Cement stabilization broken gravel matching ratio design method based on vibration tests

A mix ratio design, cement stabilization technology, applied in the direction of chemical instruments and methods, test sample preparation, batching batching instrument, etc., can solve the internal structure does not match, can not ensure that the coarse aggregate is fully contacted to form a skeleton structure, construction segregation and other problems, achieve good crack resistance and erosion resistance, significant social and economic benefits, and solve the effect of shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

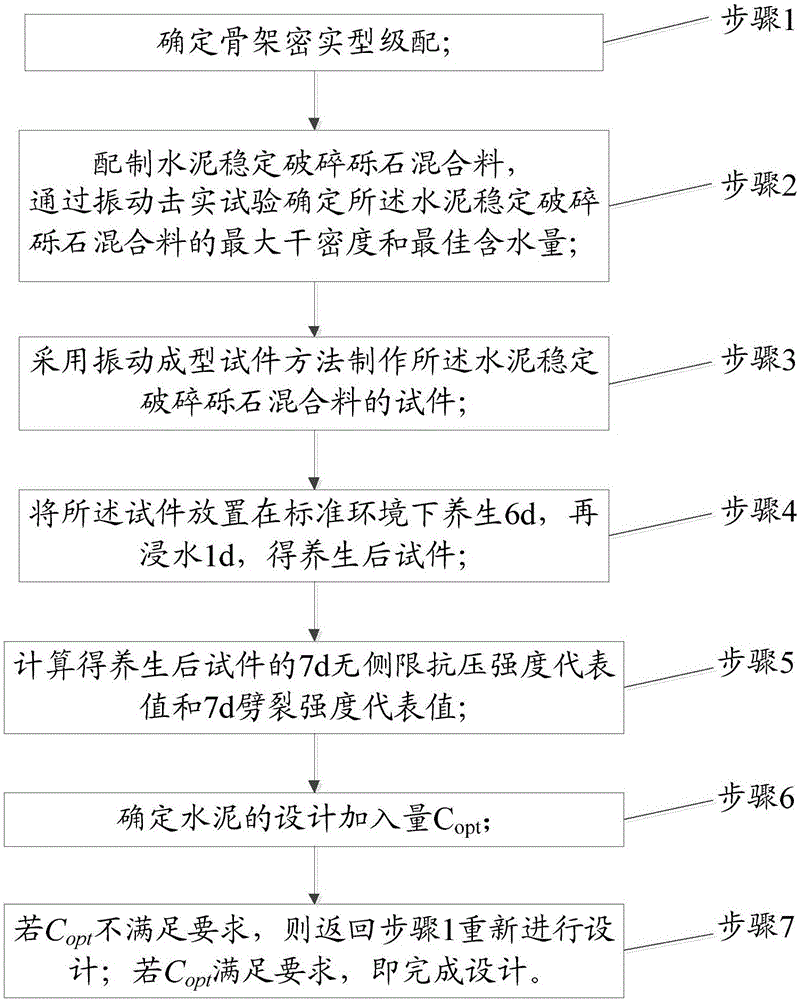

[0073] According to the cement-stabilized broken gravel mixture design method based on the vibration test proposed by the present invention, the cement-stabilized broken gravel mixture applied to the pavement base is prepared, specifically according to the following steps:

[0074] (1) Sieve the crushed gravel with different particle sizes (19-37.5mm, 9.5-19mm, 4.75-9.5mm and 0-4.75mm). The results are shown in Table 3.

[0075] According to the requirements of the gradation range of the skeleton chamber type proposed by the present invention, the proportion of broken gravel is determined to be 19-37.5mm: 9.5-19mm: 4.75-9.5mm: 0-4.75mm, which is 42:13:13:32, and the calculation is shown in the table 4.

[0076] Table 3 Screening results of broken gravel

[0077]

[0078] Table 4 Grading calculation table

[0079]

