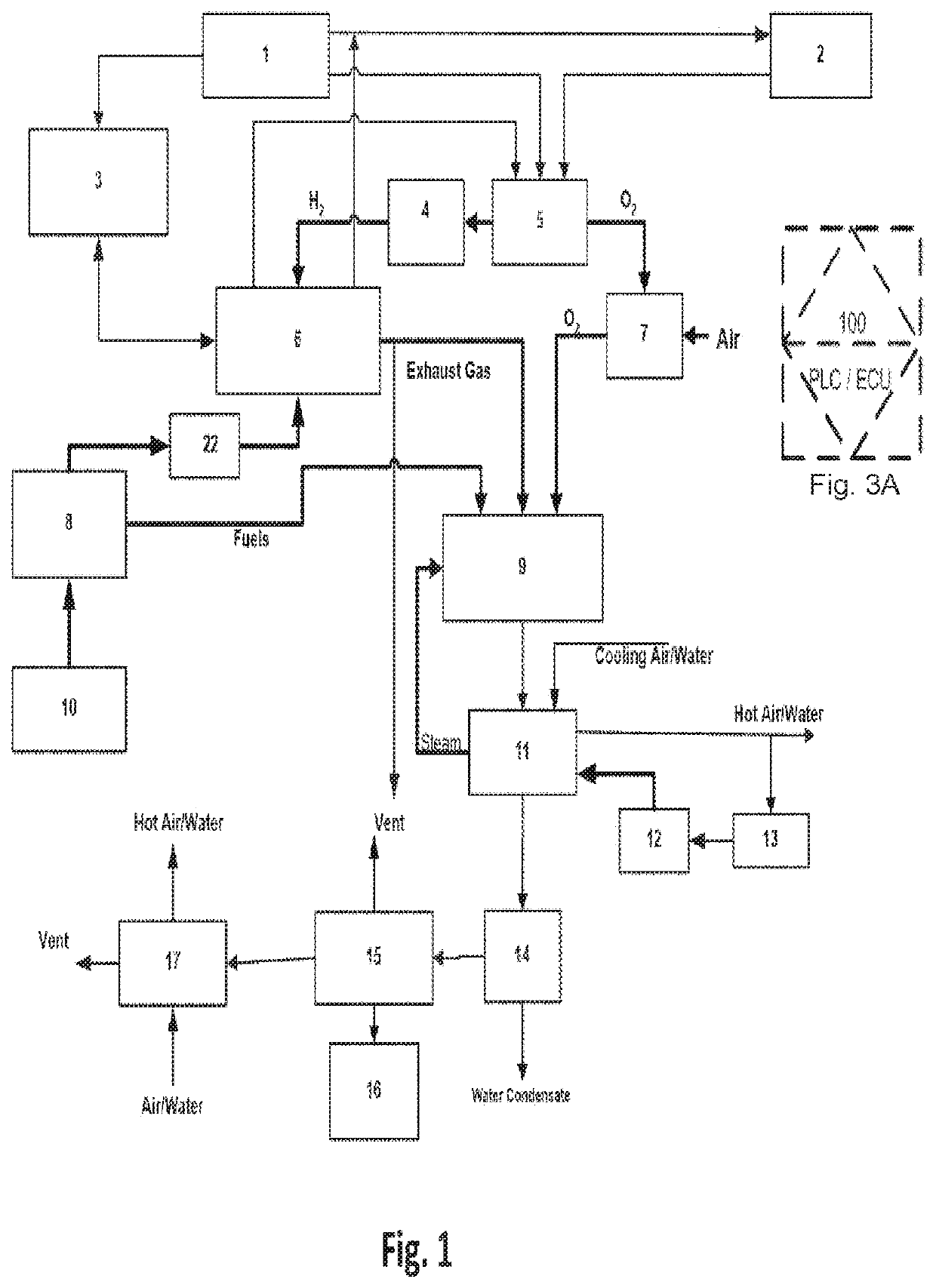

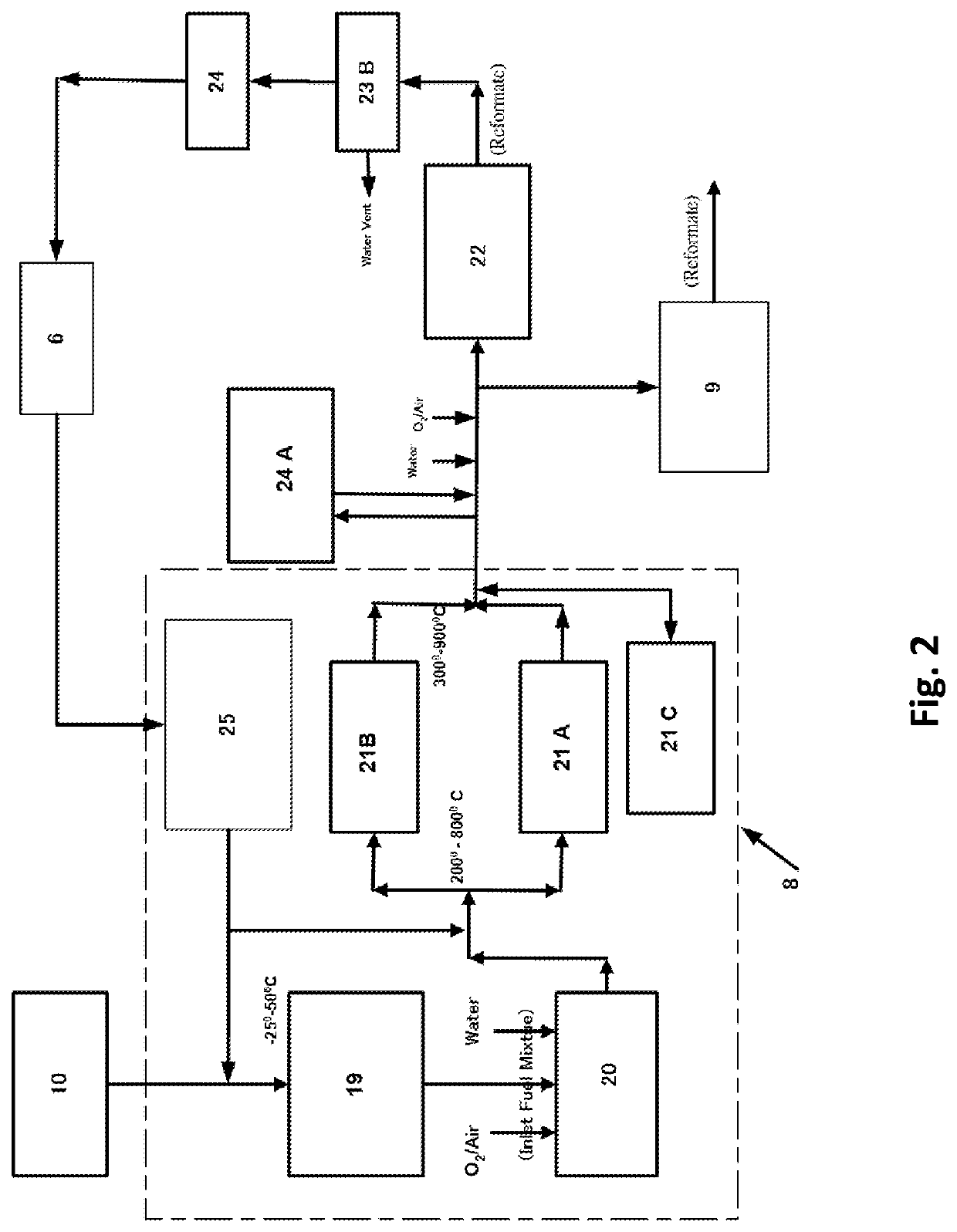

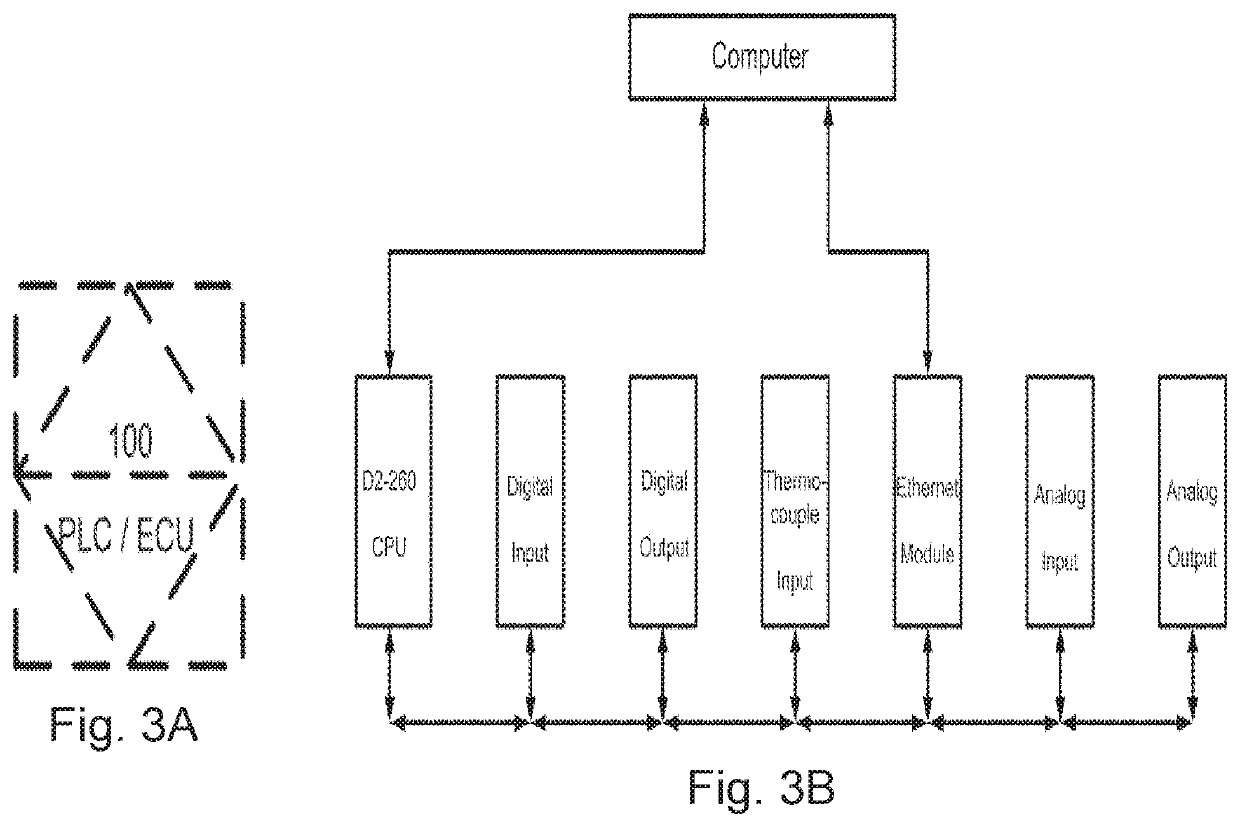

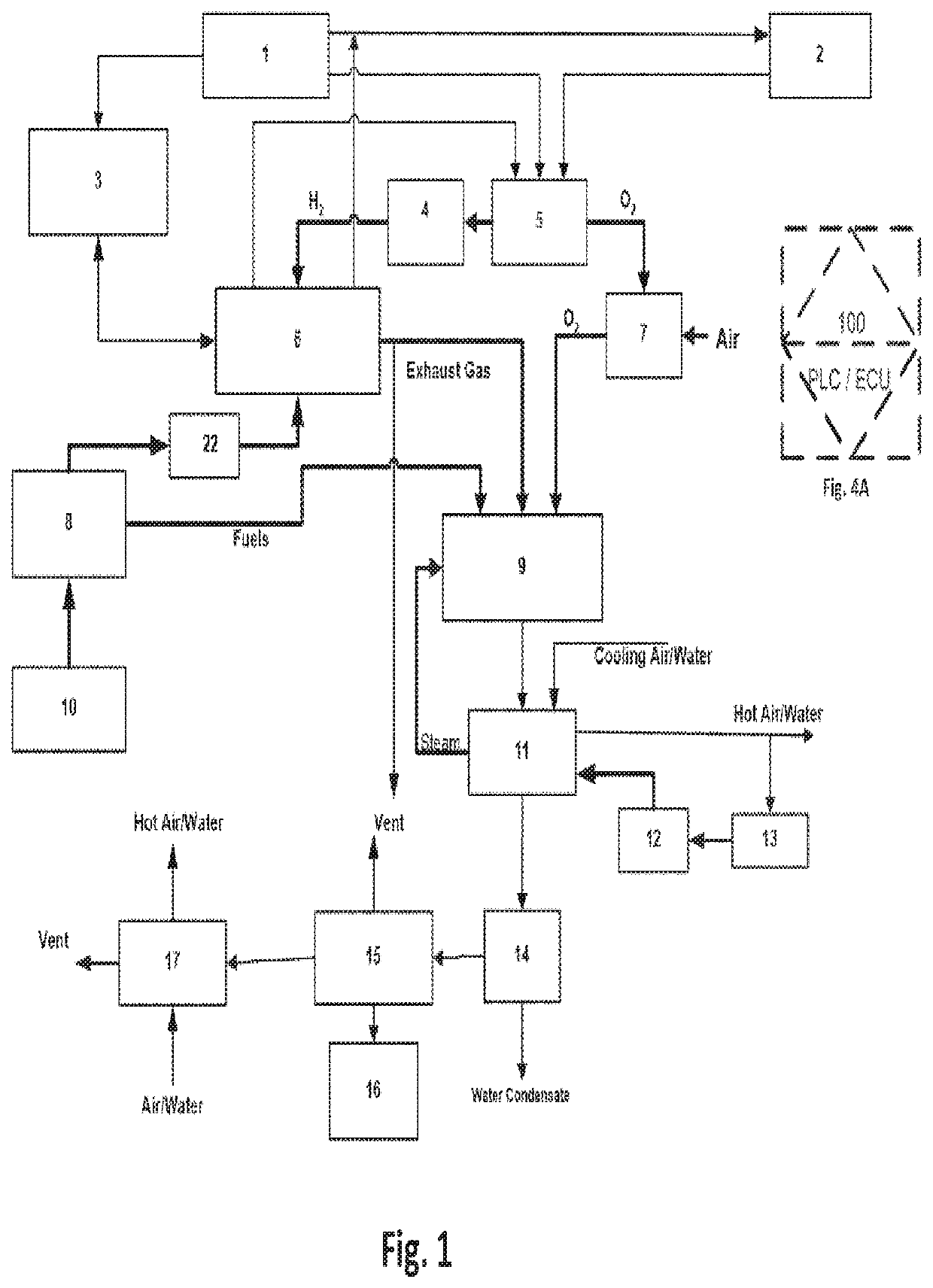

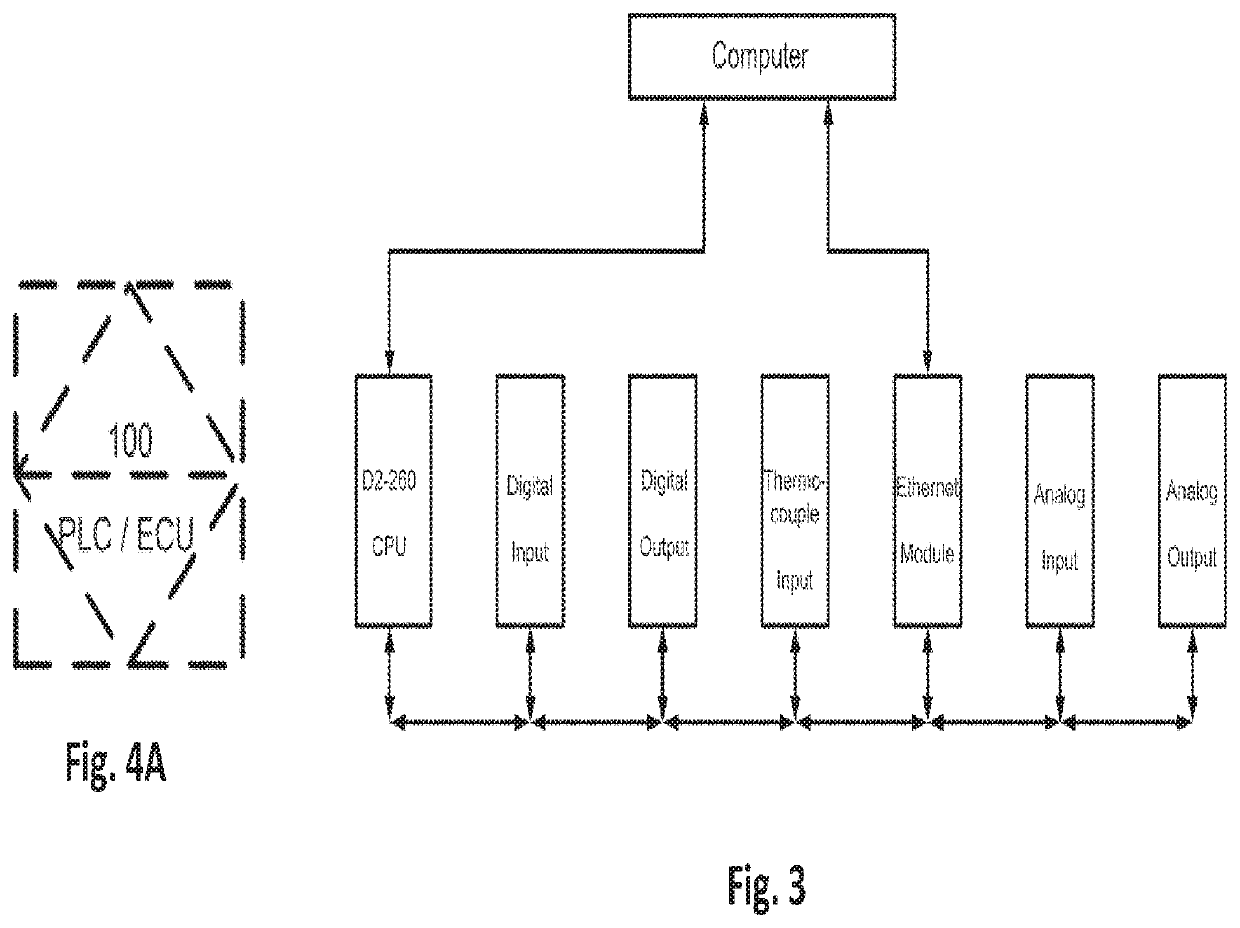

Catalytic biogas combined heat and power generator

ActiveUS10626790B2Avoid severe corrosionIncrease the H<subInternal combustion piston enginesGaseous engine fuelsPtru catalystCogeneration

A distributed Biogas Combined Heat and Power (CHP) Generator can provide automatically hot water and electricity for local applications. Since biogas is produced by an anaerobic digester from human, animal, kitchen and agriculture's wastes, it is a short term recycled product from the photosynthesis of CO2, and has a net zero carbon emission. The sulfur compounds in the biogas can be removed by the following steps: (1), converting all sulfur compounds into H2S by the hydrogen produced from the biogas over Pt group metal catalysts; (2). adsorbing the H2S at high temperature by the regenerable Pt group metal catalyst and adsorbents. The desulfurized biogas is further converted by an ATR / CPO reformer or a steam generating reformer to produce various