Preparation method and application of magnetic graphene oxide adsorbent material

An oxide stone and adsorbent technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve the problems of low utilization efficiency, low adsorption capacity, difficult recovery and separation, etc. To achieve the effect of easy separation, good dispersibility, and low adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

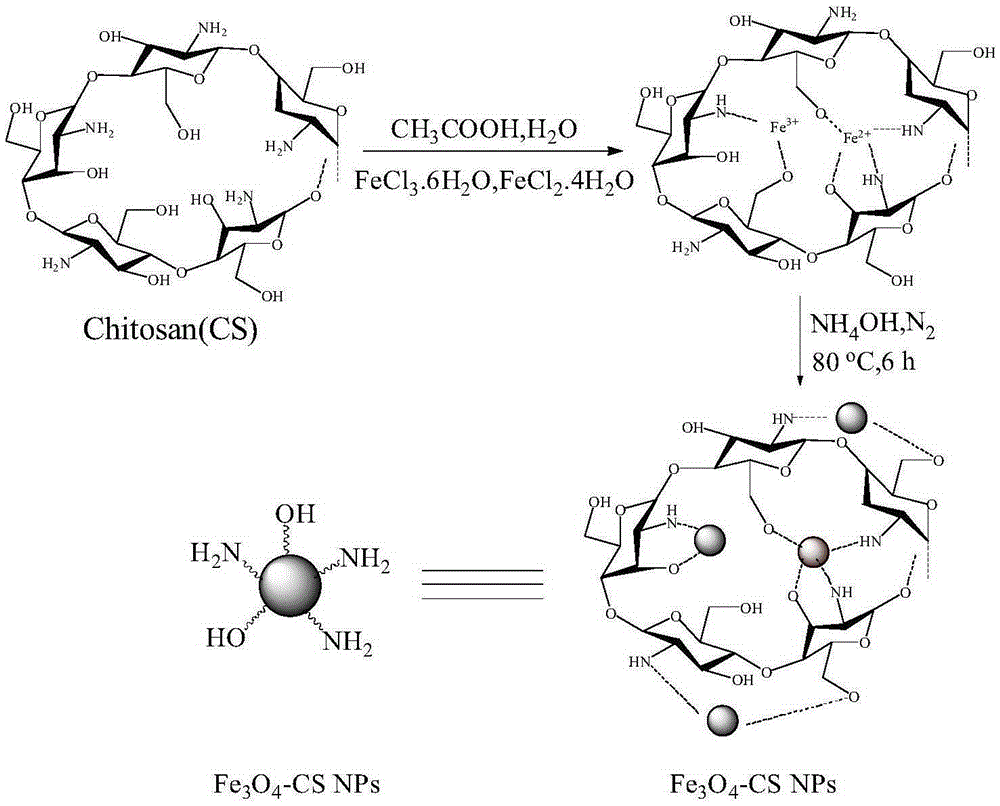

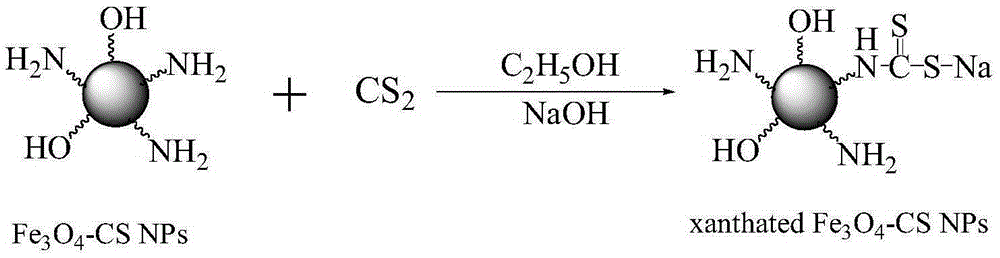

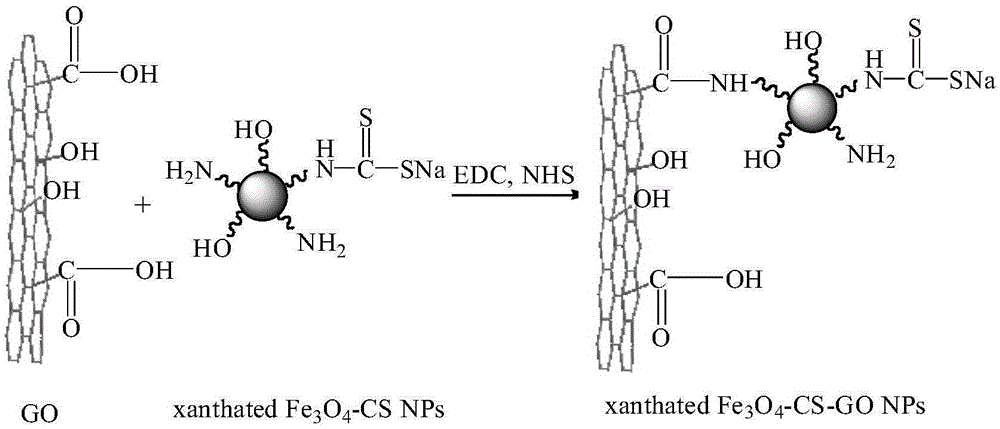

[0037] A preparation method of magnetic graphene oxide adsorbent material, comprising the steps of:

[0038] (a) Preparation of graphene oxide (GO)

[0039]Graphite oxide is prepared by the modified Hummers method of graphite powder. Weigh 2.0g of graphite powder in a 250mL conical flask, slowly pour 46mL of 98% mass fraction of concentrated sulfuric acid into the conical flask, then place it in an ice-water bath, stir and mix by magnetic force, then slowly add 1.0gNaNO 3 and 6.0 g KMnO 4 , mixed and stirred in an ice-water bath for 2 hours, and then the mixture was transferred to a constant temperature water bath at 35° C. for 12 hours. Then add 280mL of deionized water to dilute, and stir for 30min. After the temperature rises to 90°C, add 100mL of 30% H 2 o 2 , after being cooled to room temperature, filter to obtain product, wash product with volume fraction 5% HCl (until the filtrate is made of BaCl 2 Solution detection without SO 4 2- ), washed with deionized wate...

Embodiment 2

[0047] A preparation method of magnetic graphene oxide adsorbent material, comprising the steps of:

[0048] (a) Preparation of graphene oxide (GO)

