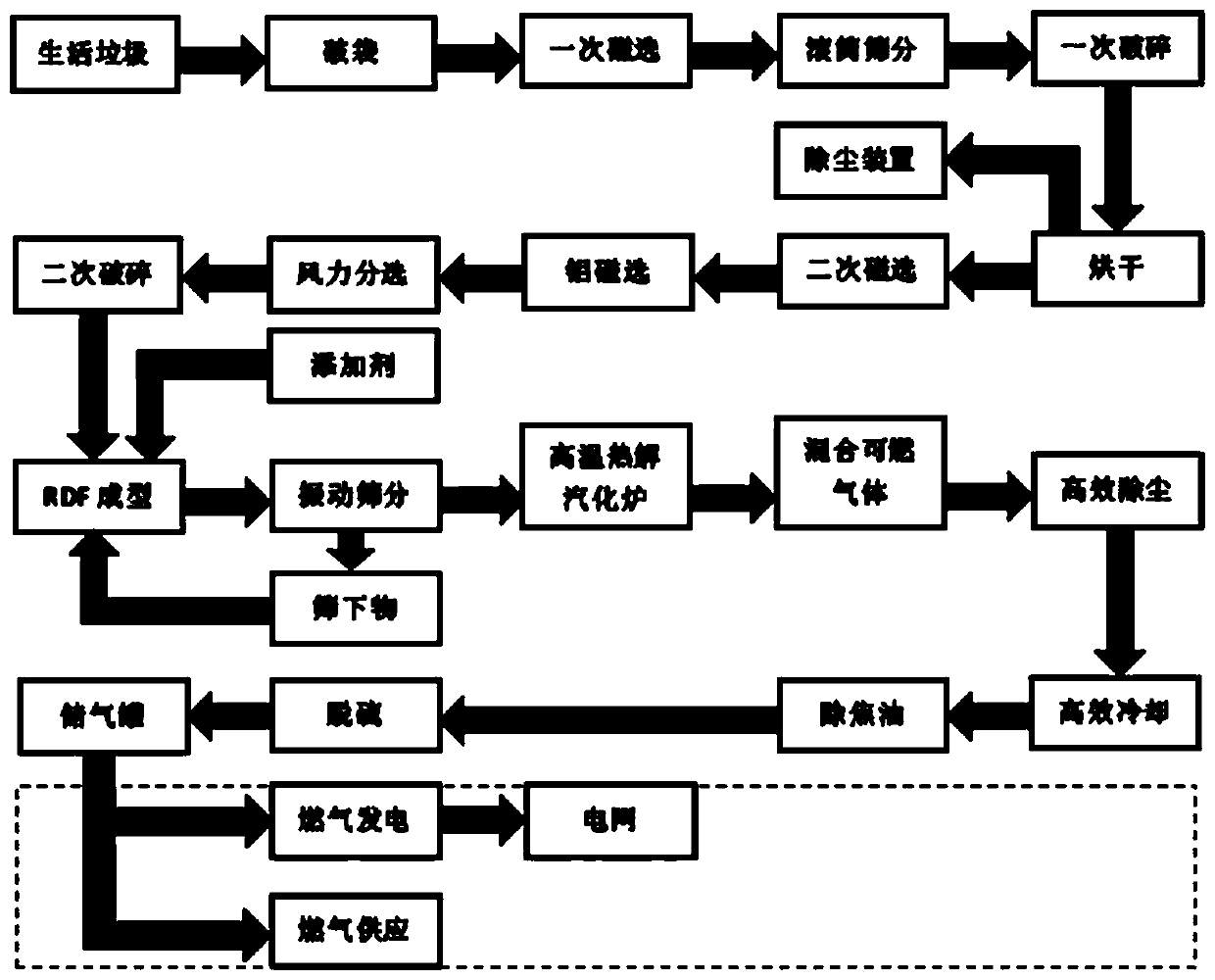

Process for making RDF from domestic garbage and high-temperature pyrolysis gasification treatment

A technology of pyrolysis and gasification of domestic waste, applied in the direction of manufacturing combustible gas, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of a large amount of leachate, insufficient compactness of derived fuels, and difficulty in popularization, and achieve economical High value, wide range of industrial application, excellent economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0029] Household waste process: Household waste is transported by waste removal vehicles to the material pit of the treatment plant. The waste pit is in a negative pressure and airtight state. There is a leachate collection pool designed. The domestic waste needs to be cleared from day to day and cannot be left overnight. The garbage is sent to the hopper of the bag breaking machine by the garbage grab.

[0030] Since the domestic garbage is cleared from day to day, it will be processed within 10 hours. The garbage will not stay overnight, and the garbage will be cleaned up before it has time to ferment. Secondary pollution.

[0031] The garbage grab machine adopts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com