Process for advanced controlling rectifying apparatus of butadiene

A device control, butadiene technology, used in chemical engineering and systems engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

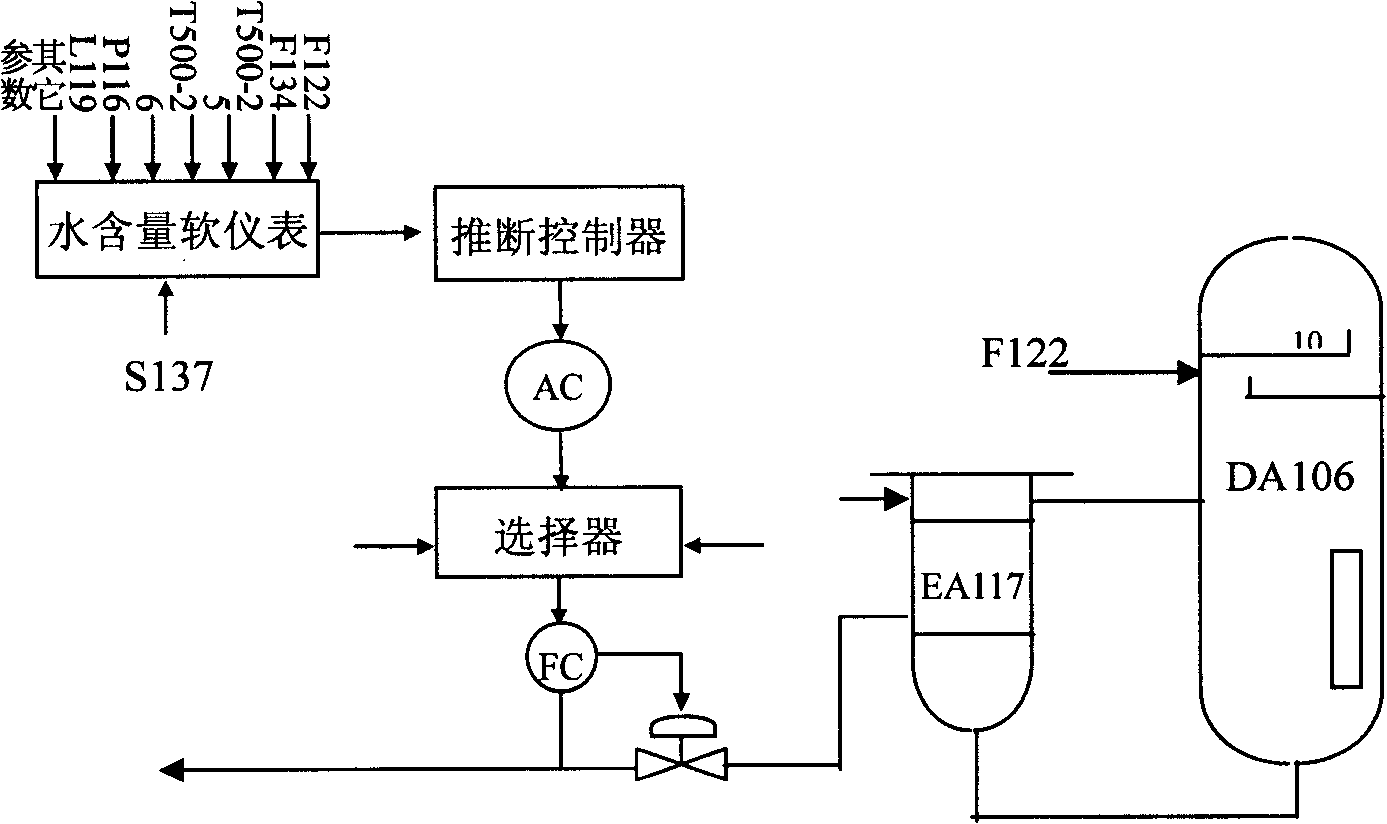

[0101] Example 1: DA106 tower kettle water content advanced control system

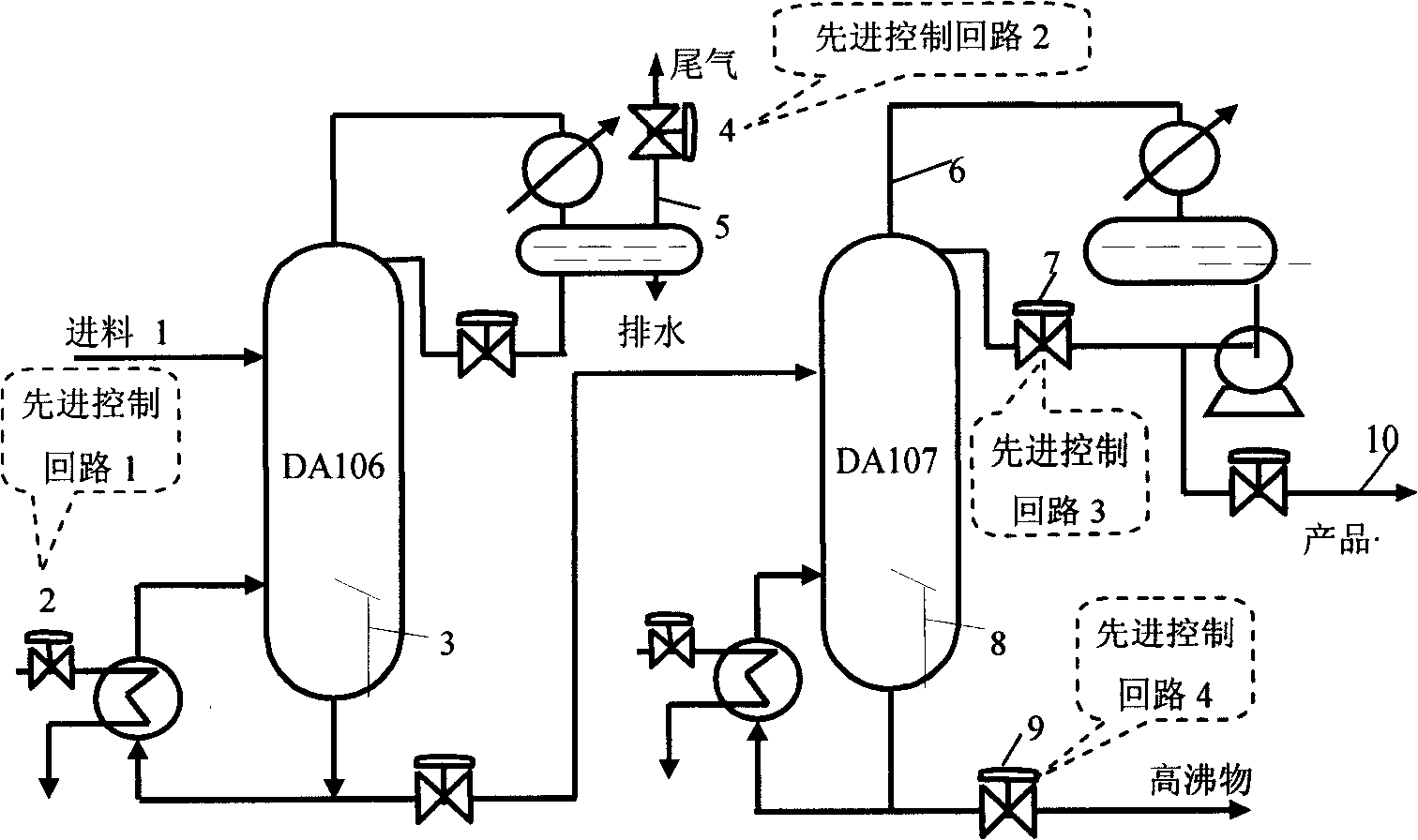

[0102] see figure 1 , DA106 column is an azeotropic distillation column, mainly used to remove low-boiling impurities (methyl acetylene, saturated water) in crude butadiene. The column has 70 trays in total, and the 11th tray is the feed tray. There is about 1200mg / kg saturated water in the feed, after forming a low-boiling azeotrope with butadiene in the DA106 tower, it is distilled from the top of the tower, and after condensation, it is naturally divided into upper and lower layers by settling in the reflux tank. All the condensate in the upper layer is sent to the DA106 tower as the reflux of the tower; a very small amount of free water formed by sedimentation in the lower layer is discharged from the boundary area. The process flow is shown in figure 1 shown.

[0103] Table 1 shows the running results of the soft sensor model for 288 hours from 06:15 on July 1, 2003 to 06:15 on July 11, 20...

