Methane reforming system

A reforming system, methane technology, applied in inorganic chemistry, chemical industry, climate sustainability, etc., can solve the problems of high energy consumption, high requirements for equipment temperature resistance, low energy utilization efficiency of methane reforming system, etc. Achieve the effect of improving methane conversion rate, energy utilization rate, and space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

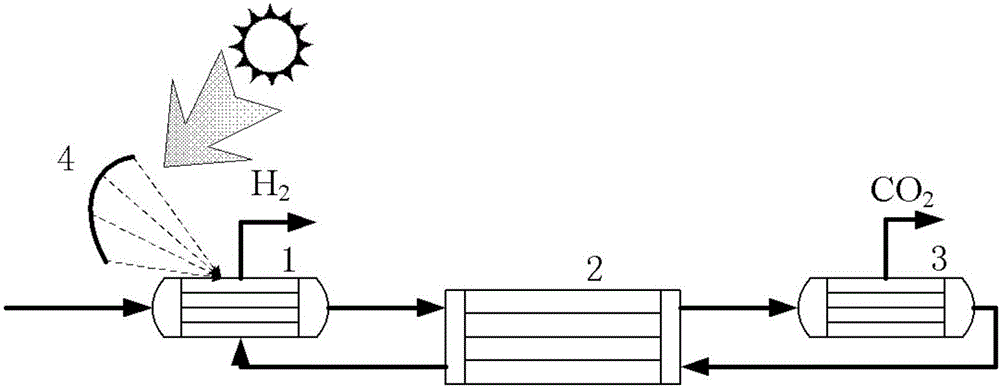

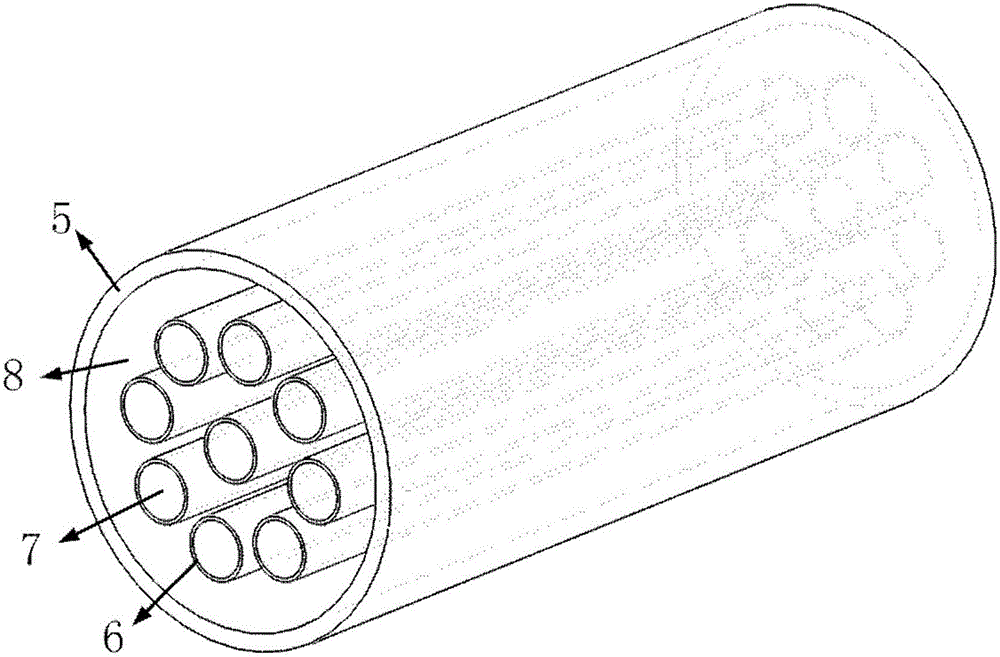

[0025] In an exemplary embodiment of the present invention, a methane reforming system is provided. figure 1 It is a schematic structural diagram of a methane reforming system according to the first embodiment of the present invention. Such as figure 1 As shown, a methane reforming system in this embodiment includes: a hydrogen separation device 1 ; a heat exchanger 2 ; a carbon dioxide separation device 3 ; and a solar concentrating device 4 . Wherein, the hydrogen separation device 1 and the carbon dioxide separation device 3 both adopt membrane material separation devices.

[0026] Please refer to figure 1 , the inner chamber of the hydrogen separation device 1 is divided into two types of areas by the hydrogen permeable membrane - the first type of area on the separation side of the hydrogen permeable membrane and the second type of area on the feed gas supply side of the hydrogen permeable membrane. Wherein, the partial pressure of hydrogen in the first type of region ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com