Clay-resisting slow-release slump-retaining type polycarboxylate superplasticizer and preparation method thereof

A slump-preserving polycarboxylate technology, applied in the field of concrete admixtures, can solve problems such as high mud content in sand and gravel, poor adaptability of polycarboxylate water-reducers, and large loss of concrete slump. Good anti-mud effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

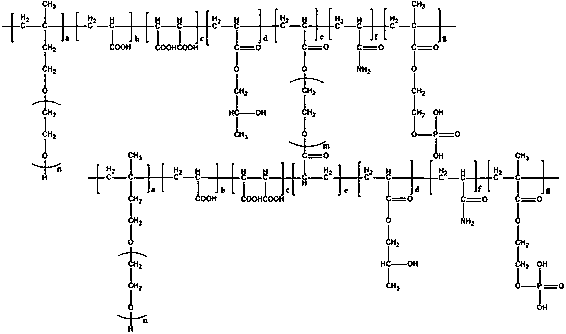

[0030] A mud-resistant, slow-release and slump-preserving polycarboxylate water reducer, which is prepared from primer, liquid A, liquid B and neutralizing liquid through copolymerization and neutralization reactions;

[0031] The base material is composed of the following raw materials in parts by weight: 340.0 parts of prenol polyoxyethylene ether, 3.0 parts of maleic anhydride, 3.0 parts of sodium hypophosphite, 2.4 parts of hydrogen peroxide, and 200.0 parts of water;

[0032] The liquid A is composed of the following raw materials in parts by weight: 0.5 parts of ascorbic acid, 1.8 parts of mercaptopropionic acid, and 120.0 parts of water;

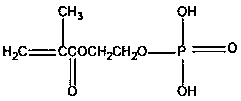

[0033] The B liquid is composed of the following raw materials in parts by weight: 15.0 parts of acrylic acid, 25.0 parts of methyl acrylate, 3.0 parts of polyethylene glycol diacrylate, 5.0 parts of acrylamide, 6.0 parts of 2-hydroxyethyl methacrylate phosphate, 80.0 parts of water;

[0034] The neutralization solution is composed o...

Embodiment 2

[0044] A mud-resistant, slow-release and slump-preserving polycarboxylate water reducer, which is prepared from primer, liquid A, liquid B and neutralizing liquid through copolymerization and neutralization reactions;

[0045] The base material is composed of the following raw materials in parts by weight: 360.0 parts of isopentenol polyoxyethylene ether, 5.0 parts of itaconic anhydride, 4.0 parts of sodium hypophosphite, 4.0 parts of ammonium persulfate, and 200 parts of water;

[0046] The A liquid is composed of the following raw materials in parts by weight: 0.7 parts of ascorbic acid, 1.5 parts of thioglycolic acid, and 120 parts of water;

[0047] The B liquid is composed of the following raw materials in parts by weight: 18.0 parts of acrylic acid, 26.0 parts of hydroxyethyl acrylate, 4.0 parts of polyethylene glycol dimethacrylate, 7.0 parts of 2-acrylamide-2-methylpropanesulfonic acid, 1 - 8.0 parts of hydroxyethyl methacrylate phosphate, 80 parts of water;

[0048] ...

Embodiment 3

[0058] A mud-resistant, slow-release and slump-preserving polycarboxylate water reducer, which is prepared from primer, liquid A, liquid B and neutralizing liquid through copolymerization and neutralization reactions;

[0059] The base material is composed of the following raw materials in parts by weight: 350.0 parts of methallyl alcohol polyoxyethylene ether, 6.0 parts of maleic anhydride, 4.0 parts of sodium hypophosphite, 3.0 parts of hydrogen peroxide, and 200.0 parts of water;

[0060] The A liquid is composed of the following raw materials in parts by weight: 1.0 parts of diaobai block, 2.0 parts of mercaptopropionic acid, and 120.0 parts of water;

[0061] The B liquid is composed of the following raw materials in parts by weight: 24.0 parts of methacrylic acid, 22.0 parts of hydroxypropyl acrylate, 6.0 parts of polyethylene glycol diacrylate, 8.0 parts of acrylamide, 2-hydroxyethyl methacrylate phosphate 9.0 parts, water 80.0 parts;

[0062] The neutralization soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com