Welding forming method of highly corrosion-resistant stainless steel composite tube

A welding forming, stainless steel technology, applied in the direction of welding equipment, welding/welding/cutting articles, tubular articles, etc., can solve the problem of affecting the structural bearing capacity and corrosion resistance, low bonding degree and bonding strength, prone to delamination cracks, etc. problems, to achieve the effect of improving welding efficiency, long service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

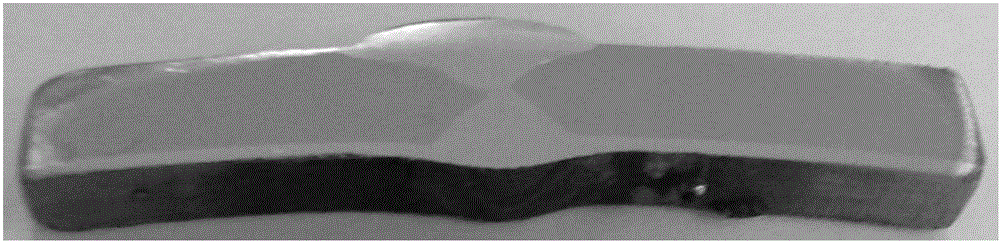

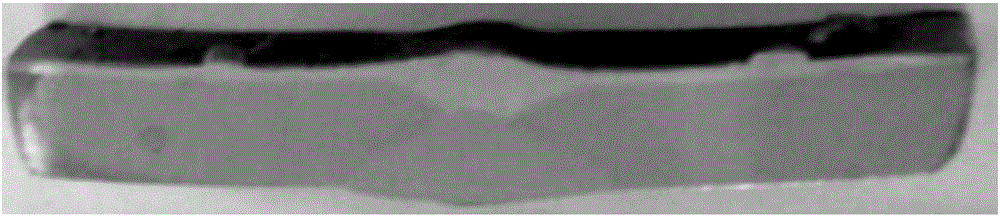

[0026] (1) Use a cutting machine to cut the 304 stainless steel composite plate into a plate with a length of 1000mm and a width of 1500mm, wherein the cladding is stainless steel with a thickness of 1mm, and the base is carbon steel with a thickness of 5mm, (the thickness of the cladding and the base ratio is 1:5);

[0027] (2) Use a grinding machine to symmetrically process the long side of the stainless steel composite plate into an "X" groove with an angle of about 50°;

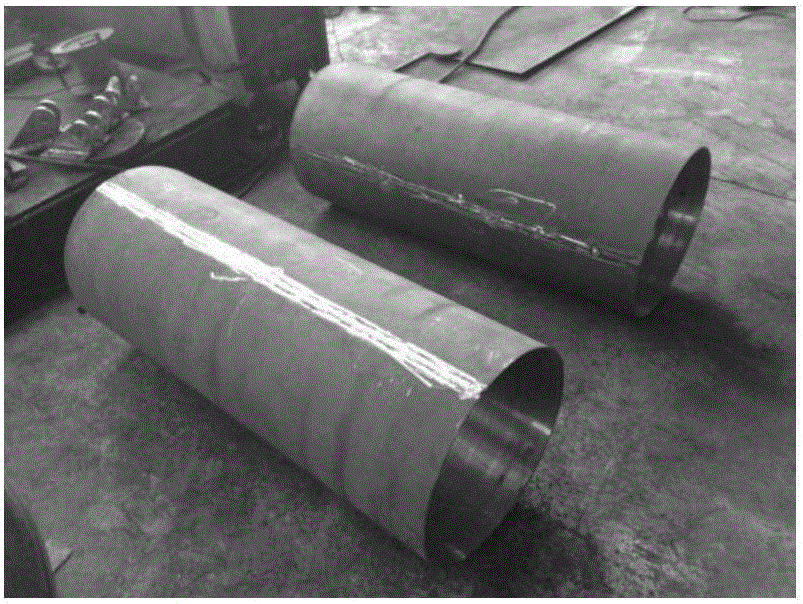

[0028] (3) Set the pipe bending parameters, use a two-roller periodic cold rolling machine to repeatedly roll the stainless steel clad plate, and bend the stainless steel clad plate into a stainless steel clad pipe with an outer diameter of 480mm;

[0029] (4) Clean up before welding, use grinding wheel and acetone to thoroughly clean the rust, grease, dust, water, etc. on the groove and both sides in order to prevent impurities from adversely affecting the quality of the weld;

[0030] (5) A302 electrod...

Embodiment 2

[0036] (1) Use a cutting machine to cut the 304 stainless steel composite plate into a plate with a length of 1000mm and a width of 1500mm, wherein the cladding is stainless steel with a thickness of 1mm, and the base is carbon steel with a thickness of 5mm, (the thickness of the cladding and the base ratio is 1:5);

[0037] (2) Use a grinding machine to symmetrically process the long side of the stainless steel composite plate into an "X" groove with an angle of about 50°;

[0038] (3) Set the pipe bending parameters, use a two-roller periodic cold rolling machine to repeatedly roll the stainless steel clad plate, and bend the stainless steel clad plate into a stainless steel clad pipe with an outer diameter of 480mm;

[0039] (4) Clean up before welding, use grinding wheel and acetone to thoroughly clean the rust, grease, dust, water, etc. on the groove and both sides, so as to prevent impurities from adversely affecting the quality of the weld;

[0040](5) A302 electrode a...

Embodiment 3

[0045] Other steps are with embodiment 1, and difference is that cladding is stainless steel, and thickness is 1mm, and base is carbon steel, and thickness is 4mm, and the thickness ratio of cladding and base is 1:4;

[0046] The resulting stainless steel composite pipe is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| pitting potential | aaaaa | aaaaa |

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com