Method for processing and utilizing electrolytic manganese waste residue

A technology of electrolytic manganese waste slag and pretreatment, applied in the direction of solid waste removal, etc., can solve the problems of reducing the utilization efficiency of manganese slag, achieve good economic benefits, low production cost, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

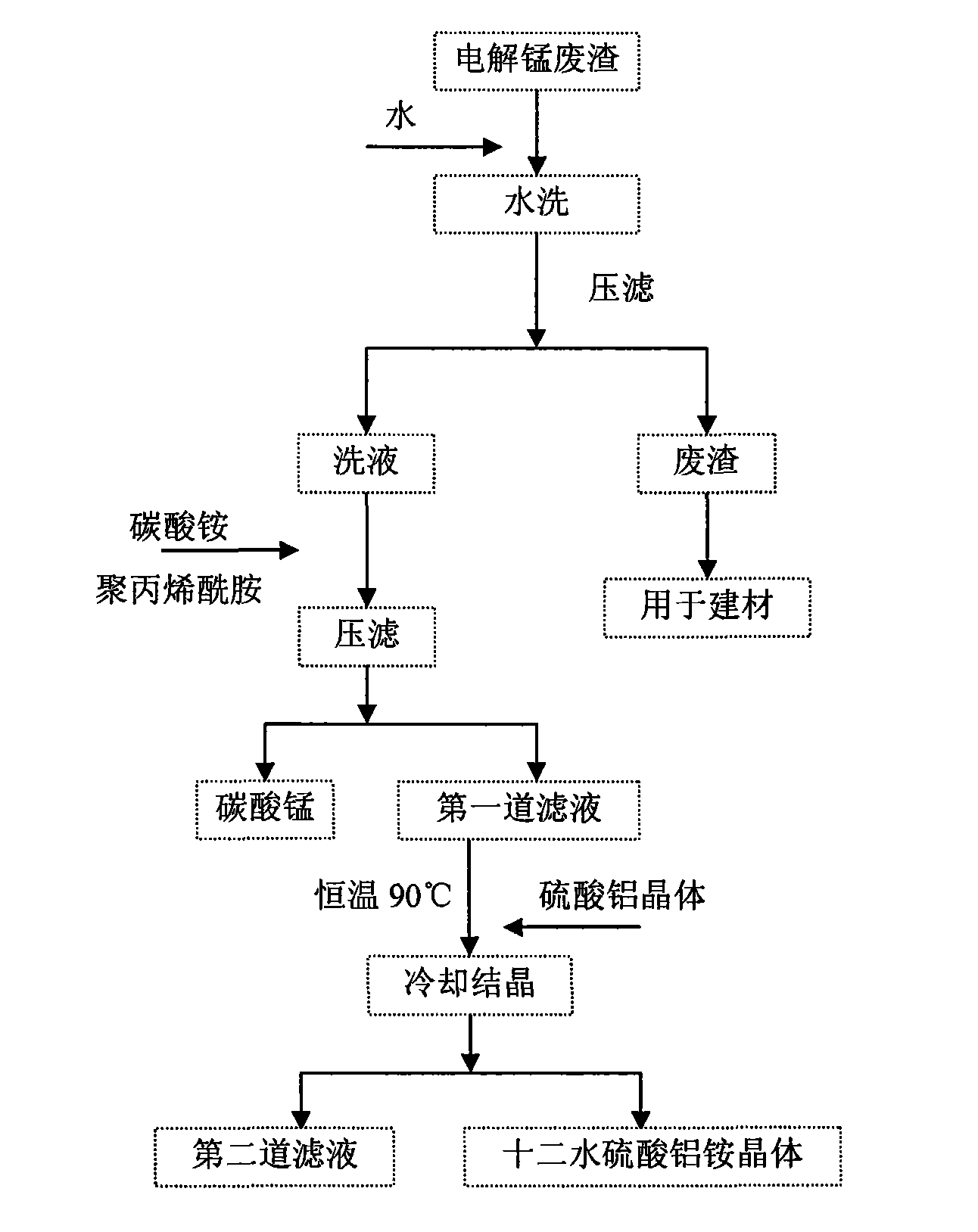

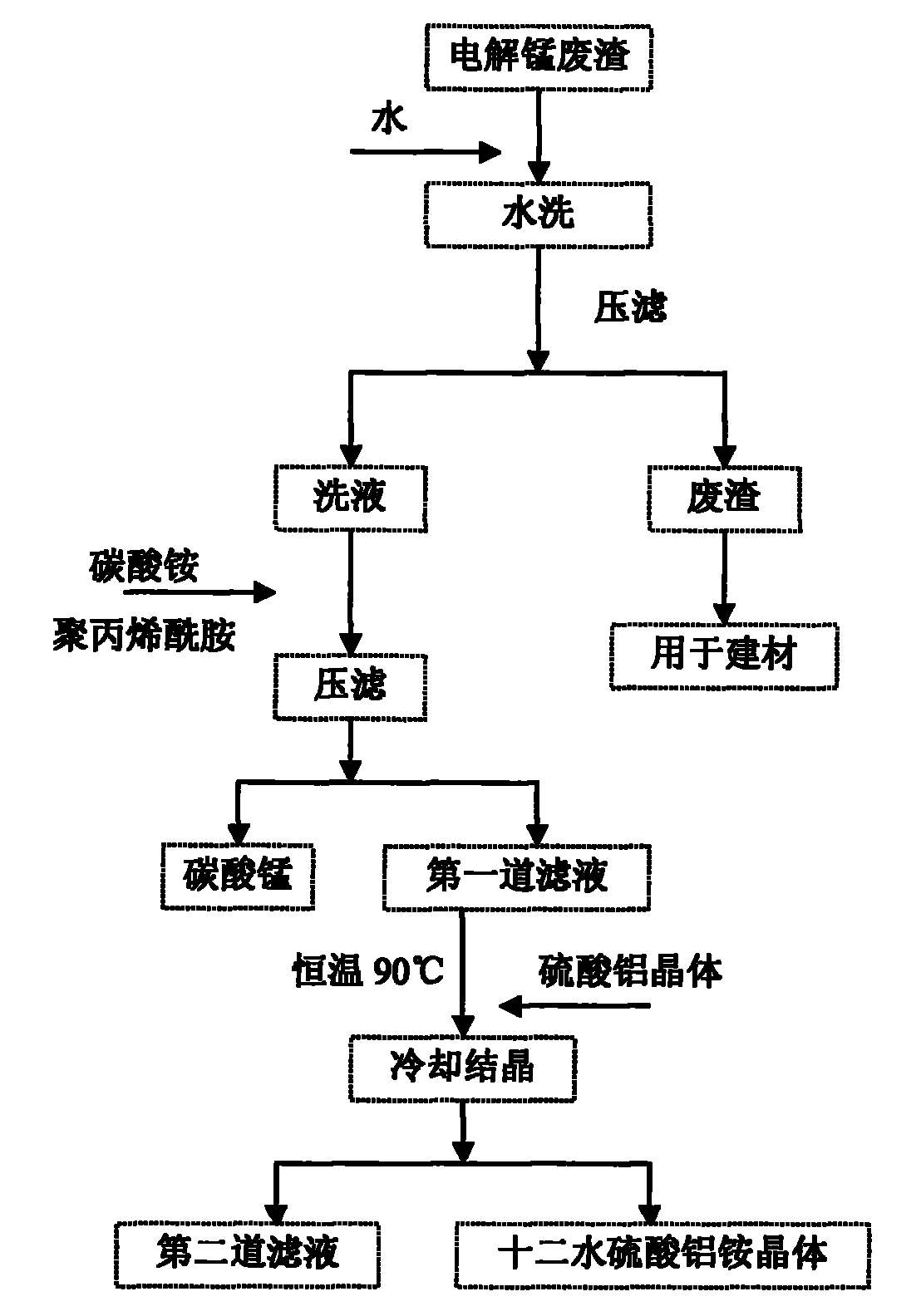

[0013] A method for processing and utilizing electrolytic manganese waste slag (refer to figure 1 ), the method includes the following steps.

[0014] a. Pretreatment of electrolytic manganese waste slag (washing): first dry the electrolytic manganese waste slag, grind, sieve, then mix the electrolytic manganese waste slag with water in a ratio of 1:5 to 8 according to the mass ratio, and stir at room temperature for at least After 60 minutes, stand still and press filter to obtain washing liquid and waste residue after washing—the waste residue is still used in building materials such as brick making and paving;

[0015] b. Manganese salt recovery: add ammonium carbonate in at least three batches to the above washing liquid, the molar ratio of the total amount of ammonium carbonate added to the manganese sulfate contained in the electrolytic manganese waste residue is 1.3:1; adjust the pH to 6.0-8.0 Finally, stir at room temperature for at least 50 minutes; then add floccula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com