reformates, which can be connected to a downstream 1C engine / gas turbine, and / or a steam turbine to drive electric generators for generating electricity. The hot reformate and the exhaust gases can be cooled in heat exchangers to produce hot water / hot air.

Owner:HWANG HERNG SHINN

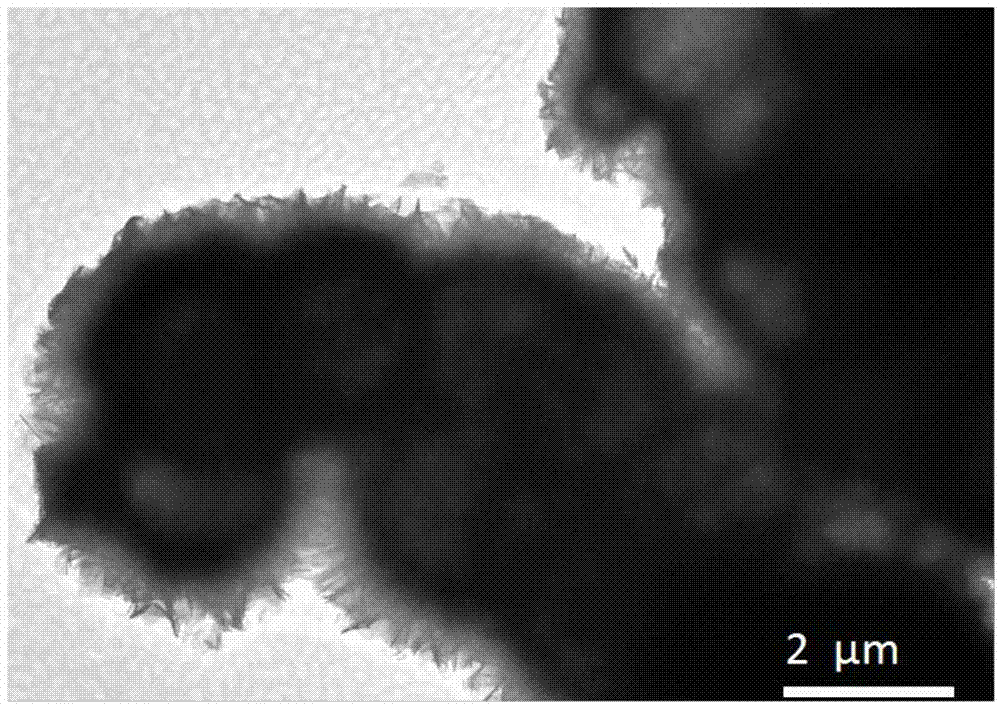

Implantation of Ni nano domains in refractory metal oxide support by means of sol-gel encapsulation—an effective solution to coke formation in the partial oxidation of natural gas

InactiveUS8658559B2Improve immunityHigh conversion rate of methaneHydrogenHydrocarbon from carbon oxidesNickel catalystPtru catalyst

A metal oxide-supported nickel catalyst includes a matrix containing a metal oxide and catalytic sites distributed throughout the matrix and having an intricate interface with the matrix, in which the catalytic sites are selected from the group consisting of nano-nickel(0) domains and nano-nickel(0)-A(0) alloy domains. Also disclosed are a method for preparing this catalyst and a method for using it to produce carbon monoxide and hydrogen by partial oxidation of a C1-C5 hydrocarbon.

Owner:NAT UNIV OF SINGAPORE

Nickel-based catalyst for obtaining synthetic gas through carbon dioxide reforming of methane and preparation method for nickel-based catalyst

ActiveCN102389801BHigh conversion rate of methaneExtend your lifeHydrogenMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to the technical field of catalysts for obtaining synthesis gas by reforming methane and carbon dioxide, and relates to a nickel-based catalyst for obtaining synthesis gas by reforming methane and carbon dioxide and a preparation method thereof; the nickel-based catalyst for obtaining synthesis gas by reforming methane and carbon dioxide consists of NiO, MgO and γ-Al2O3; the preparation method is carried out according to the following steps: the first step of preparing a mixed solution and the second step of preparation. The positive effects of the present invention are: compared with the prior art, the methane conversion rate of the nickel-based catalyst obtained in the present invention has been greatly improved, the service life has also been greatly improved, and the carbon deposition rate has been greatly reduced. The cost of the present invention Low, better economy.

