Preparation method of electronic device and display device

A technology for electronic devices and display devices, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve the problems of uneven heating and large energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the electronic device that the present invention proposes, comprises the following steps:

[0028] S10, dispersing nano-zinc oxide into a solvent (for example, ethanol) to form a dispersion liquid, and coating the dispersion liquid to form a thin film;

[0029] In this step, the concentration of nano zinc oxide in the dispersion liquid is 20-40 mg / L. Under the above concentration, the nano zinc oxide can be uniformly dispersed on the substrate to form a uniform and stable electron injection layer. The solvent can be ethanol, which can make the zinc oxide disperse evenly, which is beneficial to the subsequent uniform film formation.

[0030] S20, performing light treatment on the thin film to obtain an electron injection layer.

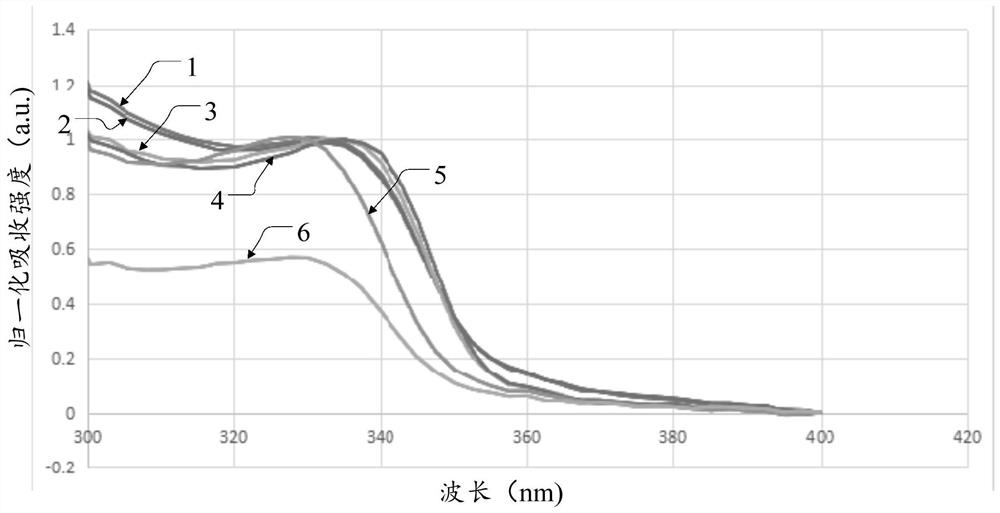

[0031] Preferably, in this step, the light treatment is treatment with ultraviolet light. The wavelength of ultraviolet rays is between 10 and 400nm, and the energy is high, which makes the film harden and dry quickl...

Embodiment 1

[0046] Disperse nano-zinc oxide in ethanol to form a dispersion with a concentration of 20mg / mL, spin-coat the dispersion on a glass sheet at a speed of 3000rmp to prepare a zinc oxide film, and then irradiate the zinc oxide film with ultraviolet rays for 2min to obtain an electron injection layer. Among them, the ultraviolet intensity of the ultraviolet lamp is 15MW / cm 2 , the wavelength is 185nm.

Embodiment 2

[0048] Disperse nano-zinc oxide in ethanol to form a dispersion with a concentration of 20mg / mL, spin-coat the dispersion on a glass sheet at a speed of 3000rmp to prepare a zinc oxide film, and then irradiate the zinc oxide film with ultraviolet rays for 2min to obtain an electron injection layer. Among them, the ultraviolet intensity of the ultraviolet lamp is 15MW / cm 2 , the wavelength is 254nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com