[0049] Graphite oxide is prepared by the modified Hummers method of graphite powder. Weigh 2.2g of graphite powder in a 250mL conical flask, slowly pour 50mL of 98% mass fraction of concentrated sulfuric acid into the conical flask, then place it in an ice-water bath, stir and mix by magnetic force, then slowly add 1.2gNaNO 3 and 6.5g KMnO 4 , mixed and stirred in an ice-water bath for 2.3 hours, and then the mixture was transferred to a constant temperature water bath at 30° C. for 12 hours. Then add 300mL of deionized water to dilute, and stir for 30min. After the temperature rises to 90°C, add 110mL of 30% H 2 o 2 , after being cooled to room temperature, filter to obtain product, wash product with volume fraction 5% HCl (until the filtrate is made of BaCl 2 Solution detection without SO 4 2- ), washed with deionized wa...

Embodiment 3

[0057] A preparation method of magnetic graphene oxide adsorbent material, comprising the steps of:

[0058] (a) Preparation of graphene oxide (GO)

[0059] Graphite oxide is prepared by the modified Hummers method of graphite powder. Weigh 2.4g of graphite powder in a 250mL conical flask, slowly pour 55mL of 98% mass fraction of concentrated sulfuric acid into the conical flask, then place it in an ice-water bath, stir and mix by magnetic force, then slowly add 1.0gNaNO 3 and 7.0 g KMnO 4 , mixed and stirred in an ice-water bath for 2.5 hours, and then the mixture was transferred to a constant temperature water bath at 33° C. for 10 hours. Then add 340mL of deionized water to dilute, and stir for 30min. After the temperature rises to 90°C, add 120mL of 30% H 2 o 2 , after being cooled to room temperature, filter to obtain product, wash product with volume fraction 5% HCl (until the filtrate is made of BaCl 2 Solution detection without SO 4 2- ), washed with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com