Flame retardant conducting polymer composition

A conductive polymer and composition technology, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of potential safety hazards, easy combustion in case of fire, poor flame retardant effect, etc., to achieve improved dispersion, bio Uniform heat distribution, high safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

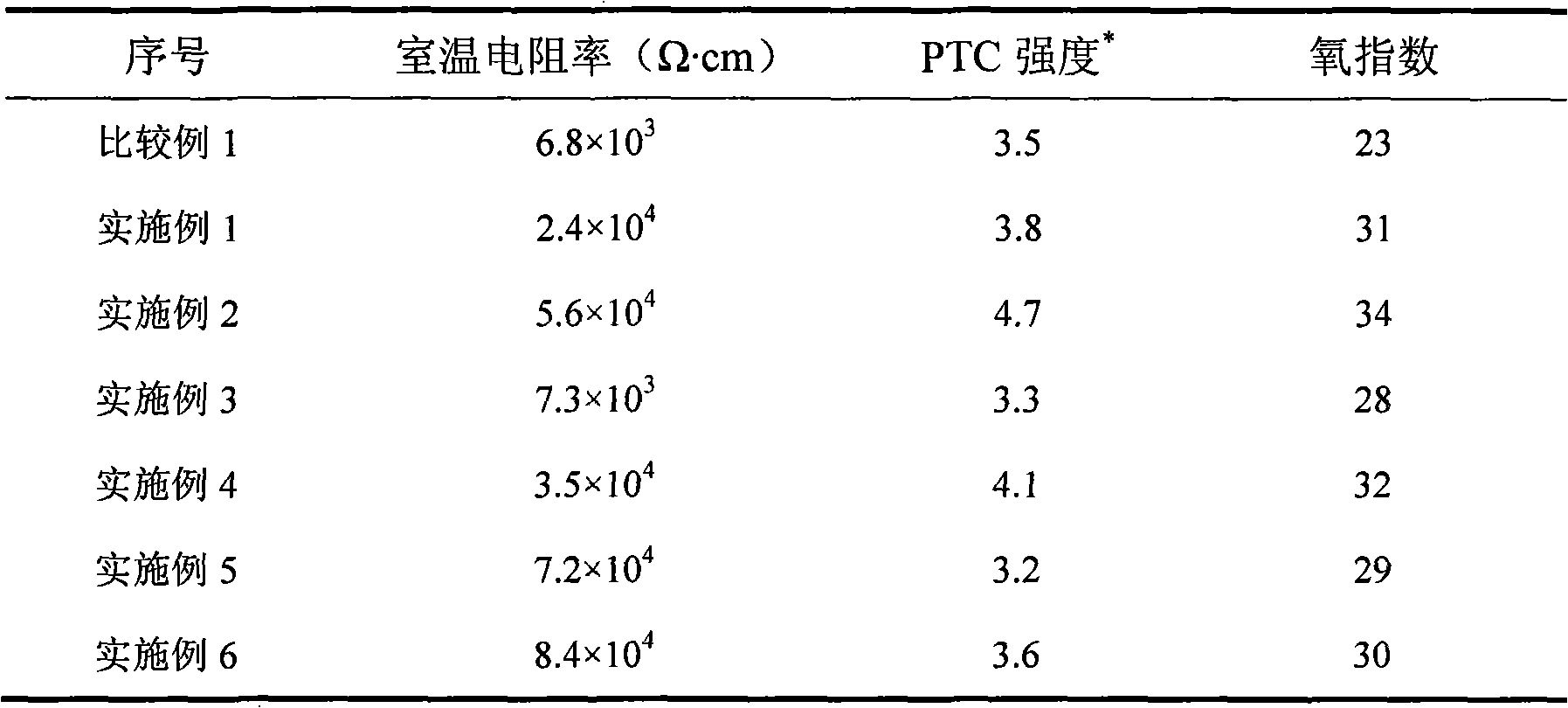

Examples

Embodiment 1

[0038] 100 parts by weight of low-density polyethylene (melting temperature 105°C-115°C)

[0039] Carbon black (particle diameter 30nm-40nm) 45 parts by weight

[0040] Ammonium polyphosphate 30 parts by weight

[0041] Melamine 20 parts by weight

[0042] Aluminum hydroxide 15 parts by weight

[0043] Ethylene-ethyl acrylate copolymer 30 parts by weight

[0044] Calcium carbonate filler 6 parts by weight

[0045] Tetrakis-(4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaerythritol ester 0.5 parts by weight

[0046]Trimethylol propane trimethacrylate 2 parts by weight

[0047] According to the above ratio, first add low-density polyethylene and ethylene-ethyl acrylate copolymer into the internal mixer, and after the polymer is completely plasticized, add carbon black, ammonium polyphosphate, melamine, aluminum hydroxide, calcium carbonate, Antioxidant and cross-linking agent, controlled mixing temperature 150°C, mixing time 20min, take out, hot press into 1mm and 3mm ...

Embodiment 2

[0049] High-density polyethylene (melting temperature 130°C-140°C) 100 parts by weight

[0050] Carbon black (particle diameter 80nm-100nm) 60 parts by weight

[0051] 30 parts by weight of triphenyl phosphite

[0052] 25 parts by weight of melamine cyanurate

[0053] Aluminum hydroxide 10 parts by weight

[0054] Ethylene-vinyl acetate copolymer 40 parts by weight

[0055] Calcium carbonate filler 6 parts by weight

[0056] Antioxidant 1010 0.5 parts by weight

[0057] Trimethylol propane trimethacrylate 2 parts by weight

[0058] According to the above ratio, first add high-density polyethylene and ethylene-vinyl acetate copolymer into the open mill, after the polymer is completely plasticized, add carbon black, triphenyl phosphite, melamine cyanurate, hydrogen Alumina, calcium carbonate, antioxidant and cross-linking agent, control the mixing temperature at 190°C, take out the mixing time for 10 minutes, hot press into samples with a thickness of 1mm and 3mm respectiv...

Embodiment 3

[0060] Linear low density polyethylene (melting temperature 120°C-130°C) 100 parts by weight

[0061] Carbon black (particle diameter 20nm-30nm) 45 parts by weight

[0062] Bisphenol A-two (diphenyl phosphate) 5 parts by weight

[0063] 35 parts by weight of melamine pyrophosphate

[0064] Magnesium hydroxide 50 parts by weight

[0065] Ethylene-acrylic acid copolymer 20 parts by weight

[0066] Zinc oxide filler 8 parts by weight

[0067] Tetrakis-(4-hydroxy-3,5-tert-butylphenylpropionic acid) pentaerythritol ester 0.5 parts by weight

[0068] Trimethylol propane trimethacrylate 0.5 parts by weight

[0069] According to the above ratio, first add linear low density polyethylene and ethylene-acrylic acid copolymer into the open mill, after the polymer is completely plasticized, add carbon black, bisphenol A-bis(diphenyl phosphate), melamine coke Phosphate, magnesium hydroxide, zinc oxide, antioxidant and cross-linking agent, control the mixing temperature at 170°C, take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com