Modified molding and gasifying method for household garbage

A technology of domestic waste and modification, applied in gasification process, biofuel, manufacture of combustible gas, etc., can solve the problems of insufficient heat, difficult heat transfer, slow gasification process, etc., to save processing cost and high gasification efficiency , the effect of reducing sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings, but it is not intended to limit the present invention.

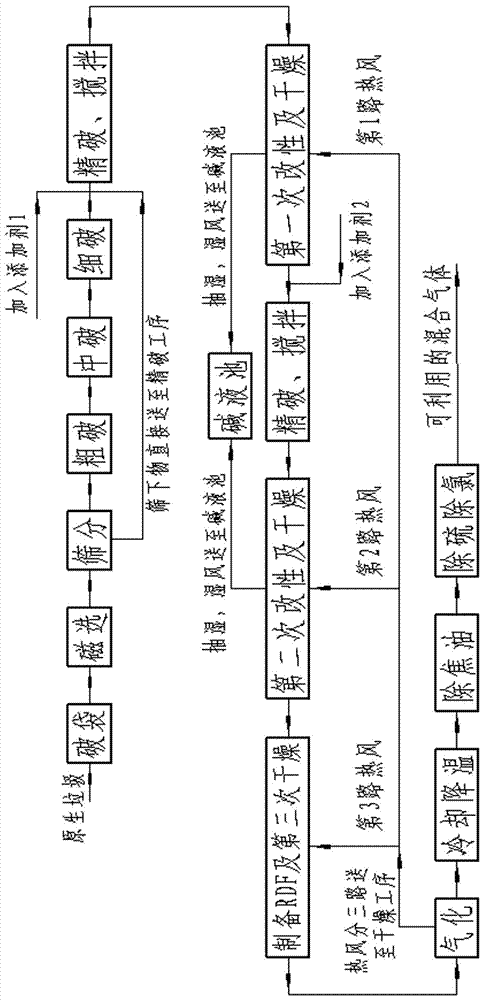

[0057] refer to figure 1 , a method for modified molding and gasification of domestic waste, including the following steps: bag breaking → magnetic separation → screening → coarse crushing → medium crushing → fine crushing → fine crushing, stirring, adding additive 1 → first modification And drying→fine crushing, stirring, adding additive 2→second modification and drying→preparation of RDF and third drying→gasification→cooling and cooling→removing tar→removing chlorine and sulfur.

[0058] Each process is described in detail as follows:

[0059] (1) Bag breaking process: There is no need for manual pre-sorting of household garbage, and the bagged household garbage is broken and disassembled with a crusher; at the same time, the hard bulky garbage is squeezed and broken.

[0060] The grabb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com