Macromolecular composite membrane modified bituminous waterproof roll

A technology of modified asphalt and waterproof membrane, which is applied in the direction of asphalt layered products, layered products, synthetic resin layered products, etc. It can solve the problems of easy delamination and separation of film layers, and the decline and disappearance of waterproof membrane materials. , to achieve optimal design, good anti-asphalt swelling and penetration performance, and prevent penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

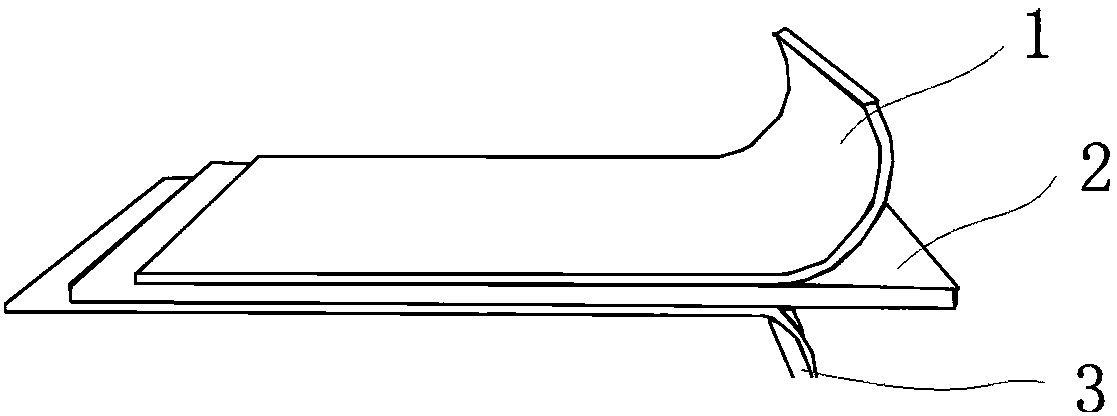

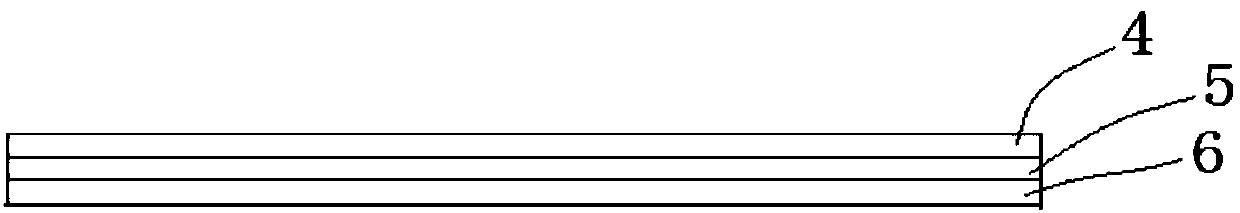

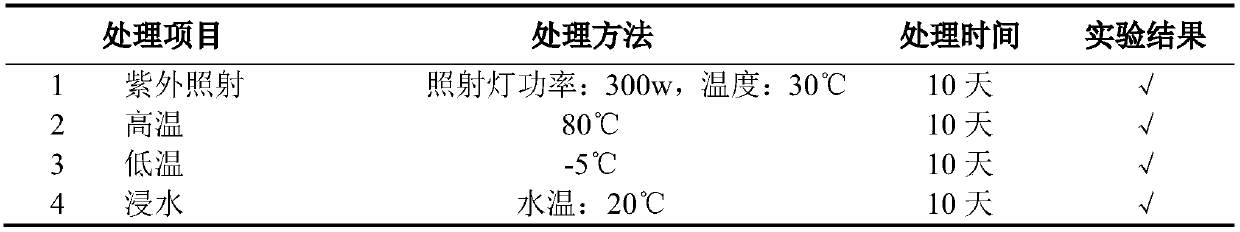

[0059] This embodiment provides a multilayer polymer composite membrane modified asphalt waterproofing membrane, which is a 3-layer structure, such as figure 1 As shown, it includes 1 layer of polymer composite film layer 1, 1 layer of rubber material layer 2 and 1 layer of isolation protection layer 3. The rubber material layer is SBR modified asphalt rubber material, and the isolation protection layer is polyethylene film (PE). The molecular composite film has a three-layer structure with a thickness of 120 μm, such as figure 2 As shown, the order of each film layer from top to bottom is: functional layer 4, connecting layer 5 and barrier layer 6, and the material parameters and dosage of each layer are shown in Table 5 below:

[0060] Table 5 Three-layer polymer composite membrane layer material parameters and dosage

[0061]

[0062] The above-mentioned three-layer polymer composite film is prepared by a blown film co-extrusion process.

[0063] Use the above-mention...

Embodiment 2

[0065] This embodiment provides a multi-layer polymer composite membrane modified asphalt waterproof membrane, which is a 5-layer structure, including 1 polymer composite membrane layer, 2 rubber layers and 2 isolation protection layers, the rubber layer It is SBS modified asphalt compound, the isolation protective layer is polyethylene film (PE), and the polymer composite film is a five-layer structure with a thickness of 155 μm. The order of each film layer from top to bottom is: barrier layer Ⅰ, connecting layer Ⅰ. Functional layer, connection layer Ⅱ and barrier layer Ⅱ. The material parameters and dosage of each layer are shown in Table 6 below:

[0066] Table 6 Five-layer polymer composite film material parameters and dosage

[0067]

[0068] The above-mentioned five-layer polymer composite film is prepared by a flat film co-extrusion process.

[0069] The above-mentioned five-layer polymer composite membrane is used to prepare waterproof coiled material. First, the ...

Embodiment 3

[0071] This embodiment provides a multi-layer polymer composite membrane modified asphalt waterproofing membrane, which is a 3-layer structure, including a polymer composite membrane layer, a rubber layer and an isolation protection layer, the rubber layer It is APP modified asphalt compound, the isolation protective layer is polyethylene film (PE), and the polymer composite film has a nine-layer structure with a thickness of 190 μm. The order of each film layer from top to bottom is: functional layer Ⅰ, connecting layer Ⅰ. Functional layer II, connecting layer II, functional layer III, connecting layer III, functional layer IV, connecting layer IV and barrier layer. The material parameters and dosage of each layer are shown in Table 7 below:

[0072] Table 7 Nine-layer polymer composite film material parameters and dosage

[0073]

[0074] The above-mentioned nine-layer polymer composite film is prepared by a blown film co-extrusion process.

[0075] Use the above-mention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com