Method and device for preparing metal base nano composite material by ultrasound stirring and continuous casting

A nano-composite material and ultrasonic stirring technology, which is applied in the field of casting, can solve the problems of limited melt amount and not very good, and achieve the effects of reducing agglomeration, good material performance and wide industrial application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

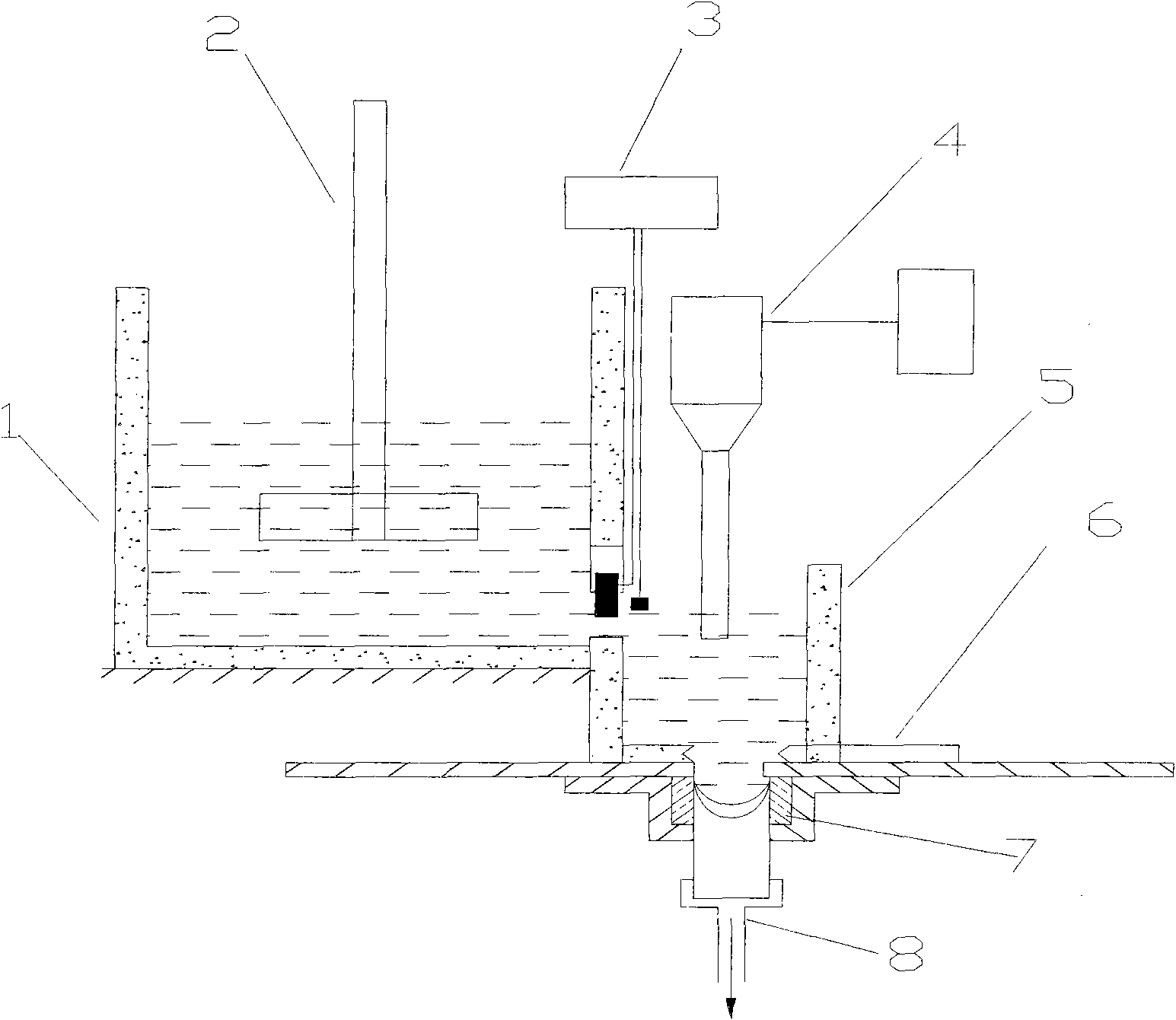

[0024] This embodiment adopts ultrasonic stirring vertical continuous casting device, its structure is as follows figure 1 As shown, the device is composed of liquid storage ladle 1, agitator 2, liquid level controller 3, ultrasonic generator 4, pouring ladle 5, control valve 6, crystallizer 7, dummy rod 8; among them The connection relationship between them is as follows: the opening below the liquid storage ladle 1 is connected with the pouring ladle 5, and the volume of the liquid storage ladle 1 is 5 times that of the pouring ladle 5; the sensor in the liquid level controller 3 is placed in the pouring ladle 5. Between 2 / 3 and 3 / 4 of the height of the ladle 5; the mechanical agitator 2 is inserted into the liquid storage ladle 1; the ultrasonic generator 4 is placed in the pouring ladle 5; the opening below the pouring ladle 5 and the vertically installed crystal The dummy rod 8 capable of continuous dummy is installed vertically at the lower end of the crystallizer 7, and...

