Steel for hydraulic breaking hammer piston and manufacturing technology of steel

A hydraulic breaker and manufacturing process technology, applied in the field of breaker piston production, can solve the problems of piston impact end face depression, low core strength, low tensile strength, etc., to reduce piston breakage, improve service life, and refine grain grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A steel for hydraulic breaker pistons, which is high-alloy steel SNCM26VMOD, and its chemical composition measured by weight percentage mainly includes: C=0.14-0.25%, Si=0.15-0.35%, Mn=0.80-1.20%, Ni=3.25 -3.65%, Cr=1.40-1.80%, Mo=0.40-0.60%, V=0.05-0.15%, S≤0.025%, P≤0.025%, the rest is Fe and unavoidable impurity elements, through Ni, C , V and other elements to adjust, this chemical composition can improve the strength and toughness of alloy steel.

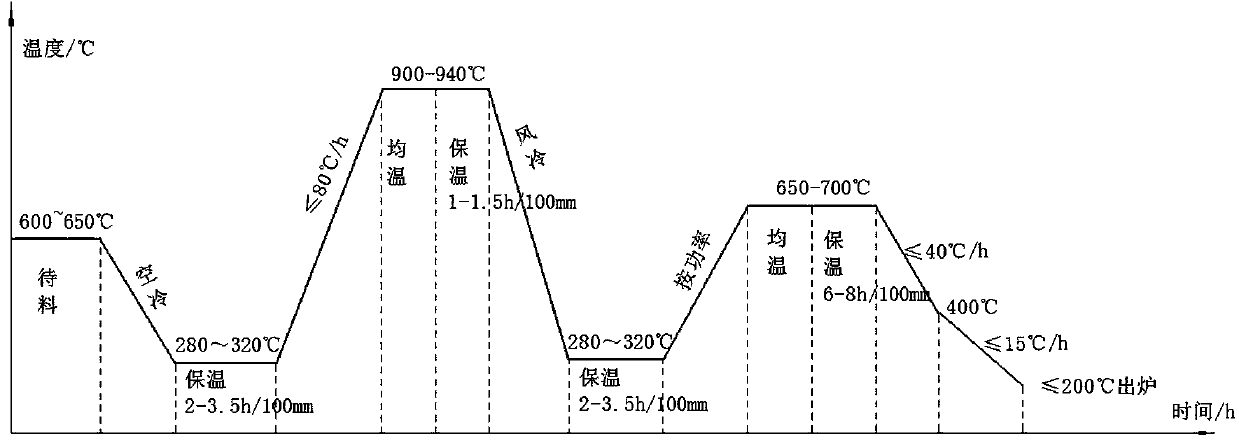

[0021] A manufacturing process of steel for hydraulic breaker pistons as described above, the entire process steps include electric arc furnace smelting, LF refining, VD refining, electroslag remelting, forging and post-forging heat treatment, using high-quality steel materials and low-phosphorus alloys, through LF refining, VD refining, electroslag remelting to obtain higher purity.

[0022] The process condition of described processing step is:

[0023] 1) Electric arc furnace smelting: use electric arc furnace to sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com