Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Save cement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

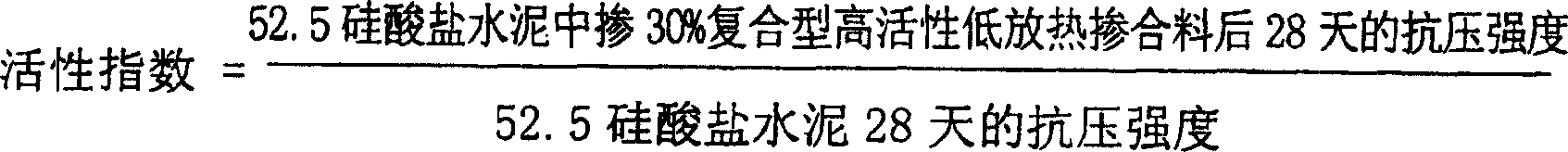

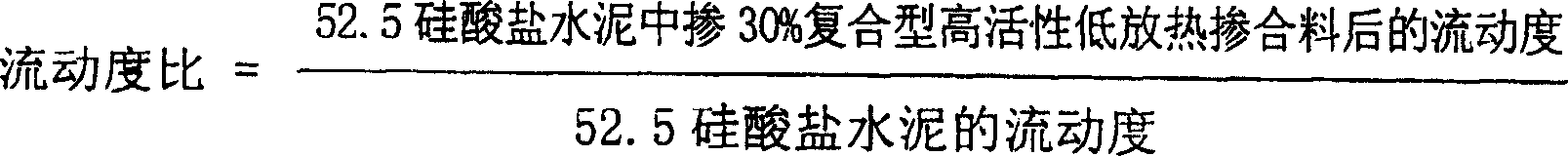

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

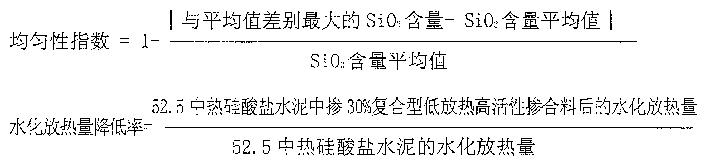

InactiveCN1401607ALow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

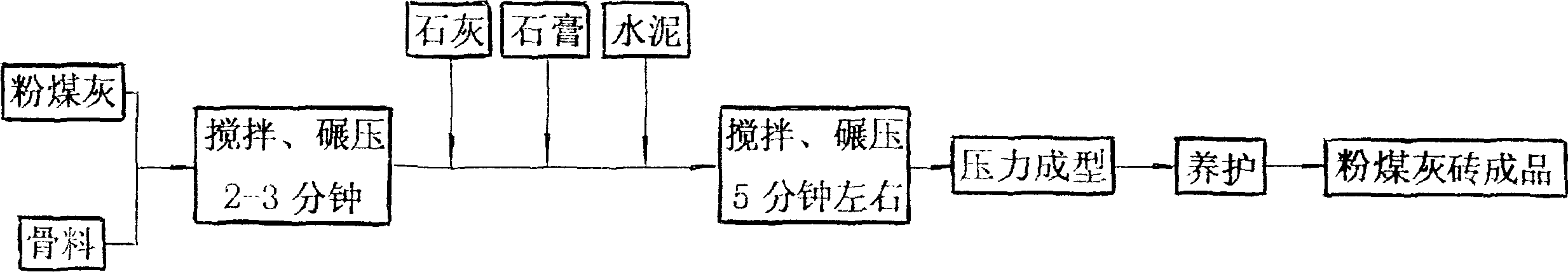

Bricks and mortar made from fly ash and preparation method

InactiveCN1686907AReduce manufacturing costReasonable proportionSolid waste managementFly ash brickBrick and mortar

The present invention belongs to a building brick made of fly ash, mortar and their production method. The raw material composition of brick includes (by wt%) fly ash 70-80, lime 7-13, gypsum 0-1.3, cement 0-5 and the rest is aggregate, and the raw material composition of mortar includes fly ash 70-80, lime 7-13, cement 0-5 and the rest is aggregate. Besides, said invention also provides the concrete steps of their production method.

Owner:韦柳青

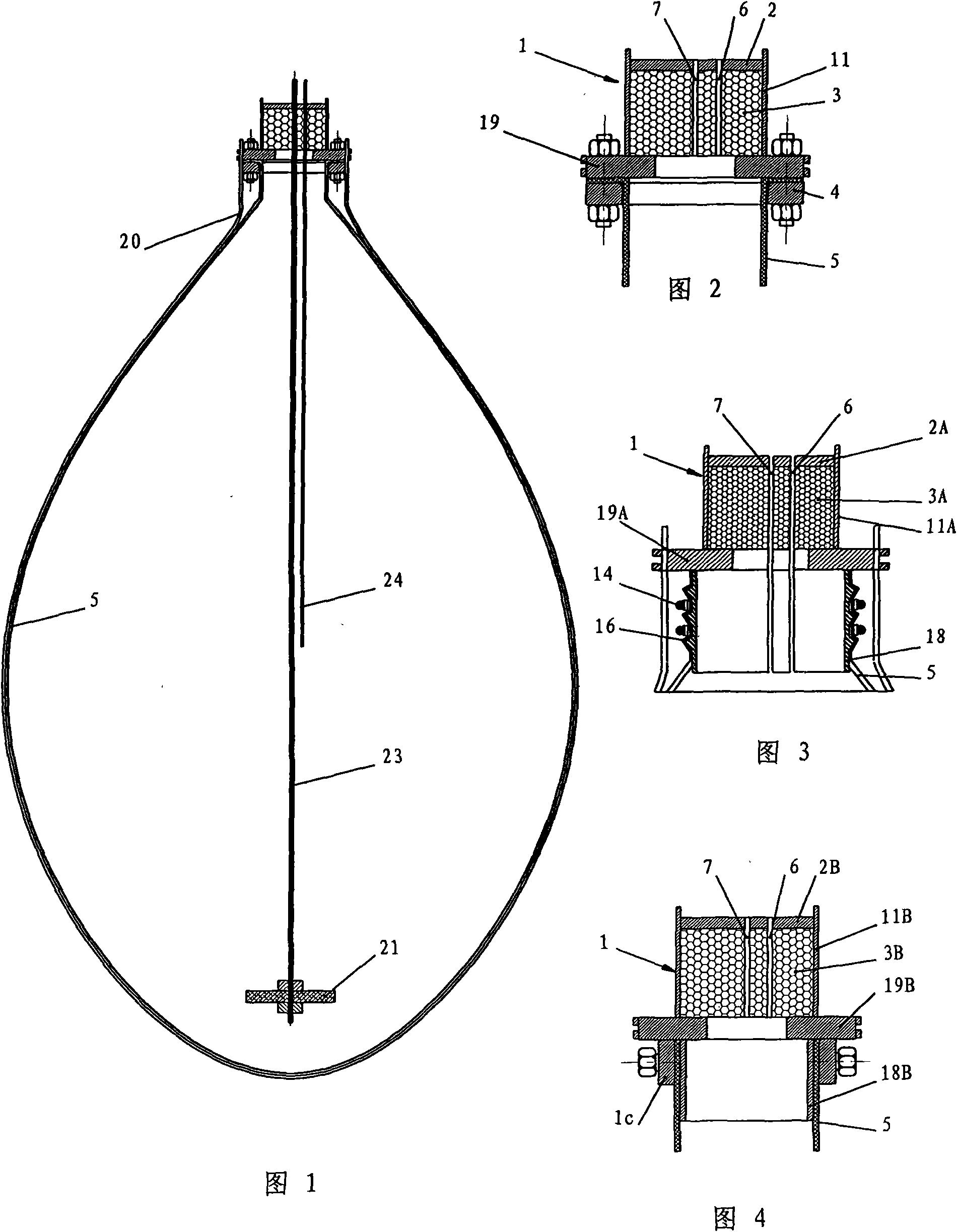

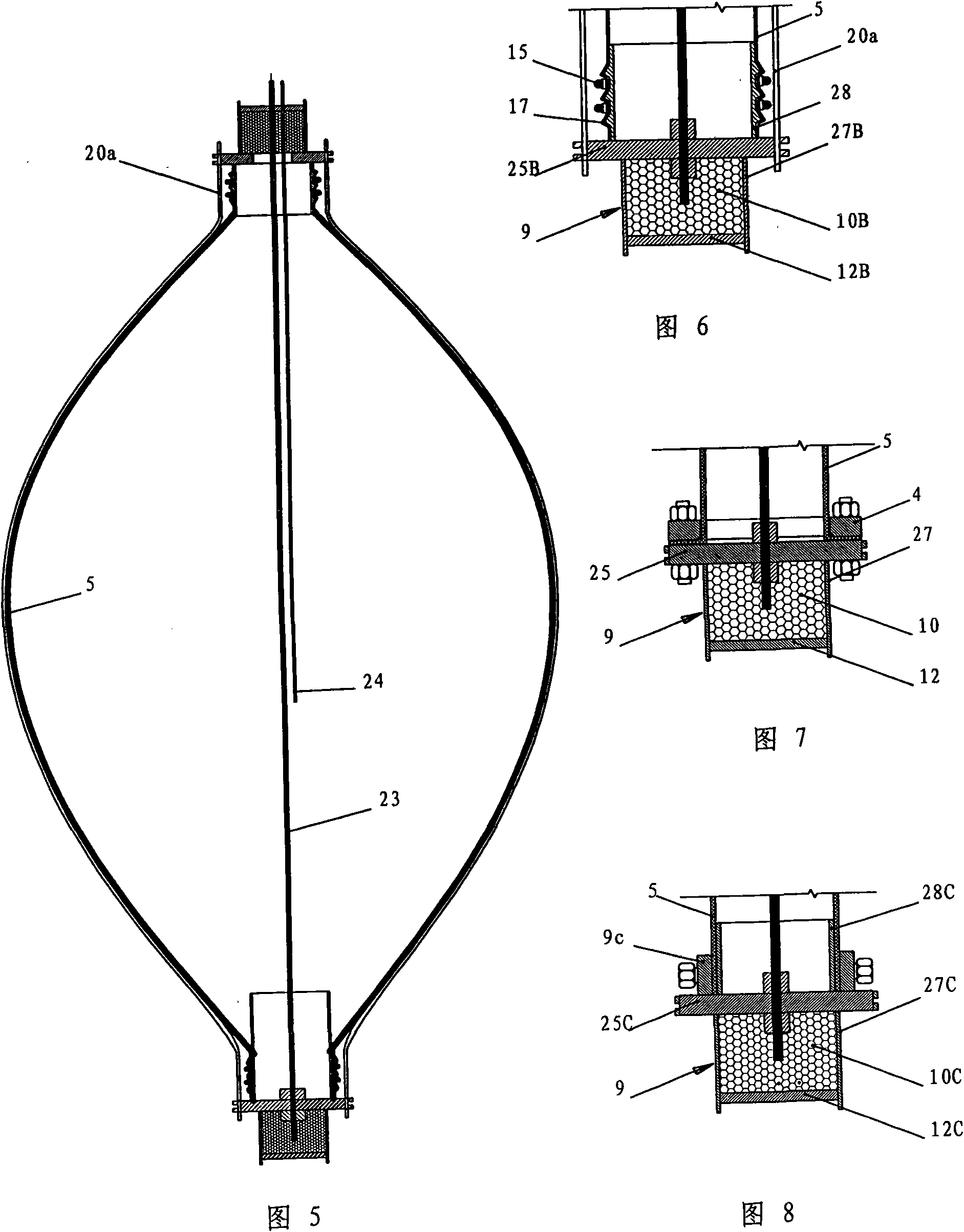

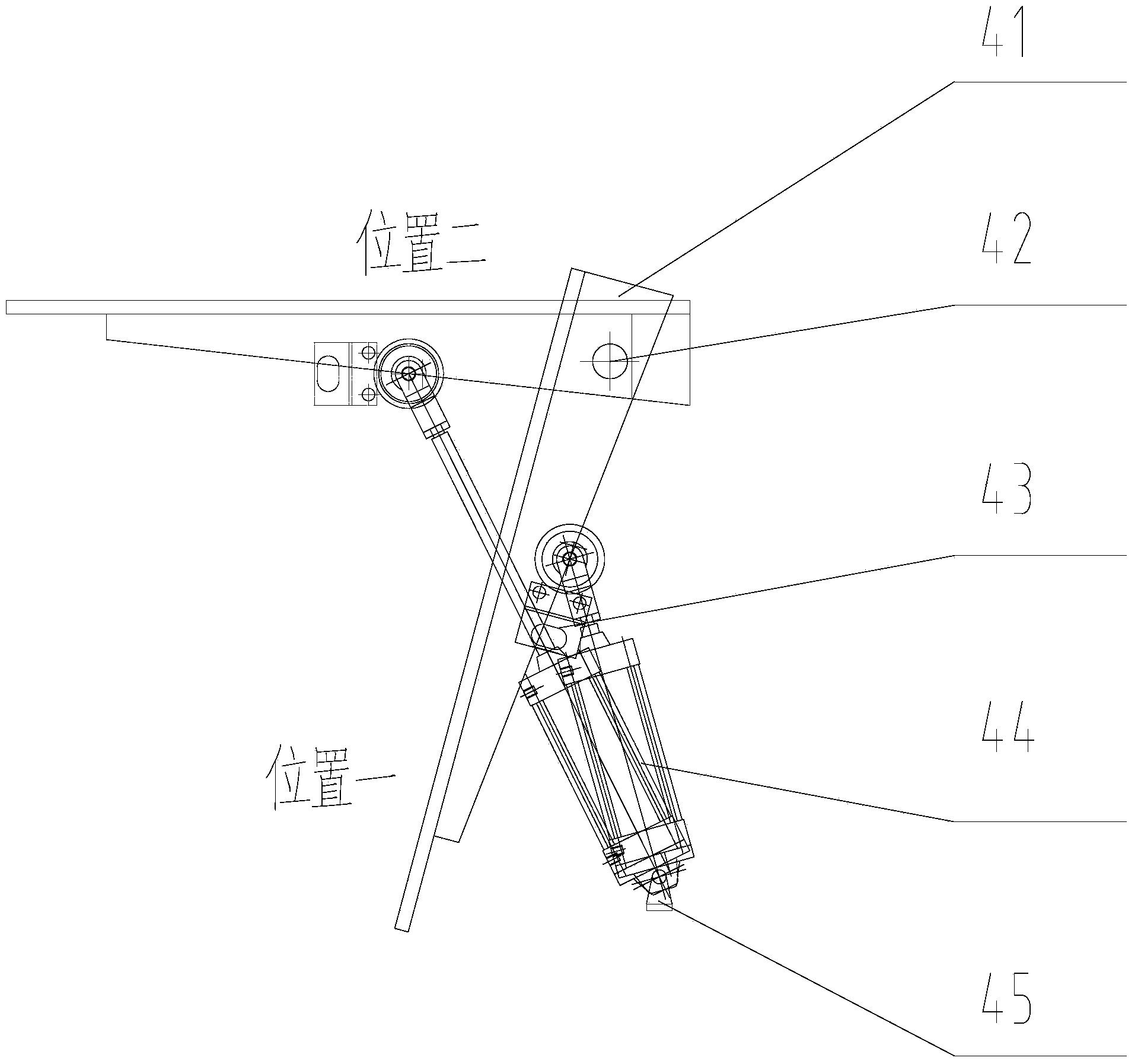

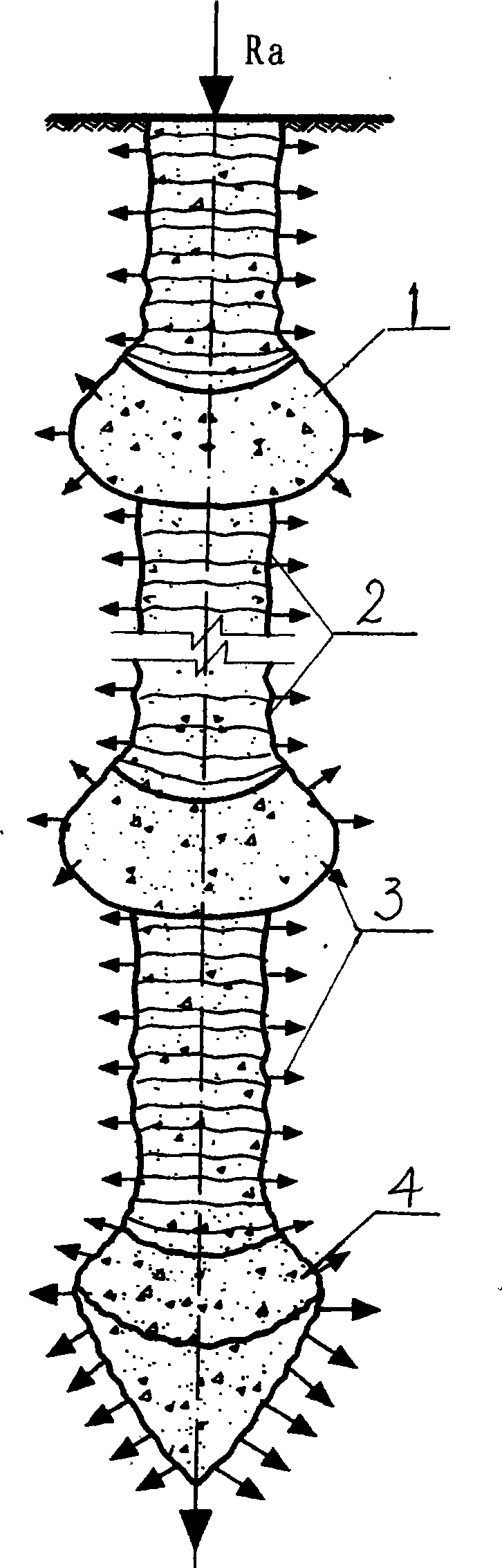

Multiple anti-corrosive controllable expansion extrusion soil anchor and construction method

InactiveCN101550696AEasy constructionFast constructionExcavationsBulkheads/pilesSlurryExpansion joint

