Composite catalyst with hollow core-shell structure and preparation method thereof

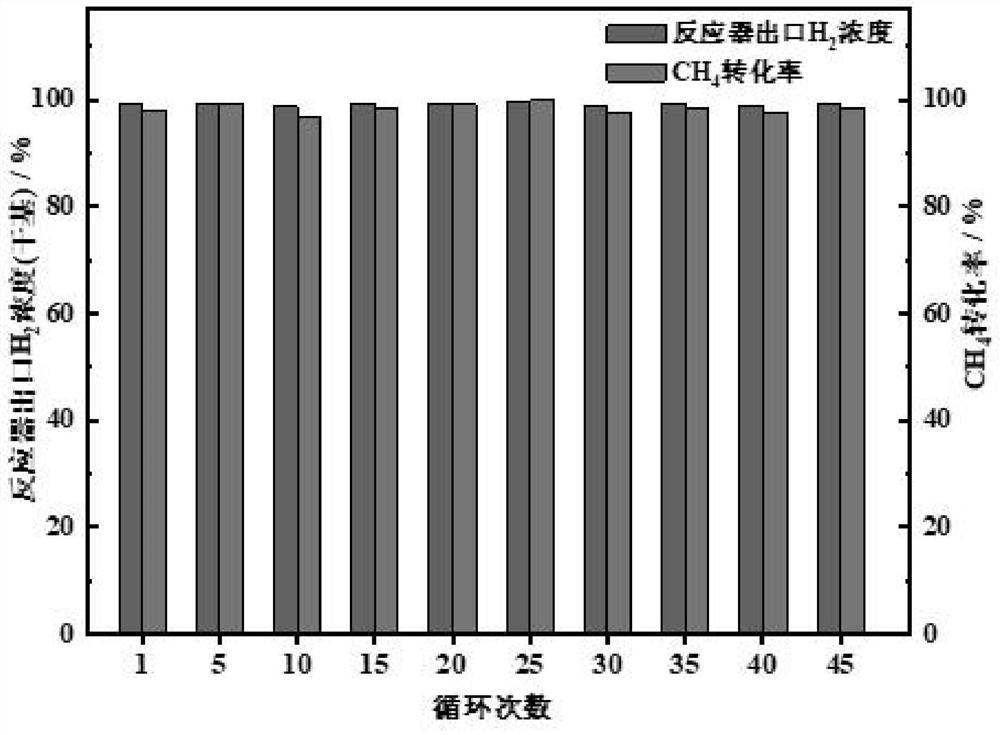

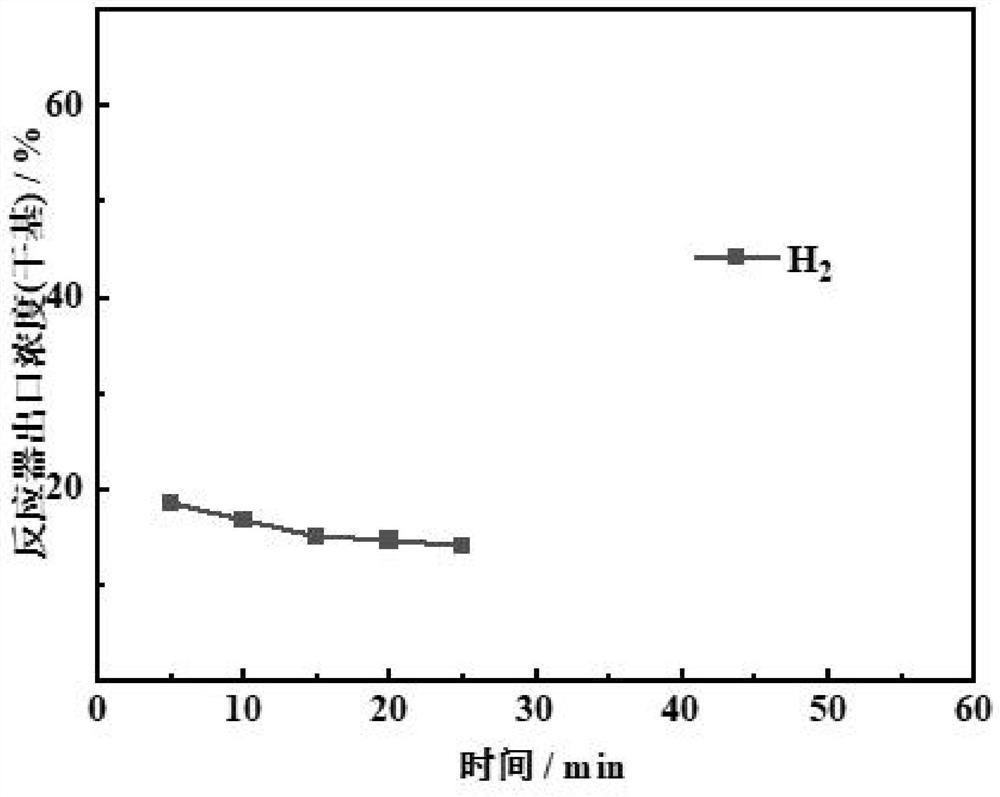

A composite catalyst and core-shell structure technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of composite catalyst structure collapse and low utilization rate of CaO problem, to achieve the effect of easy control of synthesis conditions, increase of methane conversion rate and increase of H2 concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention also provides a method for preparing the hollow core-shell composite catalyst, comprising the following steps:

[0034] 1) mixing calcium salt, aluminum salt, citric acid and water to obtain a gel;

[0035]2) Drying, roasting, and carbonating the gel in sequence to obtain the carbonation adsorption component;

[0036] 3) mixing the carbonation adsorption component, ethanol, surfactant and silicon salt to obtain an emulsion, and sequentially hydrolyzing and suction filtering the emulsion to obtain the first filter residue;

[0037] 4) After mixing the first filter residue, surfactant, etchant and water, performing etching and suction filtration in sequence to obtain the second filter residue;

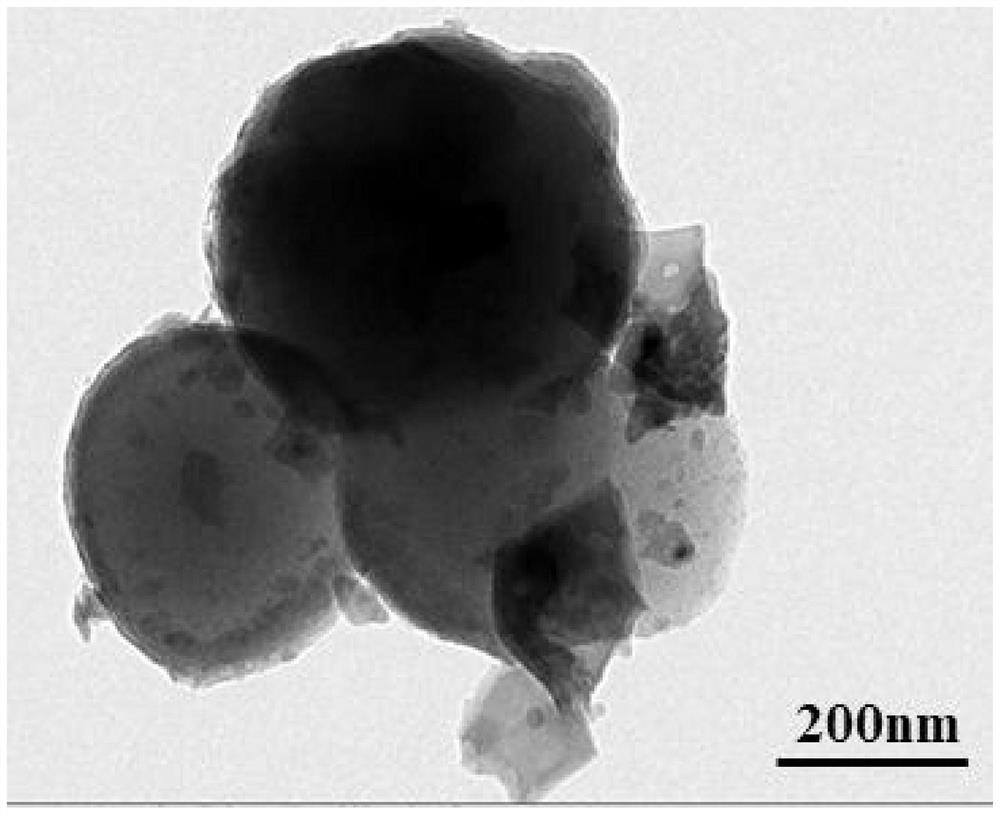

[0038] 5) The second filter residue, surfactant, nickel salt and water are mixed and reacted, and the filter residue obtained by the reaction is dried and calcined in sequence to obtain a composite catalyst with a hollow core-shell structure.

[0039] The p...

Embodiment 1

[0055] Dissolve calcium nitrate, aluminum nitrate and citric acid with a molar ratio of 1:0.03:5 in deionized water. The concentration of calcium ions in the resulting solution is 0.3mol / L. Stir the solution at 80°C for 7h until a gel is formed. , the resulting gel was dried at 125°C for 18h, and then calcined at 850°C for 1.5h to obtain the adsorption component, which was placed in CO 2 Atmosphere, carbonation treatment at 750°C for 5 hours to obtain the carbonation adsorption component.

[0056] The carbonation adsorption component was dispersed in ethanol (the mass concentration of ethanol was 94%), and ammonia water was added to adjust the pH value to 10 to obtain a mixed solution. Add cetyltrimethylammonium bromide and ethyl orthosilicate to the mixed solution and mix evenly to obtain an emulsion. In the emulsion, the concentration of cetyltrimethylammonium bromide is 2.5mmol / L , the concentration of calcium ions is 0.3mol / L, and the molar ratio of calcium ions and silic...

Embodiment 2

[0060] Dissolve calcium chloride, aluminum chloride and citric acid with a molar ratio of 1:0.1:1.5 in deionized water, and the concentration of calcium ions in the obtained solution is 1mol / L, and the solution is stirred at 60°C for 8h until a gel Gel, the resulting gel was dried at 100°C for 24h, and then calcined at 750°C for 3h to obtain the adsorption component, which was placed in CO 2 Atmosphere, carbonation treatment at 720°C for 4 hours to obtain carbonation adsorption components.

[0061] Disperse the carbonation adsorption component in ethanol (the mass concentration of ethanol is 96%), add ammonia water to adjust the pH value to 10, and obtain a mixed solution. Add cetyltrimethylammonium bromide and ethyl orthosilicate to the mixed solution and mix uniformly to obtain an emulsion. In the emulsion, the concentration of cetyltrimethylammonium bromide is 4mmol / L. The concentration of calcium ions is 0.5mol / L, and the molar ratio of calcium ions to silicon ions is 1:0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com