Embodiment 2

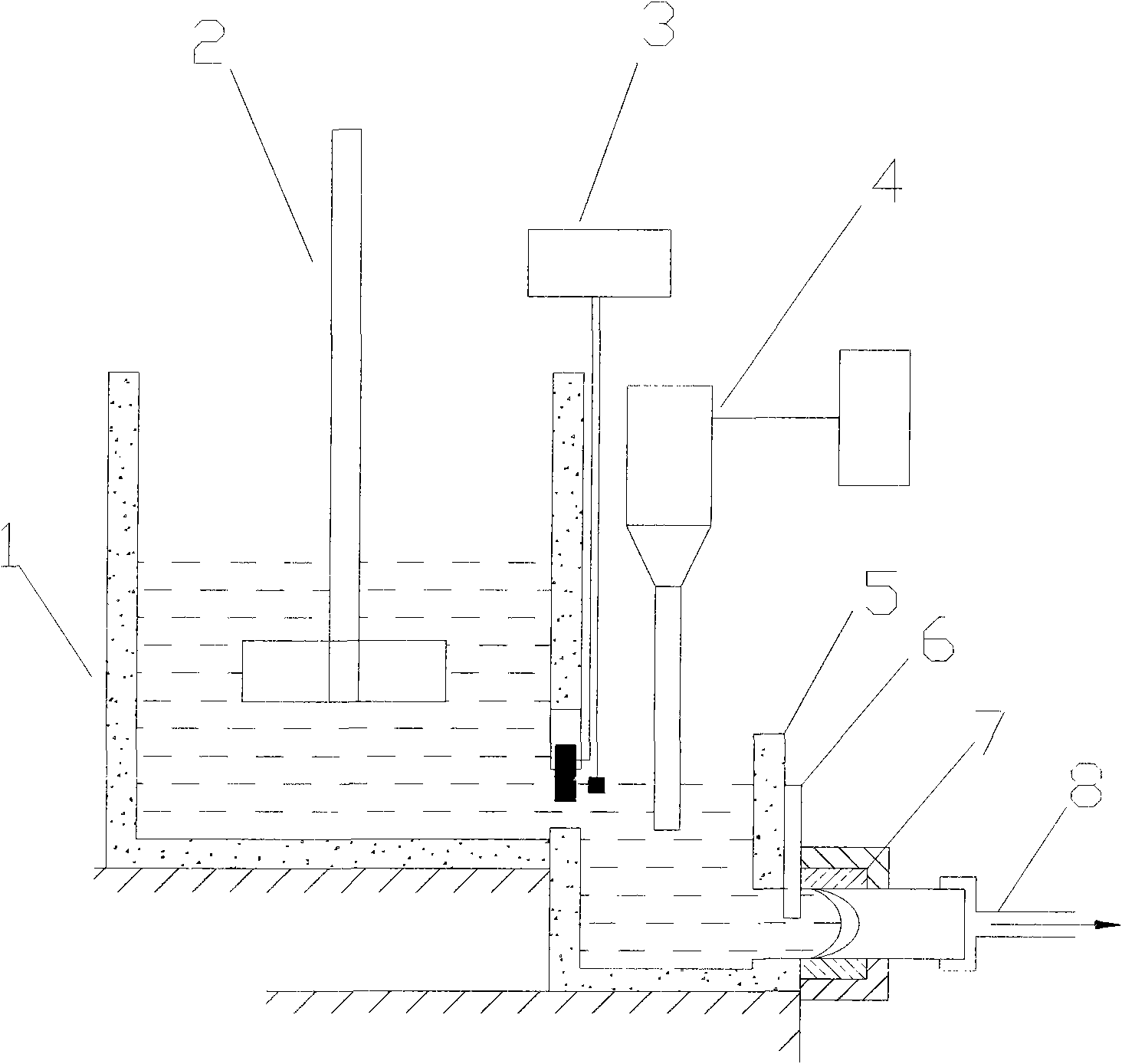

[0031] This embodiment adopts the horizontal continuous casting device, its structure is as follows figure 2 As shown, the device is composed of liquid storage ladle 1, agitator 2, liquid level controller 3, ultrasonic generator 4, pouring ladle 5, control valve 6, crystallizer 7, dummy rod 8; among them The connection relationship between them is as follows: the hole at the bottom of the liquid storage ladle 1 is connected with the pouring ladle 5; the sensor in the liquid level controller 3 is placed in the pouring ladle 5; the mechanical agitator 2 is inserted into the liquid storage ladle 1; The ultrasonic generator 4 is placed in the pouring ladle 5; the opening on the side of the pouring ladle 5 is connected to one end of the horizontally installed crystallizer 7, the pouring ladle 5 communicates with the crystallizer 7, and the dummy bar 8 capable of continuous dummy is installed horizontally At the other end of the crystallizer 7 , the control valve 6 is located at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com