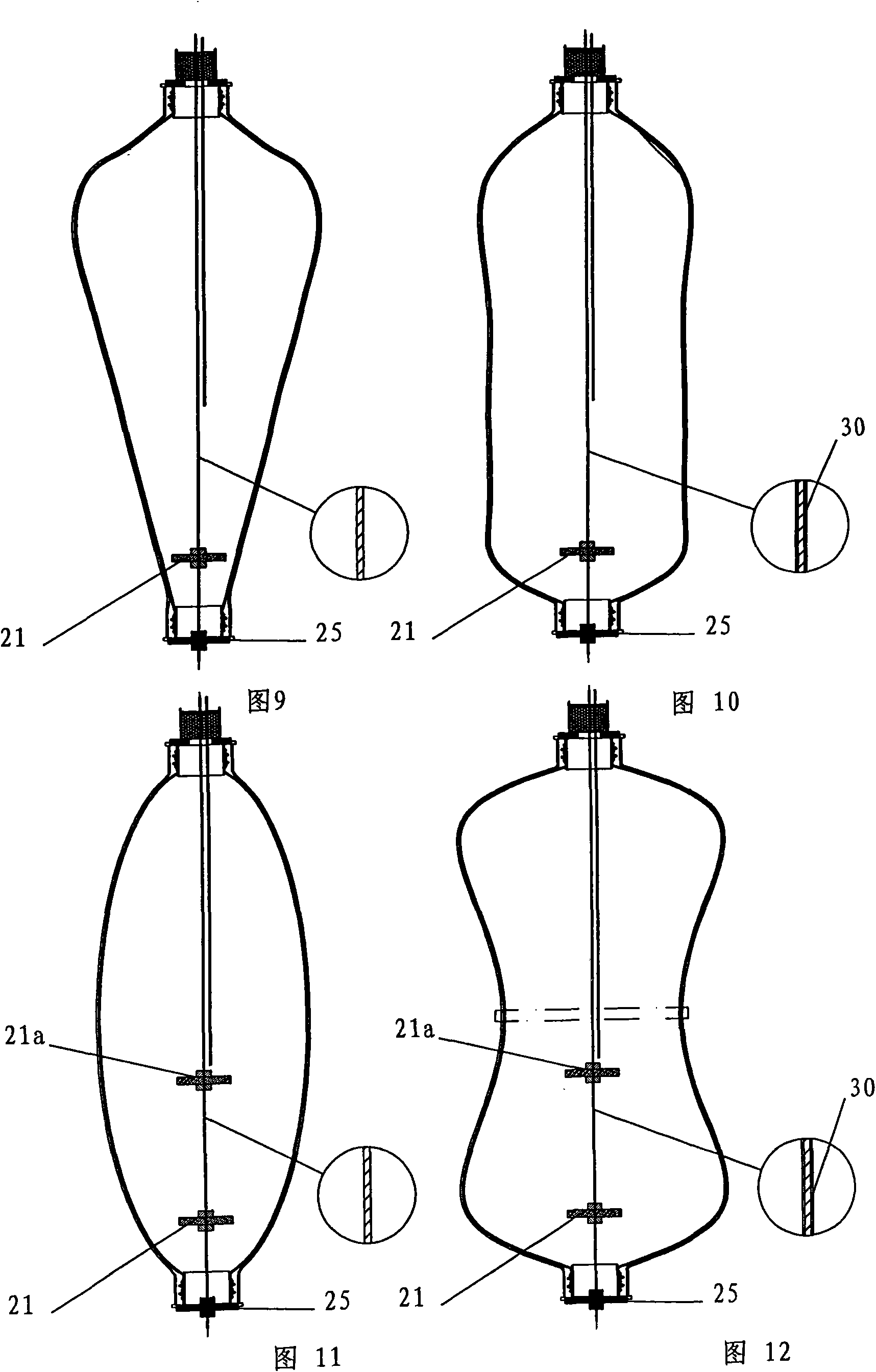

Multiple anti-corrosive controllable expansion extrusion soil anchor, including anchorage segment, free-tensioned segment, outer anchor, grouting pipe, at least one power transmission member and more than one loading plates, the anchorage segment includes controllable expansion extrusion soil apparatus for geotechnical engineering use, which includes upper sleeve components, lower sleeve components and expansion extrusion barrel which is filled of cement-based slurry or cement-based slurry containing expansion agent inside. The construction method of the multiple anti-corrosive controllable expansion extrusion soil anchor includes inject the cement-based slurry or cement-based slurry containing expansion agent into the expansion extrusion barrel of deep anchor hole. The objective is to provide a multiple anti-corrosive controllable expansion extrusion soil anchor and construction method which is suitable for complicated, flaccidity, corrosivity stratum, being capable of repressing anchorage slurry loss and controlling expansion size of anchorage segment, high bearing capacity, good durability, low cost.

Owner:CHINA JINGYE ENG TECH CO LTD +1

Concrete tube pile with fine milled slag micropowder and production me thod thereof

InactiveCN1598164AExtend the mixing timeReduce breakage rateSolid waste managementCeramic shaping apparatusCrack resistanceSlag

The invention relates to a concrete pipe pile mixed into size reduction slag miropowder, used in civil construction industry, and its production method. It includes cement, 1 (weight portion) yellow sand (1.5 to 2.9), broken stone (3.2 to 5.0), water (0.3 to 0.6), water reducing agent (0.025 to 0.045), size reduction slag miropowder (0.2 to 1). Its production method is premixing for thirty seconds, stirring with the water and the water reducing agent uniformly and poured continuously at one end of pipe pile mould, centrifugal forming, conserved. The advantages are improving its concrete intension, impermeability, crack resistance, and resistance to bending saving concrete and water and low cost.

Owner:CHINA MCC20 GRP CORP

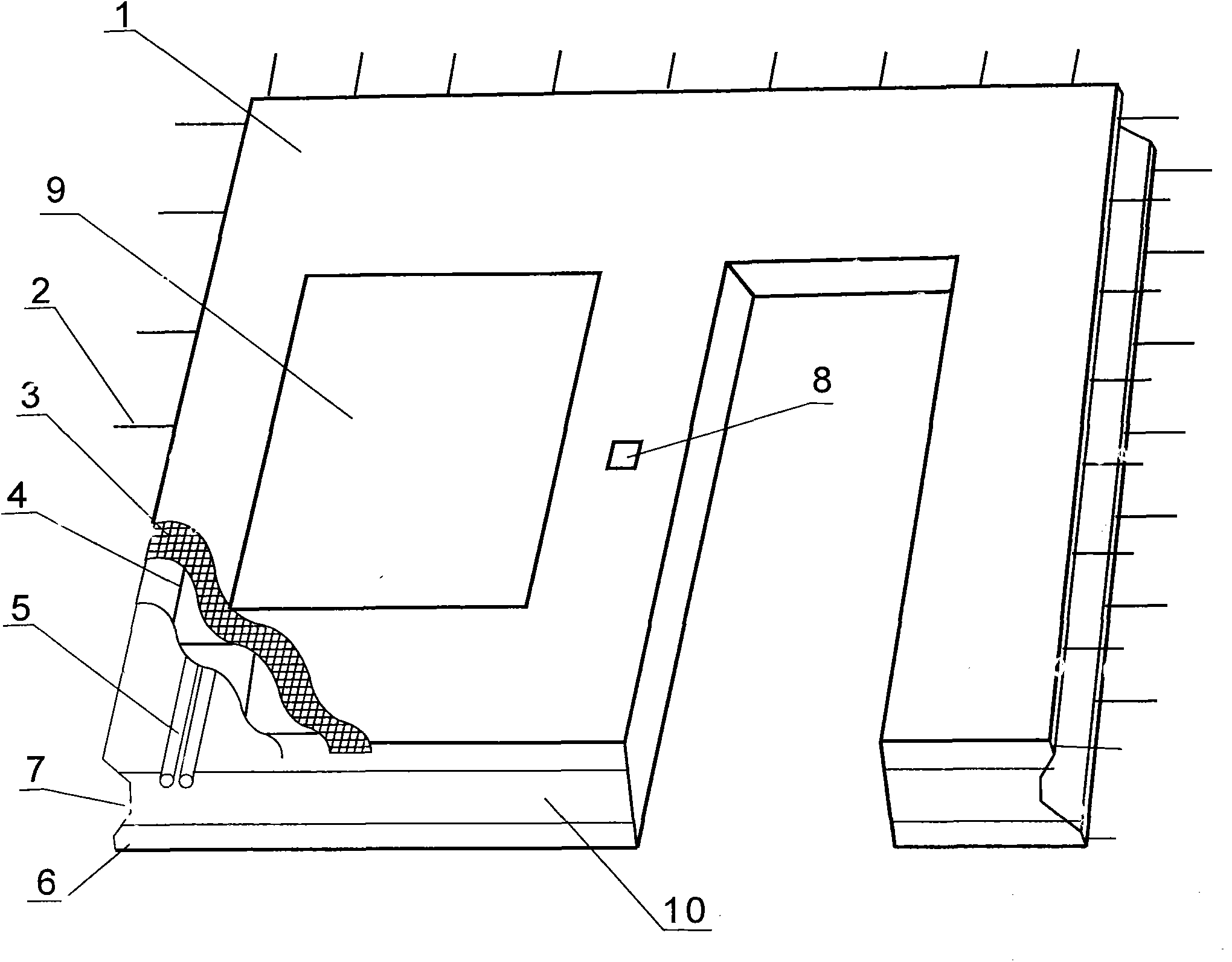

Integral load-bearing heat-insulating wall plate and production and construction technology thereof

ActiveCN103352537APut an end to the phenomenon that the wall collapses and the house collapses a lotReduce casualtiesWallsBuilding material handlingSocial benefitsEconomic benefits

The invention provides an integral load-bearing heat-insulating wall plate and a production and construction technology thereof. The invention provides the integral load-bearing heat-insulating wall plate, which can bear load, keep warm, allow doors and windows to be constructed outside and allow water, electric and gas pipes to be constructed well, and does not need walling or splicing. During building construction, the integral load-bearing heat-insulating wall plate ensures that a house is formed into a whole through a sitting mortar construction method, a direct welding method, a frame connection method and a hanging pouring method. The integral load-bearing heat-insulating wall plate ensures that a building not only is heat-proof, thermal, energy-saving and low carbon but also is firm and shock-proof, and not only is high in construction speed but also saves time and labor and saves prime cost and construction cost; besides, the raw material is saved, and pollution caused by waste gas and refuse is reduced. The integral load-bearing heat-insulating wall plate and the production and construction technology thereof both provided by the invention cater to the demand of the time, the society and the people, can create a new world of green construction, and can generate huge economic benefits and social benefits in urbanization construction and new rural construction.

Owner:张领然

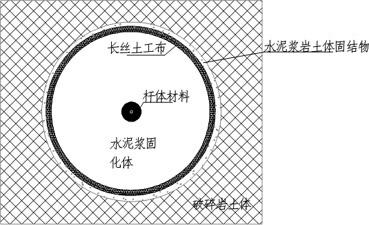

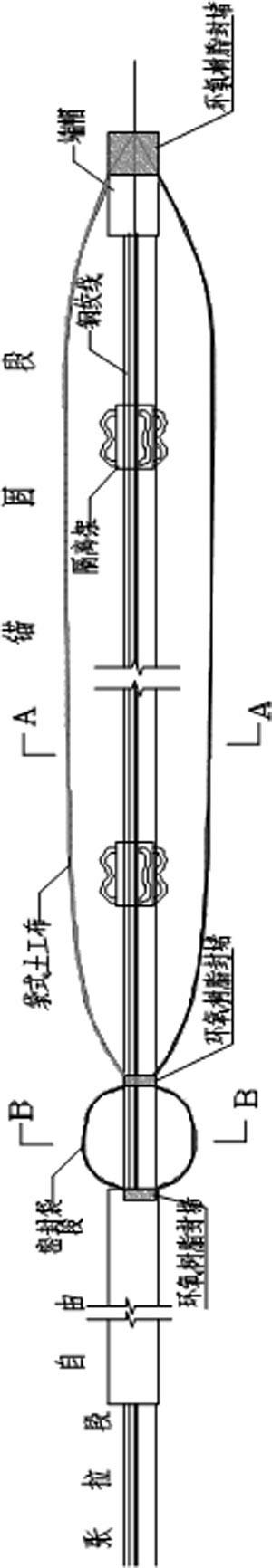

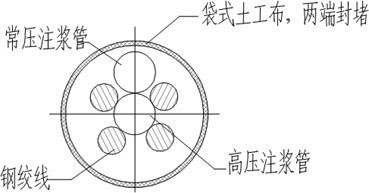

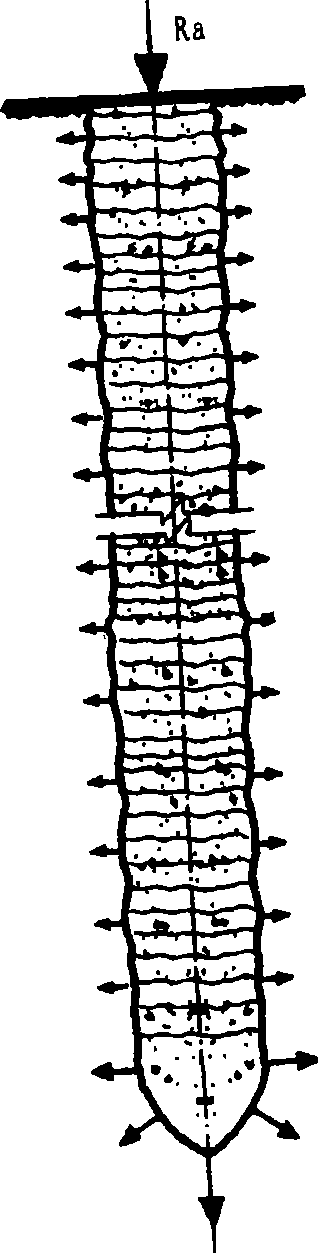

Method for compounding anchor rod by geotextile reinforcing

ActiveCN102168419ASave cementReduce construction costsBulkheads/pilesSoil preservationGeotextileRock bolt

The invention discloses a method for compounding an anchor rod by geotextile reinforcing, comprising the following steps: (1) drilling to form a hole; (2) manufacturing an anchor rod; (3) placing the anchor rod; (4) grouting; (5) stopping grouting; and (6) finishing grouting. The method has the advantages of solving two problems of anchoring and grouting in loose deposits and broken stratums. According to the method, a great quantity of cement can be saved, and the construction cost is lowered; a full anchoring body is formed by the ballooning effect of the geotextile; the uplift resistance of the anchor rod can be improved by the reinforcing performance of the geotextile; according to the practical situations in the Yangchun New Steel No.2 and 3 landslide management projects, the artificial unloading slot and double turnover system foundation pit support projects and the like of the Yangchun New Steel, the anchoring and grouting amount is about 5-10% of the common grouting amount; and the anchor rod uplift resistance can be improved by 1.5 times by the destructive anchor rod tension test.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

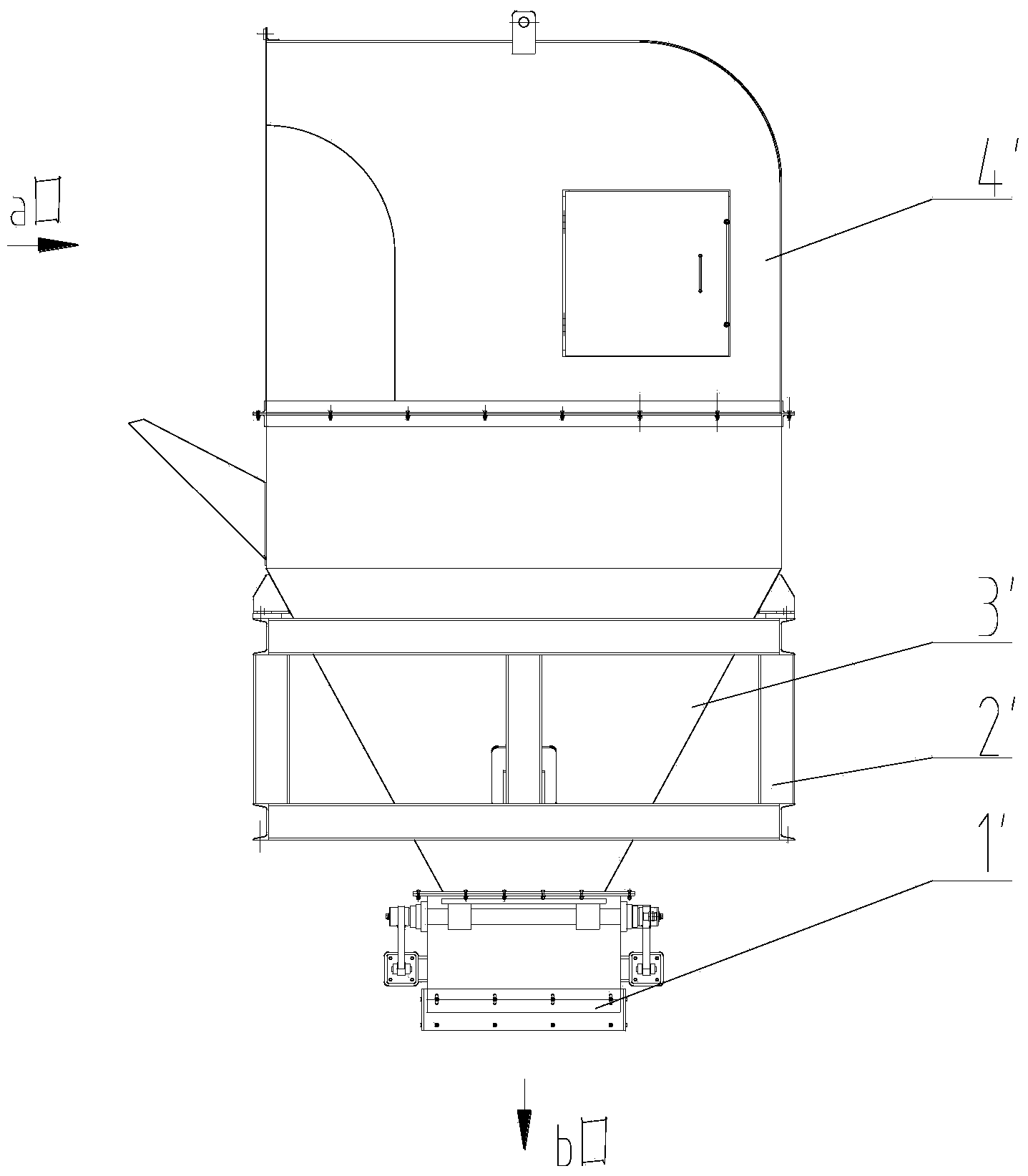

Aggregate holding hopper, concrete stirring station and aggregate distributing control method

ActiveCN104385464AHigh strengthReduce stirring resistanceIngredients storageControl apparatusEngineeringMechanical engineering

The invention discloses an aggregate holding hopper, a concrete stirring station and an aggregate distributing control method. The aggregate holding hopper comprises a hopper body and a hopper valve, the hopper valve is arranged at the lower end of the hopper body, and the hopper is inside provided with a material discharge channel; and the aggregate holding hopper also comprises a material distributing device arranged on the hopper body; and the material distributing device comprises a revolving door mechanism and a driving mechanism, the driving mechanism is used to drive the revolving door mechanism to switch the close state and the open state, the close state of the revolving door mechanism is a state that the material discharge channel is closed, and the open state of the revolving door mechanism is a state that the material discharge channel is opened. The provided aggregate holding hopper is capable of realizing batch-wise pouring of two materials, avoids overlarge stirring resistance in a main machine, and improves the stirring efficiency and the stirring effect.