Owner:XINJIANG UNIVERSITY

Catalytic Biogas Combined Heat and Power Generator

ActiveUS20190383212A1Avoid severe corrosionIncrease the H<subInternal combustion piston enginesEngine controllersSorbentCogeneration

Owner:HWANG HERNG SHINN

Catalyst for preparation of synthetic gas through partial oxidation of methane, and preparation method and application thereof

ActiveCN103785395AStrong methane activation abilityHigh conversion rate of methaneHydrogenMetal/metal-oxides/metal-hydroxide catalystsPartial oxidationMoisture

The invention discloses a catalyst for preparation of synthetic gas through catalytic partial oxidation of methane. According to the invention, inorganic refractory oxide is used as a carrier, and crystalline nickel cobalt vanadium oxide is used as an active component; in terms of the weight of the catalyst, the active component accounts for 1 to 50%, preferably, 10 to 30%; the molar composition of the crystalline nickel cobalt vanadium oxide is represented by NixCoyVzOdelta, wherein x is equal to 0 to 1.0, y is equal to 0 to 1.0, z is equal to 0.1 to 1.0, x+y is less than 0, and delta refers to a value when O in the oxide reaches an equilibrium amount. A preparation method for the catalyst used for preparation of synthetic gas through catalytic partial oxidation of methane comprises the following steps: respectively dissolving nitrates of Ni and Co and an oxyacid ammonium salt of V to prepare aqueous solutions; mixing the catalyst carrier or a carrier precursor with the aqueous solutions; adjusting a pH value to 3 to 12, preferably, 5 to 10; carrying out a coprecipitation reaction under the condition of stirring; and carrying out moisture removal, drying and roasting so as to obtain the loaded crystalline nickel cobalt vanadium oxide catalyst. The catalyst has the advantages of good comprehensive performance, high dispersion of the active component, high catalytic activity, excellent carbon deposit resistance, high stability and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

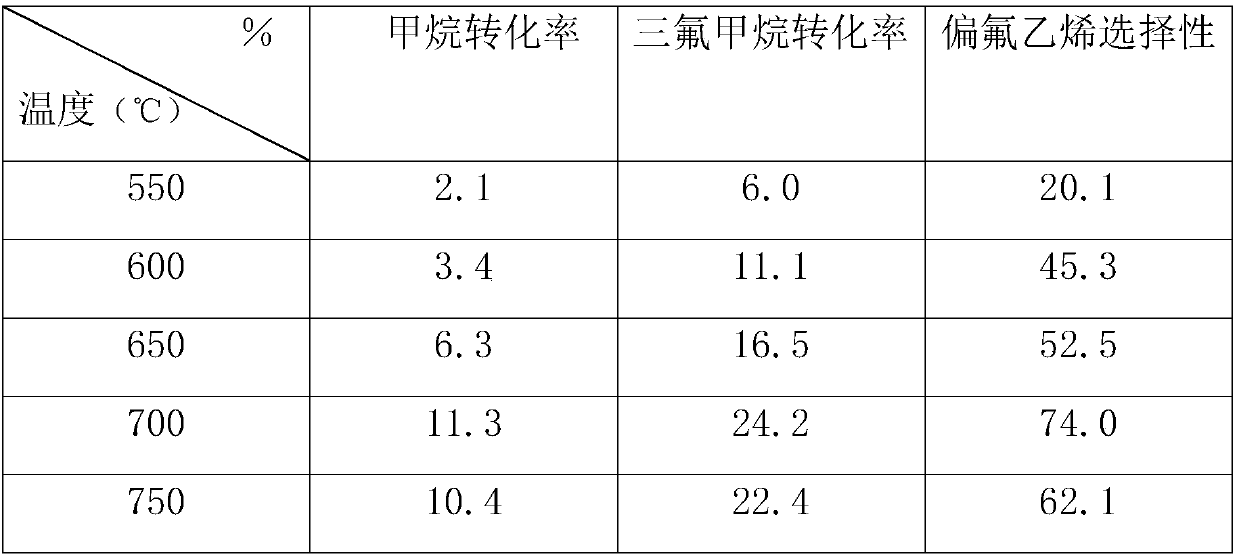

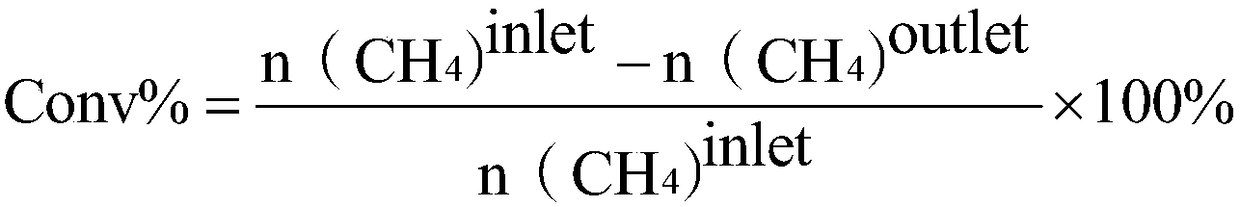

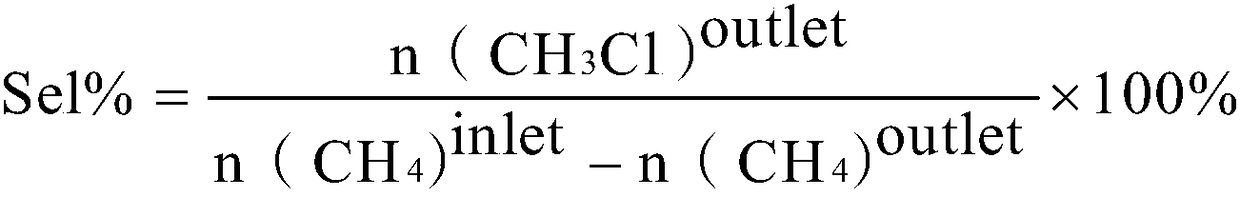

Method for preparing vinylidene fluoride by resource conversion of trifluoromethane

PendingCN111217669AHigh selectivityHigh conversion rate of methanePhysical/chemical process catalystsHalogenated hydrocarbon preparationLanthanumFluoromethane

The invention discloses a method for preparing vinylidene fluoride by a reaction of trifluoromethane and methane under the action of a composite catalyst, wherein the composite catalyst comprises a component 1 and a component 2, the component 1 comprises a lanthanum-based metal, and the component 2 comprises an IIA group metal. The method provided by the invention has the characteristics of high vinylidene fluoride selectivity, high methane conversion rate, low reaction temperature and the like.

Owner:ZHEJIANG RES INST OF CHEM IND CO LTD +2

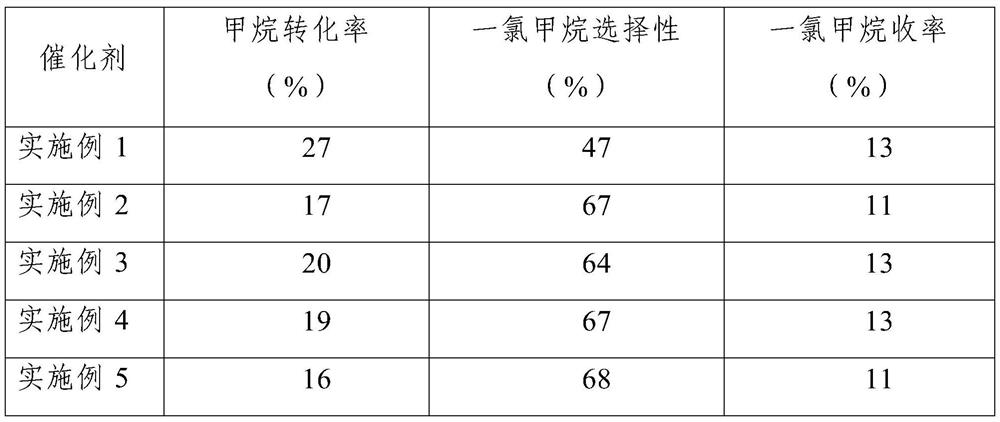

Ruthenium dioxide catalyst applied to oxychlorination of methane and preparation method thereof

ActiveCN108144632AGood dispersionHigh conversion rate of methaneCatalyst activation/preparationHalogenated hydrocarbon preparationRare earthBiological activation

The invention discloses a ruthenium dioxide catalyst applied to oxychlorination of methane. The ruthenium dioxide catalyst comprises a carrier, an active component loaded on the carrier, co-catalysiscomponents and a carrier modification additive, wherein the carrier comprises titanium dioxide; the active component is ruthenium dioxide; the co-catalysis components comprise alkali metal componentsand rare-earth metal components; the carrier modification additive is silicon dioxide. The invention also discloses a preparation method of the ruthenium dioxide catalyst. According to the catalyst, through the co-catalysis components including alkali metal components and rare-earth metal components, the dispersibility of ruthenium dioxide as the active component is improved; the active site structure of ruthenium dioxide is changed; the catalyst has two high-activity sites for activating C-H bonds and activating O2; the activation of methane is facilitated; the excessive oxidization of the product is avoided; the catalyst also has high methane conversion rate and monochloro methane selectivity; the catalyst obtained by the preparation method can be directly used for catalyzing oxychlorination reaction of methane without pretreatment.

