Automatic control method and equipment for C3 liquid phase hydrogenation reactor

A liquid-phase hydrogenation and reactor technology, applied in non-electrical variable control, hydrogenation to hydrocarbons, comprehensive factory control, etc., can solve problems such as poor propylene selectivity, and achieve the effect of improving propylene selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] There are two main operating conditions affecting the carbon three-phase liquid-phase hydrogenation reactor: inlet hydrogen-alkyne ratio and material temperature.

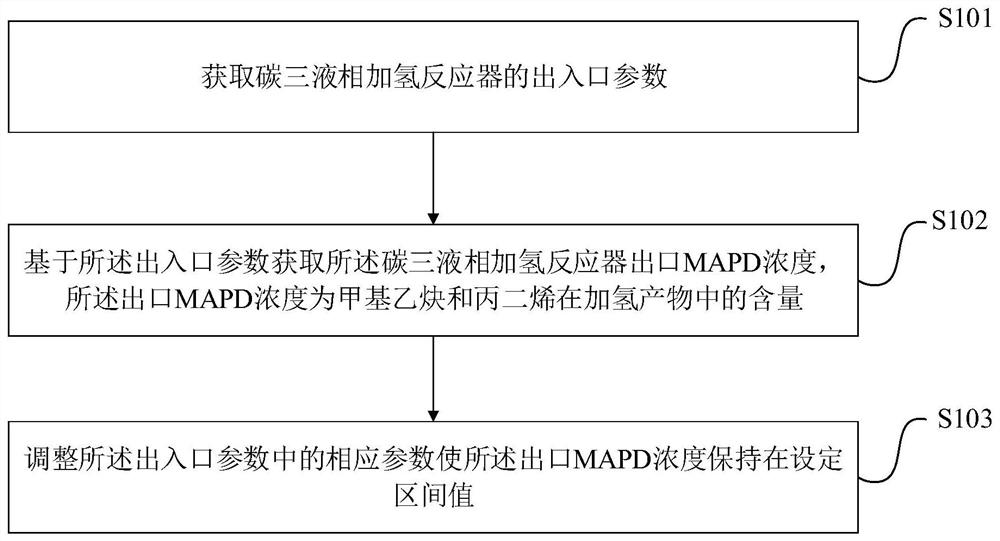

[0049] Such as figure 1 Shown, a kind of carbon three liquid phase hydrogenation reactor automatic control method, comprises:

[0050] Step S101: Acquiring the inlet and outlet parameters of the carbon three-phase liquid-phase hydrogenation reactor;

[0051] Inlet and outlet parameters, including: carbon three liquid phase hydrogenation reactor inlet material temperature, carbon three liquid phase hydrogenation reactor inlet material hydrogen-alkyne ratio, carbon three liquid phase hydrogenation reactor inlet material pressure, carbon three liquid phase hydrogenation reaction Material flow at the inlet of the reactor, MAPD concentration at the inlet of the carbon three-phase liquid-phase hydrogenation reactor, hydrogen flow at the inlet of the carbon three-liquid-phase hydrogenation reactor, hydrogen concen...

Embodiment 2

[0087] Such as figure 2 As shown, an automatic control device for a carbon three-phase liquid-phase hydrogenation reactor, including: a control server, a network device system control network and an embedded server, etc.

[0088] The control server includes at least a memory storing executable instructions;

[0089] A processor, the processor runs the executable instructions in the memory, so as to realize the automatic control method of the carbon three-phase liquid-phase hydrogenation reactor in Embodiment 1.

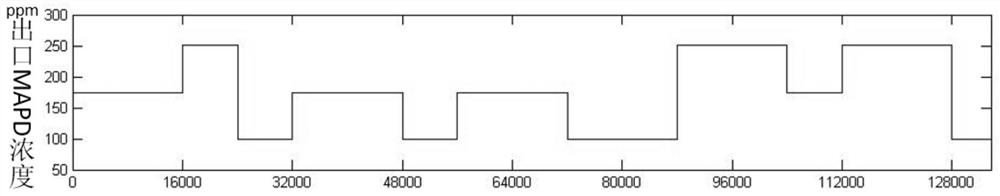

[0090] The processor (controller) is located in the distributed control system of the carbon three-phase liquid-phase hydrogenation reactor, that is, the DCS system or the server connected to the DCS. The control logic program in the controller collects the concentration of MAPD at the outlet, and automatically collects and analyzes the result data for storage. Inside a fixed memory unit (storage).

[0091] The control logic program in the controller automatically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com