Owner:三一西北重工有限公司

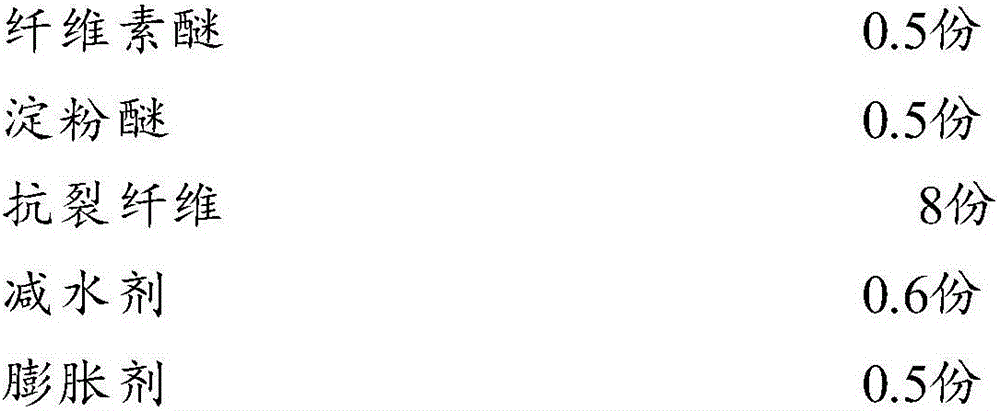

Concrete repairing dry-mixed mortar and preparation method thereof

The invention discloses concrete repairing dry-mixed mortar being prepared from the components including, by mass, 100 parts of Portland cement, 80-120 parts of ferrous aluminate cement, 220-280 parts of fine aggregate, 30-40 parts of fly ash, 60-90 parts of silicon micro-powder, 0.5-1 part of methyl cellulose ether, 0.5-1 part of starch ether, 8-12 parts of anti-cracking fibers, 0.6-1.5 parts of a water reducing agent, and 0.5-2 parts of an expanding agent. The invention also relates to a preparation method of the mortar. The mortar has strong adhesive property, can be effectively bond with concrete, is anti-corrosion and has good anti-cracking performance, and prolongs service life of concrete.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

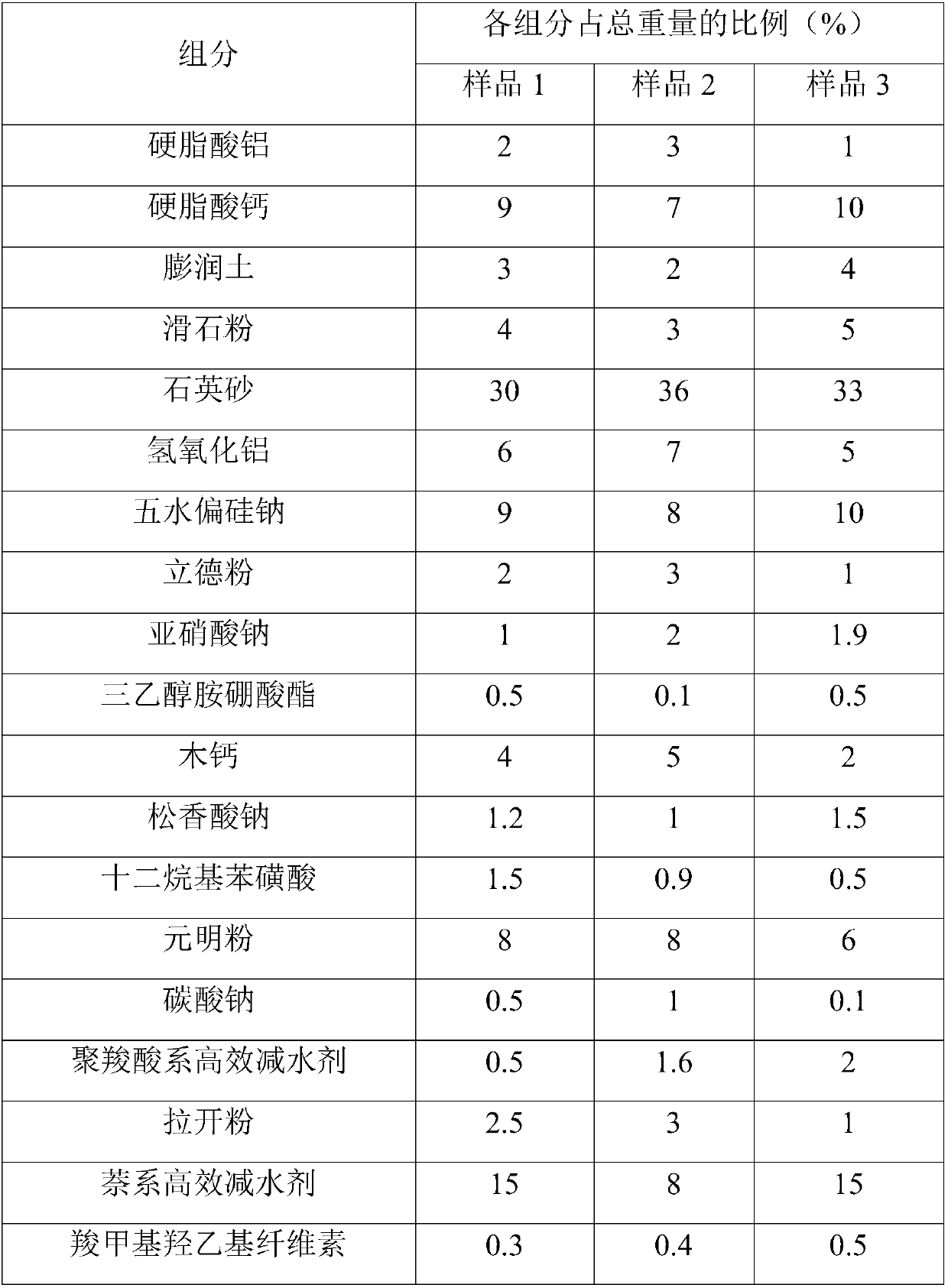

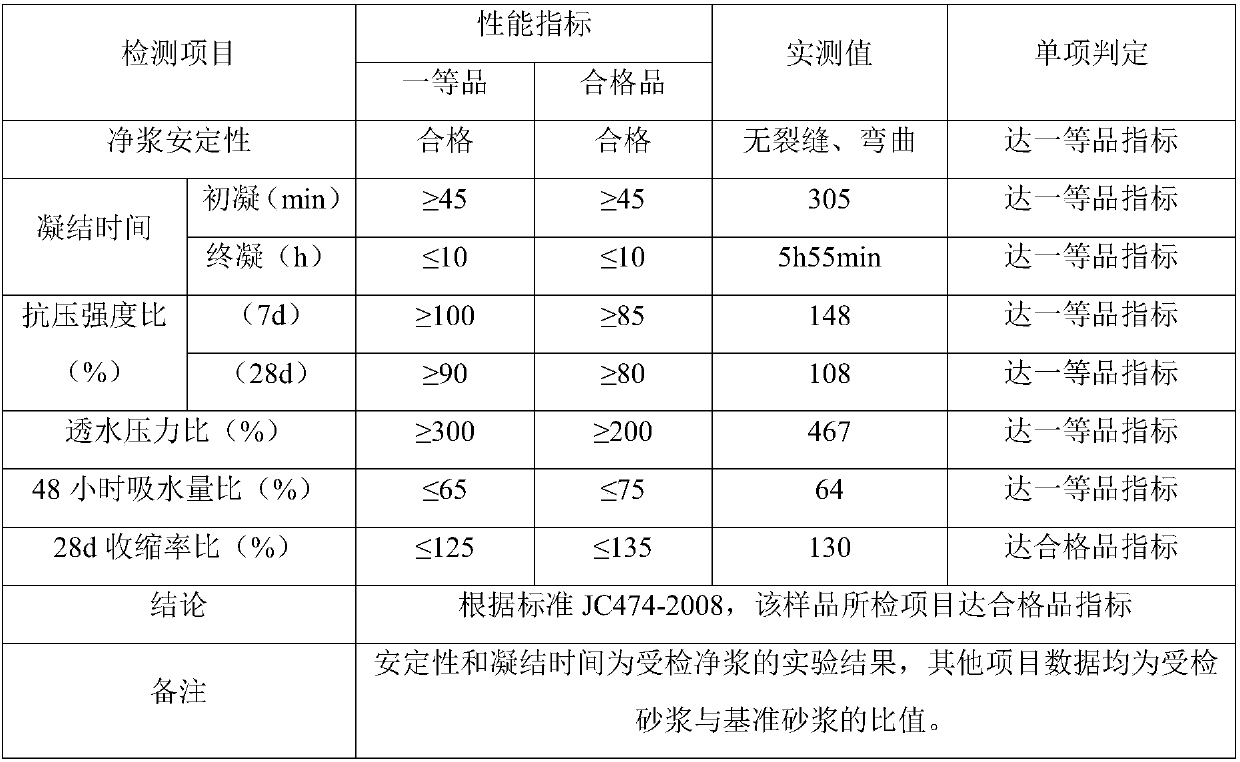

Waterproofing agent for mortar concrete and preparation method thereof

The invention relates to a waterproofing agent for mortar concrete and a preparation method thereof in the field of building materials. The waterproofing agent for mortar concrete is prepared by compounding multiple inorganic and organic admixtures and comprises the following components accounting for total weight of the waterproofing agent: 5-15% of moisture-proof agent, 50-60% of inorganic substance waterproofing agent, 1-3% of inorganic water reducing agent, 1-2.5% of rust inhibitor, 6-9% of early strength agent, 3-10% of surfactant, 0.1-30% of superplasticizer, 1-5% of dispersant and 0.1-1% of thickener. The waterproofing agent integrates various waterproofing and anti-permeability functions into a whole, is small is usage amount of water and excellent in waterproof effect, not only improves the compactness, compressive strength and waterproof and anti-permeability performance of the concrete, but also has multiple functions such as rust resistance, cracking resistance, hydration heat release delaying and reduction, crack prevention, freezing resistance and bleeding reduction. The waterproofing agent is a powder additive, is simple in production process, low in cost, easy to package and transport and capable of better solving problems such as inconvenience in measurement. Through detection, the performance indexes of the waterproofing agent reach or exceed the national building material industry JC474-2008 standard.

Owner:CHINA PETROLEUM & CHEM CORP +1

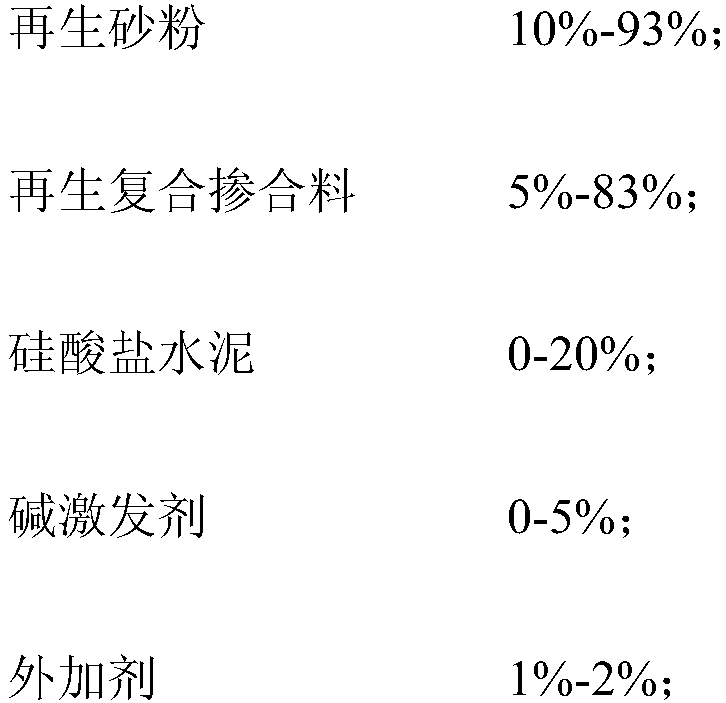

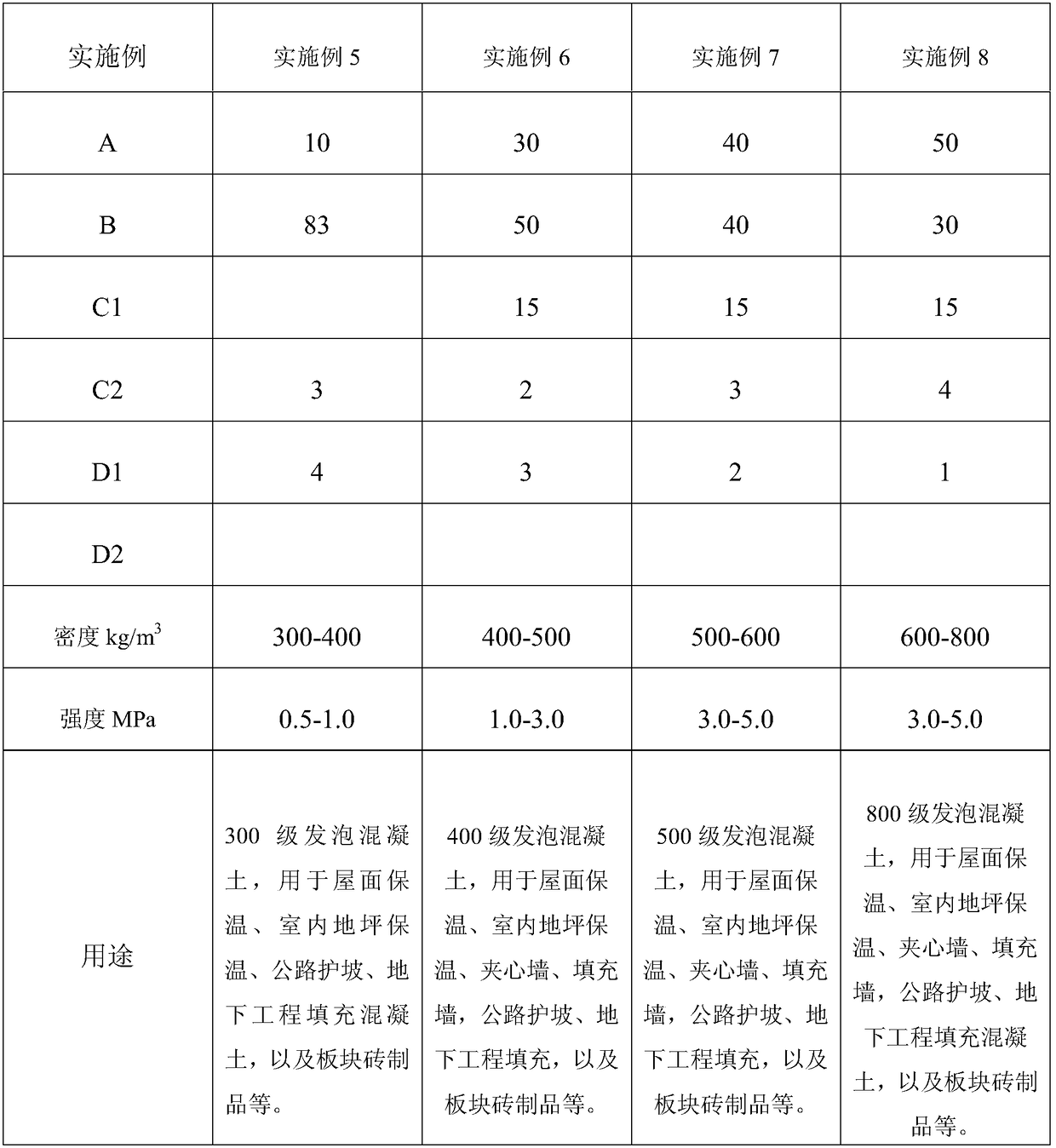

Regenerated sand powder green concrete, and preparation method thereof

The invention provides a regenerated sand powder green concrete. The regenerated sand powder green concrete comprises, by mass, 10 to 93% of regenerated sand powder, 5 to 83% of a regenerated composite admixture, 0 to 20% of Portland cement, 0 to 5% of an alkali-activator, and 1 to 2% of an additive; a coarse aggregate free lightweight concrete with a density smaller than 1900kg / m<3> is prepared from regenerated sand powder and regenerated composite admixture at a double component doping amount of 70% or larger. The invention also discloses a preparation method of the regenerated sand powder green concrete. According to the preparation method, waste concrete cement stone flour and brick-concrete regenerated sand powder are subjected to mixing grinding so as to obtain the regenerated composite admixture which is a multi-component composite gelling material and possesses composite gelling and superimposed effect. The regenerated sand powder green concrete possesses the filling effect andmicro-aggregate effect of regenerated sand powder, and the gelling performance of the regenerated composite admixture, the double component doping amount is higher than 70%, so that regenerated material large amount doping is realized, and it is beneficial for promotion of building waste resource utilization and green development of concrete industry.

Owner:SHANGHAI GUOTONG ENVIRONMENTAL PROTECTION EQUIP

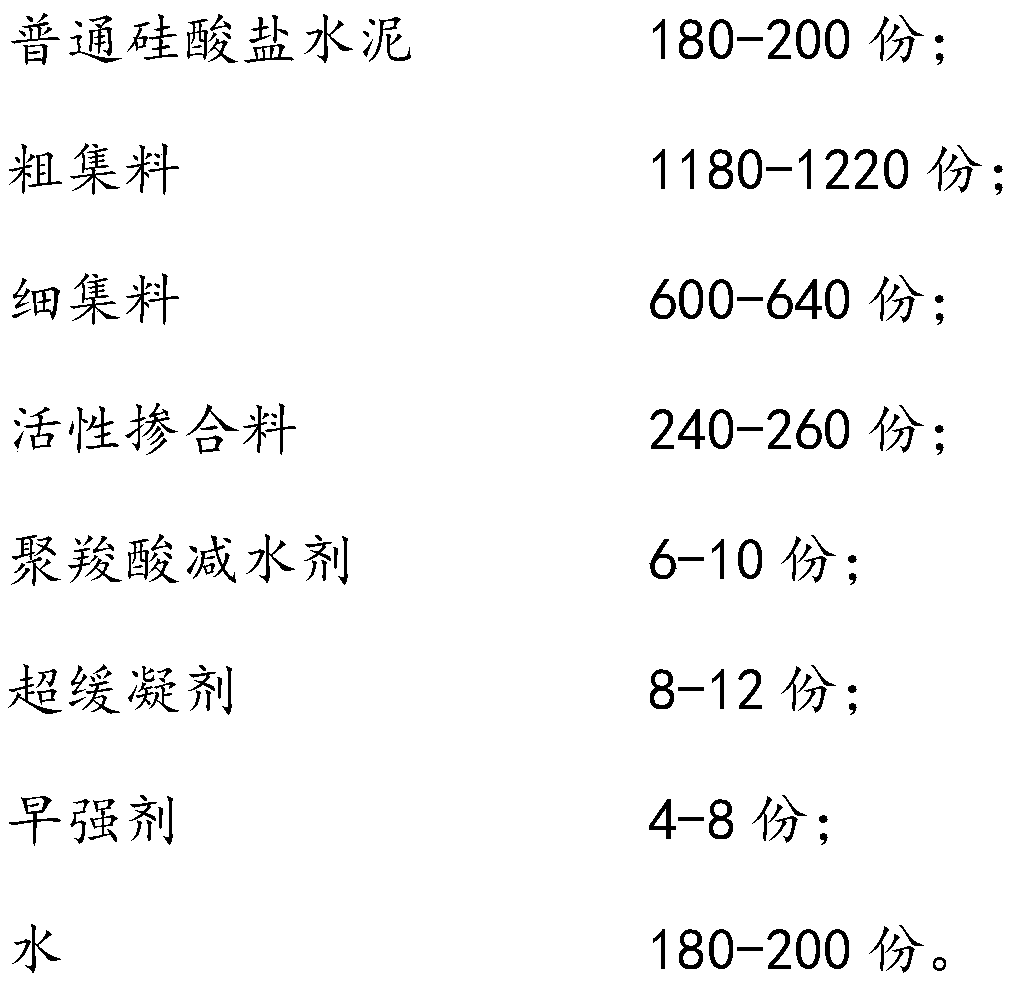

Early strength concrete with super retarding effect, and preparation process thereof

InactiveCN111116135ALarge specific surface areaImprove wear resistanceAnti-corrosive paintsEpoxy resin coatingsPortland cementSuperplasticizer

The invention relates to an early strength concrete with a super retarding effect, and a preparation process thereof, and relates to the technical field of concrete preparation. The early strength concrete is prepared from, by weight, 180-200 parts of ordinary Portland cement, 1180-1220 parts of coarse aggregate, 600-640 parts of fine aggregate, 240-260 parts of an active admixture, 6-10 parts ofa polycarboxylate superplasticizer, 8-12 parts of a super retarder, 4-8 parts of an early strength agent and 180-200 parts of water. Addition of the super retarder and the early strength agent prolongs the initial setting time of the concrete and improves the early strength of the concrete.