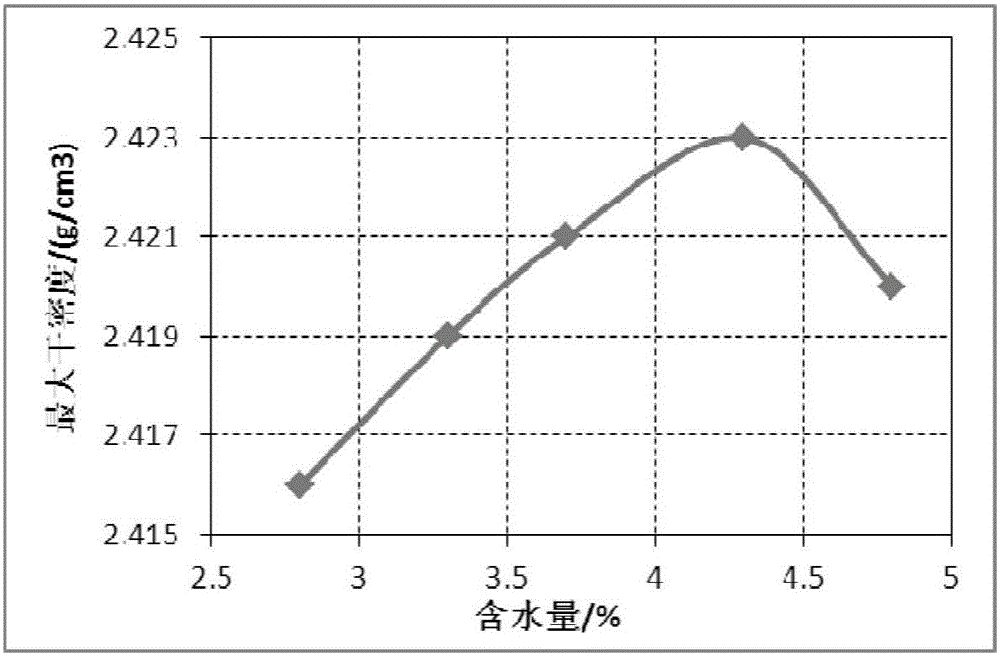

[0080] (2) Using 42.5 ordinary Portland cement, select the addition amount of five kinds of cement: 3%, 3.5%, 4%, 4.5% and 5% to carry out the vibration com...

Embodiment 2

[0115] According to the cement-stabilized broken gravel mixture design method based on the vibration test proposed by the present invention, the cement-stabilized broken gravel mixture applied to the pavement subbase is prepared, specifically according to the following steps:

[0116] (1) Aggregate screening result is the same as embodiment 1, see table 3.

[0117] And according to the requirements of the skeleton chamber type gradation range proposed by the present invention, the proportion of broken gravel is determined to be 19-37.5mm: 9.5-19mm: 4.75-9.5mm: 0-4.75mm, which is 39:12:13:36. For calculation, see Table 9.

[0118] Table 9 Gradation calculation table

[0119]

[0120]

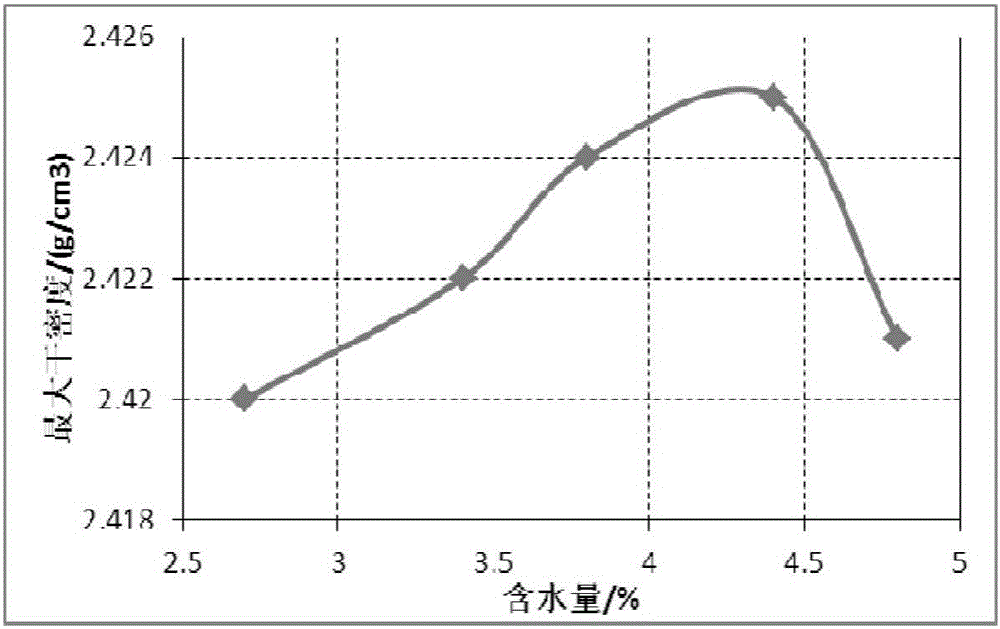

[0121] (2) Using 42.5 ordinary Portland cement, select the addition amount of five kinds of cement: 3%, 3.5%, 4%, 4.5% and 5% to carry out the vibration compaction test, the time of vibration compaction is 120s, and determine the stability of the cement The best dry density and the best w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com