Tube drawing forming method and forming mould

A technology for pipe drawing and forming die, applied in the method and forming die, the field of pipe drawing and forming, can solve the problems of cracking, insufficient strength, affecting the safety and reliability of aircraft pipelines, and achieve a large degree of deformation, changing shape and The effect of distributing, eliminating internal tissue defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment is a device with a diameter of The drawing method of the aluminum tube with a wall thickness of 1 mm and a length of 20 mm.

[0042] The method for drawing and forming aluminum tube proposed in this embodiment includes the following steps:

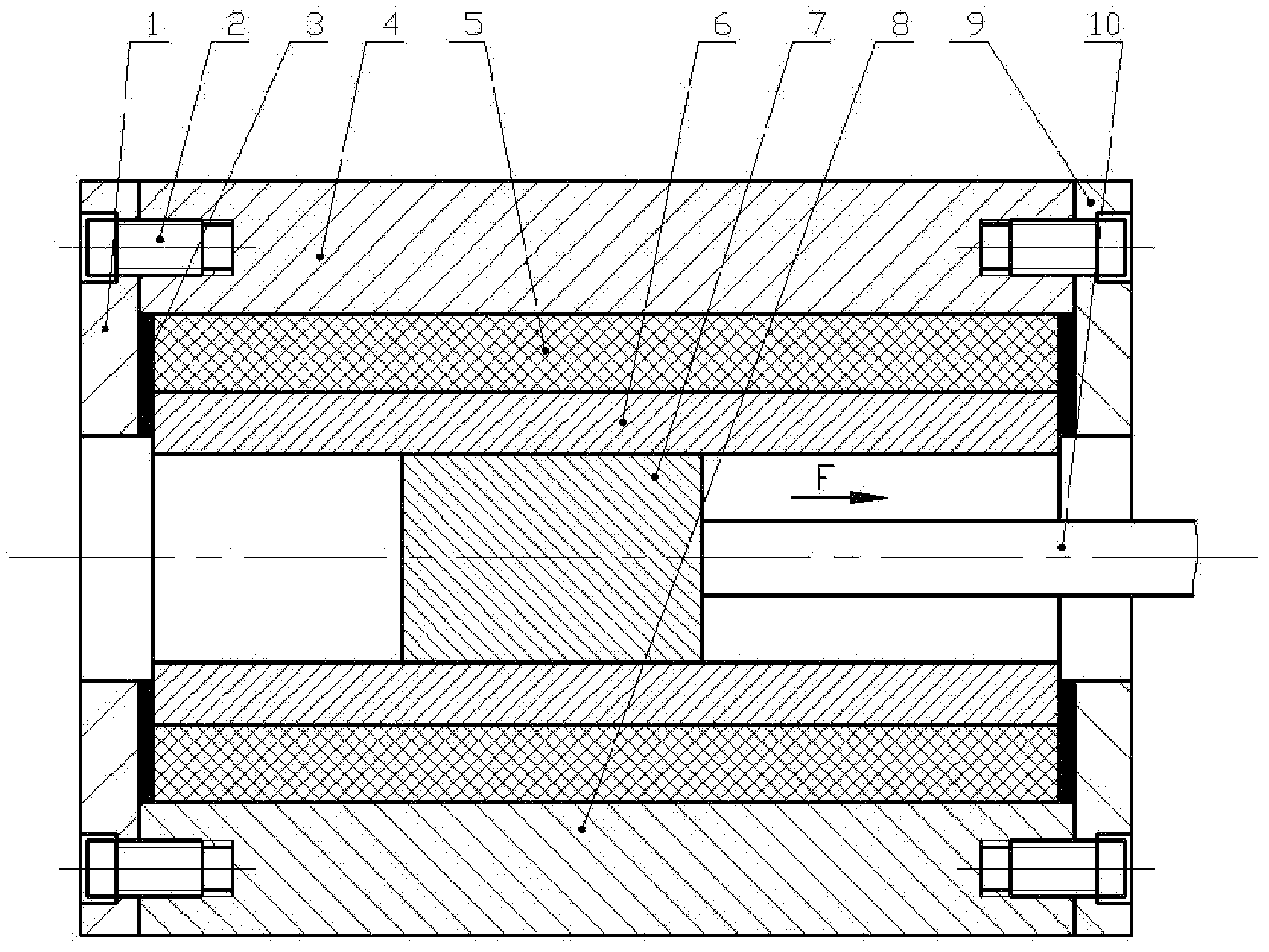

[0043] Step one, mold loading. The inner wall and the outer wall of the pipe material 6 are smeared with lard lubricant. Put the pipe 6 coated with lubricant into the polyurethane filling layer 5 . The polyurethane filling layer 5 with the pipe 6 is placed in the lower mold case 8, and gaskets 3 are placed on the end faces of the two ends of the polyurethane filling layer 5; the length of the pipe 6 and the polyurethane filling layer 5 are the same. Put the upper die case 4 on the lower die case 8, and make the parting surfaces of the upper die case 4 and the lower die case 8 tightly fastened, and the two ends of the upper die case 4 and the lower die case 8 are aligned. The inlet end cover 1 and the outlet end ...

Embodiment 2

[0048] This embodiment is a device with a diameter of The drawing method of the copper pipe with a wall thickness of 3mm and a length of 30mm.

[0049] The method that the present embodiment proposes for copper pipe drawing and forming comprises the following steps:

[0050] Step one, mold loading. The inner wall and the outer wall of the pipe material 6 are smeared with lard lubricant. Put the pipe 6 coated with lubricant into the polyurethane filling layer 5 . The polyurethane filling layer 5 with the pipe 6 is placed in the lower mold case 8, and gaskets 3 are placed on the end faces of the two ends of the polyurethane filling layer 5; the length of the pipe 6 and the polyurethane filling layer 5 are the same. Put the upper die case 4 on the lower die case 8, and make the parting surfaces of the upper die case 4 and the lower die case 8 tightly fastened, and the two ends of the upper die case 4 and the lower die case 8 are aligned. The inlet end cover 1 and the outlet ...

Embodiment 3

[0055] This embodiment is a device with a diameter of The variable cross-section drawing forming method of steel pipe with a wall thickness of 5mm and a length of 50mm.

[0056] The method for steel pipe drawing and forming proposed by the present embodiment comprises the following steps:

[0057] Step one, mold loading. The inner wall and the outer wall of the pipe material 6 are smeared with lard lubricant. Put the pipe 6 coated with lubricant into the polyurethane filling layer 5 . The polyurethane filling layer 5 with the pipe 6 is placed in the lower mold case 8, and gaskets 3 are placed on the end faces of the two ends of the polyurethane filling layer 5; the length of the pipe 6 and the polyurethane filling layer 5 are the same. Put the upper die case 4 on the lower die case 8, and make the parting surfaces of the upper die case 4 and the lower die case 8 tightly fastened, and the two ends of the upper die case 4 and the lower die case 8 are aligned. The inlet end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com