Owner:杭州三中新型建材科技有限公司

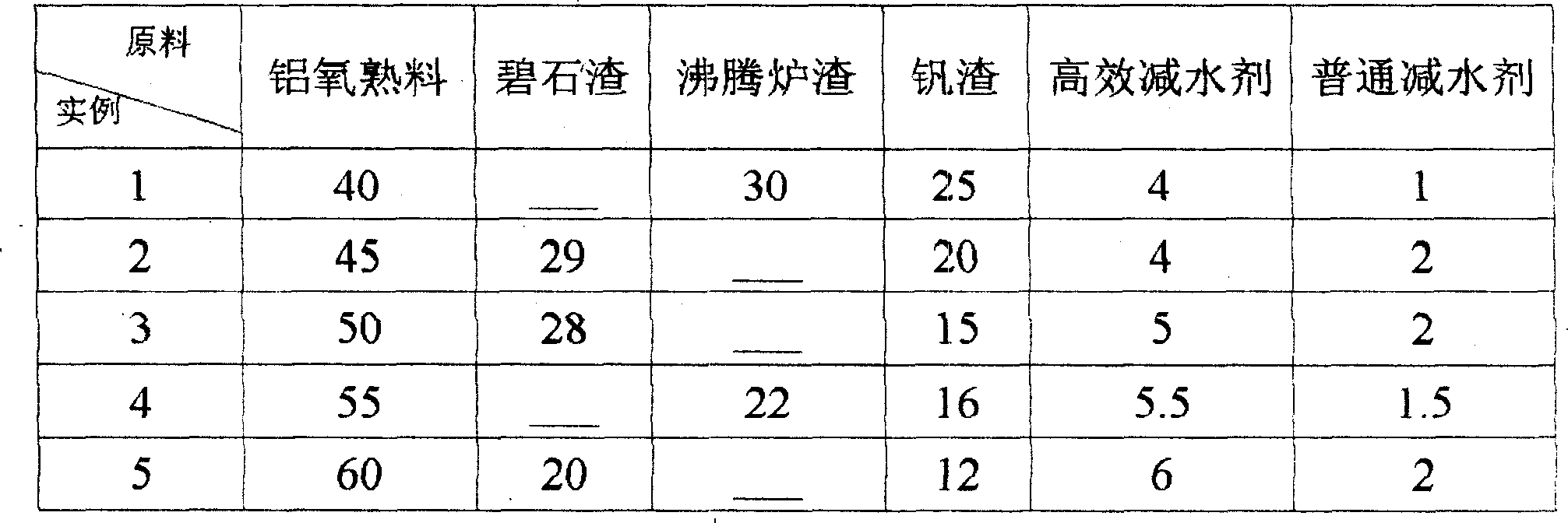

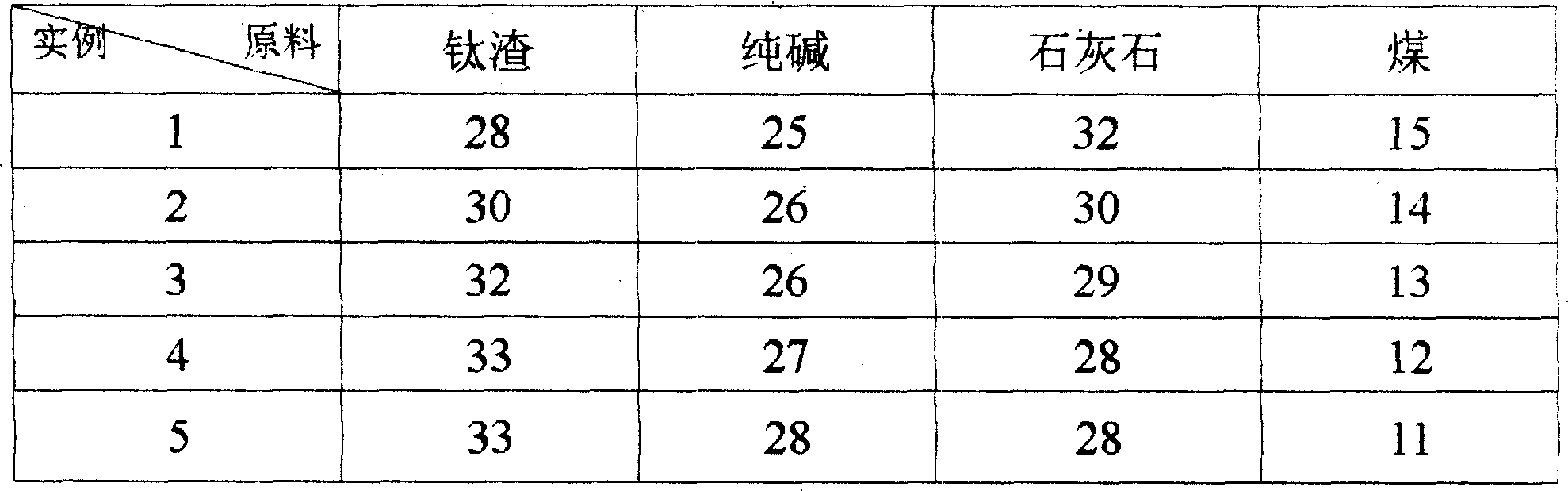

High-strength concrete accelerator

The invention discloses a high-strength concrete accelerator, which comprises the following parts: 40-60% alundum clinker, 20-30% green stone slag or boiling stove slag, 12-25% vanadium slag, 4-6% high-effective dehydragent and 1-2% common dehydragent, wherein the alundum clinker is composed of 28--33% titanium slag, 25-28% pure alkaline, 28-32% limestone and 11-15% coal.

Owner:葫芦岛市辽西混凝土外加剂有限公司

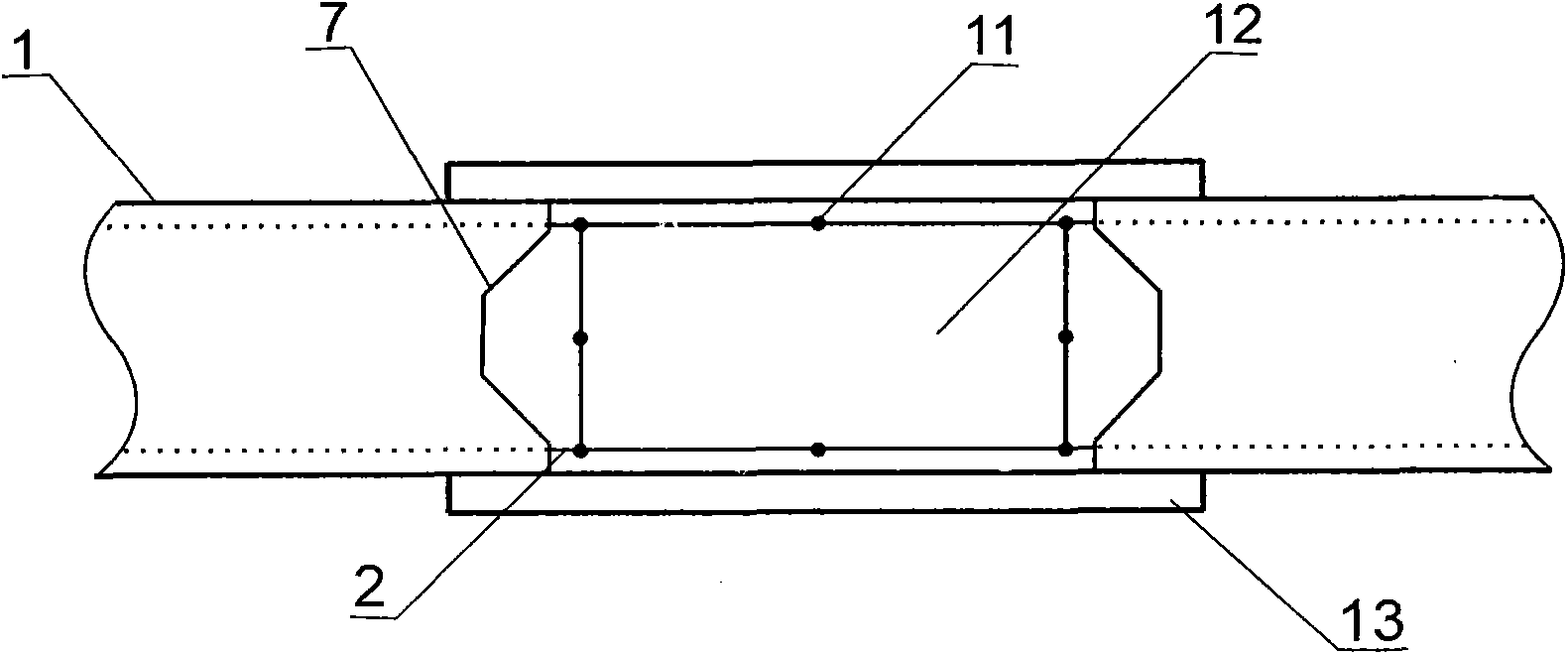

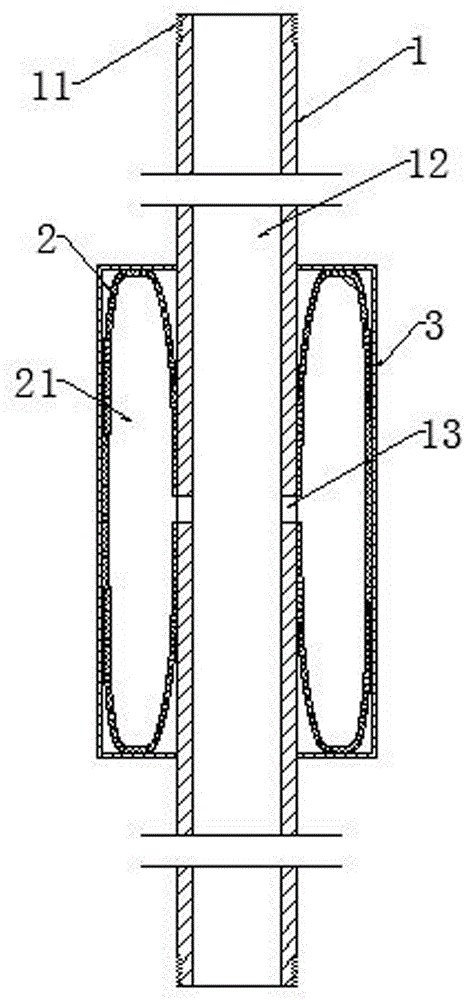

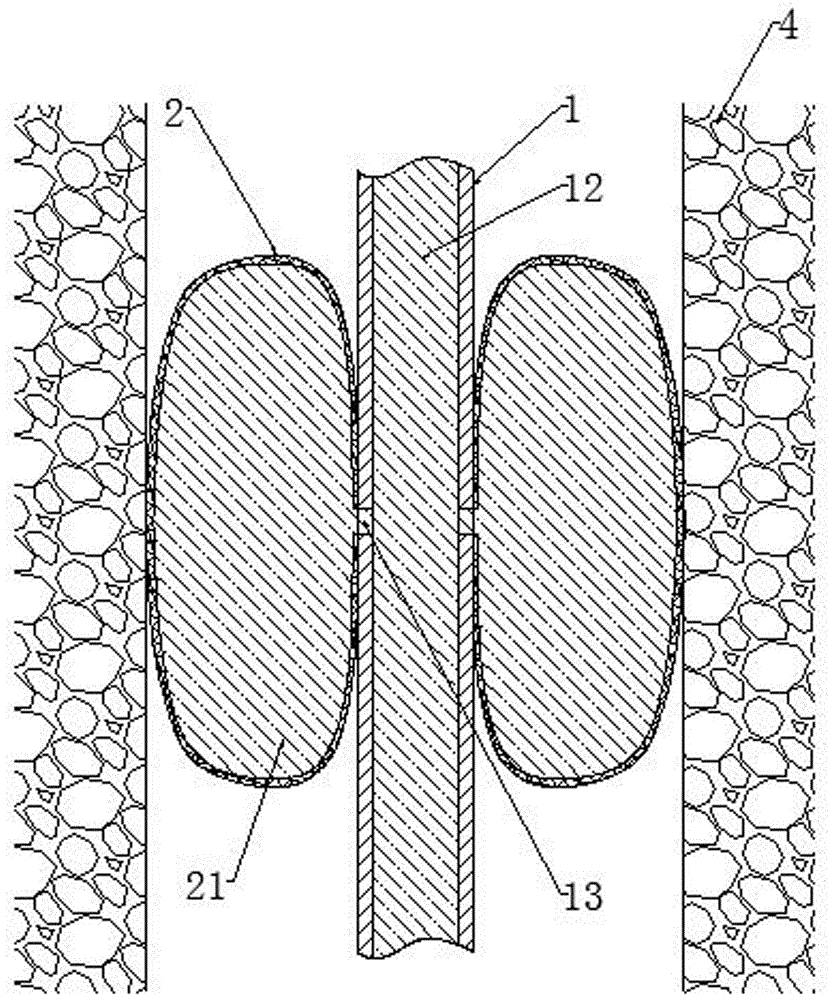

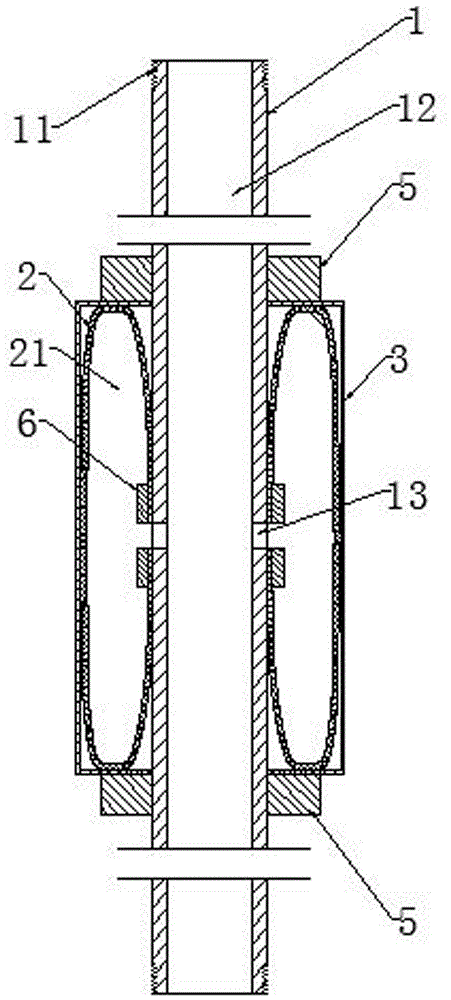

Integral grouting and water blocking and plugging device

InactiveCN105672940AImprove water blocking effectSave cementSealing/packingAnchoring boltsDrill holeWater block

A grouting, water-stopping and water-blocking integrated device, including an anchor rod, the anchor rod is provided with a central hole passing through both ends, the pipe wall of the anchor rod is provided with side holes, and the outer circumference of the anchor rod is provided with a destructible protective shell, A pouch made of elastic material is arranged inside the protective shell, and the pouch cavity of the pouch communicates with the central hole of the anchor rod through the side hole. The all-in-one device for grouting, water-stopping and water-blocking of the present invention is provided with a capsule bag, if encountering the situation that the anchor bit drills into the groundwater layer, inject cement into the central hole immediately, the cement flows into the capsule cavity of the capsule bag from the side hole, and the capsule When the bag expands, the protective shell will be broken, and the expanded bag will block the drill hole, which can quickly block the water and improve the water blocking effect. Since the cement will not flow out of the bag, a large amount of cement can be saved.

Owner:HENAN POLYTECHNIC UNIV

Method for producing concrete building block by using pipe pile wastewater slurry

The invention relates to a method for producing concrete water conservancy prefabricated-part with tubular pile waste water slurry. Firstly concrete, medium sand and gravel are launched into a concrete mixer to be mixed for 30 seconds to 60 seconds according to proportion by weight; and then the tubular pile waste water slurry is added when stirring; the quantity of the water slurry added into is subject to slump constant of the concrete mix which is between 30 mm to 120mm; the concrete mix is produced after the wet mixture is acted for 30 to 60 seconds. And then the concrete mix is launched into a prefabricated-part mould; a concentrated vibro is adopted for processing, and the distance between vibro points is 0.8 times to 1.2 times of the working radius of a vibrating spear. When in pouring, the concrete mix needs to be processed for pouring layer upon layer in the mould in a horizontal plane rising way. At last maintenance is processed according to a conventional maintenance process method. Aiming at the mechanical property requirements of the concrete water conservancy prefabricated-part, the pressive strength grade of the produced concrete water conservancy prefabricated-part is C30 through improving the mix proportion of the concrete and the pouring technology; the appearance quality measures up to the standard requirements.

