Casting nozzle device

A casting nozzle and shunt block technology, applied in the field of casting, can solve problems such as easy generation of turbulent flow and structural defects of cast-rolled sheets, and achieve the effects of improving uniformity, reducing local cold spots and eliminating structural defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

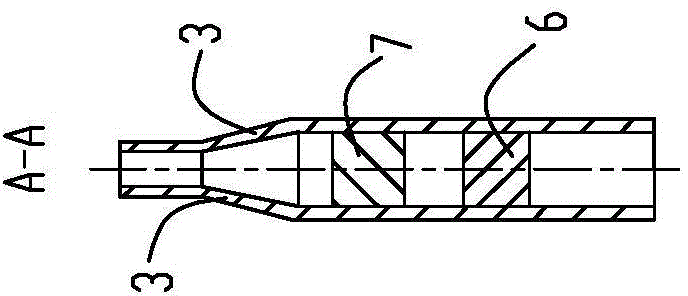

[0019] Such as figure 1 , 2 As shown, a casting nozzle device includes: two upper and lower plates 3 oppositely arranged, an edge baffle 4 connecting the sides of the two upper and lower plates 3 , and connecting the two upper and lower plates 3 and two edge baffles 4 The bottom plate 5 of the bottom plate 5 is provided with a melt inlet 1 in the middle of the bottom plate 5, and the opposite side of the melt inlet 1 is a melt outlet 2, wherein the casting nozzle device also includes a first-stage splitter unit 6 and a Secondary split unit 7. The distance from the primary flow distribution unit 6 to the bottom plate 5 is greater than the distance from the secondary flow distribution unit 7 to the bottom plate 5 . The primary branching unit 6 includes several primary branching blocks 61 whose cross-sectional shapes are rectangular and arranged at inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com