Owner:XIAN ORIGIN CHEM TECH

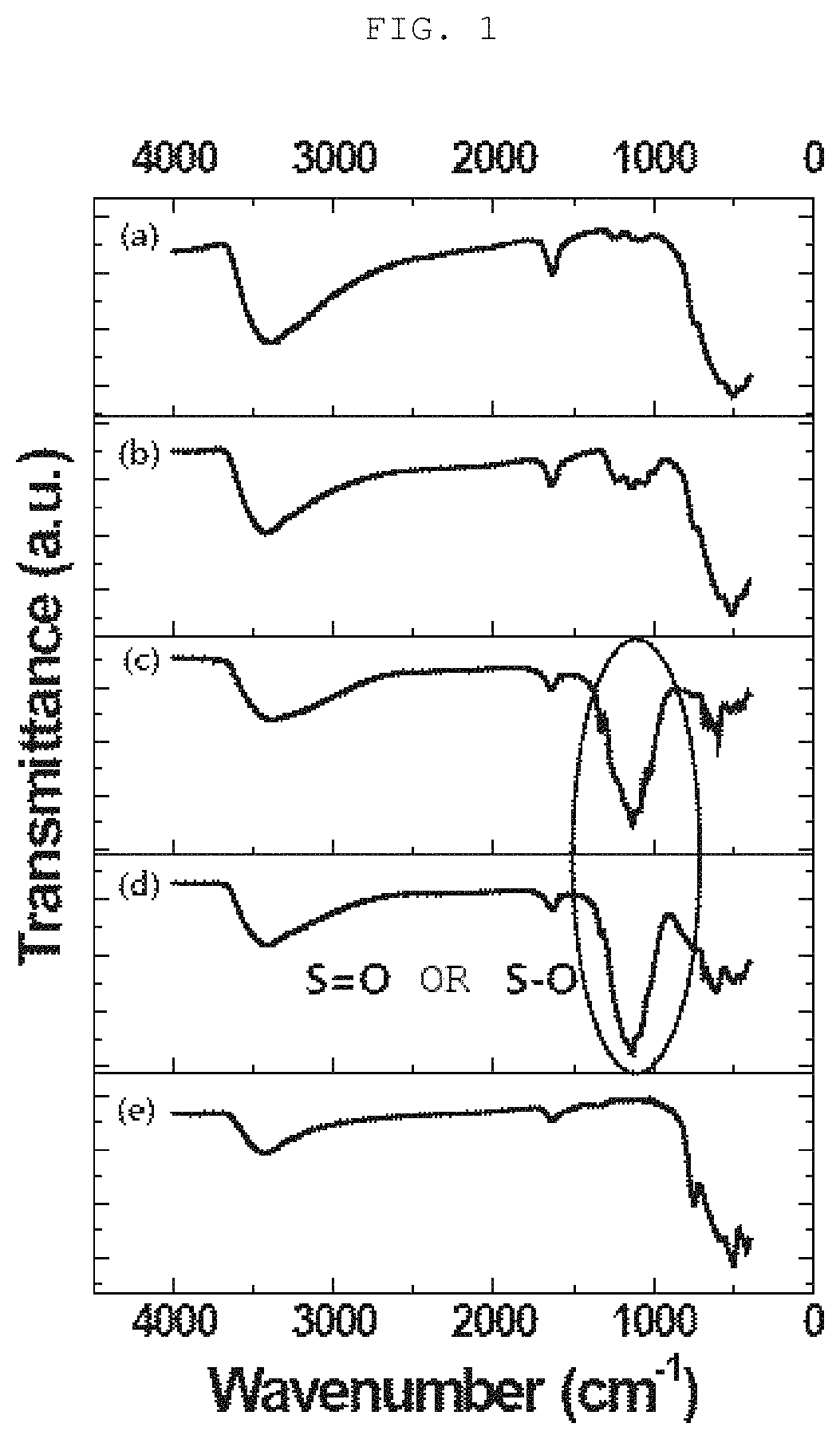

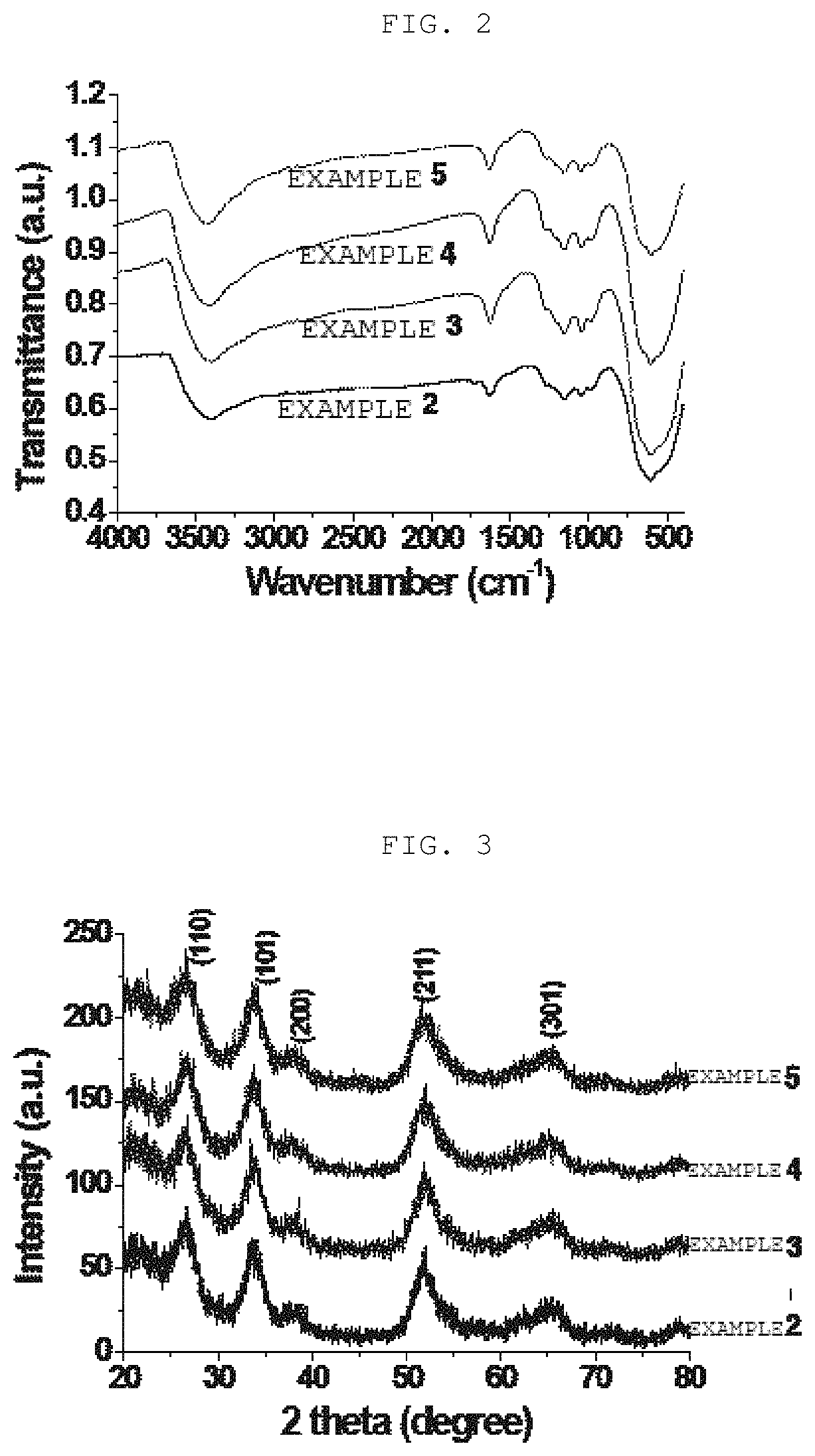

Preparation method of γ-alumina nanomaterial and nickel/γ-alumina catalyst

ActiveCN104709932BLow equipment requirementsCheap and easy to getMetal/metal-oxides/metal-hydroxide catalystsAluminium oxides/hydroxidesNickel saltSynthesis methods