Owner:上海亿航工贸发展有限公司

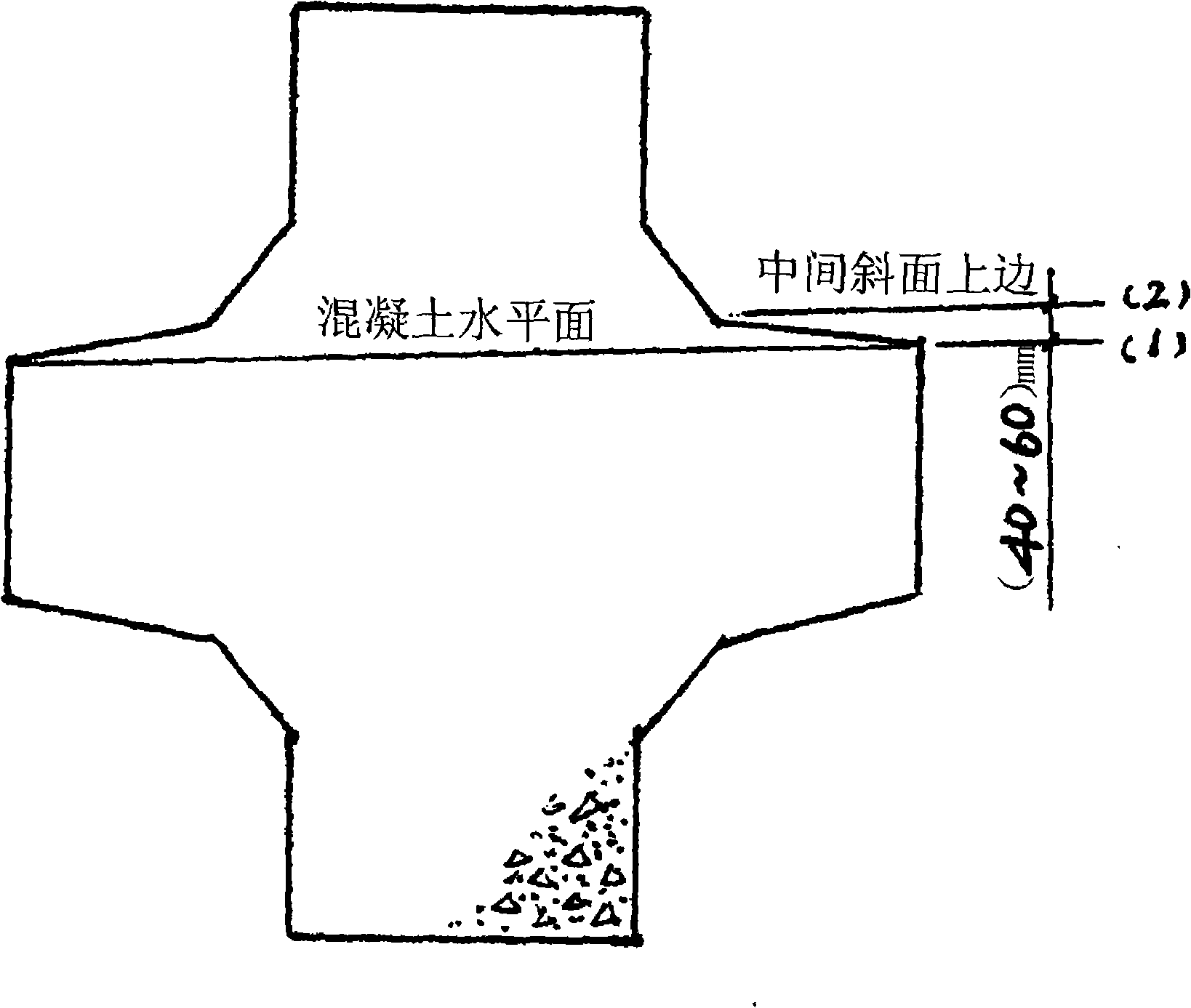

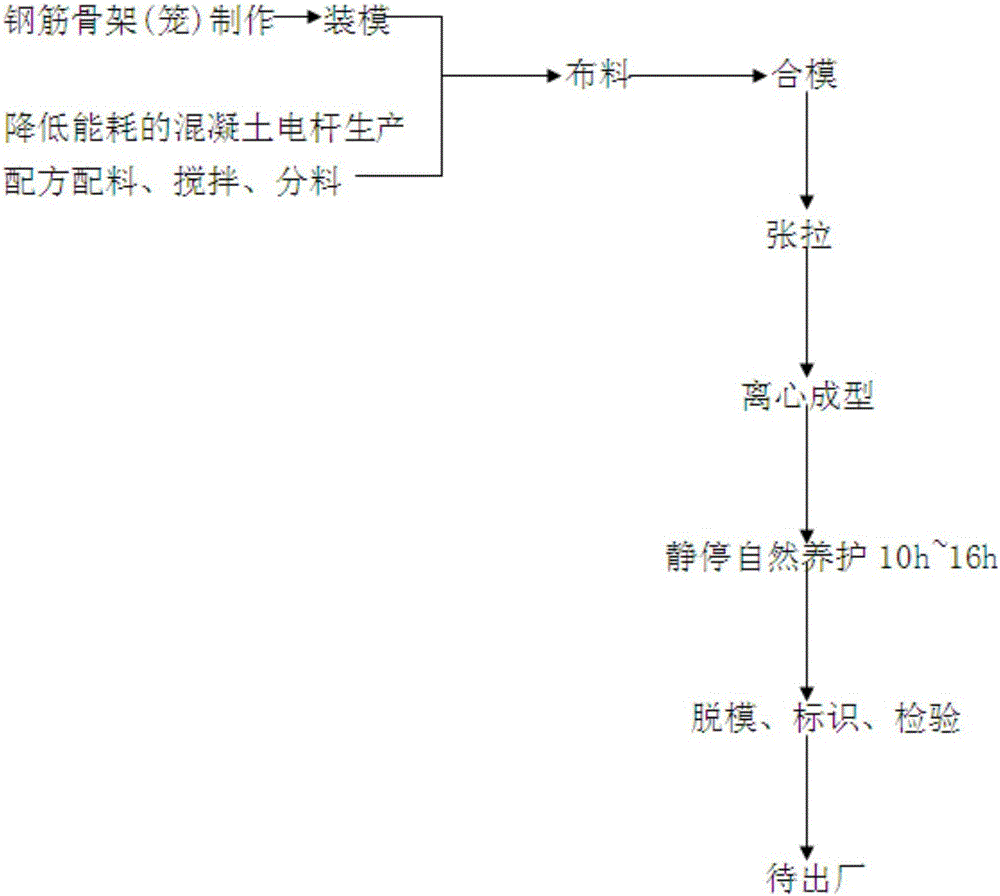

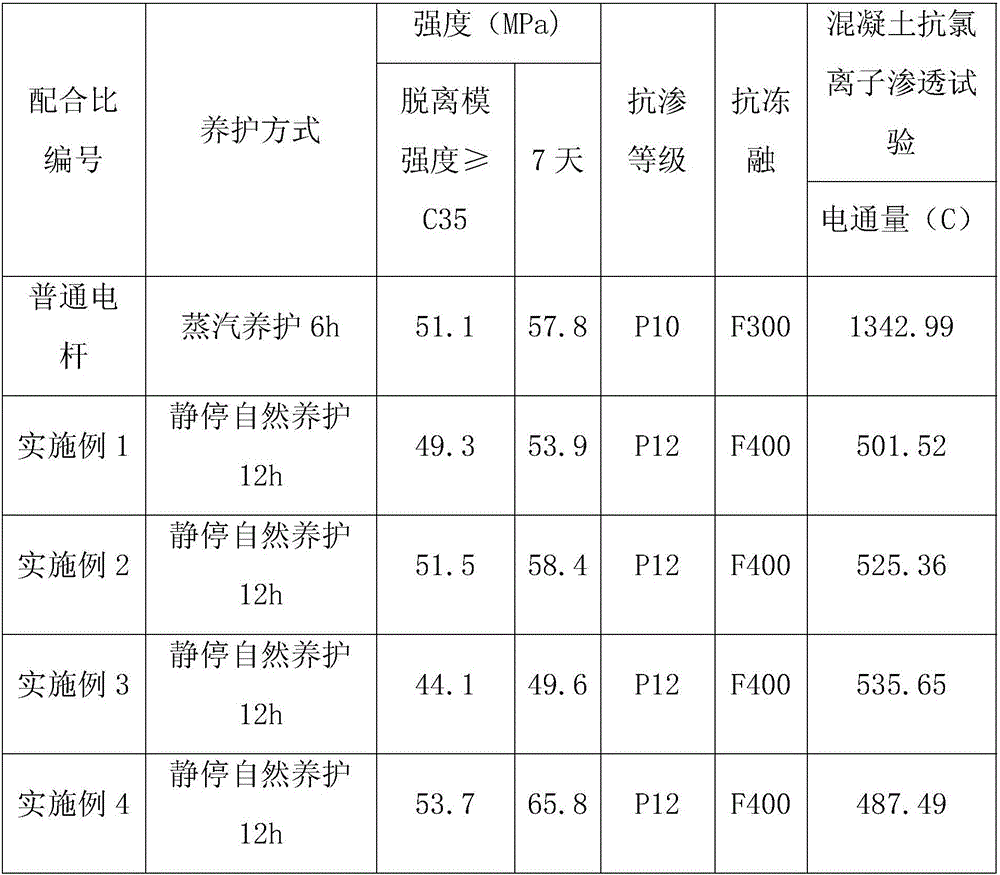

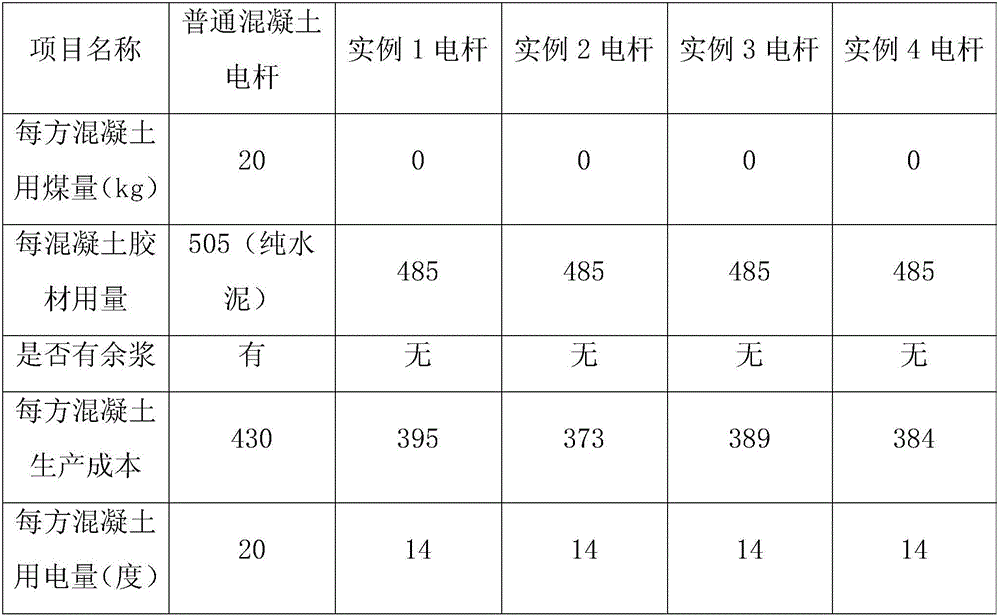

Concrete utility pole production formulation lower in energy consumption and utility pole production method

The invention belongs to the technical field of concrete utility pole production and particularly relates to a concrete utility pole production formulation lower in energy consumption, characterized in that each cubic meter of concrete comes with 180-250 kg / m<3> of cement, 130-180 kg / m<3> of mineral powder, 70-130 kg / m<3> of flyash, 600-700 kg / m<3> of fine aggregate, 1300-1400 kg / m<3> of coarse aggregate, 17-35 kg / m<3> of silica micro-powder, 9.0-15.0 kg / m<3> of a polycarboxylate superplasticizer, and 130-160 kg / m<3> of water; a production method includes the process steps of 1), producing a reinforcement cage by a conventional process, and setting a framework; 2), producing concrete according to the ratio of the components; 3), distributing concrete to the formwork, closing the formwork, tensioning, and centrifugally forming; 4), standing, and naturally curing for 10-16 h; 5), knocking out, marking, and inspecting. The concrete per cubic meter uses cement 20 kg less than that for traditional concrete per cubic meter and uses coal about 20 kg less than that for traditional concrete per cubic meter.

Owner:儋州宇顺实业有限公司

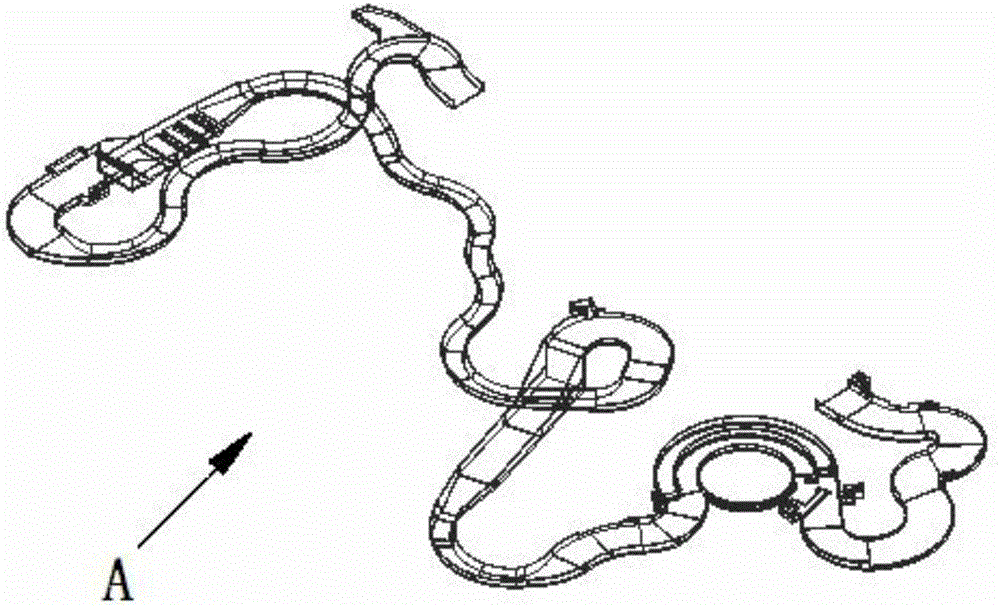

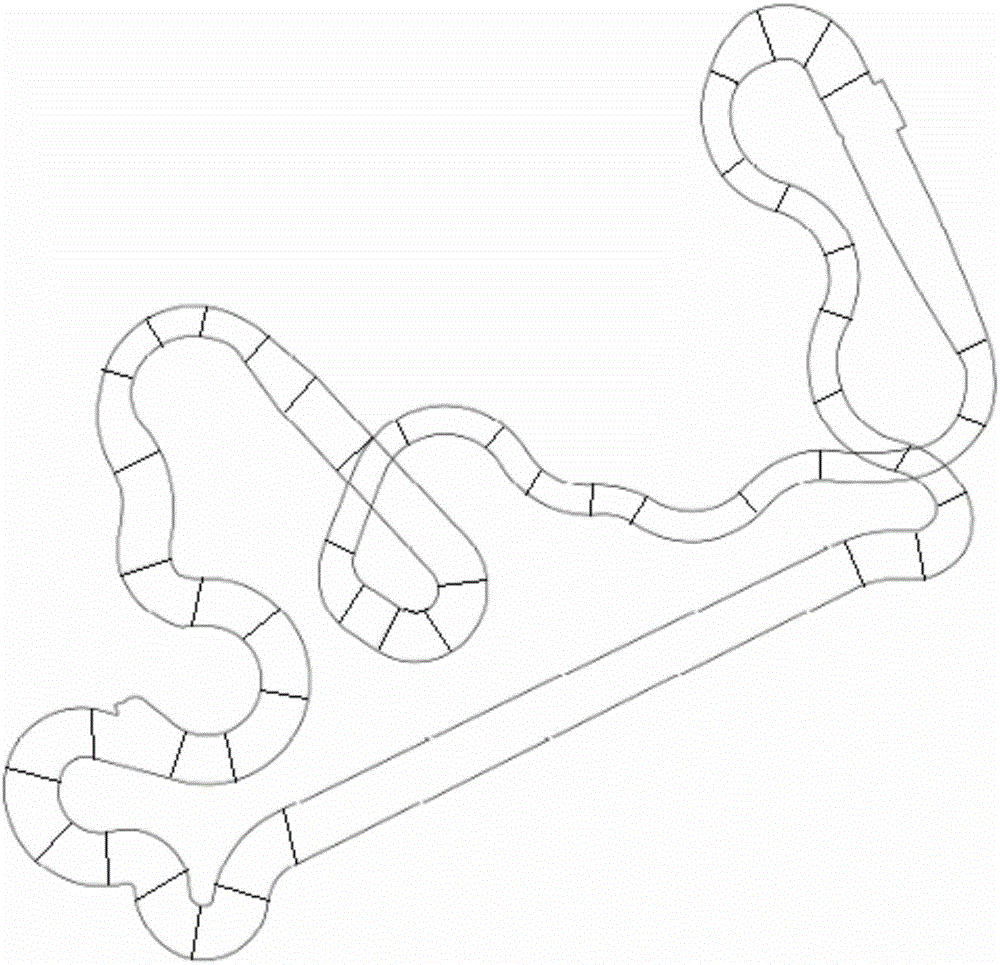

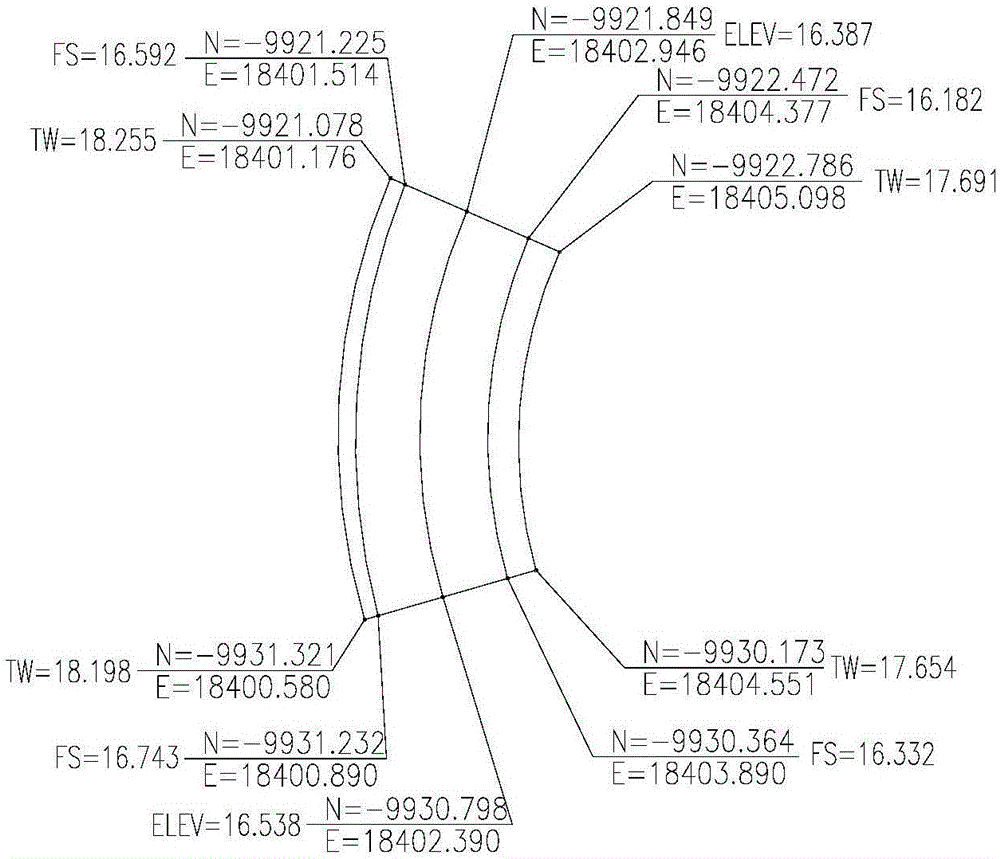

Method for constructing special-shaped solid concrete structure through wet sprayed concrete technique

The invention provides a method for constructing a special-shaped solid concrete structure through the wet sprayed concrete technique. The method comprises the following steps of constructing a special-shaped solid concrete structure building model; conducting batching on concrete materials, wherein dry mixed materials include cement, sand, stones, fiber, an anti-permeability agent and a water reducing agent; mixing the dry mixed materials with water; adding the mixed concrete into a spraying machine and spraying the mixed concrete onto the special-shaped solid concrete structure building model through an air pressure spraying system; trowelling and calendaring the concrete sprayed onto the building model when one-time spraying thickness reaches the design thickness of the concrete structure; and conducting maintenance on the concrete structure constructed through spraying. Through the method, the high-quality and high-precision special-shaped solid concrete structure can be obtained.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