Embodiment 2

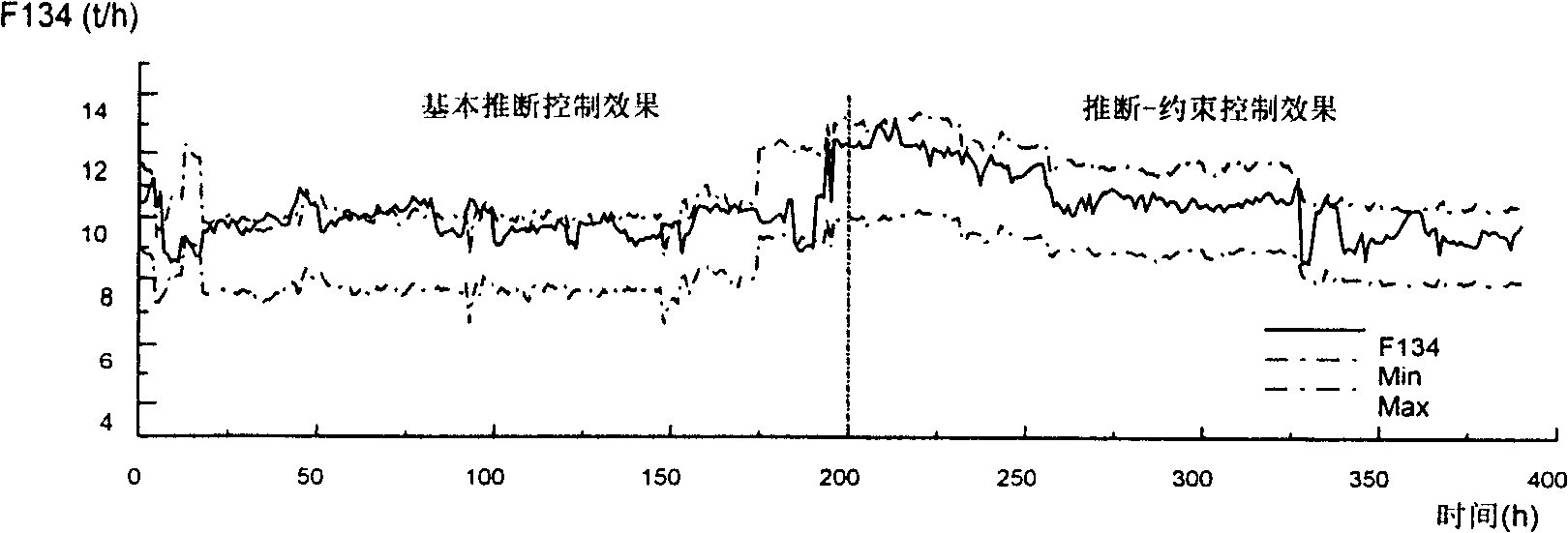

[0109] Example 2: Advanced Control System for Tail Gas Discharge at the Top of DA106 Tower

[0110] In the design of the industrial soft-sensing model, the above-mentioned soft-sensing modeling technology is still used to establish the industrial soft-sensing model of the MA content at the top of the tower. Figure 5It shows the real-time operation effect of the MA concentration soft measuring instrument in the tail gas of the DA106 rectification tower during the real-time operation period from December 1, 2002 to December 09, 2002. The soft measurement model is simple and practical, and the online correction function is reliable and effective. The design of the control scheme is advanced, practical and reliable, achieving the effect of significantly reducing energy consumption, increasing product yield and ensuring safe operation.

[0111] The key to the design of this advanced control scheme is to calculate an optimal tower top tail gas discharge, because if the discharge...

Embodiment 3

[0113] Example 3: DA107 tower return flow advanced control subsystem

[0114] Based on the variable analysis of the process operation of the plant and the simulation study of the mathematical model of the process mechanism of the DA107 distillation column, a soft sensor model for the content of butadiene and total alkyne in the top product of the DA107 column was established. The product quality soft sensor model developed in this project has high precision, which lays the foundation for the next step to realize the closed-loop advanced control of product quality. Figure 8 It shows the real-time operation effect of the DA107 tower top product quality butadiene-1,3 concentration soft measuring instrument during the real-time operation of the DA107 rectification tower from 16:15 on September 20, 2002 to 16:15 on October 1, 2002 . Table 2 shows the comparison results between the online estimated value and the test value of the actual operation of the product quality soft inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com