The invention discloses a synthesis method for a gamma-aluminium oxide nanometer material. The synthesis method comprises the following steps: at room temperature, adding alum and carbamide into deionized water, cooling, centrifugating and washing the sediment after the hydrothermal reaction; calcining the dried hydrothermal products to obtain the gamma-aluminium oxide nanometer material. The gamma-aluminium oxide nanometer material prepared by adopting the synthesis method has a relatively high specific surface area and a certain pore structure. The invention further provides a method for prepare a nickel / gamma-aluminium oxide catalyst by adopting the gamma-aluminium oxide nanometer material obtained by adopting the synthesis method as the raw material. The method comprises the following steps: impregnating the gamma-aluminium oxide nanometer material into a nickel salt solution in the appropriate concentration, carrying out magnetic stirring till the solvent evaporates; collecting the dried impregnating products and grinding into powders, and carrying out heating reduction in the reducing atmosphere to obtain the nickel / gamma-aluminium oxide catalyst. The catalyst can be used for catalyzing the methane dry-process reforming reaction, has a relatively high methane conversion rate, and can still maintain excellent stability and carbon formation resistance in the long-term catalytic reaction under high temperature.

Owner:SHANGHAI JIAOTONG UNIV

A kind of preparation method of solid acid catalyst for producing ethylene by oxidative coupling of methane

ActiveCN109289833BImprove response resultsInhibit deep oxidationCatalystsHydrocarbon preparation catalystsPtru catalystSolid acid

The present invention relates to a kind of preparation method of methane oxidative coupling ethylene solid acid catalyst, the method comprises the following steps: (1) TiO 2 Fully grind to 6000~7000 mesh, add it to the tungsten salt solution, impregnate with ultrasonic, stir and evaporate to dryness in a water bath to obtain the tungsten-titanium solid acid precursor; the tungsten-titanium solid acid precursor is roasted and ground into powder to obtain WO 3 Solid acid WO with a content of 5 wt%~15 wt% 3 / TiO 2 Carrier; (2) Add LiNO sequentially in ionized water 3 , Mn(NO 3 ) 2 , and make it completely dissolved, and then impregnate the solid acid WO with excess impregnation method 3 / TiO 2 carrier to obtain impregnation; (3) stirring and evaporating the impregnation in a water bath, grinding it into powder and roasting to obtain a solid acid catalyst. The preparation method of the invention is simple, the preparation conditions are mild, and the three industrial wastes are less, and the obtained catalyst has the advantages of good performance, long service life and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

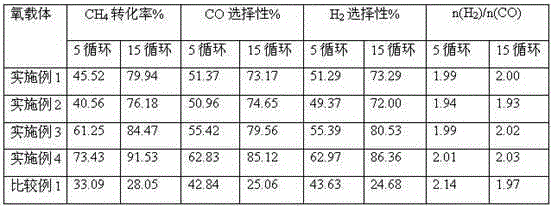

Oxygen carrier for chemical cycle dry gas reforming and its preparation method and application

ActiveCN105056955BEasy to prepareEase of industrial productionHydrogenMetal/metal-oxides/metal-hydroxide catalystsHigh rateBarium titanate

An oxygen carrier for dry gas reforming in chemical circulation and its preparation method and application, the oxygen carrier is a composite metal oxide with a hexaaluminate structure, the general formula is AMxAl12‑xO19, wherein A is rare earth metal lanthanum and / or barium, M is transition metal iron, 0<x<5. The temperature of the oxygen carrier in the fuel reactor is 750-1000 DEG C, the temperature in the oxidation reactor is 750-1000 DEG C, and the reaction pressure is normal pressure. The preparation process is: using ferric nitrate, aluminum nitrate, lanthanum nitrate and / or barium nitrate as precursors, preparing nitrate solution, adding ammonium carbonate as precipitant for co-precipitation, and then suction filtration, washing, drying and roasting. have to. The oxygen carrier has high oxygen loading rate and reactivity, and has the advantages of excellent impact resistance mechanical properties, high temperature stability, environmental friendliness, low cost and easy preparation.

Owner:NORTHWEST UNIV

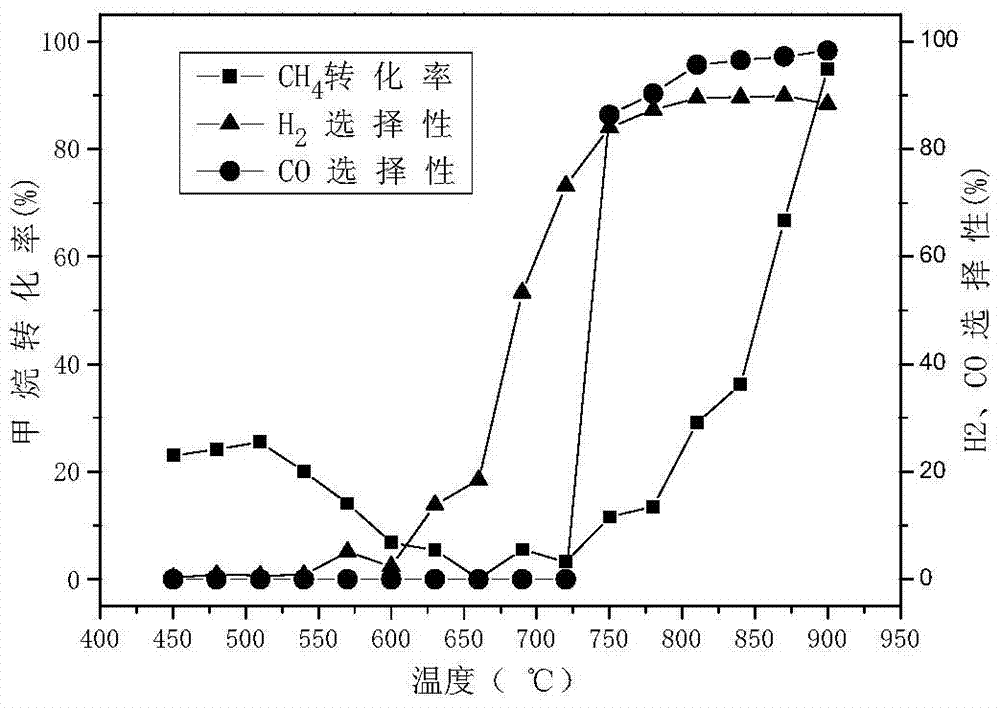

A kind of oxygen carrier for methane synthesis gas and its preparation method and application

ActiveCN103551156BSimple preparation processLow costHydrogenMetal/metal-oxides/metal-hydroxide catalystsOxygenPhotochemistry

The invention relates to an oxygen carrier for methane to prepare synthesis gas. The oxygen carrier is characterized by comprising Fe2O3, CeO2 and Al2O3, wherein the mass ratio of CeO2 to the sum of Fe2O3 and Al2O3 is 0.05 to 0.4; the mass ratio of Fe2O3 to Al2O3 is 0.75 to 1.5. The oxygen carrier has the advantages of high methane conversion rate as well as high CO and H2 selectivity.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for preparing sulfated metal oxide catalyst for chlorination, and chlorination method using sulfated metal oxide catalyst

ActiveUS11179712B2High conversion rate of methaneGood choiceCatalystsHydrocarbon preparation catalystsPtru catalystChloromethane

The present invention relates to a method for preparing a sulfated metal oxide catalyst for chlorination, and a method for producing a reaction product containing methyl chloride (CH3Cl) by using the sulfated metal oxide catalyst. A sulfated zirconia catalyst and a sulfated tin oxide catalyst are disclosed as the sulfated metal oxide catalyst for chlorination.