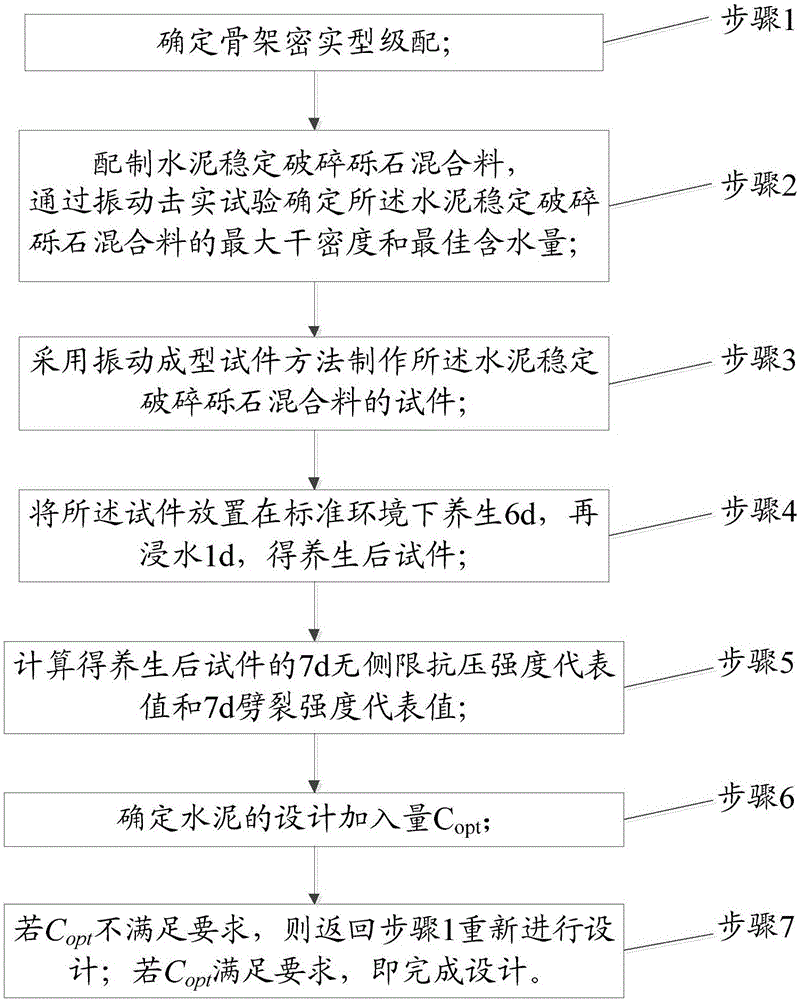

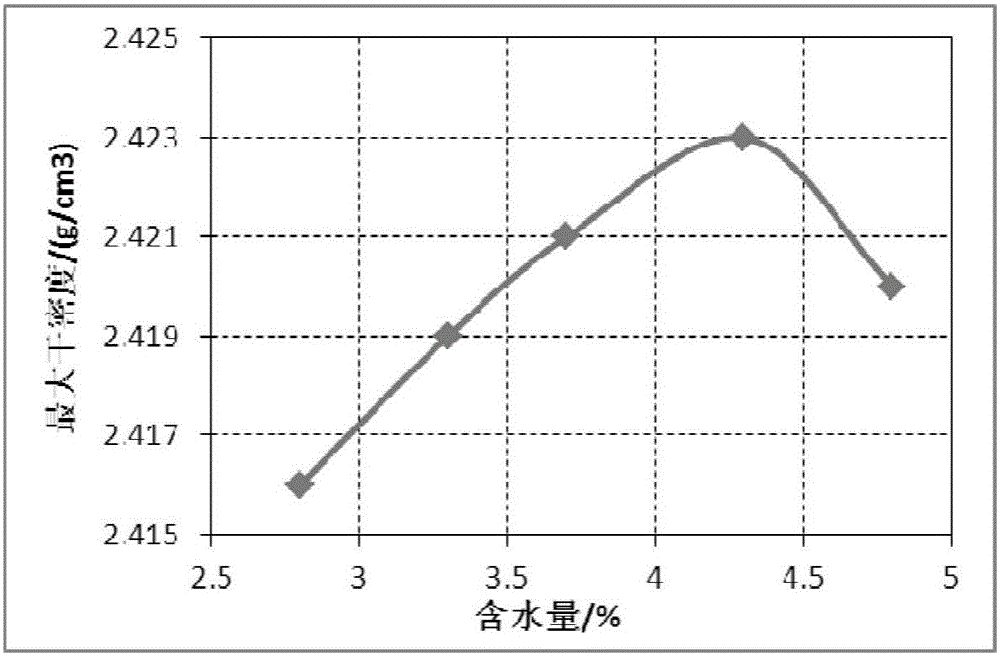

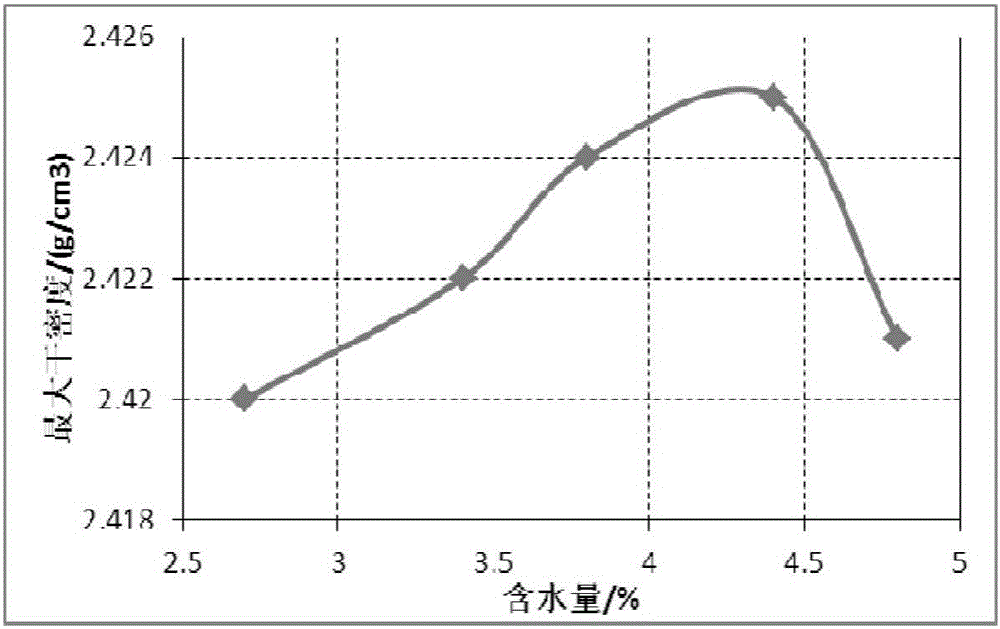

Cement stabilization broken gravel matching ratio design method based on vibration tests

InactiveCN106738205ANot easy to segregateSave cementMixing operation control apparatusPreparing sample for investigationMaximum dry densityMaterial Design

The invention discloses a cement stabilization broken gravel matching ratio design method based on vibration tests. The cement stabilization broken gravel matching ratio design method includes the following steps that firstly, dense skeleton type grading is determined; secondly, cement is added into broken gravel, and a cement stabilization broken gravel mixed material is prepared, and the maximum dry density and the best water content of the mixed material are determined; thirdly, a test piece of the cement stabilization broken gravel mixed material is manufactured; fourthly, the test piece is cured by 6 d in a standard environment and is immersed in water by 1 d; fifthly, the 7 d unconfined compressive strength and the 7 d splitting strength of the test after curing are tested, and the 7 d unconfined compressive strength representative value and the 7 d splitting strength representative value are calculated; sixthly, the designed adding amount Copt of the cement is determined; and if the Copt meets the requirement, design can be completed. By means of the cement stabilization broken gravel mixed material designed through the method, a dense framework structure can be well formed and is not likely to be separated, the cement is saved by 20% to 40%, the strength is improved by about 30%, and social and economic benefits are obvious.

Owner:CHANGAN UNIV

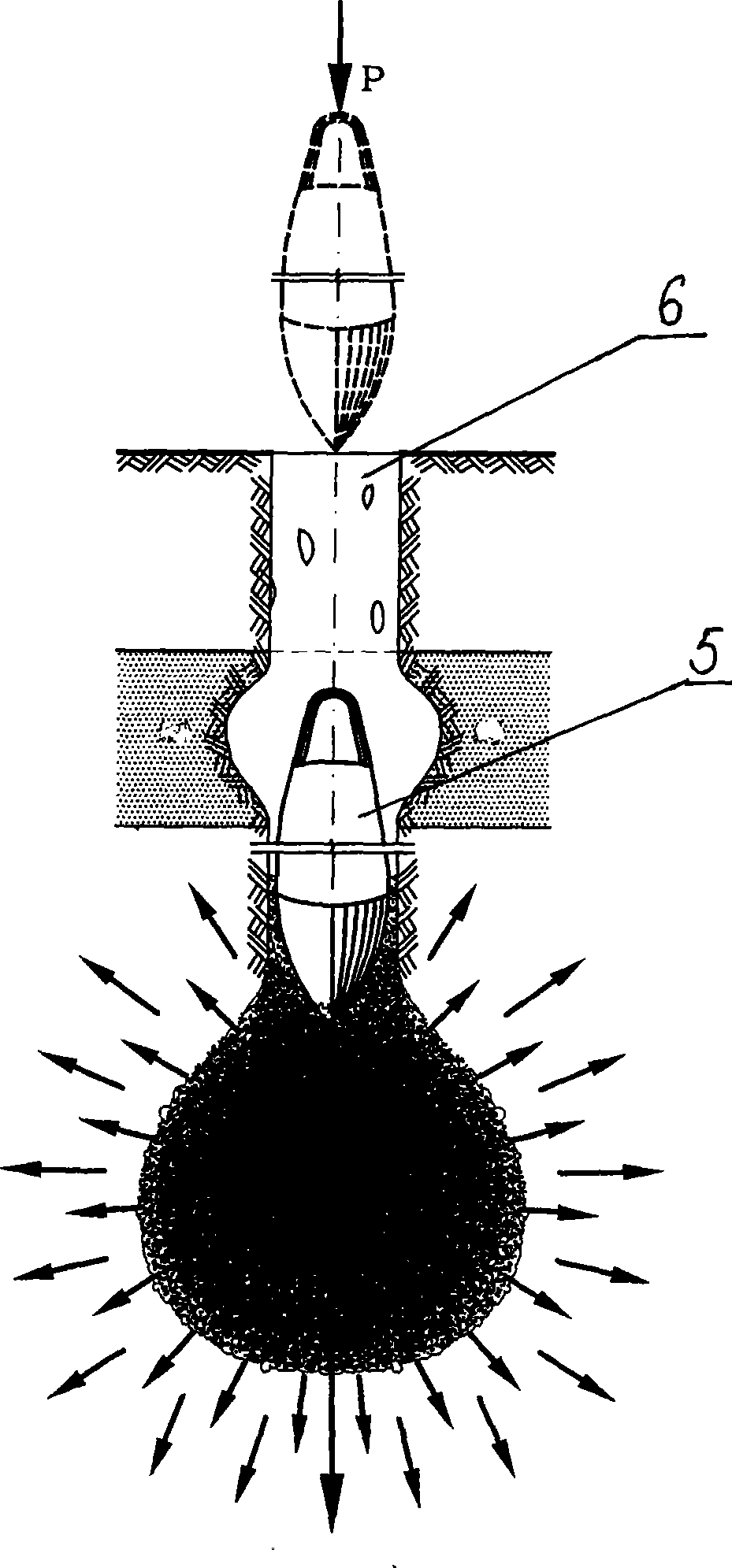

Five in one pre-expansion ecological pile body processing foundation method

The invention relates to a five-in-one pre-expanding ecological pile treating foundation method suitable for foundation, foundation collapse, gold ore dressing and construction application of environment-friendly field. The method comprises: after the foundation is drilled with holes, filling the holes, injecting hammer blocks into the holes, carrying out five-in-one power consolidation of vertically and transversely pre-expanding, extruding, transmitting and propelling by super-pressure kinetic energy through impacting, smashing, extruding, pressing and chopping; then filling the holes repeatedly and carrying out forced ramming and piling consolidation of vertically and transversely pre-expanding, extruding, transmitting and propelling for the super-pressure kinetic energy hammer blocks through impacting, smashing, extruding, pressing and chopping; and finally manufacturing a deep foundation of a composite foundation of a pre-expanding ecological pile with high bearing capacity, a specific pile foundation and the pre-expanding ecological pile. The method is advanced, has low construction cost, effectively solves problems of various thick difficult foundations, can eliminate pollution of pollutant to environment, and make human live on the foundation of firmness, safety and free pollution.

Owner:司炳文 +2

Cement-free slag powder concrete

The invention provides a cement-free slag powder concrete which is characterized in that proportioning of main raw materials in per cubic meter concrete is as follows: 0kg of cement, 100-400kg of slag powder, 0-250kg of fly ash and 140-220kg of water. As in the invention, no cement is adopted in the concrete and quantities of slag powder and fly ash are doped, the activity effect of the slag powder and fly ash is fully utilized, thus ensuring the working performance and quality thereof, efficiently utilizing waste resource, saving cement and energy, reducing production cost and mitigating environment pollution. The invention has wide application range, can be applied to various project parts, is especially suitable for temporary structure and underground structure projects, and has broad market prospect.

Owner:GUANGDONG FOUND ENG GRP CO LTD

Amino concrete pumping aid and preparation method thereof

The invention discloses an amino concrete pumping aid and a preparation method thereof, wherein the amino concrete pumping aid is composed of following raw materials, by weight, 30-60% of a naphthalene water reducer, 5-15% of an aliphatic-series water reducer, 5-20% of an amino water reducer, 0-6% of a retarder, 0.1-0.7% of an air entraining agent and the balanced being water. The preparation method includes following steps: weighting the raw materials according to the weight percentage ratio, pumping the naphthalene water reducer, the aliphatic-series water reducer and the amino water reducer into a stirring pot, stirring the materials for 25-30 min, adding the retarder with stirring for 5-10 min, adding the air entraining agent and the water with stirring for 1 h, and finally pumping out the pumping aid. The amino concrete pumping aid, which is formed by compounding multiple water reducers with single retardant, is high in strength, is good in pumpability, is good in flowability and is low in cost.

Owner:ZHOUSHAN HUIBON BUILDING MATERIAL CO LTD

Composite low-heat-release high-active superfine powder concrete admixture and making method thereof

InactiveCN1185178CLow exotherm High hydration reactivityIncreased hydration reactivitySolid waste managementSlagHomogeneity index

A high-activity superfine additive for concrete is prepared from at least two of steel slag, flyash, granular slag of blast furnace and phosphur slag, and gypsum through grinding, proportional mixing and further pulverizing. Its advantages are high specific surface area (more than 400 sq.m / kg), high activity, and low heat release.

Owner:CHINA BUILDING MATERIALS ACAD +2

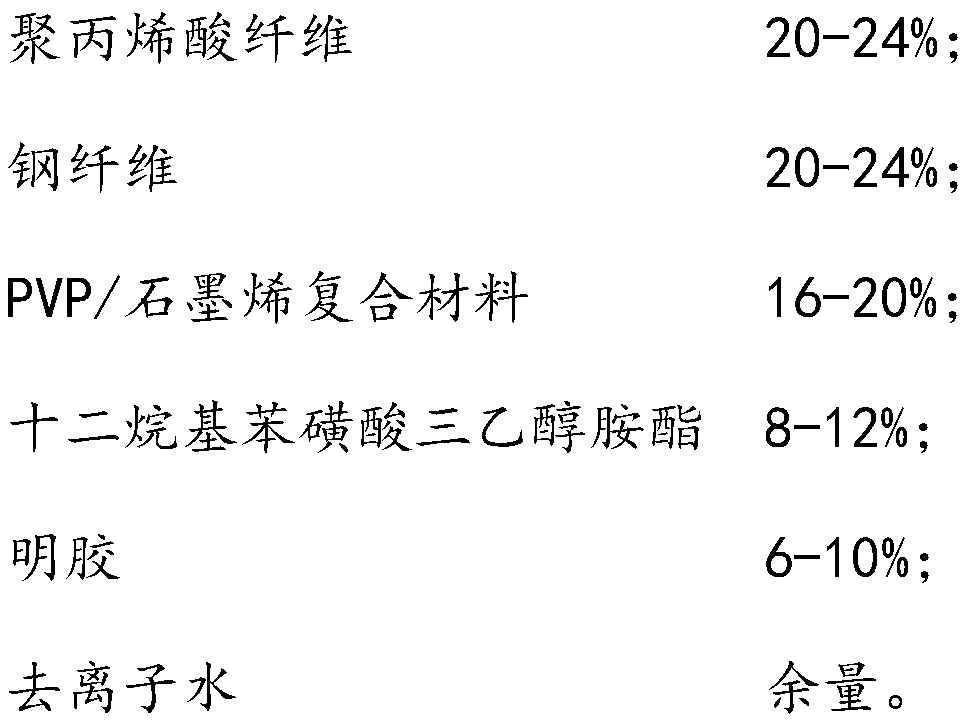

High-strength anti-crack concrete and preparation process thereof

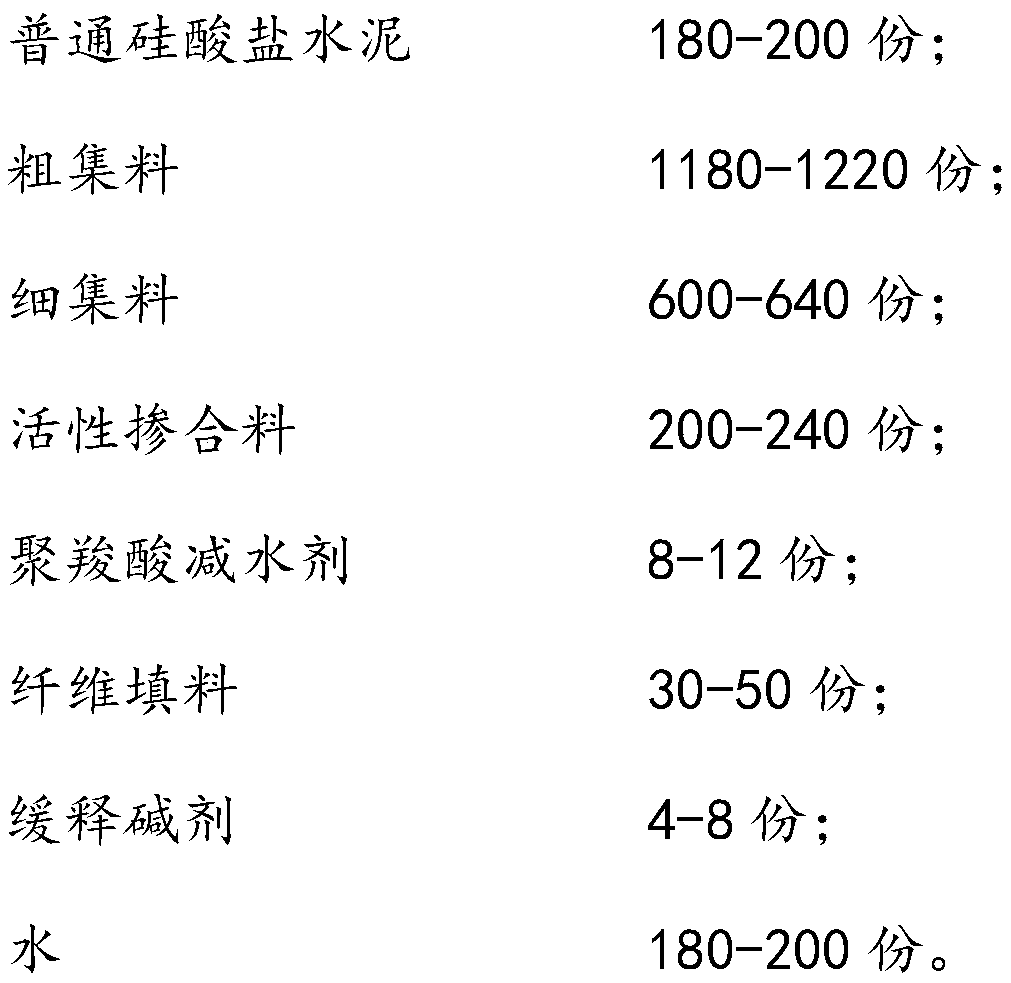

The invention relates to high-strength anti-crack concrete and a preparation process thereof. The high-strength anti-crack concrete is prepared from the following raw materials in parts by weight: 180-200 parts of ordinary Portland cement; 1180-1220 parts of coarse aggregate; 600-640 parts of fine aggregate; 200-240 parts of an active admixture; 8-12 parts of a polycarboxylate superplasticizer; 30-50 parts of fiber filler; 4-8 parts of a slow-release alkaline agent; 180-200 parts of water. The fiber filler is added to toughen the concrete, so that the anti-cracking effect and strength of the concrete are improved.

