Preparation method of coal-based granular activated carbon with molecular sieving effect and application thereof in pressure-transformation adsorption and separation concentrated gas

A technology of granular activated carbon and pressure swing adsorption, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as inability to block pipes, etc., and achieve the effects of low pollution, low cost, and easy control of product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

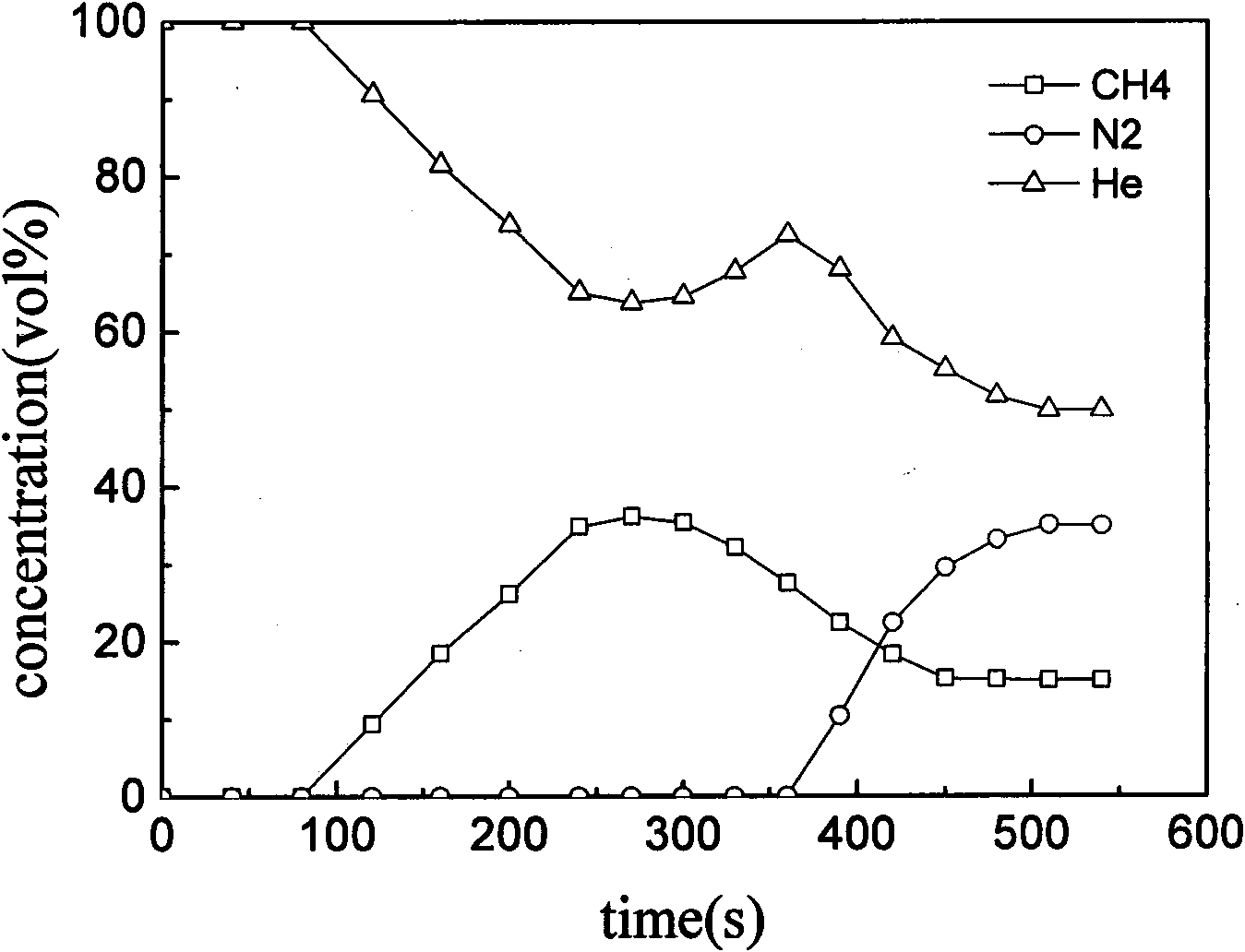

[0021] Example 1 The preparation method of coal-based granular activated carbon of the present invention and its application in pressure swing adsorption concentration and drainage of methane in coalbed methane

[0022] (1) Preparation of coal-based granular activated carbon adsorbent: crush and sieve lignite to 200 mesh, weigh 200g of coal powder, coal tar binder and water and mix evenly, and shape it into a column with a bottom diameter of 4mm and a height of 5mm on a molding machine Granules were dried in an oven at 120°C for 2 hours; then the molded samples were placed in a heating furnace, under the protection of nitrogen, the nitrogen flow rate was 12ml / h, heated to 700°C at a heating rate of 10°C / min, and after constant temperature for 1h, the Continue heating to 800°C at a heating rate of 10°C / min, and activate with water vapor at a constant temperature for 4 hours; after the reaction of the material is completed, cool to room temperature and discharge, then wash with w...

Embodiment 2

[0025] Example 2 The preparation method of coal-based granular activated carbon of the present invention and its application in pressure swing adsorption to concentrate carbon dioxide in flue gas

[0026] (1) Preparation of coal-based granular activated carbon adsorbent: brown coal is crushed and sieved to 160 mesh, 200g of coal dust and coal tar binder are evenly mixed, and formed into columnar particles with a bottom diameter of 4mm and a height of 5mm on a molding machine, Dry in an oven at 90°C for 4 hours; then place the molded sample in a heating furnace under nitrogen protection with a nitrogen flow rate of 12ml / h and heat to 500°C at a heating rate of 10°C / min. / min heating rate continued to heat to 800°C, and water vapor was activated at constant temperature for 3 hours; after the reaction of the material was completed, it was cooled to room temperature and discharged, then washed with water and dried to obtain 62g of the product.

[0027] (2) For pressure swing adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com