Owner:KOREA RES INST OF CHEM TECH

A kind of ruthenium dioxide catalyst of methane oxychlorination and preparation method thereof

ActiveCN108144632BGood dispersionHigh conversion rate of methaneCatalyst activation/preparationHalogenated hydrocarbon preparationPtru catalystOver oxidation

The invention discloses a ruthenium dioxide catalyst applied to oxychlorination of methane. The ruthenium dioxide catalyst comprises a carrier, an active component loaded on the carrier, co-catalysiscomponents and a carrier modification additive, wherein the carrier comprises titanium dioxide; the active component is ruthenium dioxide; the co-catalysis components comprise alkali metal componentsand rare-earth metal components; the carrier modification additive is silicon dioxide. The invention also discloses a preparation method of the ruthenium dioxide catalyst. According to the catalyst, through the co-catalysis components including alkali metal components and rare-earth metal components, the dispersibility of ruthenium dioxide as the active component is improved; the active site structure of ruthenium dioxide is changed; the catalyst has two high-activity sites for activating C-H bonds and activating O2; the activation of methane is facilitated; the excessive oxidization of the product is avoided; the catalyst also has high methane conversion rate and monochloro methane selectivity; the catalyst obtained by the preparation method can be directly used for catalyzing oxychlorination reaction of methane without pretreatment.

Owner:XIAN ORIGIN CHEM TECH

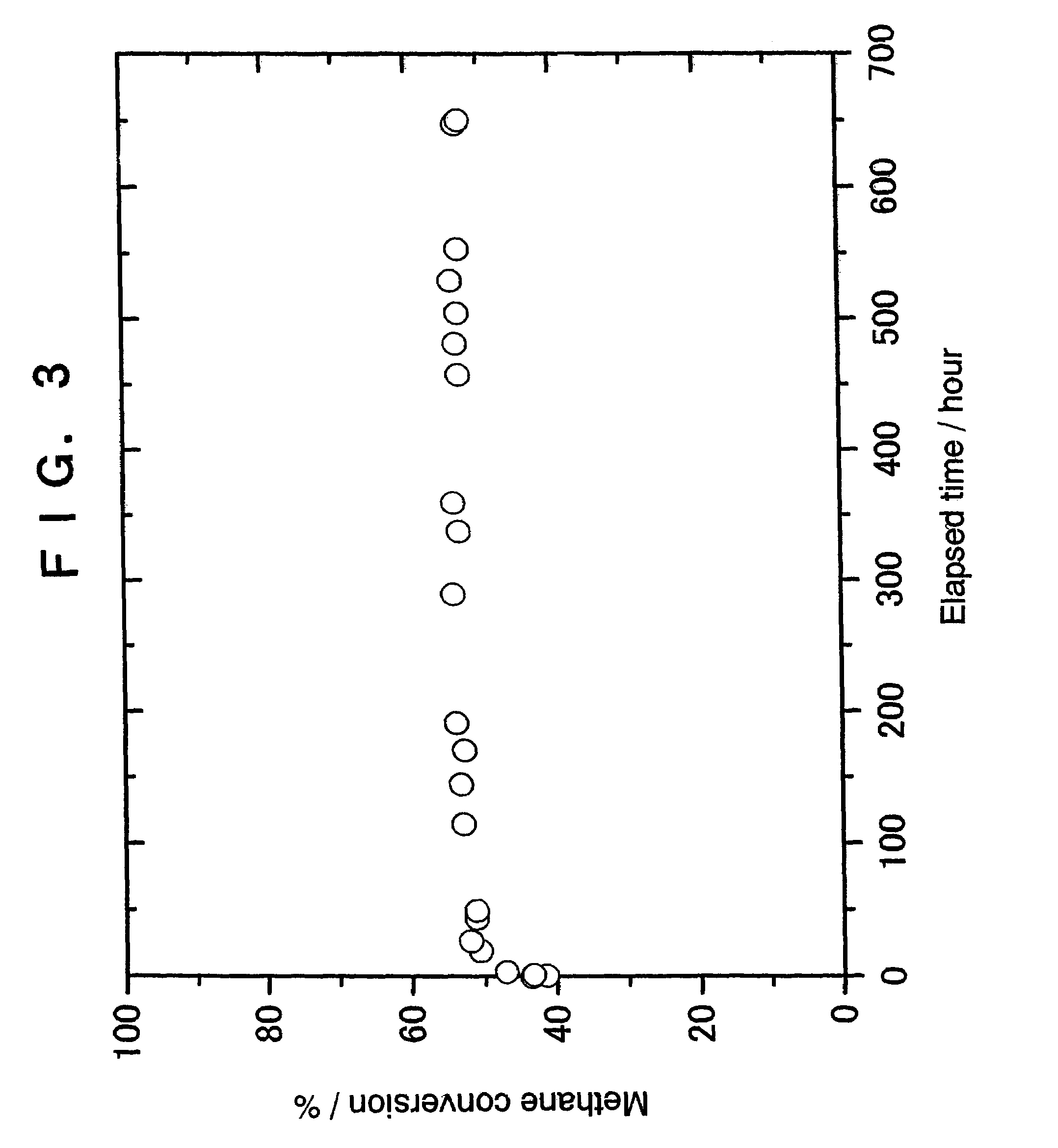

Composite catalyst with hollow core-shell structure and preparation method thereof

PendingCN114260013AImprove stabilityHigh conversion rate of methaneHydrogenMetal/metal-oxides/metal-hydroxide catalystsComposite materialCatalysis

The invention belongs to the technical field of catalysts. The invention provides a composite catalyst with a hollow core-shell structure. The composite catalyst is prepared from CaO, Ca3Al2O6, Ni and SiO2, in the composite catalyst, the molar ratio of Ca to Al to Ni to Si is 1: (0.01-0.5): (0.01-0.15): (0.01-0.15). The invention also provides a preparation method of the composite catalyst with the hollow core-shell structure. The composite catalyst with the hollow core-shell structure has catalysis and adsorption properties, the repeated volume expansion and shrinkage process of adsorption components in the reaction-regeneration cycle process is carried out in a SiO2 cavity, collapse of the structure of the composite catalyst cannot be caused, and the stability of the composite catalyst is improved; the methane conversion rate and the H2 concentration can be obviously improved.