Owner:杭州三中新型建材科技有限公司

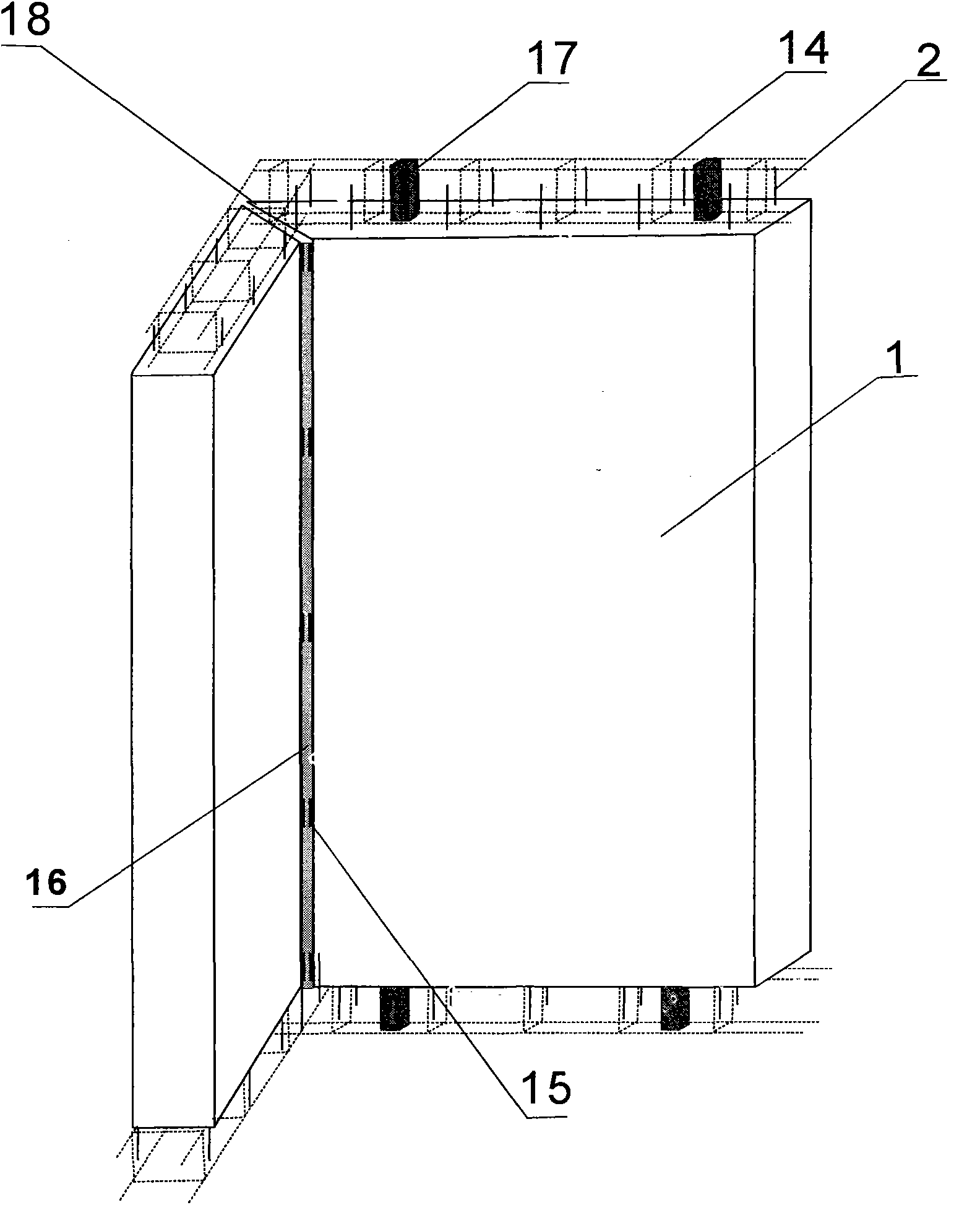

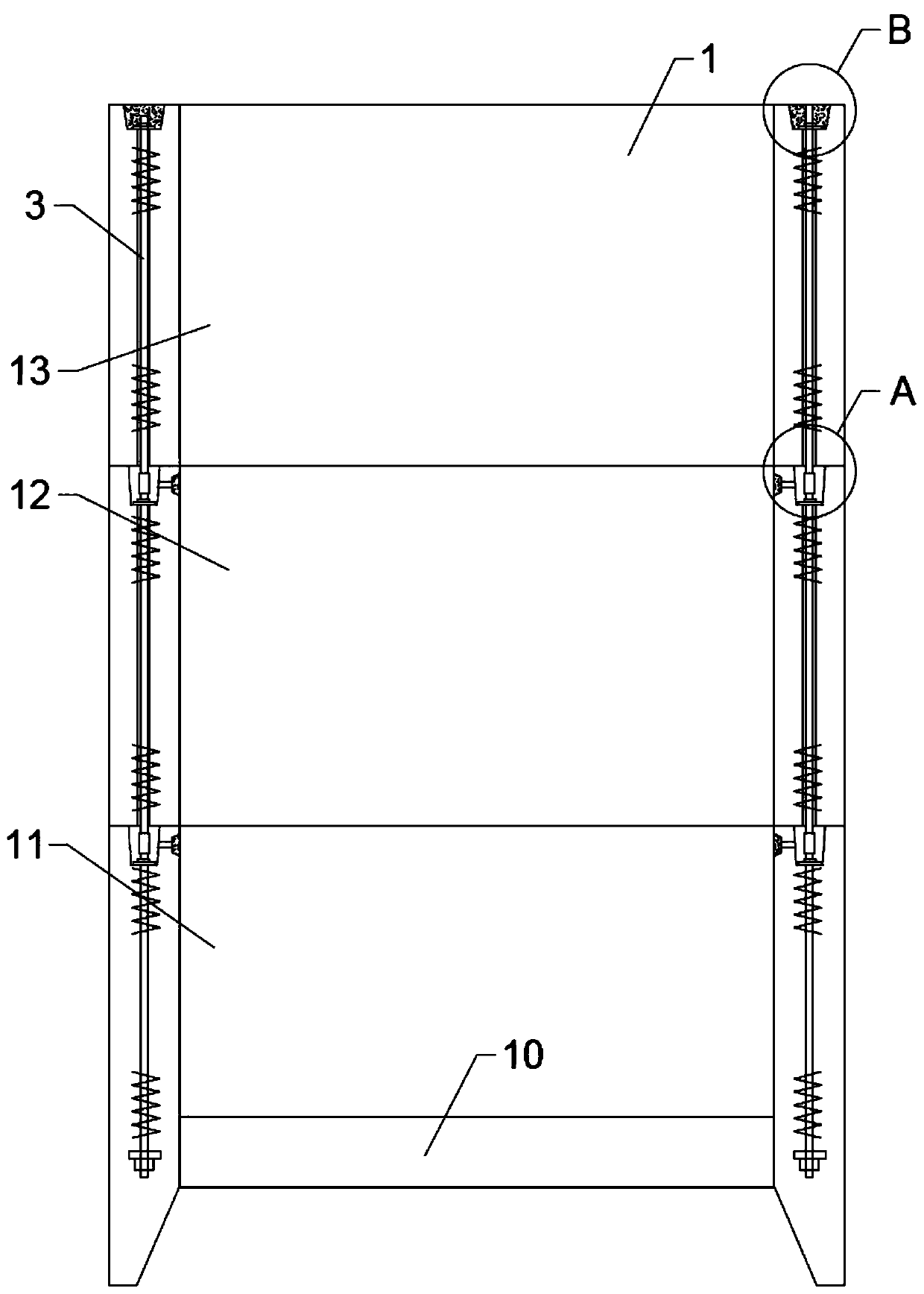

Prefabricated assembly type open caisson and construction method thereof

ActiveCN110952581AReduce the amount of waterReduce pollutionCaissonsArchitectural engineeringCaisson

The invention provides a construction method of a prefabricated assembly type open caisson, and relates to the technical field of open caisson construction. The open caisson is formed by splicing multiple sections. The construction method comprises the following steps of 1, designing the open caisson and prefabricating sections; 2, leveling a field, mounting a bottom section at the open caisson position determined in advance, and excavating soil below at the position of the open caisson; 3, mounting a middle section or an upper section in an aligning manner, and anchoring temporarily; 4, continuing to excavate the soil below until a next section is higher than the ground by a preset distance; 5, repeating the step 3 and the step 4 until the mounting of all the sections is finished; 6, grouting and performing anchor sealing in a steel bar channel; and 7, continuing to excavate the soil below, and enabling the open caisson to sink until the open caisson sinks to the design elevation. Theconstruction method is high in construction speed and reliable in construction quality, reduces the pollution to the surrounding environment, includes temporary anchoring and permanent anchoring in the splicing process of the sections, enhances the open caisson integrity, and is high in safety performance.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

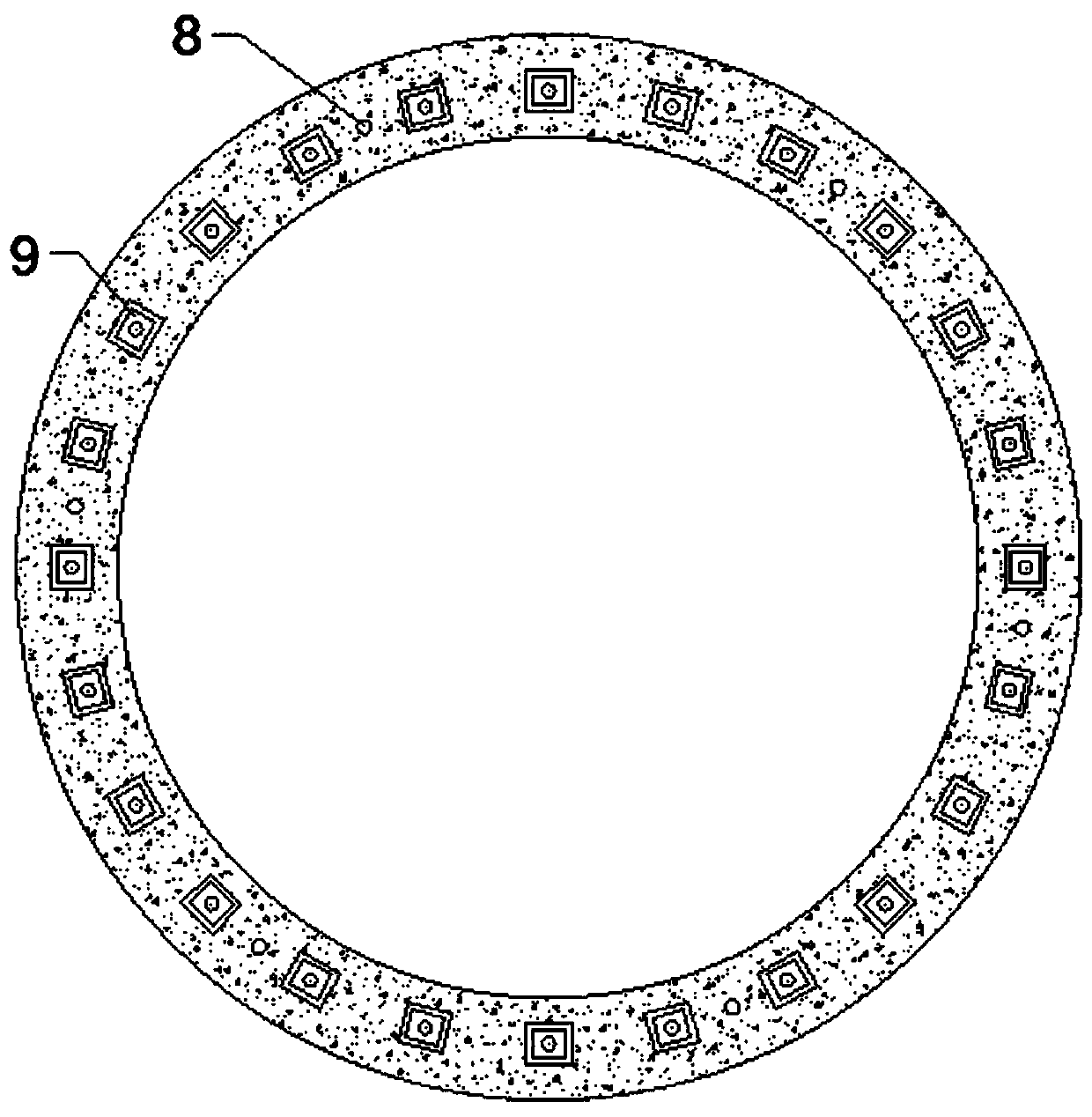

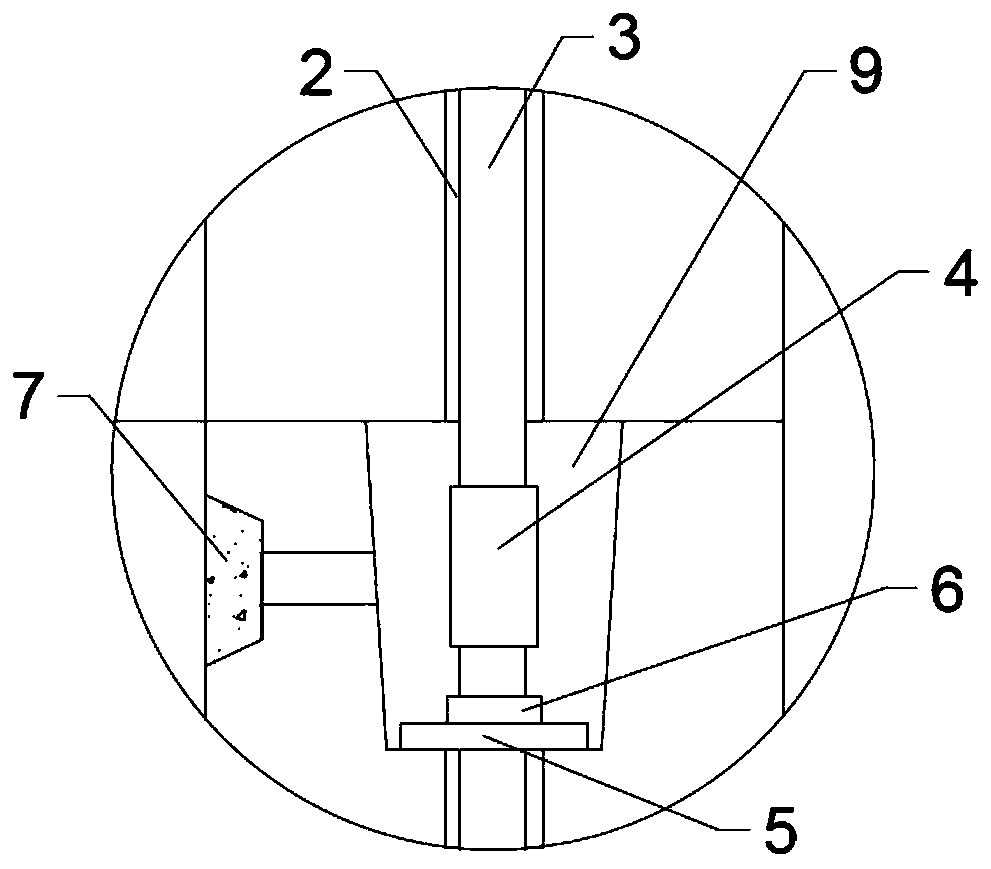

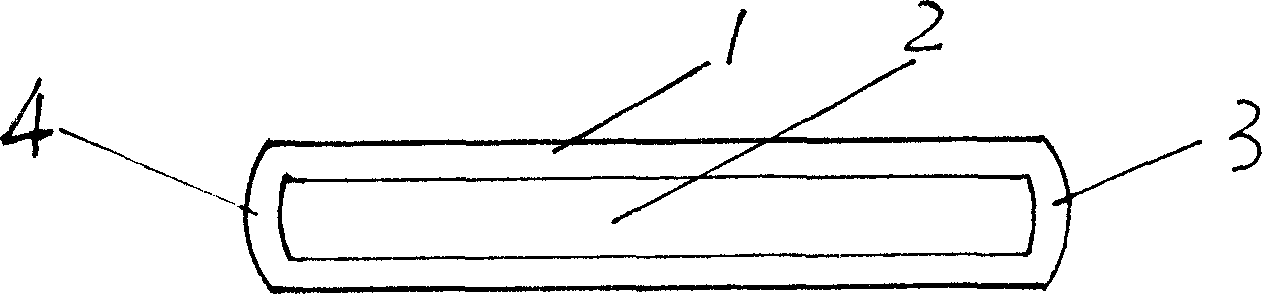

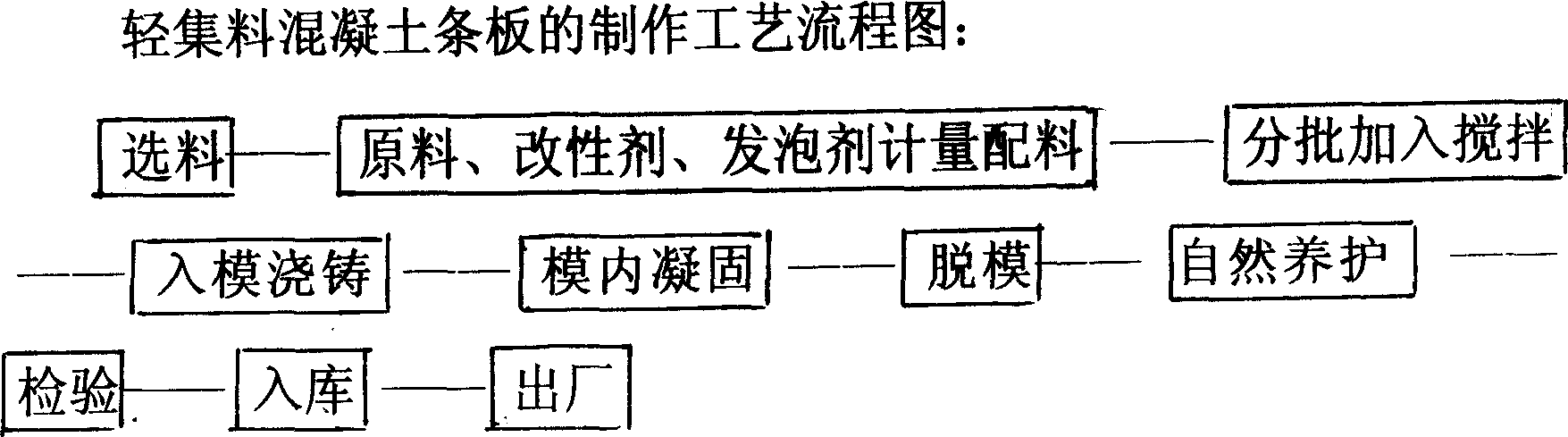

Process for producing light aggregate concrete plate

InactiveCN1899784ALight weightPrevent sinkingLaminationLamination apparatusPolystyreneMaterials science

The present invention discloses the production process of light aggregate concrete plate, which consists of foamed light aggregate concrete strips and middle foamed polystyrene plastic layer. The foamed light aggregate concrete plate has at least two arced sides, and each two plates are rigid connected with oxychloride cement, etc as the cementing material in the connection. The production process of the light aggregate concrete plate includes the steps of selecting material, modifier and forming agent; mixing; molding and solidifying; demolding; natural curing; etc. The light aggregate concrete plate is used in building sandwiched wall.

Owner:傅金松

Iron tailing-fly ash-polystyrene blended concrete wall material and preparation method thereof

The invention relates to an iron tailing-fly ash-polystyrene blended concrete wall material and a preparation method thereof, and belongs to the technical field of building material engineering, the iron tailing-fly ash-polystyrene blended concrete wall material comprises the following raw materials by weight: 45 parts to 60 parts of iron tailings, 12.4 parts to 15 parts of cement clinker, 4.2 parts to 5 parts of micro silica fume, 7 parts to 11.4 parts of machine-made sand, 16 parts to 23 parts of fly ash, 0.4 part to 0.6 part of polystyrene foam particles, 0.2 part to 0.4 part of polypropylene fiber, 20 parts to 30 parts of water, 0.8 part to 1.5 parts of a high-efficiency water reducing agent, 0.05 part to 0.2 part of hydroxypropyl methyl cellulose HPMC and 0.05 part to 0.2 part of redispersible latex powder. The material has the advantages that the cost is reduced, the environmental pollution is reduced, and the resource waste is avoided; the process is simple, operation is convenient, and installation is convenient; and the material has the advantages of light weight, fire resistance, sound insulation, moisture resistance, shock resistance, good durability, strong adhesiveness and the like.

