Method for preparing organic-inorganic hybrid total heat exchange membrane through sol-gel method

A technology of total heat exchange membrane and sol-gel method, which is applied in the field of preparing organic-inorganic hybrid total heat exchange membrane, and can solve the problem of inability to effectively isolate harmful gases and bacteria, secondary pollution of indoor air, ineffective ventilation, etc. problems, to achieve the effect of facilitating large-scale development and production, increasing interaction, and promoting dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

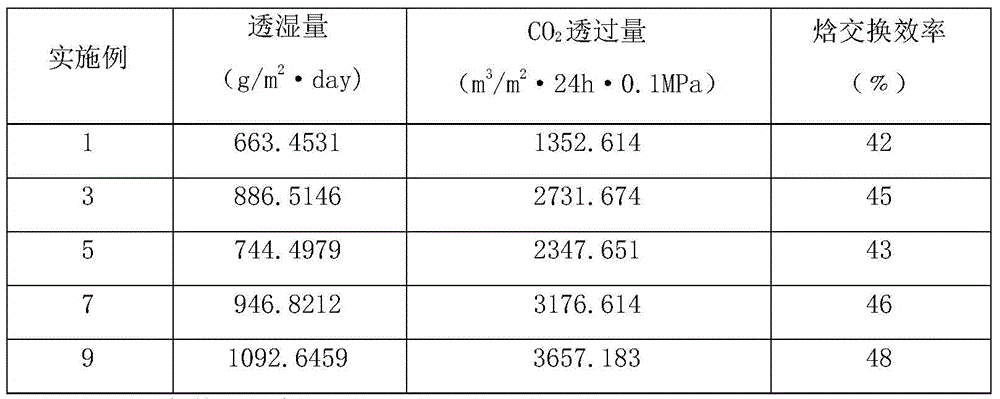

Examples

Embodiment 1

[0018] Dissolve 5 g of cellulose acetate (degree of esterification 280-300, acetyl content 42.5%-44.8%) in 95 g of acetic acid, dissolve at 55°C for 3 h, let stand for defoaming, and obtain a uniform and transparent cellulose acetate solution.

[0019] Add 1g of aluminum isopropoxide to the cellulose acetate solution, add 2 drops of hydrochloric acid, and stir at 95°C for 2 hours to fully hydrolyze and polycondense the precursor to form nano-sized particles, and then reflux in a constant temperature water bath for 8 hours to make the nano-particles The particles are uniformly dispersed in the cellulose acetate forming solution.

[0020] The prepared organic-inorganic hybrid casting solution was subjected to vacuum defoaming, and flow-casted on a glass plate, with a wet film thickness of 150 μm. Then put the film into a vacuum oven at 60°C and dry for 3 hours. Finally, peel off the film and leave it at room temperature for 24 hours to test its performance.

[0021] The water ...

Embodiment 2

[0023] Dissolve 4g of cellulose acetate (degree of esterification 240-260, acetyl content 39.5-41.5) in 96g of acetone-methanol mixed solution, the volume ratio of the solvent is 1:1, stir at 70°C for 4 hours, let it stand for defoaming , to obtain a transparent and stable casting solution.

[0024] Add 2g of butyl titanate to the cellulose acetate solution, add 3 drops of hydrochloric acid, and stir at 60°C for 3 hours to fully hydrolyze and polycondense the precursor to form nano-sized particles, and then reflux in a constant temperature water bath for 10 hours to make the nano-particles The particles are uniformly dispersed in the cellulose acetate forming solution.

[0025] The prepared organic-inorganic hybrid casting solution was subjected to vacuum defoaming, and flow-casted on a glass plate, with a wet film thickness of 200 μm. Then put the film into a vacuum oven at 50°C and dry it for 4 hours. Finally, peel off the film and leave it at room temperature for 24 hours...

Embodiment 3

[0028] Dissolve 7g of cellulose acetate (degree of esterification 230-240, acetyl content 38.0-39.5) in 93g of acetone solution, stir at 75°C for 2 hours, let stand for defoaming, and obtain a transparent and stable casting solution.

[0029] Add 4g tetraethyl orthosilicate to the prepared cellulose acetate solution, add 2 drops of 2mol / L sodium hydroxide solution, stir at 50°C for 3h, fully hydrolyze and polycondense the precursor to form nano-sized particles, and then keep the temperature The water bath was refluxed for 12 hours, so that the nanoparticles were uniformly dispersed in the solution for forming cellulose acetate.

[0030] The prepared organic-inorganic hybrid casting solution was subjected to vacuum defoaming, and flow-casted on a glass plate, with a wet film thickness of 300 μm. Then put the film into a vacuum oven at 60°C and dry for 3 hours. Finally, peel off the film and leave it at room temperature for 24 hours to test its performance.

[0031] The novel ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com