Owner:TAIYUAN UNIV OF TECH

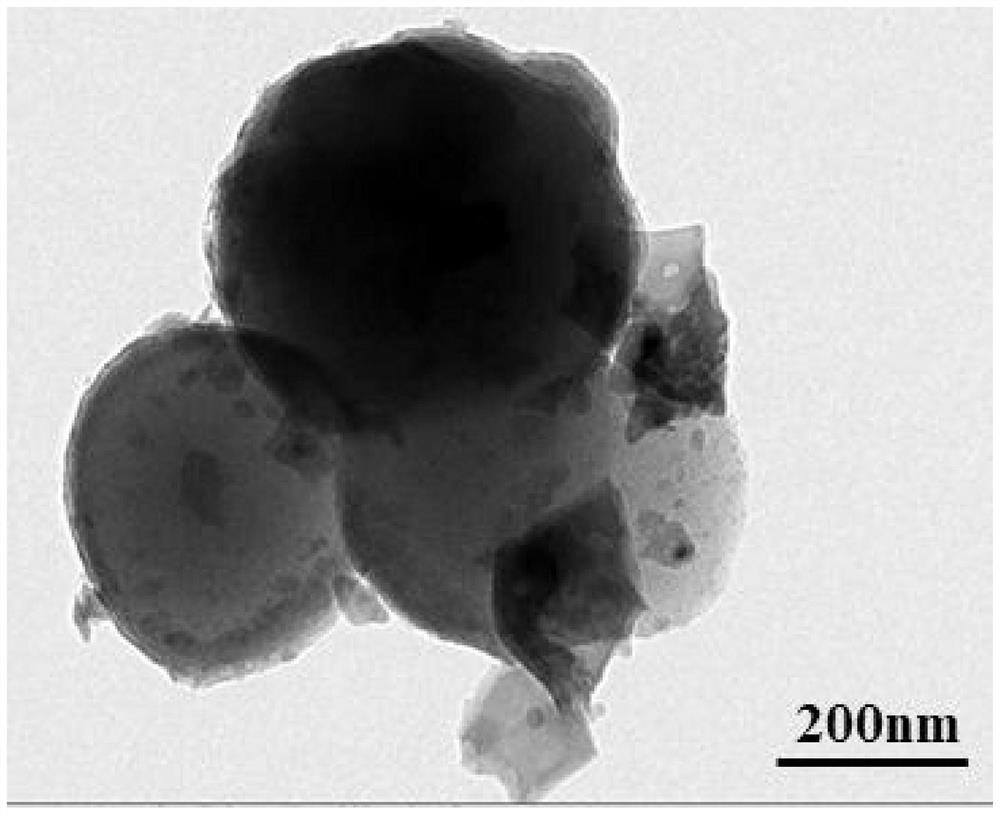

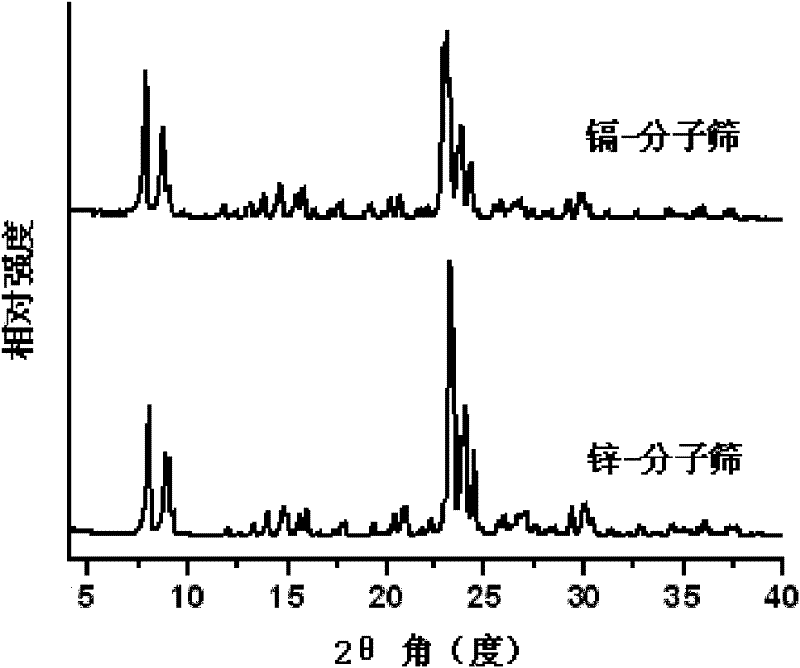

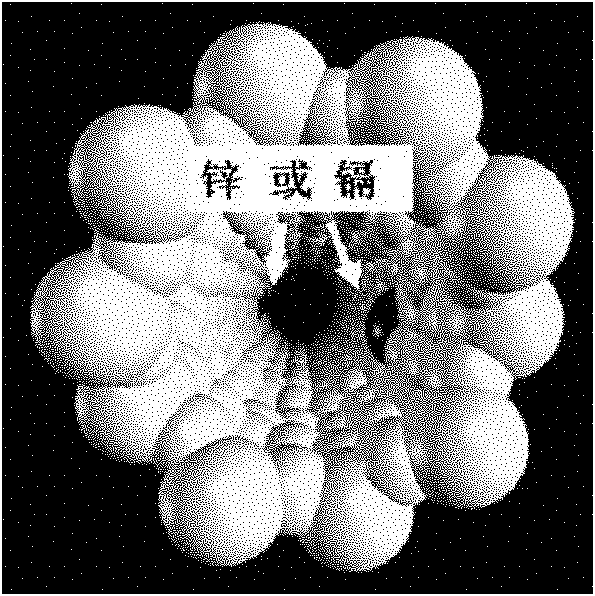

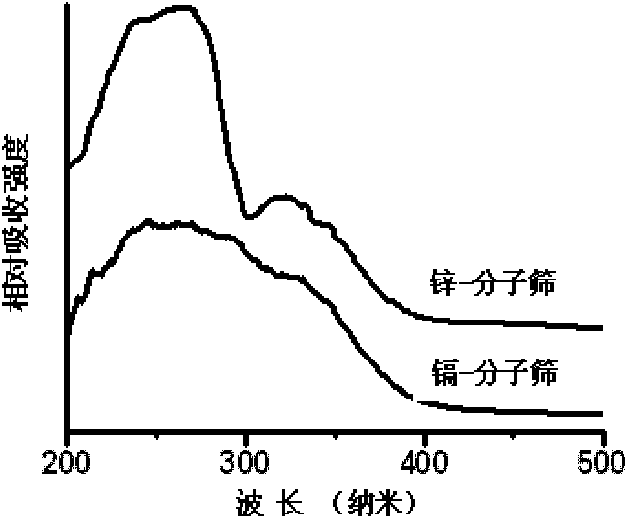

Photocatalytic metal-molecular sieve composite catalyst and preparation method thereof

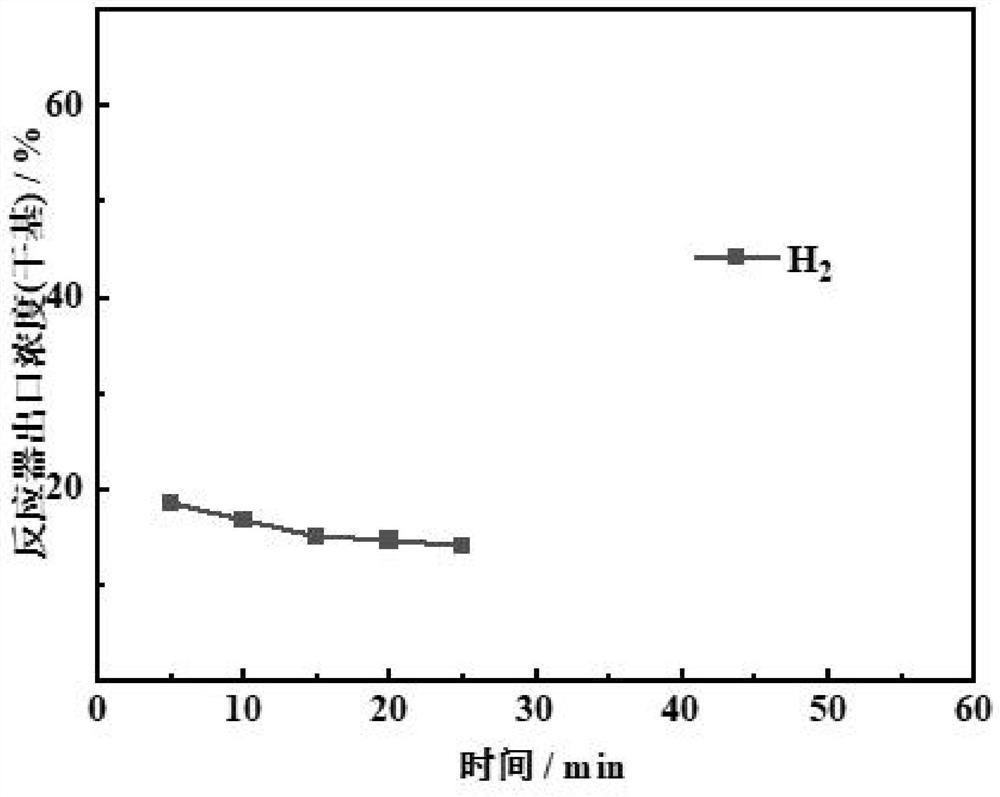

InactiveCN102069006BReduce pollutionShort timeMolecular sieve catalystsChemical industryMolecular sieveHydrogen

The invention provides a photocatalytic metal-molecular sieve composite catalyst and a preparation method thereof, and belongs to the technical field of methane catalysis. The catalyst prepared by the method can generate a large quantity of stable monovalent metal cations (Zn+ or Cd+) through ultraviolet radiation, thus the catalyst has extremely high photocatalytic methane conversion activity; and driven by sunlight, the catalyst can efficiently catalyze methane to couple thereby producing ethane and meanwhile generate equimolar hydrogen under normal temperature and normal pressure. Comparedwith the existing methane conversion photocatalyst, the catalyst has the advantages of the highest methane conversion ratio (23.5%), the highest ethane selectivity (99.7%), the minimum photon energy requirement (wavelength is less than 390nm) and the like.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com