Owner:NORTHEASTERN UNIV +1

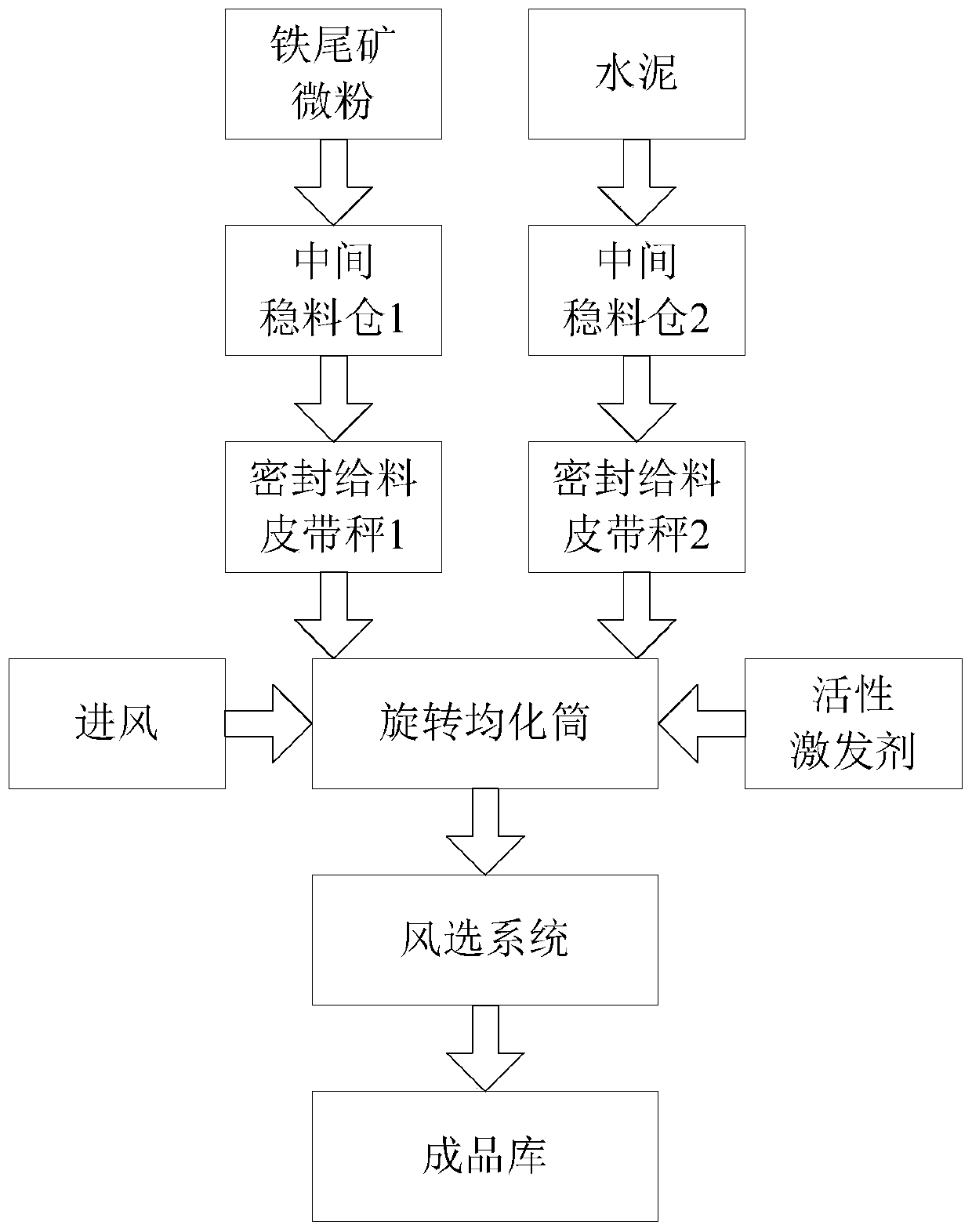

Iron tailing micro-powder mortar dry powder for building mortar and preparation method thereof

ActiveCN110395956AReduce manufacturing costReduce production energy consumptionBreaking strengthCrack resistance

The invention relates to iron tailing micro-powder mortar dry powder for building mortar. The iron tailing micro-powder mortar dry powder is obtained by mixing the following raw materials and carryingout two-time homogenization. The raw materials comprise, by weight, 70%-85% of iron tailing micro-powder, 15%-30% of P.O 42.5R cement, and 0.1%-0.15% of an active activator. The fineness of the irontailing micro-powder is that the screen residue of a 45 [mu]m square hole screen is not greater than 5%, and the specific surface area is greater than 500m <2> / kg. The cement is at least one of ordinary Portland cement, aluminate cement and sulphoaluminate cement with the label of 42.5R. The fineness of the cement is that the screen residue of a 45 [mu]m square hole screen is not greater than 3%.The specific surface area is greater than 360 m<2> / kg. The active excitant is a mixture of triethanolamine and potassium sulfate. According to the invention, the problem that the cost of the cementingmaterial for the building mortar needs to be further reduced is solved, and the technical problems of low early strength, low breaking strength, high mortar breaking ratio and poor crack resistance when the fly ash cementing material is used for the building mortar are solved. The industrial solid waste iron tailing micro powder can be comprehensively utilized, so that the environmental pollutionis reduced. Because the waste utilization amount is large, cement and lime are saved.

Owner:TIANJIN VOCATIONAL & TECHNICAL COLLEGE OF MECHANICAL & ELECTRICAL ENG

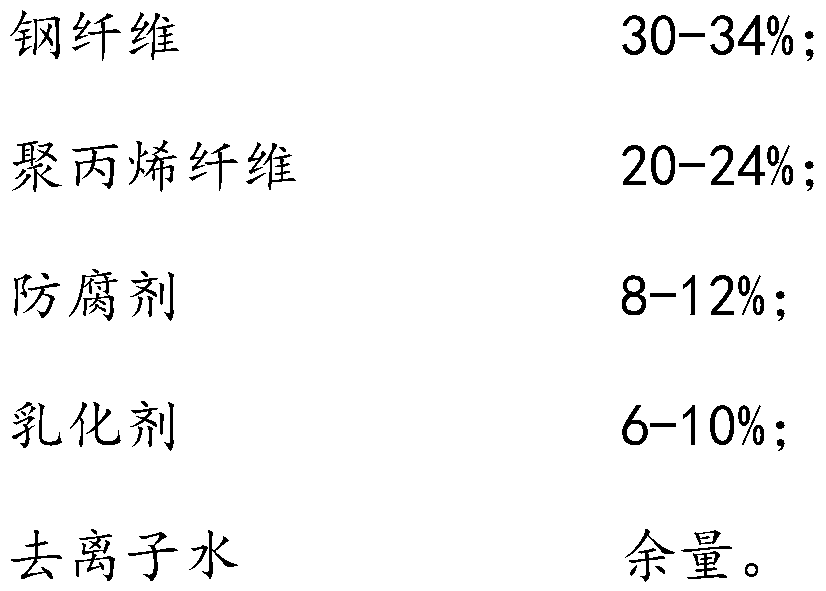

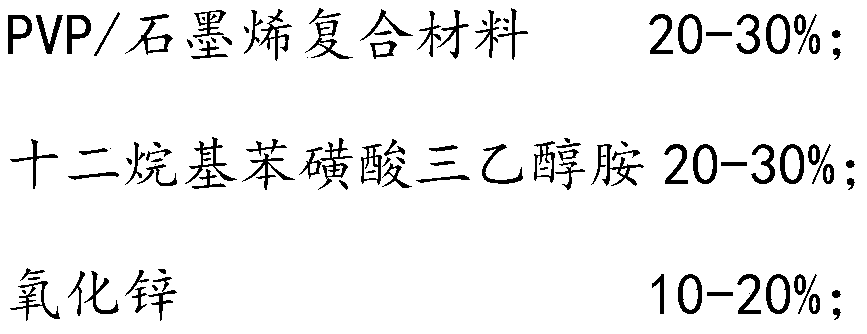

Preparation technology of concrete electric pole

The invention belongs to the technical field of concrete, and discloses a preparation technology of concrete electric pole. The preparation method comprises the following steps: (1) preparing an auxiliary material (A); (2) preparing an auxiliary material (B); (3) preparing an auxiliary material (C); (4) preparing concrete; (5) moulding and demoulding. The technology is simple and feasible, the raw material cost is low, and the prepared electric pole has the advantages of high strength, salt corrosion resistance, and good anti-cracking and anti-permeability performance.

Owner:HANGZHOU FUYANG GAOBO INFORMATION TECH SERVICE

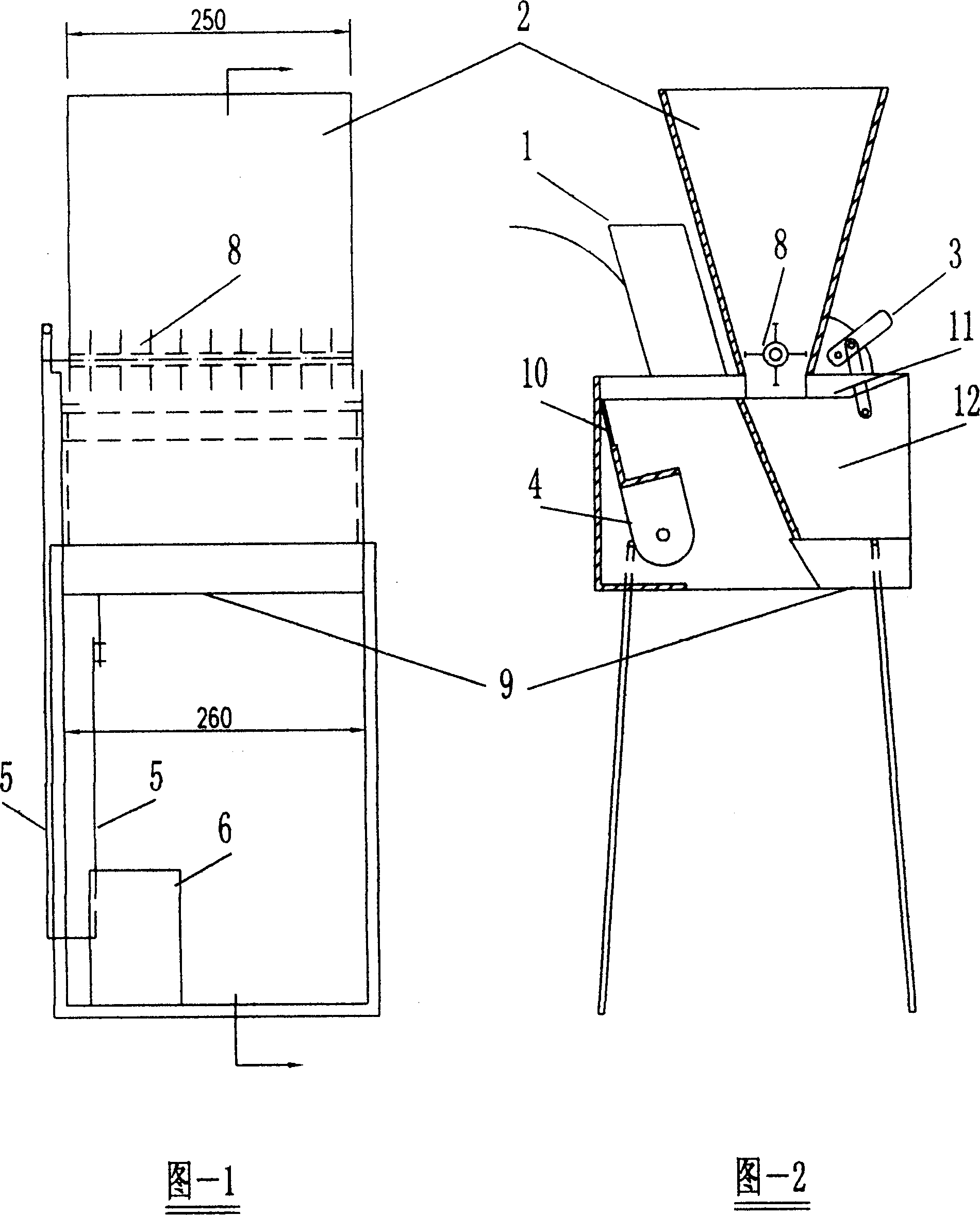

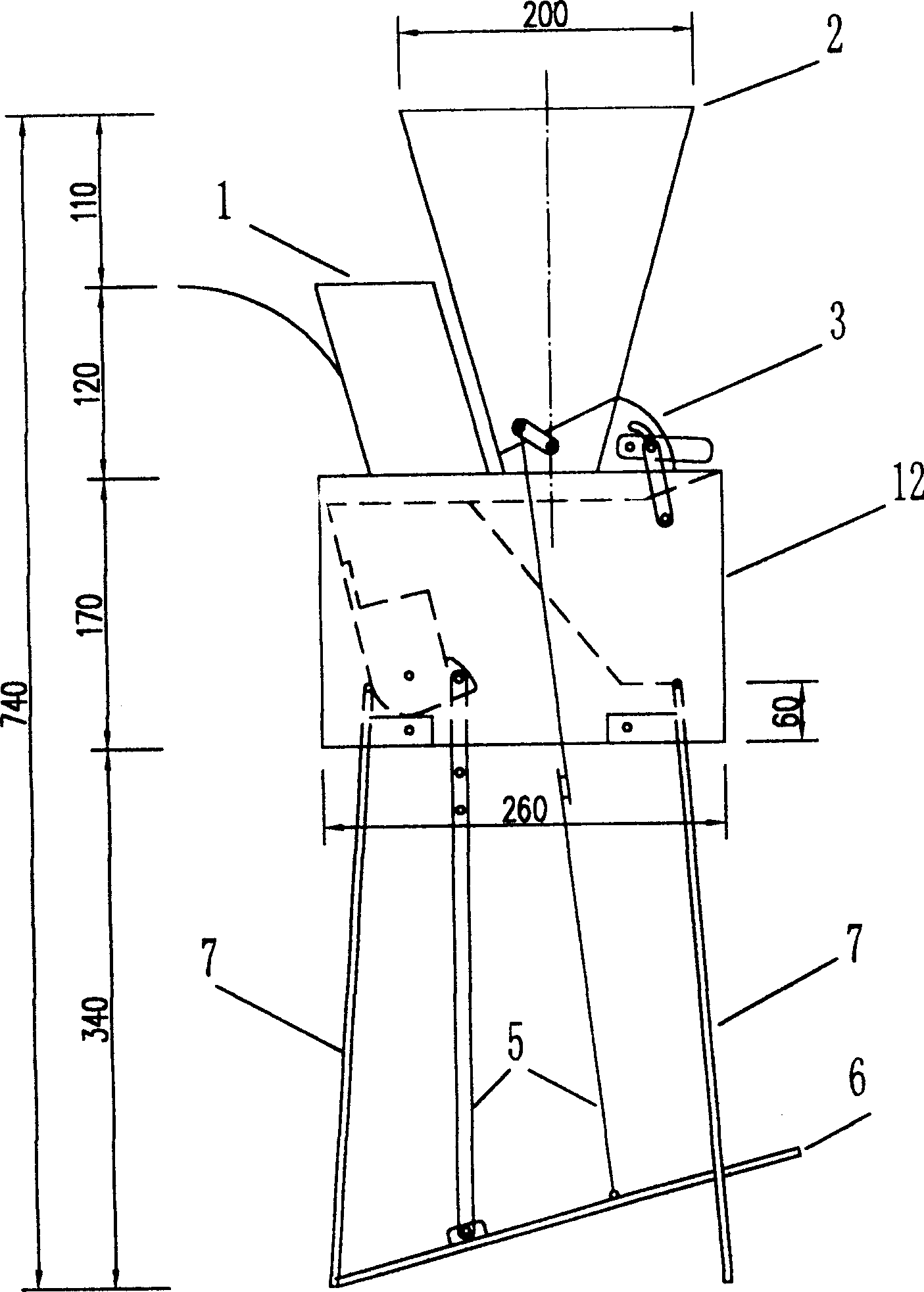

Tool-type plaster-applying device for tile

The plastering equipment for tiling is mainly characterized by that A. cement paste is passed through the funnel of the paste-adding equipment for tiling and applied on the surface of the tile, then the pedal is pedaled once by foot, the tile on which the cement paste is applied can be moved forwards to one tile position (60 mm) by means of its coupled pushing device so as to implement plasteringprocess for tiling; B. in the funnel a stirring device is mounted for raising fluidity and water retensitivity of cement paste; C. it is equipped with a thickness-regulating device, its range is 5 mm-20 mm; and D. it has a waste paste collecting device. It can raise working efficiency for paving tile.

Owner:张高松

Six-prevention plate capable of preventing water, fire, earthquakes, ageing, cracks and noises

InactiveCN104453082AImprove the use effectReduce environmental pollutionConstruction materialWallsAluminium saltsAdhesive

The invention relates to a six-prevention plate capable of preventing water, fire, earthquakes, ageing, cracks and noises. The six-prevention plate is formed by extruding a base material, a binder, a modifier, a reinforcing material and water, wherein the base material is light burning powder, saw timber grass powder and coal ash; the binder is polyamide, polyethylene, chloroprene rubber adhesive, acrylate or vinyl acetate; the modifier is a mixture of oxalic acid, trisodium phosphate, iron pentasulfate, aluminum sulfate and calcium lignosulphonate; and the reinforcing material is a carbon fiber or a glass fiber. The six-prevention plate which is produced by taking the light burning powder, the saw timber grass powder and the coal ash as main raw materials is provided, can be used for replacing a red brick and a hollow brick, can be widely applied to modification and decoration of various low-rise and high-rise buildings, moving houses and old houses as well as wall partition of plant enclosing walls, marketplaces and work sheds. The six-prevention plate has the effects of preventing the water, the fire, the earthquakes, the ageing, the cracks and the noises. By virtue of the modifier and the reinforcing material, the various functions of the six-prevention plate can be sufficiently realized, so that the using effects of a building material are improved.

Owner:遂宁市金安建材有限公司

Dynamic water environment three-pipe jet grouting pile in-pit construction method

InactiveCN113089655AImprove mobilitySmall footprintExcavationsBulkheads/pilesStructural engineeringSlurry

The invention discloses a dynamic water environment three-pipe jet grouting pile in-pit construction method. The method comprises the steps of construction preparation, pile position lofting, drainage ditch excavation, sewerage system building, drilling machine in-place, slurry preparation, drilling pipe insertion, jet grouting lifting, in-pit jet grouting pile construction, compaction grouting, well repairing and the like. According to the method, the construction equipment is simple, high in maneuverability and small in occupied area; the requirement for low-clear-height construction can be met, a machine conducts construction in the limited space from the pit bottom to an upper tunnel support, and movement of the machine on the excavated foundation soil surface is not hindered; the construction machine is small in vibration, low in noise, high in speed and convenient to operate; earth excavation and peripheral foundation structures can be carried out at the same time, and cross construction is achieved; and in the dynamic water environment, compared with a traditional double pipe method, the pile forming diameter and the consolidated stone rate are good in quality, and the construction efficiency is high.

Owner:启东建筑集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com