Concrete repairing dry-mixed mortar and preparation method thereof

A technology for dry-mixing mortar and concrete, which is applied in the field of preparation of the mortar, can solve the problems of poor corrosion resistance, poor construction performance, short service life, etc., and achieves the effects of strong structure, improved adhesion and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

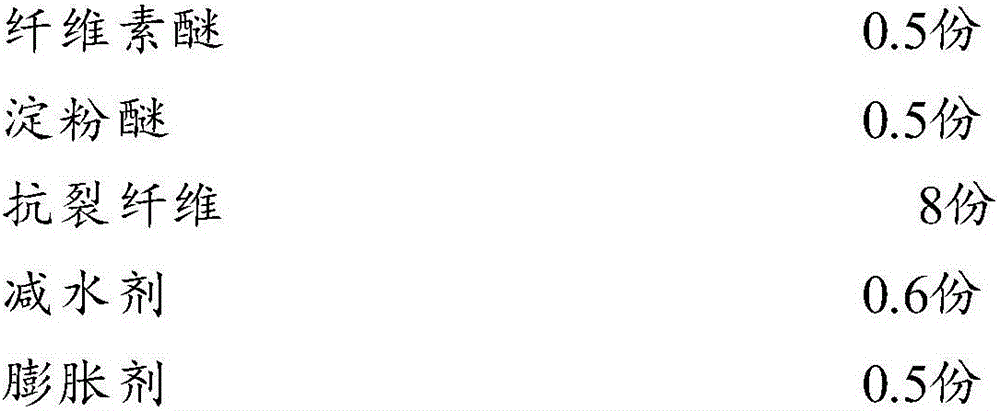

[0041] Concrete repair dry mix mortar of the present embodiment, the mass parts of each component are as follows:

[0042]

[0043]

[0044] Preparation Process:

[0045] A. Raw material preparation: Weigh Portland cement, ferroaluminate cement, fine aggregate, fly ash, micro silica fume, cellulose ether, starch ether, anti-cracking fiber, water reducer and expansion agent in order by mass parts ;

[0046] B. Stirring: Weigh Portland cement, aluminate iron cement, fine aggregate, fly ash, micro silica fume, cellulose ether, starch ether, anti-cracking fiber, water reducing agent and swelling Add the agent into the dry powder mortar mixer one by one and stir for 15 to 20 minutes until they are evenly mixed.

[0047] Prepare concrete repair dry-mix mortar according to the above preparation process, and add appropriate amount of water. Form and maintain a prism specimen of 40mm×40mm×160mm according to the regulations of DL / T5126-2001 of "Test Regulations for Polymer Modi...

Embodiment 2

[0051] Concrete repair dry mix mortar of the present embodiment, the mass parts of each component are as follows:

[0052]

[0053]

[0054] Preparation process is with embodiment 1.

[0055] Prepare concrete repair dry-mix mortar according to the above preparation process, and add appropriate amount of water. Form and maintain a prism specimen of 40mm×40mm×160mm according to the regulations of DL / T5126-2001 of "Test Regulations for Polymer Modified Cement Mortar", and measure the 7-day compressive strength and 28-day flexural strength of the mortar according to the test procedures specified in the specification , compressive strength; according to the "polymer modified cement mortar test procedures" DL / T5126-2001 regulations forming and curing bonded tensile test specimen, the upper part of the test specimen is the tested mortar, its size is 40mm × 40mm × 10mm, The lower part is ordinary mortar, the size of the base block is 70mm×70mm×20mm, the mix ratio of the mortar ...

Embodiment 3

[0059] Concrete repair dry mix mortar of the present embodiment, the mass parts of each component are as follows:

[0060]

[0061]

[0062] The preparation process is the same as in Example 1.

[0063]Prepare concrete repair dry-mix mortar according to the above preparation process, and add appropriate amount of water. Form and maintain a prism specimen of 40mm×40mm×160mm according to the regulations of DL / T5126-2001 of "Test Regulations for Polymer Modified Cement Mortar", and measure the 7-day compressive strength and 28-day flexural strength of the mortar according to the test procedures specified in the specification , compressive strength; according to the "polymer modified cement mortar test procedures" DL / T5126-2001 regulations forming and curing bonded tensile test specimen, the upper part of the test specimen is the tested mortar, its size is 40mm × 40mm × 10mm, The lower part is ordinary mortar, the size of the base block is 70mm×70mm×20mm, the mix ratio of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com